Electromagnetic voltage adjusting multi freedom degree spherical ultrasonic electromotor

An ultrasonic motor, degree of freedom technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Pressure is not easy and other problems, to achieve the effect of improving output torque, reliable motor structure, and simplifying design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

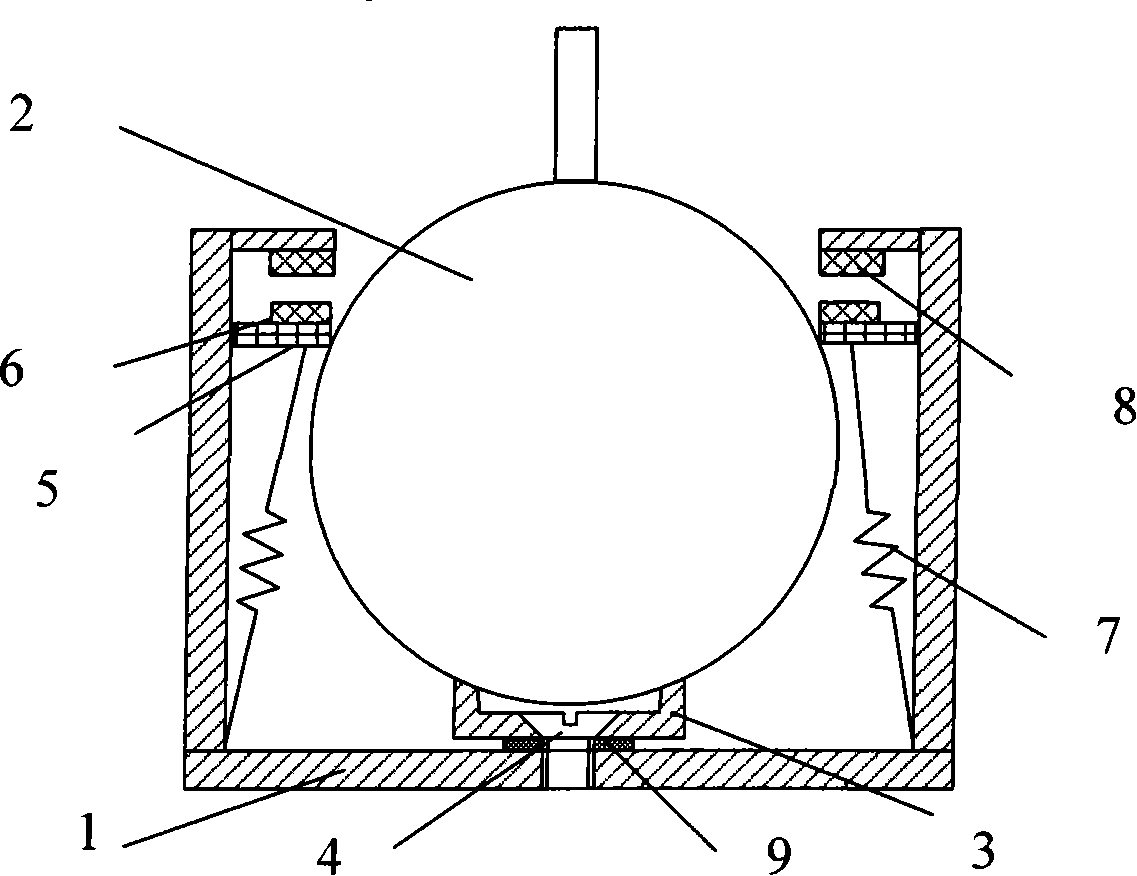

[0022] The electromagnetic pressure regulating spherical ultrasonic motor includes two parts: the motor body and the pre-pressure electromagnetic control system. Among them, the motor body part is composed of the casing 1, the ball rotor 2 and the stator 3. Magnetic sheet 6, spring 7, electromagnetic pole 8 constitute. The basic structure of the motor is as figure 1 shown.

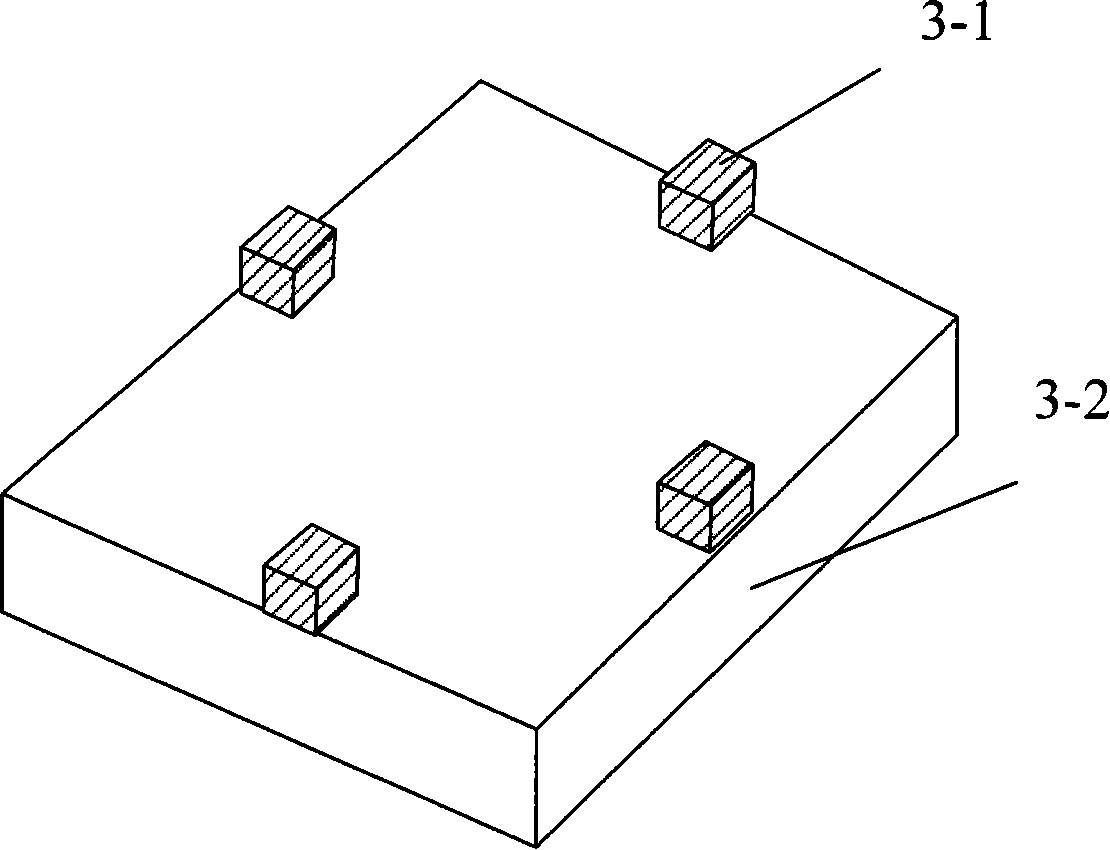

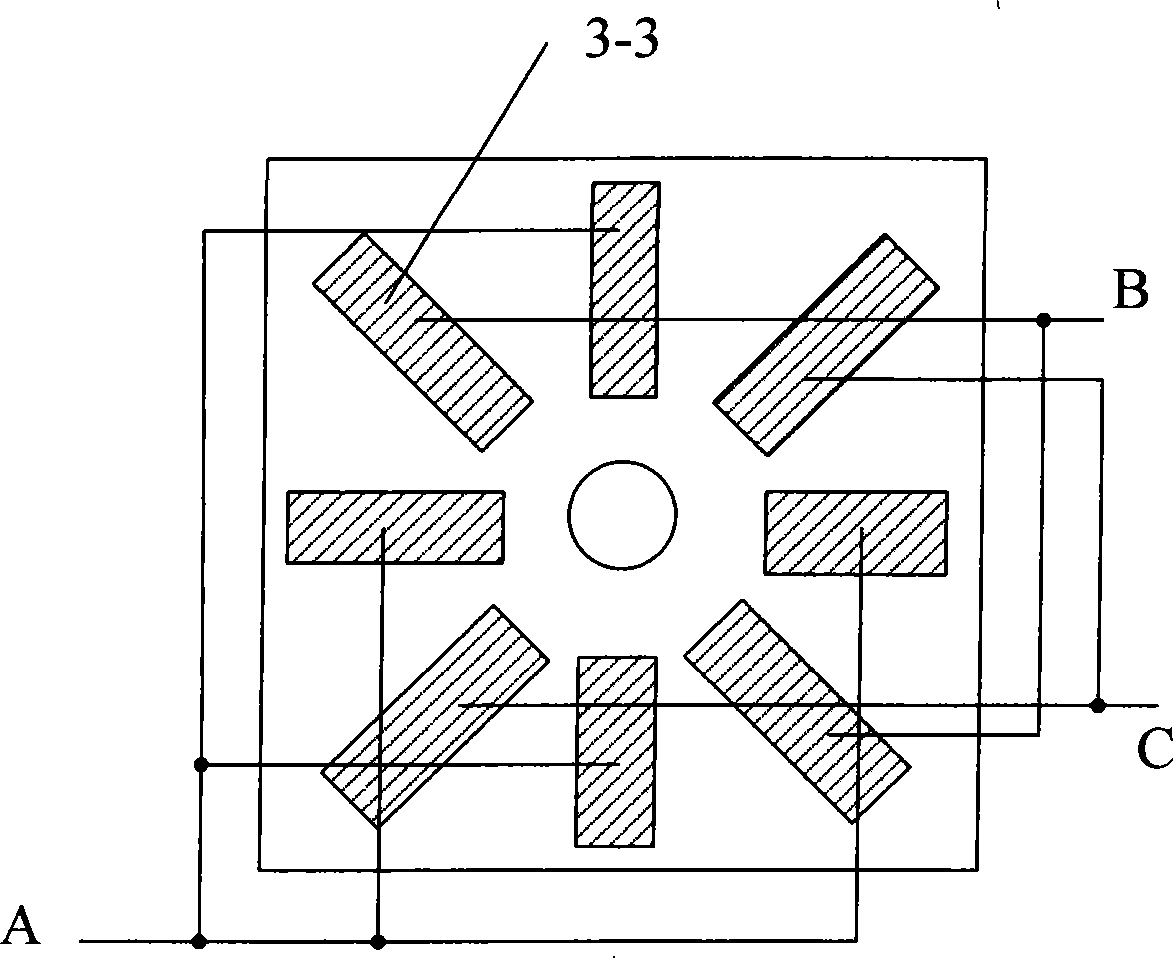

[0023] The motor casing 1 is square column-shaped, and its width is slightly larger than the diameter of the ball rotor 2 . The stator 3 is a square elastic metal flat plate 3-1, four driving feet 3-2 are pasted on the front side, and a piezoelectric film 3-3 is pasted on the back side. At the intersection of the two diagonal lines of the stator, the stator is fixed on the casing by bolts 4 superior. The stator structure diagram is as follows figure 2 As shown, the arrangement of the piezoelectric sheets is as follows image 3 shown. The ball rotor is made of non-magnetic material, with an output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com