Device and method for removing burr

A burr removal and burr technology, which is applied in the field of burr devices, can solve problems such as uneven wear of brushes and unreliable deburr removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

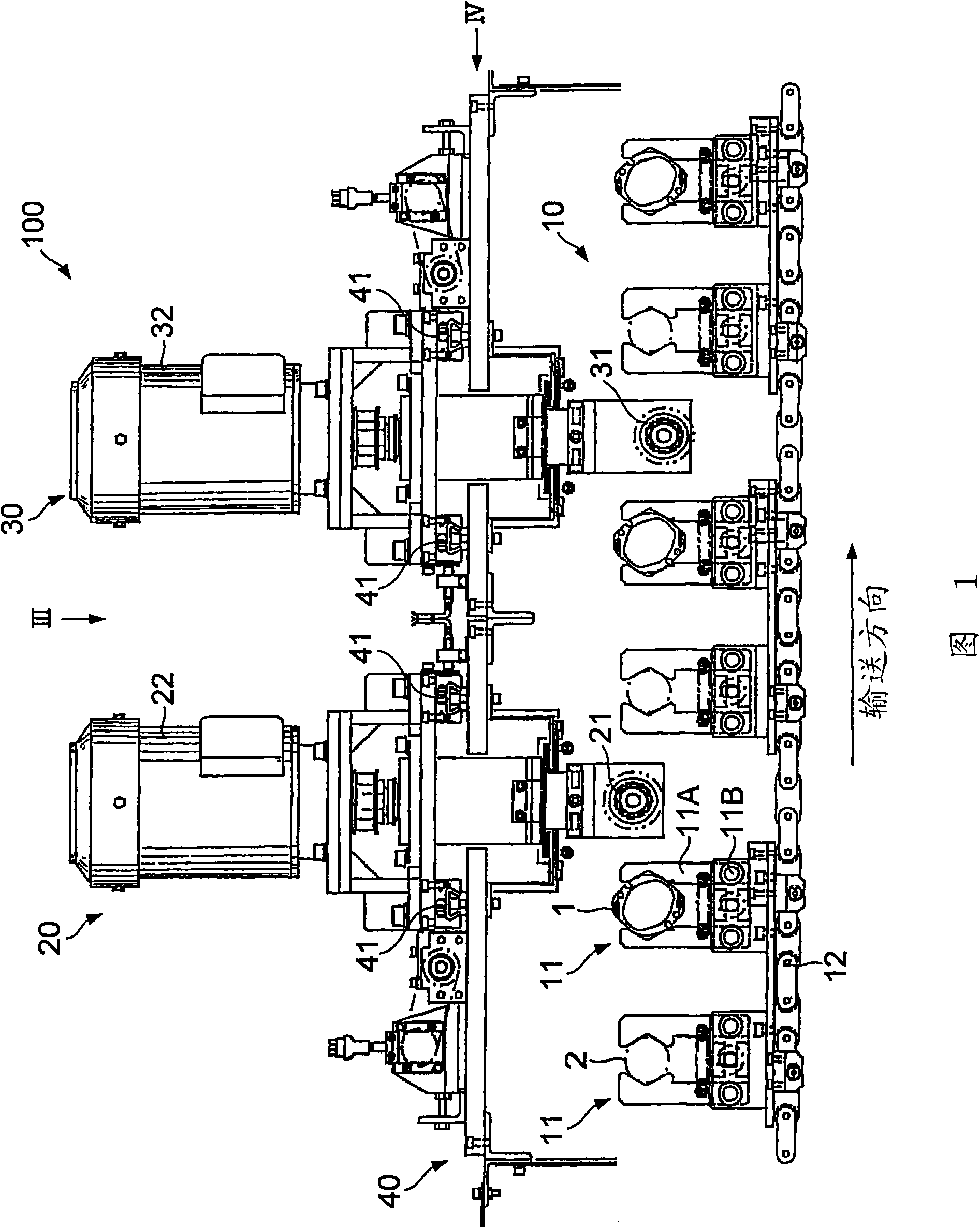

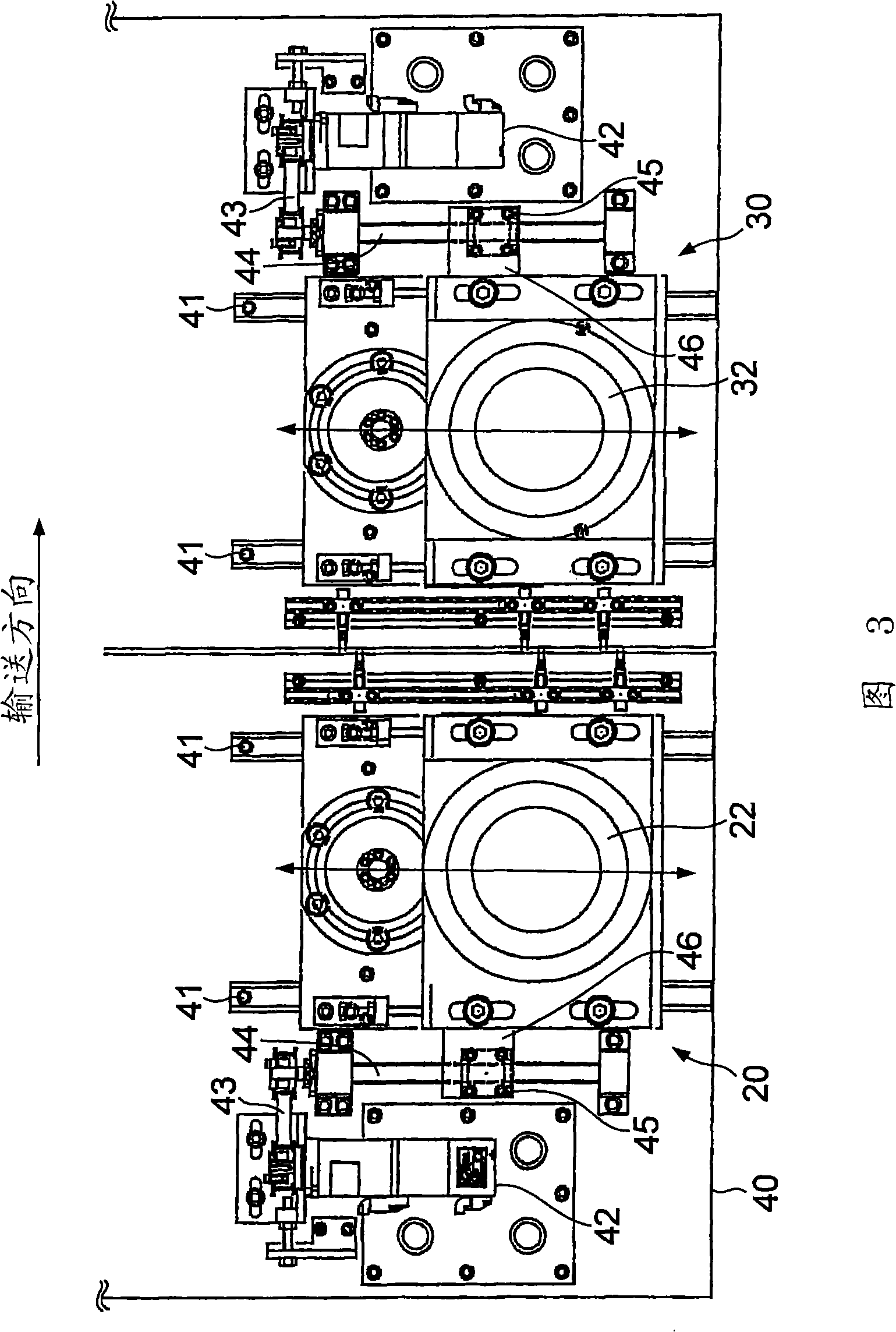

[0016] The structure of the deburring device 100 of the present invention will be described with reference to FIGS. 1 to 5 .

[0017] The deburring device 100 is a device for removing burrs formed on the end surfaces of the stator 1 and the rotor 2 of the vane pump.

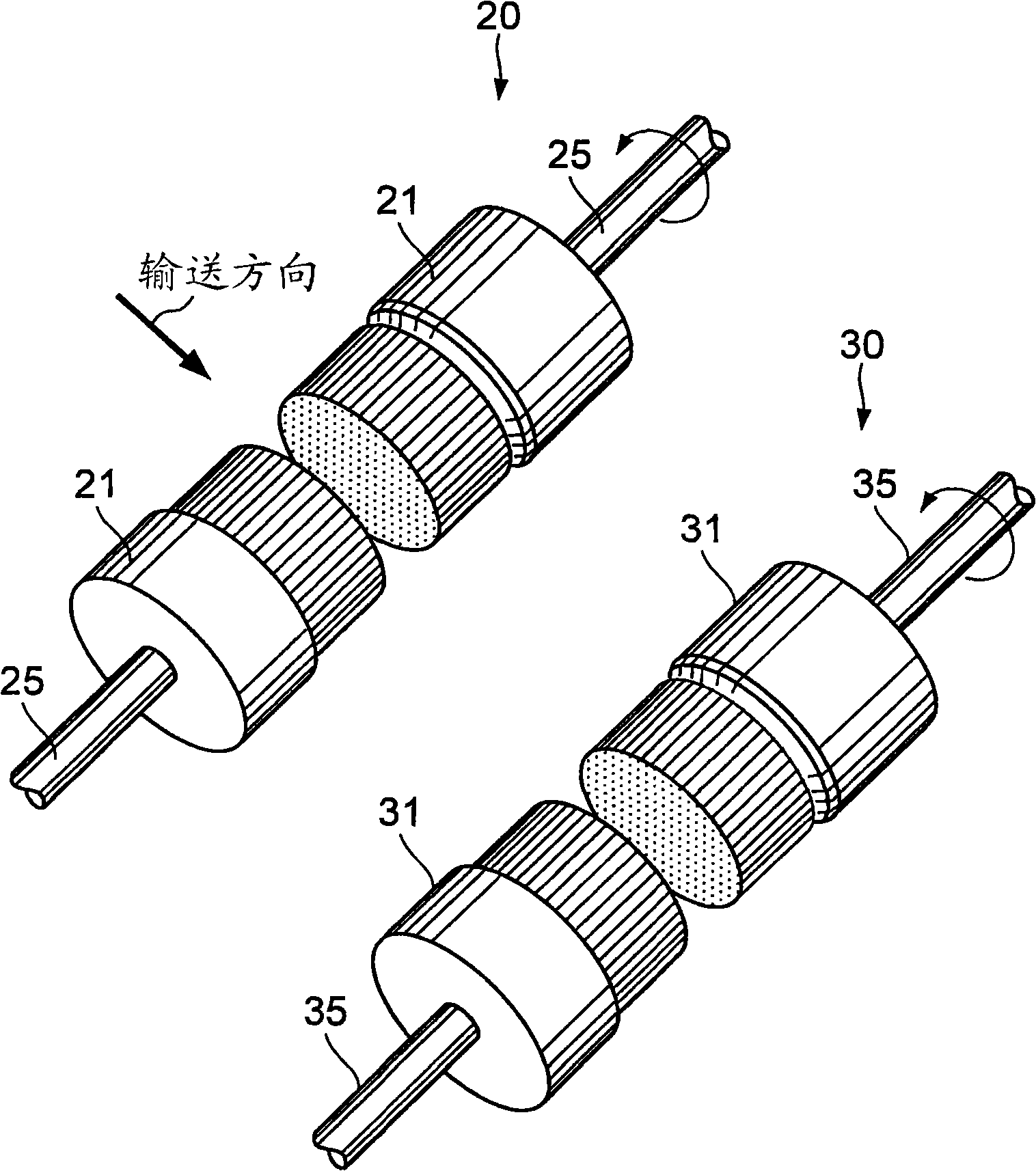

[0018] Referring to Fig. 1, the deburring device 100 has: a conveying part 10, which conveys the components to be ground such as the stator 1 and the rotor 2; . The deburring device 100 deburrs the stator 1 and the rotor 2 , but the deburring method for both is the same, and therefore, the member to be polished described below is the stator 1 .

[0019] The transport unit 10 is constituted by a holding unit 11 for holding the stator 1 and a conveyor belt 12 for moving the holding unit 11 .

[0020] The base portion 11B of the holding portion 11 has a pair of arms 11A. These arms 11A hold the stator 1 . The base portion 11B of the holding portion 11 is fixed to the conveyor belt 12 with bolts.

[0021] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com