Control device of full-automatic lower discharging centrifuge

A technology of unloading centrifuge and control device, applied in centrifuges and other directions, can solve the problems of aging drum, shortened service life, major accidents, etc., and achieve the effect of personal safety and reliability, accident avoidance, and personal safety protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

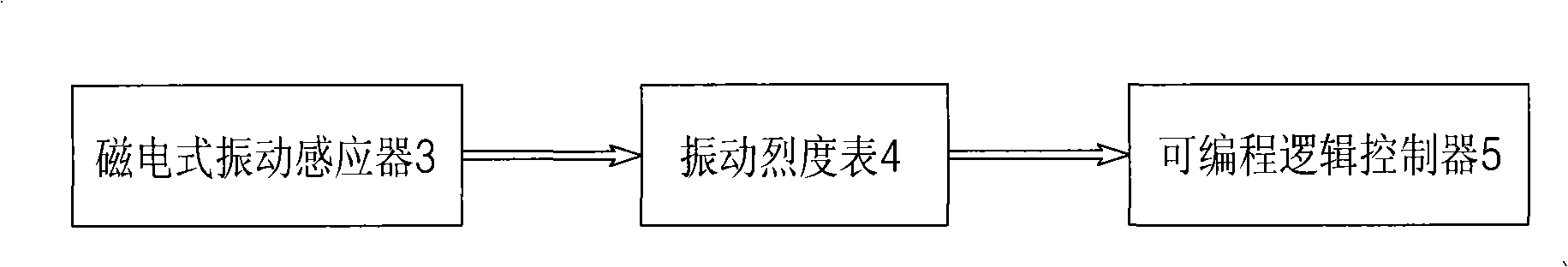

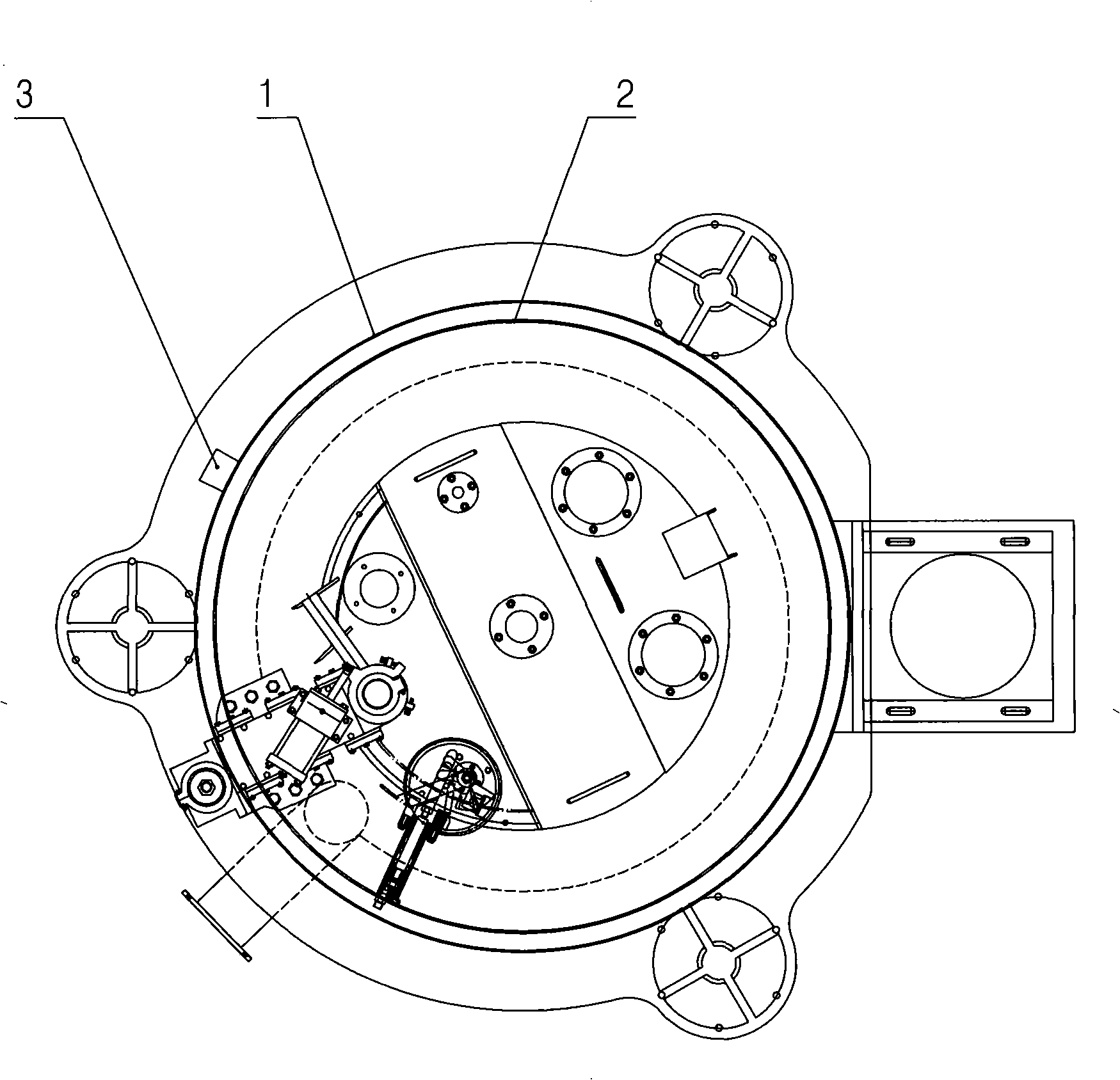

[0012] Such as figure 1 , figure 2 As shown, the control device of the fully automatic unloading centrifuge of the present invention includes: a controller, a vibration intensity meter 4 and a vibration sensor arranged on the centrifuge casing 1, and the output end of the vibration sensor It is connected to the input end of the vibration intensity meter 4, and the output end of the vibration intensity meter 4 is connected to the input end of the controller. In this embodiment, the vibration sensor is a magnetoelectric vibration sensor 3, and the controller is a programmable logic controller 5, namely PLC.

[0013] When vibration occurs during the operation of the centrifuge, the coil inside the magnetic vibration sensor cuts the magnetic force line and outputs different equivalent voltage signals

[0014] After the present invention instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com