Inflating and stretching integral film

A technique for tensioning integral and inflatable membranes, applied in building components, roof coverings, roofs, etc., can solve the problems of less engineering applications, small spanning force of airbag membranes, and low structural rigidity, etc., and achieves increased spanning capacity and simple installation and forming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

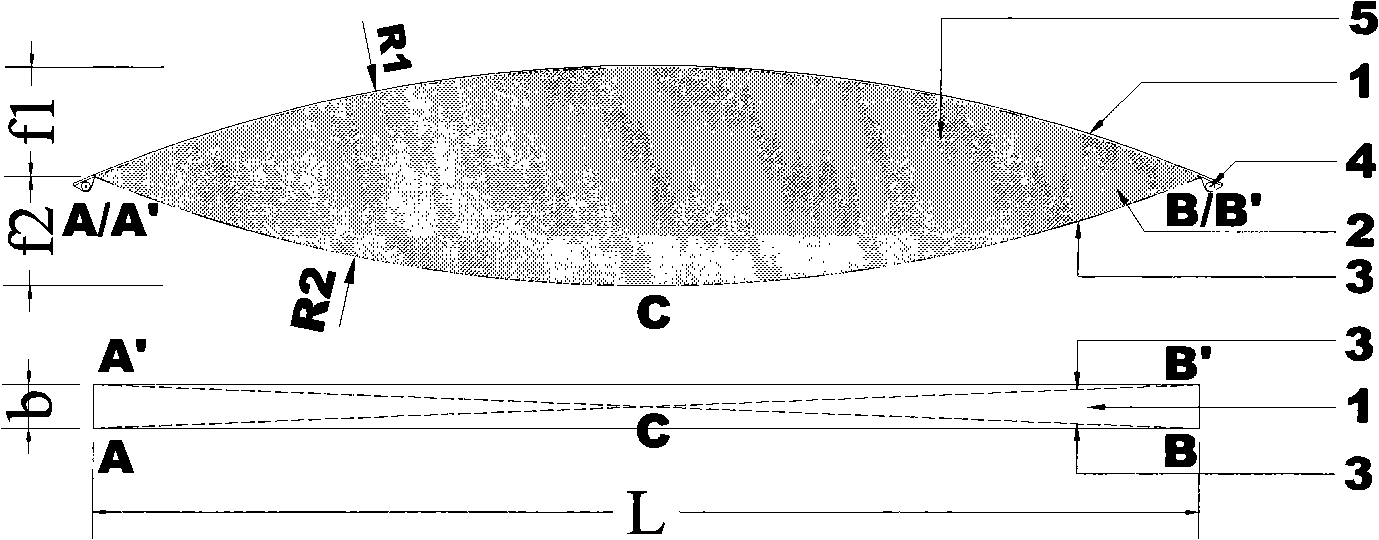

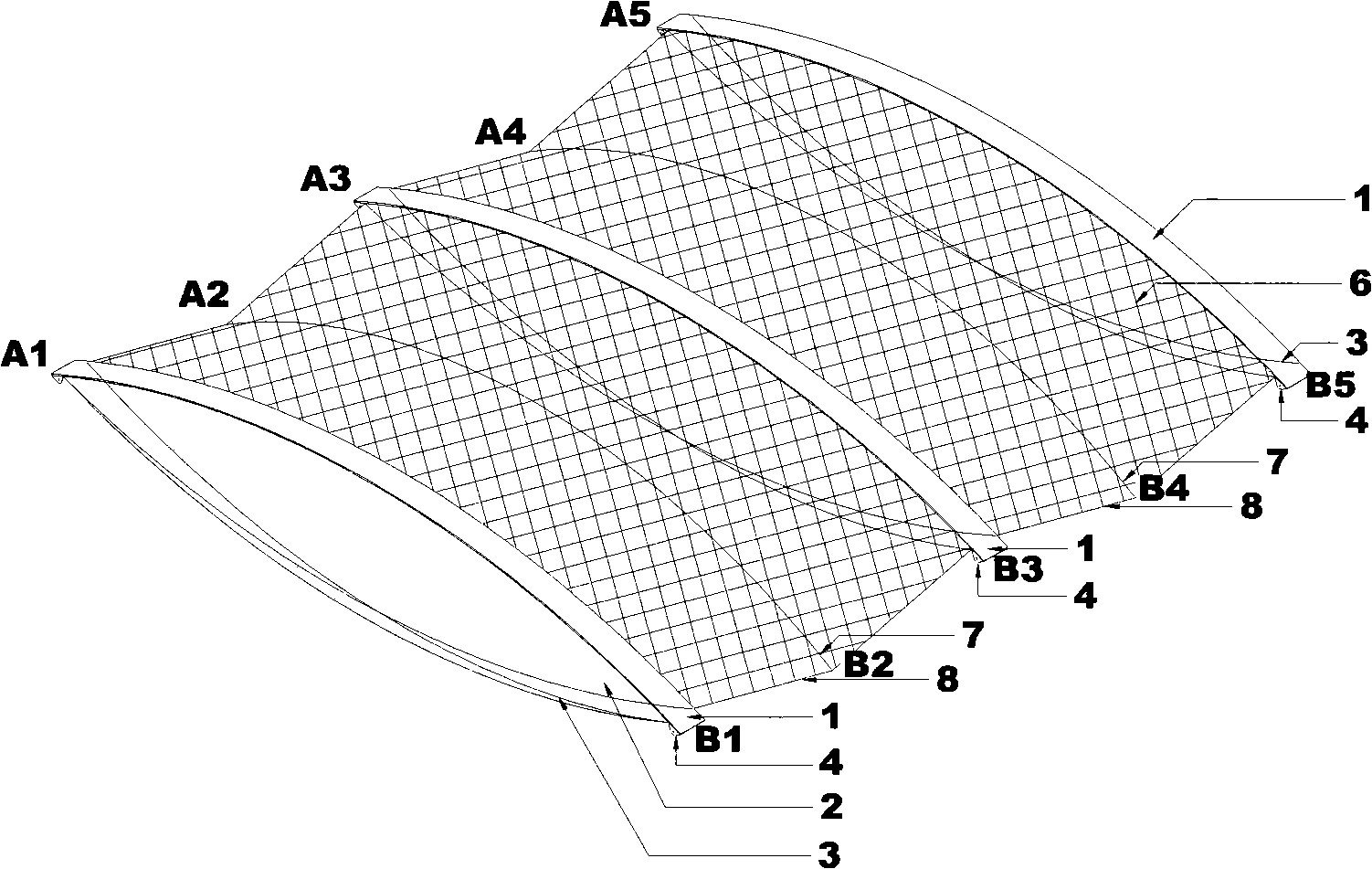

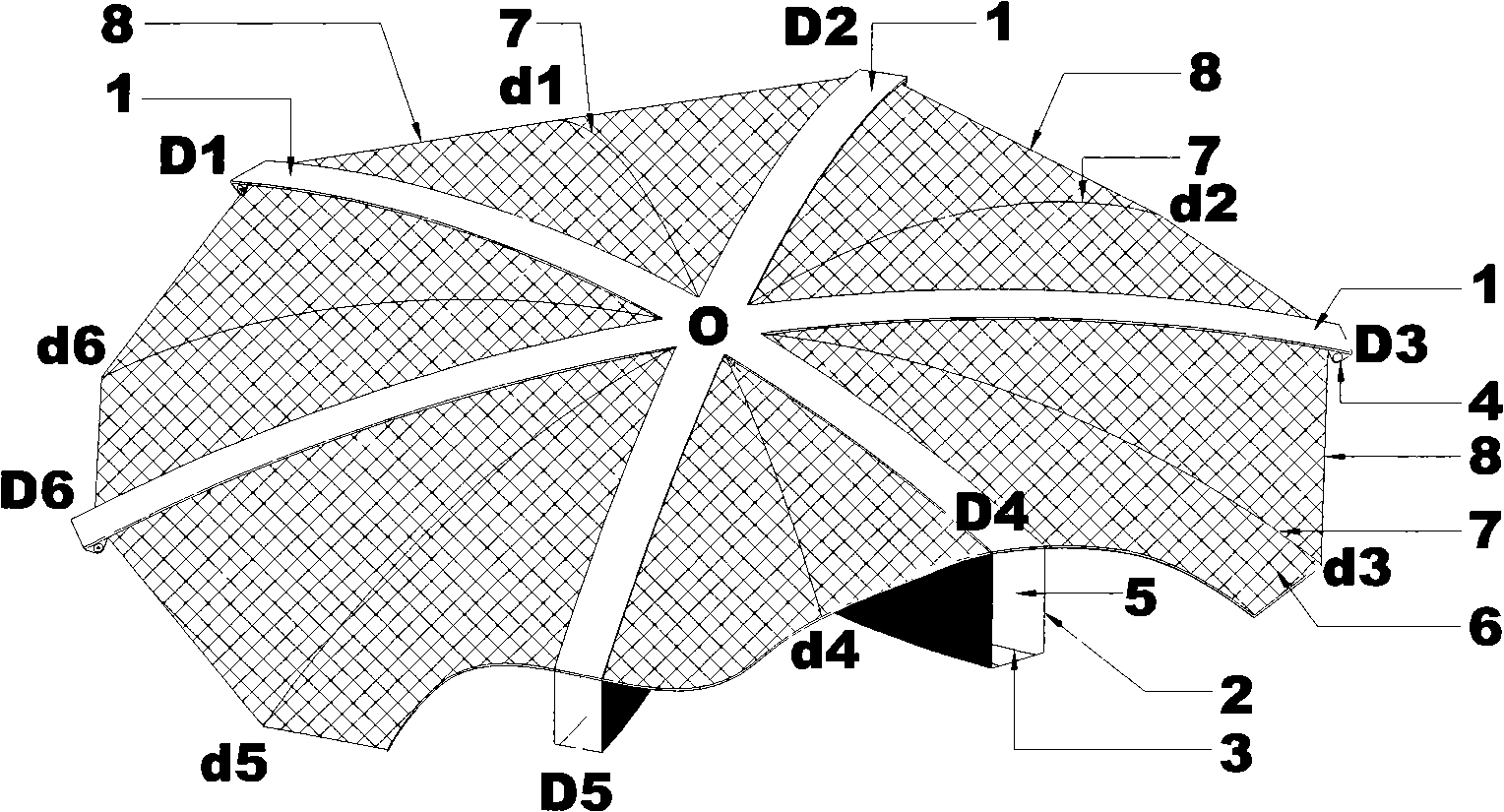

[0017] figure 1 The plane and elevation views of the integral tension beam of the inflatable membrane of the present invention are given. Such as figure 1 As shown, the integral tension beam of the inflatable membrane includes an air-bearing elastic plate 1, a spindle-shaped inflatable membrane 2, and a spiral tension cable 3, which constitute the main structural components of the inflatable tension integral membrane structure. The air-bearing elastic plate 1 (upper radius of curvature R1) spanning L and width b is fixed on the spindle-shaped inflatable membrane 2 by spiral tension cables 3 (A-C-B', A'-C-B), and the inside of the spindle-shaped inflatable membrane 2 Air 5 is pumped in by a blower (greater than atmospheric pressure 150-250 mBar), and a hinge joint 4 is respectively fixed at both ends of the air-bearing elastic plate 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com