Intermittent cement core fishing net braided rope

A technology for weaving rope and cement, applied in the direction of braid, textile cable, textile and paper making, etc., can solve problems such as cost increase, and achieve the effect of cost reduction, high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

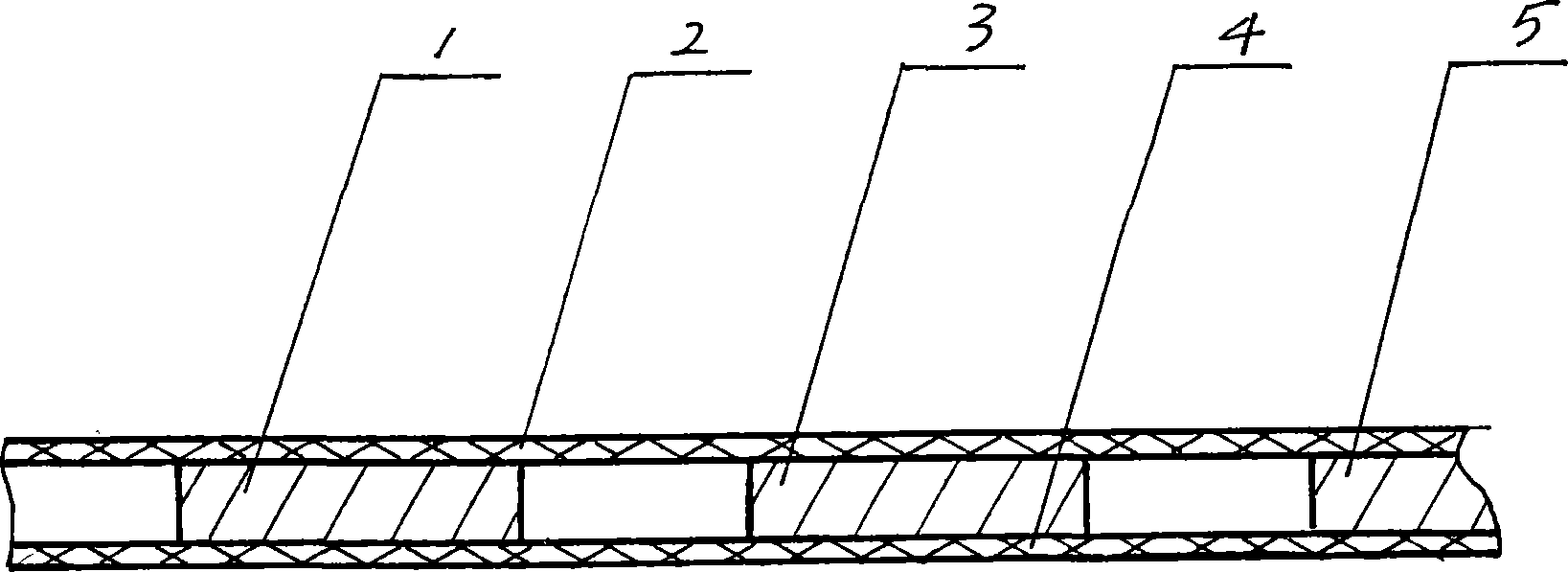

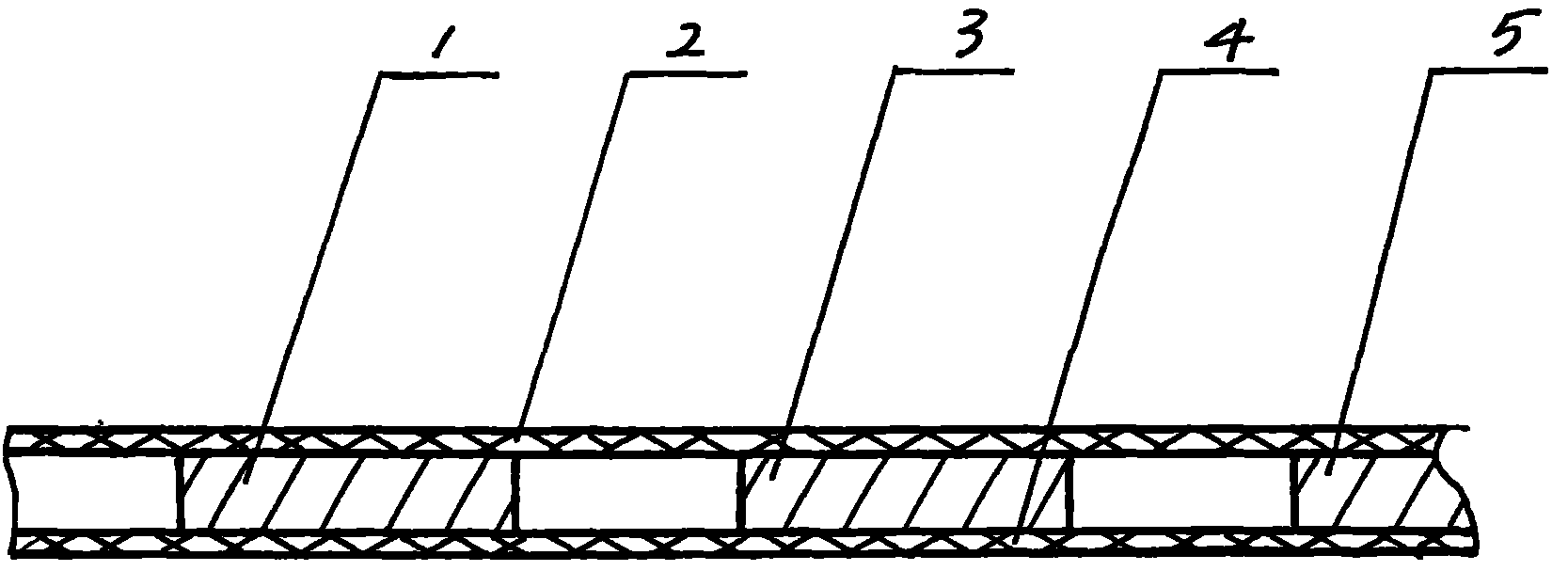

[0009] In the figure, the braided rope includes two parts: cement cores 1, 3, 5 and braided wires 2, 4; its characteristic is that on the outer diameters of a section of independent cement cores 1, 3, 5, braided ropes are evenly wound Lines 2 and 4, the braided wires evenly and tightly surround the cement core to form a long braided rope. The distance between the cement cores 1, 3 and 5 is 0 mm to 1000 mm, and the diameter of the cement cores 1, 3 and 5 is Φ1 mm to 100 mm. Its cement core 1, 3, 5 can be cement, also can be replaced by stone material, plastics, pottery and pottery clay non-metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com