Low-temperature refrigerating method using carbon dioxide as circulating working substance and heat pump system thereof

A carbon dioxide and circulating refrigerant technology, applied in chemical instruments and methods, irreversible cycle compressors, refrigerators, etc., can solve the problems of ozone layer destruction, global warming, and limited refrigeration temperature, so as to achieve non-combustibility and expand the refrigeration temperature Effects of small range, global warming coefficient, and ozone depletion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

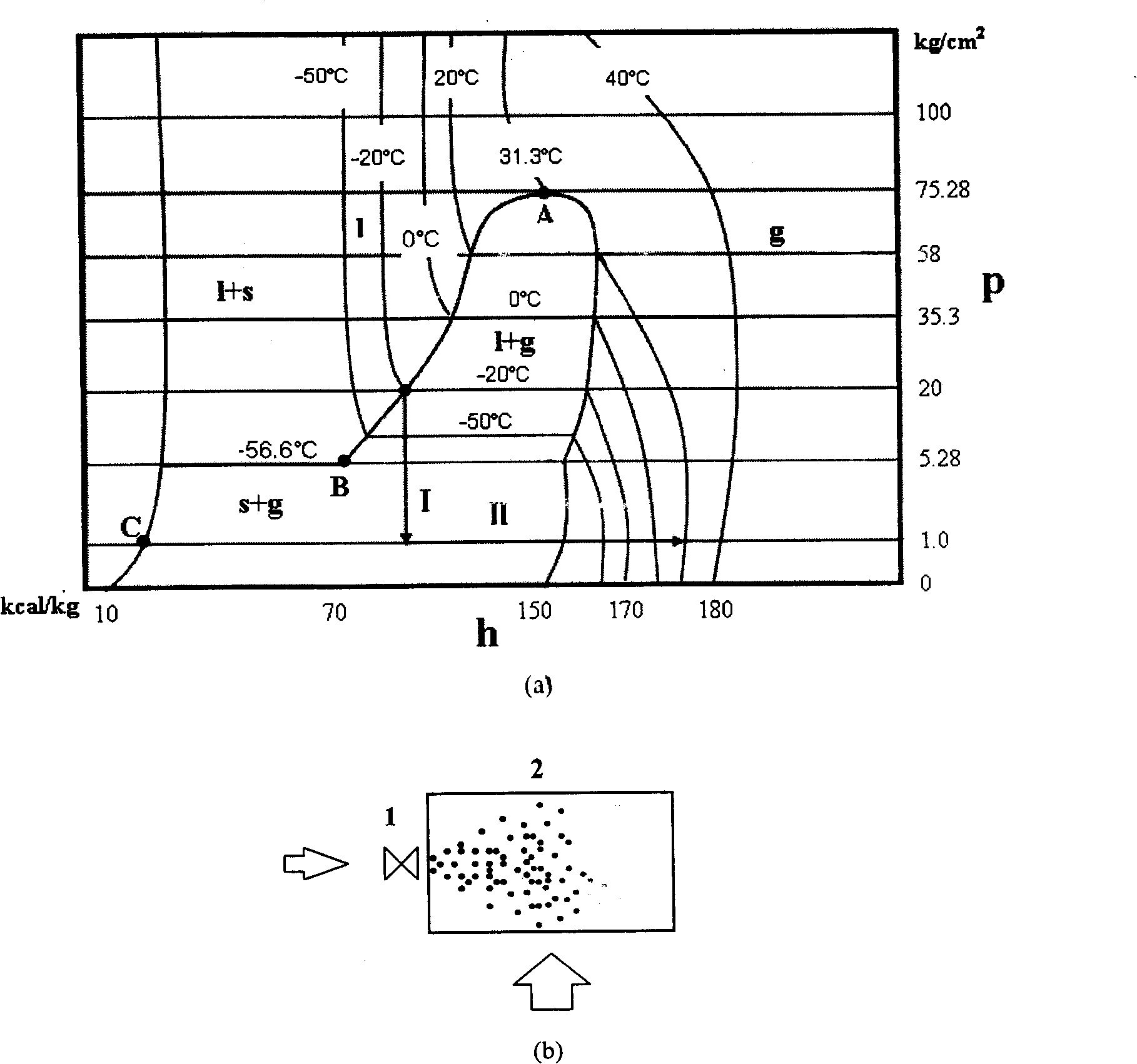

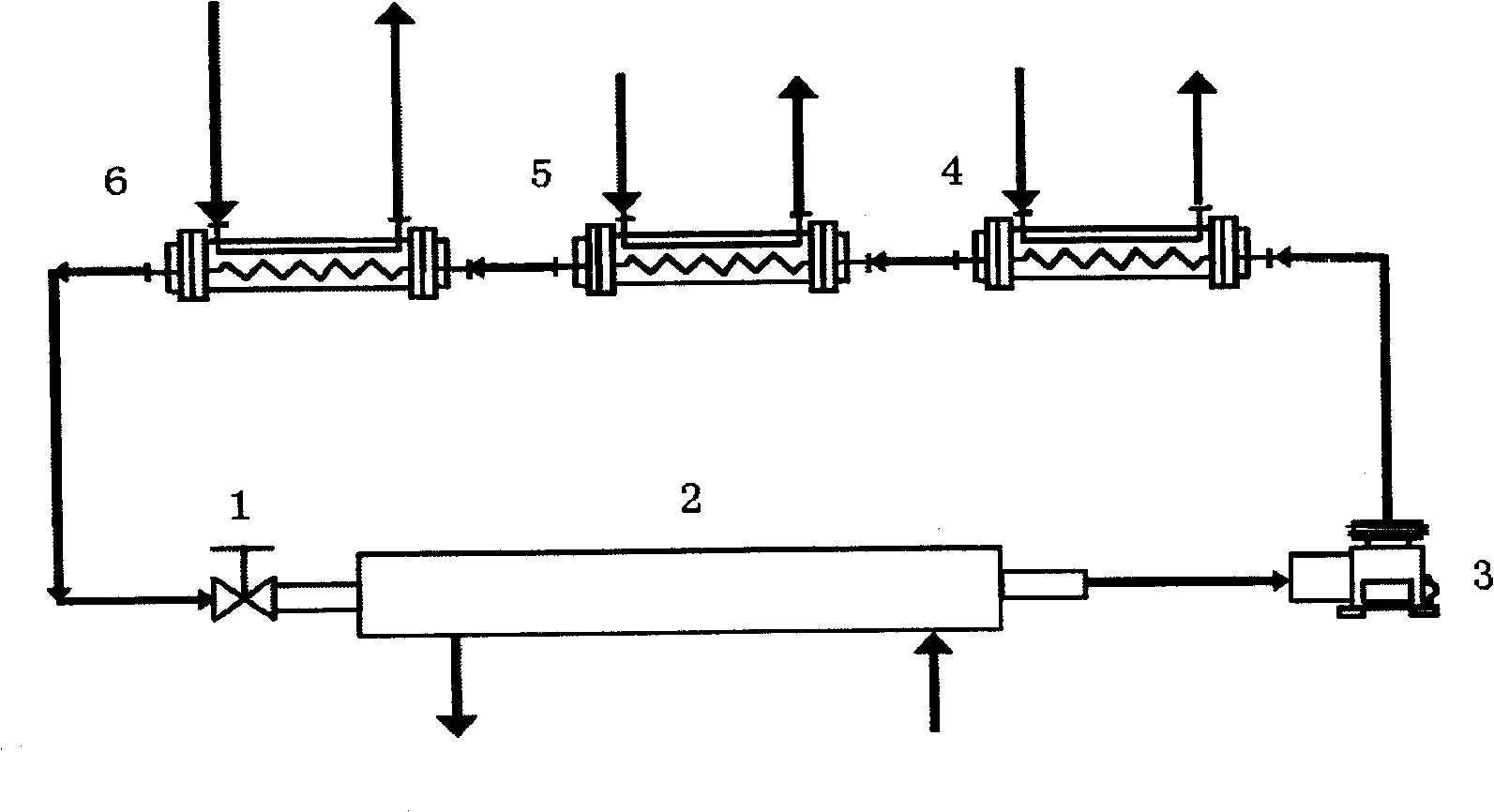

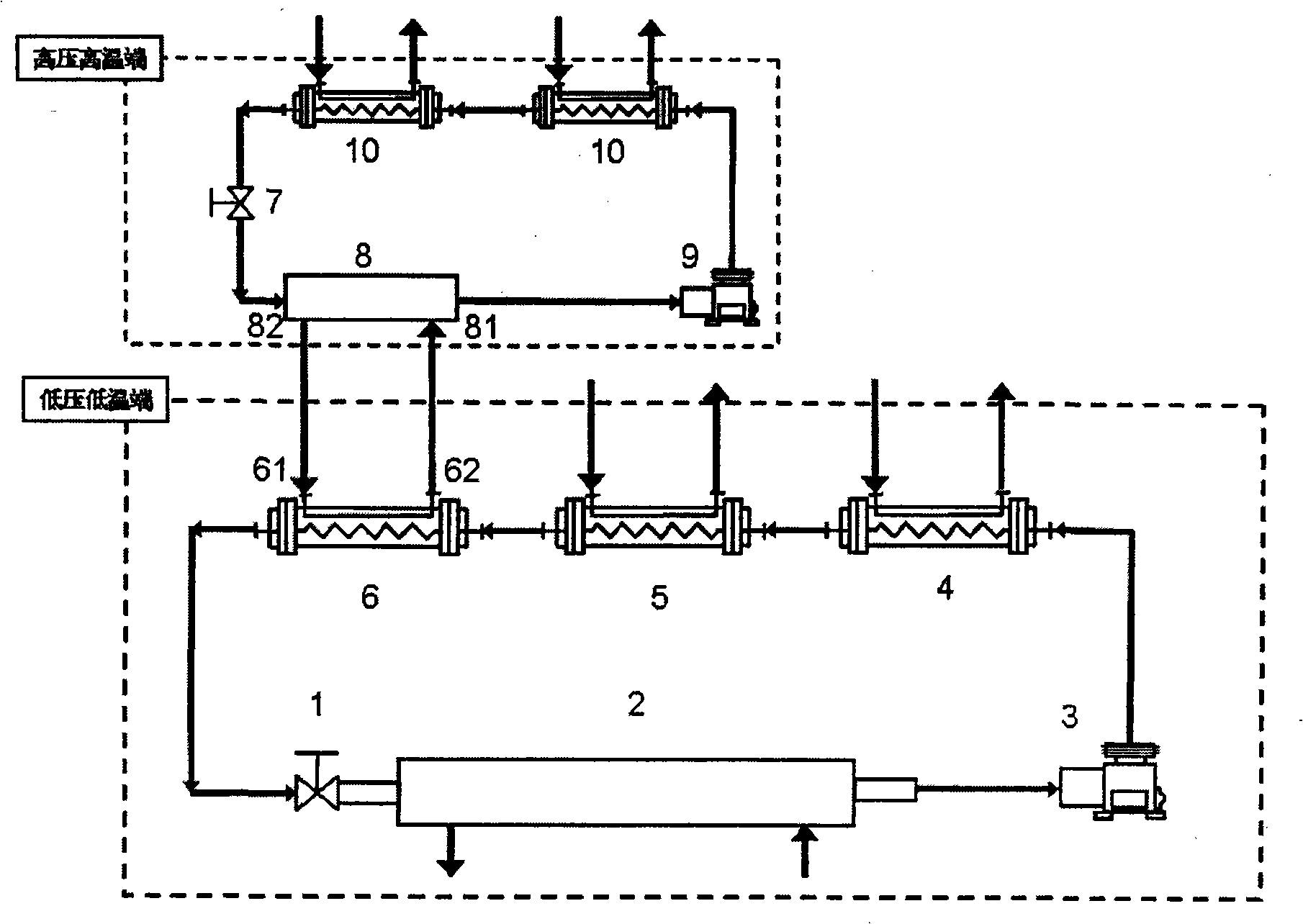

[0036] The structure and process flow of the method of the present invention and its low-temperature heat pump system will be described in detail below in conjunction with the accompanying drawings:

[0037] The present invention utilizes the low-temperature refrigeration method of carbon dioxide, comprises the following steps:

[0038] 1) Expand liquid (or liquid-gas two-phase) carbon dioxide to become solid-gas carbon dioxide two-phase fluid;

[0039] 2) The solid-gas carbon dioxide two-phase fluid absorbs the heat of the environment to be refrigerated, and sublimates into a gaseous state;

[0040] 3) Gaseous carbon dioxide is compressed into high-pressure gas, and then cooled to liquid (or liquid-gas two-phase carbon dioxide);

[0041] 4) The liquid state (or liquid-gas two-phase carbon dioxide) is returned to step 1) and the cold and heat exchange process of steps 1)-4) is repeated, so as to realize the low-temperature refrigeration of the environment to be refrigerated. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| triple point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com