Mixed type cable-supported bridge

A hybrid and cable technology, applied in construction and other directions, can solve the problems that the span cannot reach the ground-anchored suspension bridge, the ground-anchored suspension bridge has a large span capacity, and the span cannot be too large, so as to improve driving comfort, save engineering cost, Solve the effect of insufficient stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

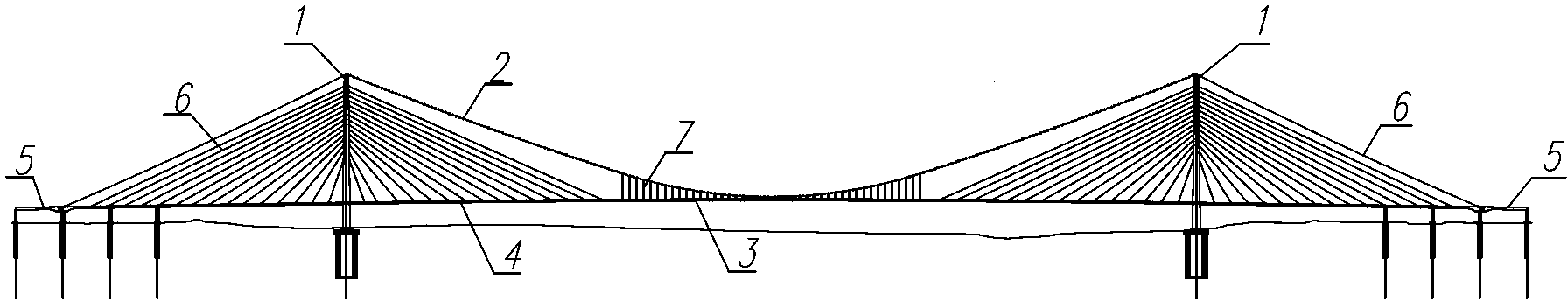

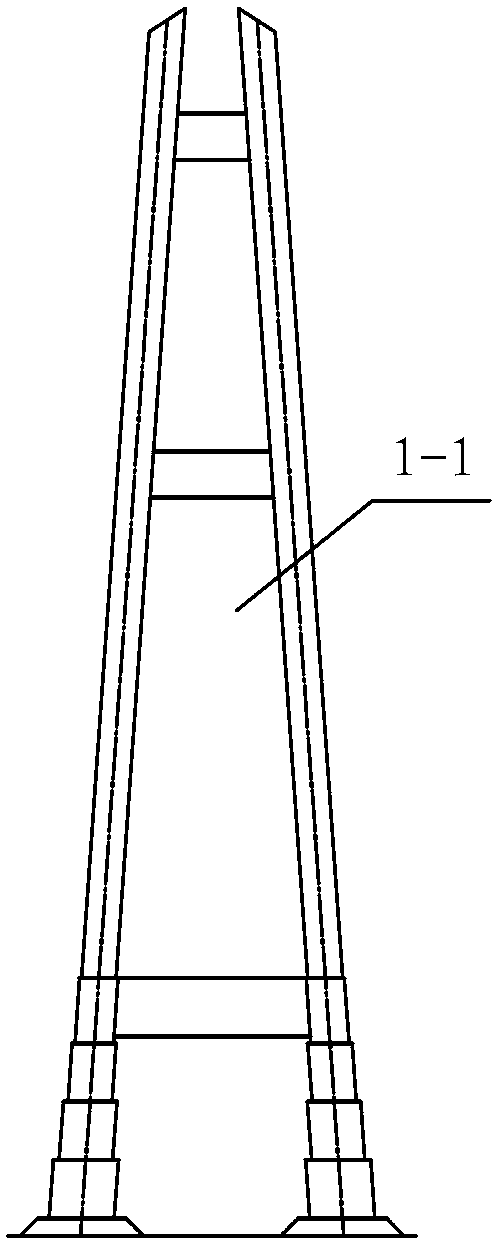

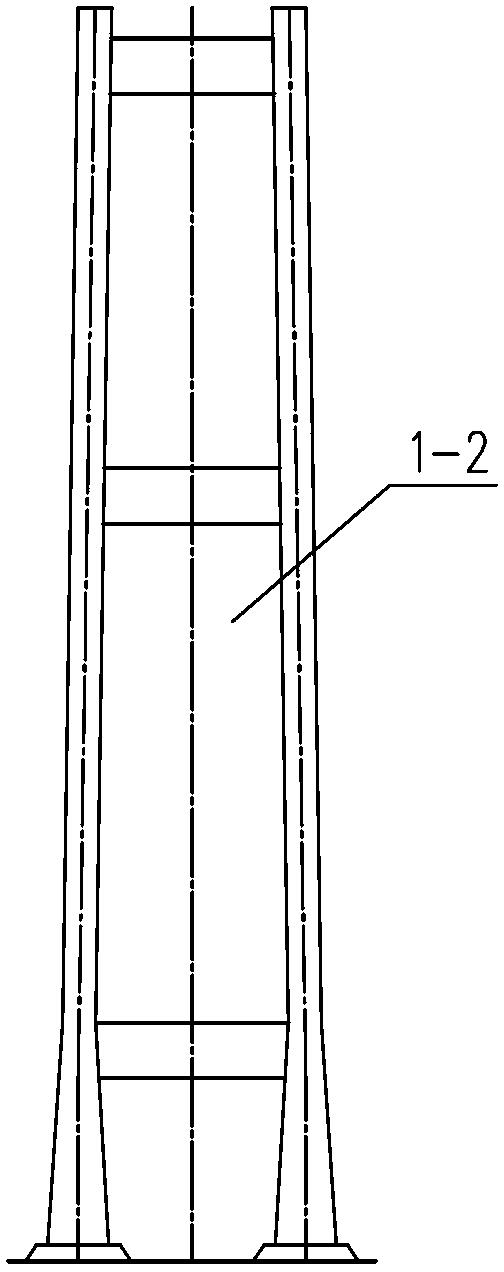

[0017] refer to figure 1 , the main span L between the two main towers 1 of the present invention reaches 2500m or hundreds of m; Between the main towers on both sides and the anchor span main beam 5 are side spans L1, L2, and the anchor span main beam 5 places are anchor span L3, L4; the span of the central suspension cable area of the main span is L5, up to 1000m, and the spans of the stay cable areas on both sides of the main span are L6, L7, up to 750m; the vertical distance between the IP point on the top of the main cable tower and the lowest point in the main span is the main Cable vector degree H, H=(1 / 4~1 / 7)L.

[0018] figure 1 The mark 1 in the figure is the main tower, 2 is the main cable, 3 is the main beam in the sling area, 4 is the main beam in the cable-stayed area, 5 is the main beam in the anchor span, 6 is the stay cable, and 7 is the sling.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com