Organosilane compounds for modifying dielectrical properties of silicon oxide and silicon nitride films

一种氧化硅膜、氮化硅膜的技术,应用在电路、电气元件、气态化学镀覆等方向,能够解决没有提供支持等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

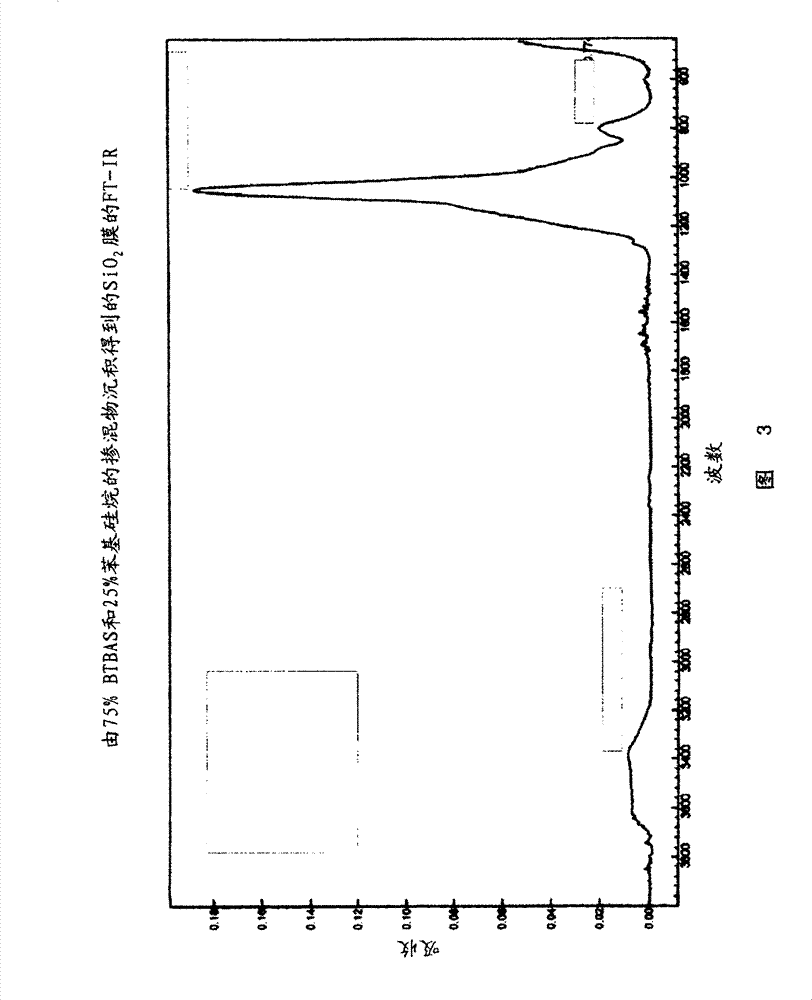

[0064] Embodiment 1 adopts LPCVD method to prepare SiO from BTBAS 2 standard method. This example serves as a baseline for other data.

[0065] Examples 2-5 are data supporting the first method of the present invention, which is the production of modified silica by using a combination of an organosilane-containing precursor and an oxygen source.

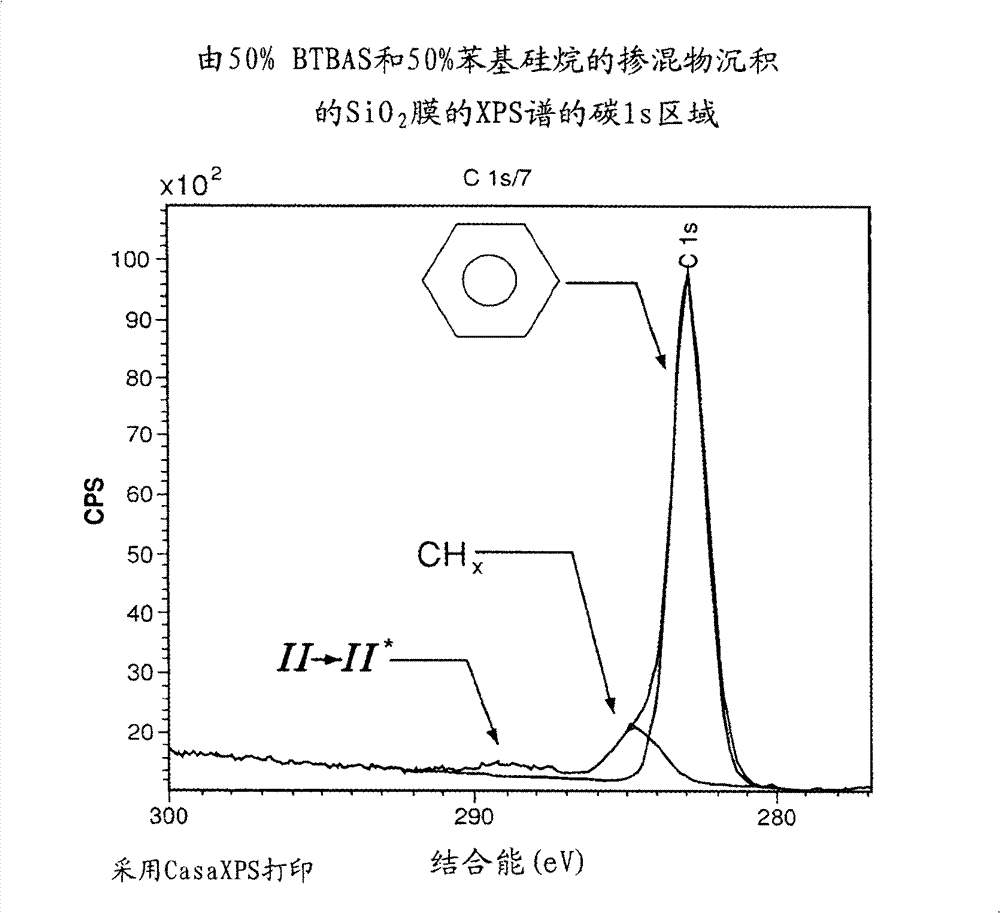

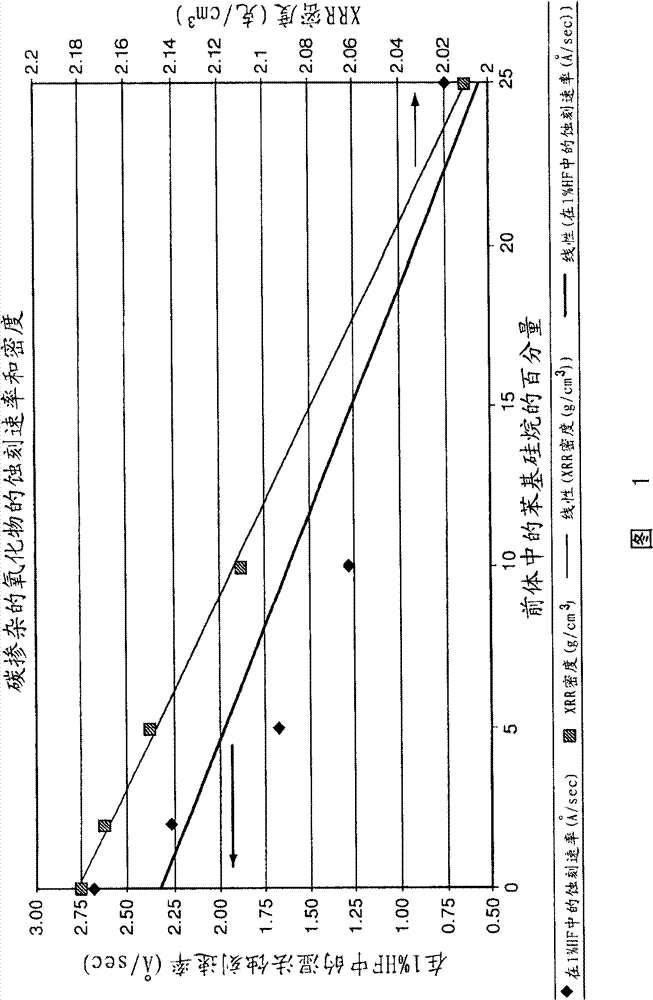

[0066] Examples 6-9 are data supporting the second method of the present invention, the modification of silicon oxide or silicon nitride by carbon doping. More specifically, methods of depositing modified silicon oxides or silicon nitrides using existing precursor chemistries, such as BTBAS, doped with organosilanes (containing carbon), such as phenylsilanes. The advantage of this method is that the membranes are derived from already used chemicals. Thus, fewer device and method problems need to be dealt with than if entirely new chemicals were used. Furthermore, by varying the ratio of the two chemicals present in the formulatio...

Embodiment 2

[0072] Example 2: Deposition of silicon oxide from phenylsilane

[0073] The process condition of this embodiment is:

[0074] LPCVD deposition, temperature range from 400°C to 500°C, pressure 600mtorr, precursor (phenylsilane):O 2 The current ratio is from 2:1 to 4:1. Table 2 shows the results.

[0075] Deposition temperature (°C) Precursor: O 2 Refractive index Dielectric constant 1% wet etch rate 400 3∶1 1.5311 not measured 0.10 450 4∶1 1.5163 3.81 0.16 500 2∶1 1.5117 4.12 0.56

Embodiment 3

[0076] Example 3: Deposition of silicon oxide from tetravinylsilane

[0077] The process condition of this embodiment is:

[0078] LPCVD deposition, temperature range from 500°C to 600°C, pressure range from 600mtorr to 1torr pressure, precursor (tetravinylsilane):O 2 The current ratio is from 1:1 to 1:2. Table 3 shows the results.

[0079] table 3

[0080]

[0081] ND: No etch rate detected, assumed to be

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com