Diaphragm valve

A technology of diaphragm valve and spool, which is applied in the direction of lift valve, valve detail, valve device, etc., which can solve problems such as difficult to ensure and complex structure of the device, and achieve the effect of high responsiveness and increased volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

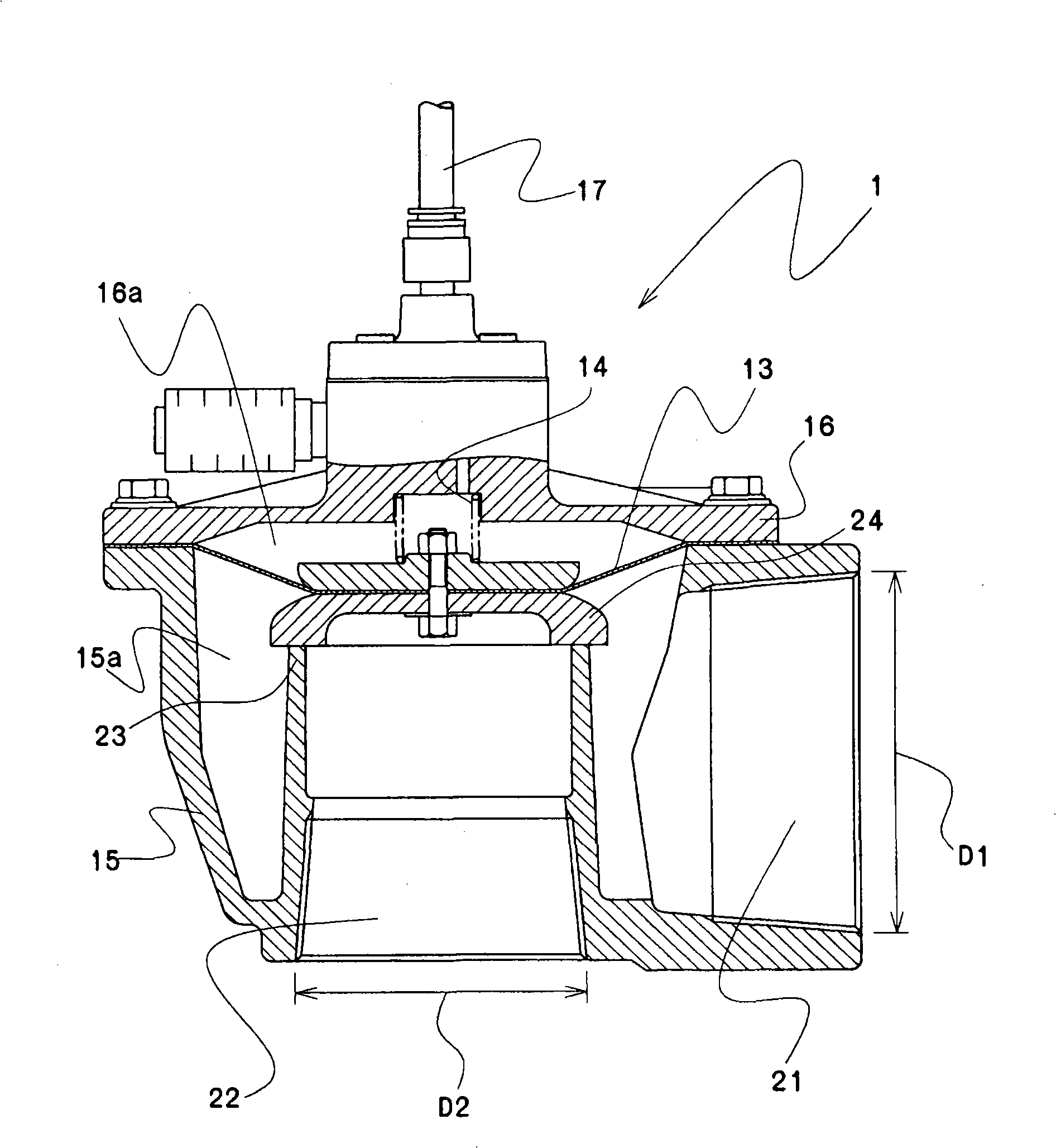

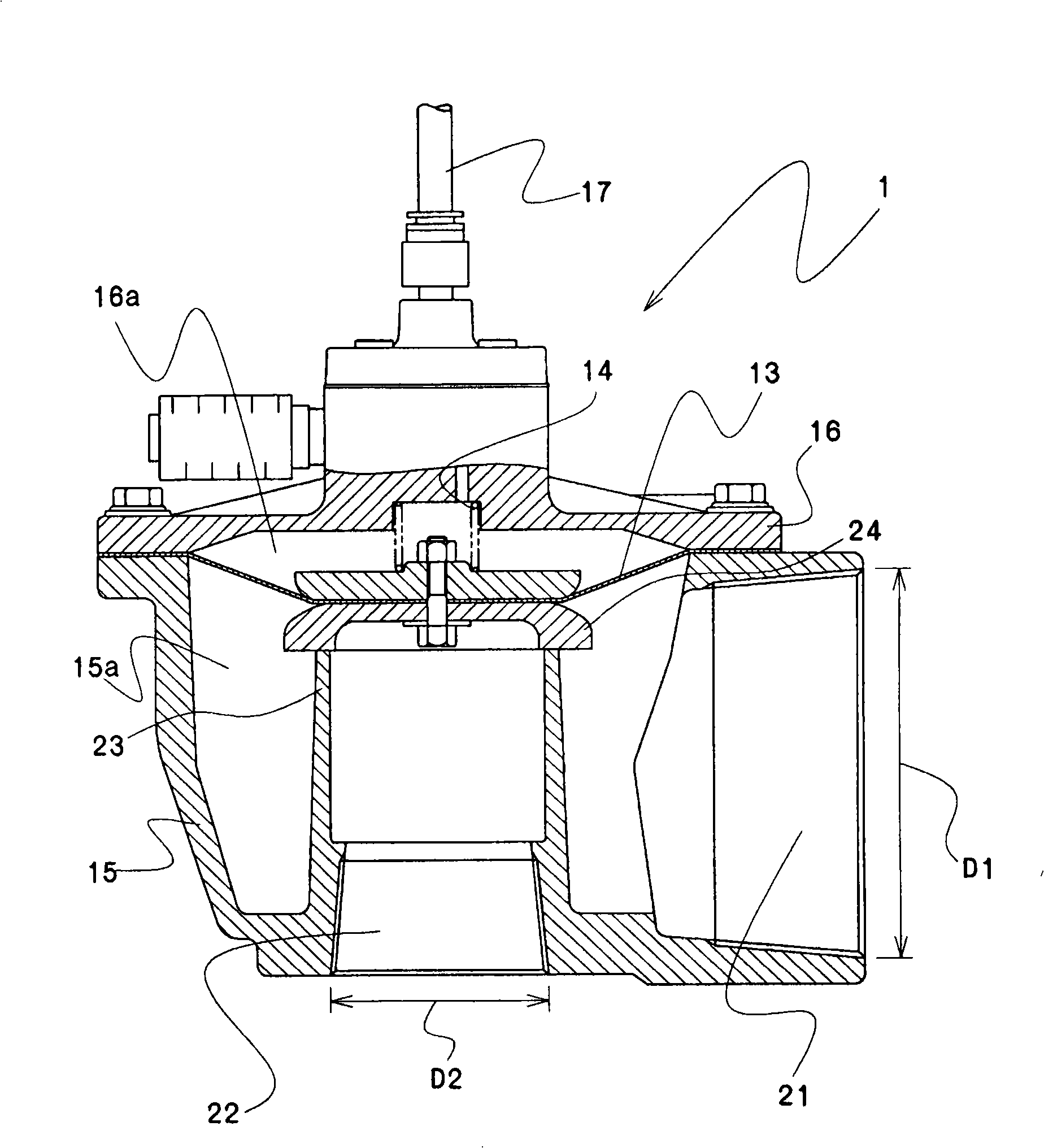

[0051] Figure 1 ~ Figure 2 An example of the diaphragm valve of the present invention is shown.

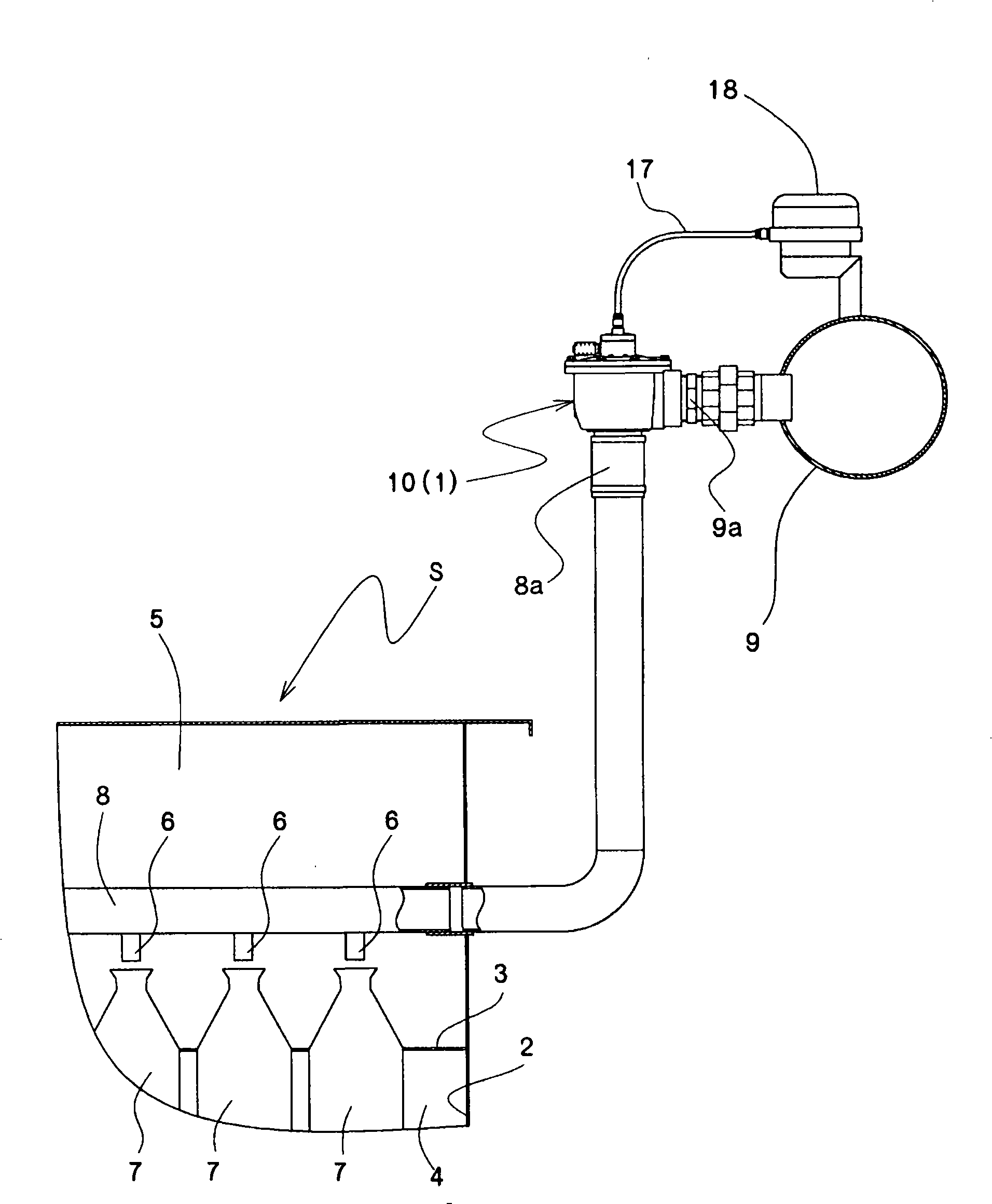

[0052] The diaphragm valve 1 is image 3 The diaphragm valve shown for the same bag type dust collector S as in the past is installed with the outer port 22 through the connecting pipe 8a provided at the opening end of the cleaning air supply pipe 8 of the bag type dust collector S, and the pressure air is supplied The pipe 9 and the connection pipe 9a are provided with an air inlet 21 through which the compressed air supply pipe 9 and the cleaning air supply pipe 8 are intermittently communicated.

[0053]The diaphragm valve 1 is composed of a main body 15, a cover member 16 having the inside as a valve chamber 16a, and a valve element 24 as in the conventional example. And the air inlet 21 connected with the pressure air supply pipe 9, and the outer port 22 with the inner end as the valve seat 23, and connected with the cleaning air supply pipe 8, the valve core 24 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com