Method and machine for rubberizing an annular surface of a body

A gluing machine and gluing technology, applied to tires, household utensils, and other household utensils, etc., can solve problems such as changes in stretching amount and uncontrolled third stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

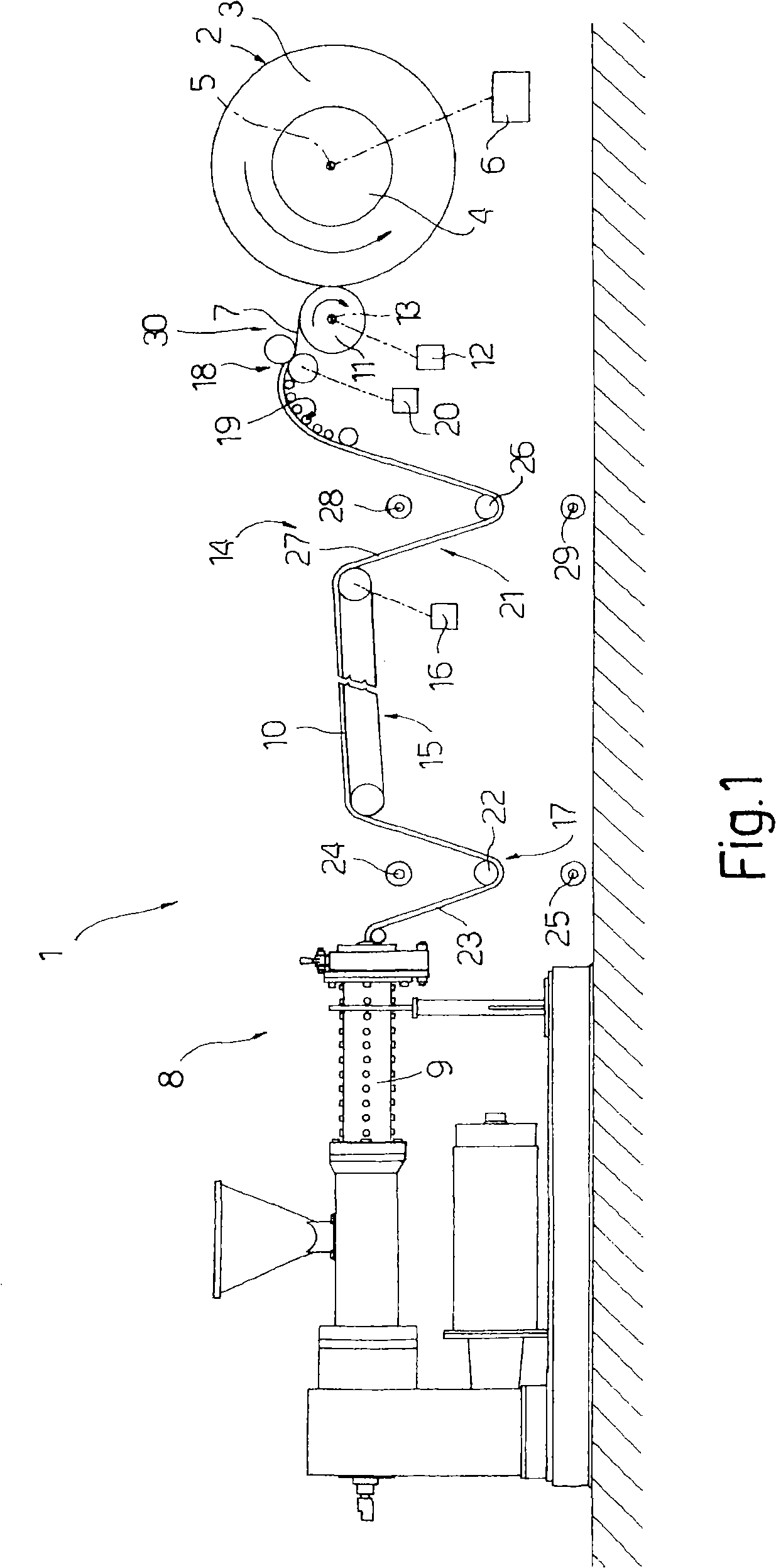

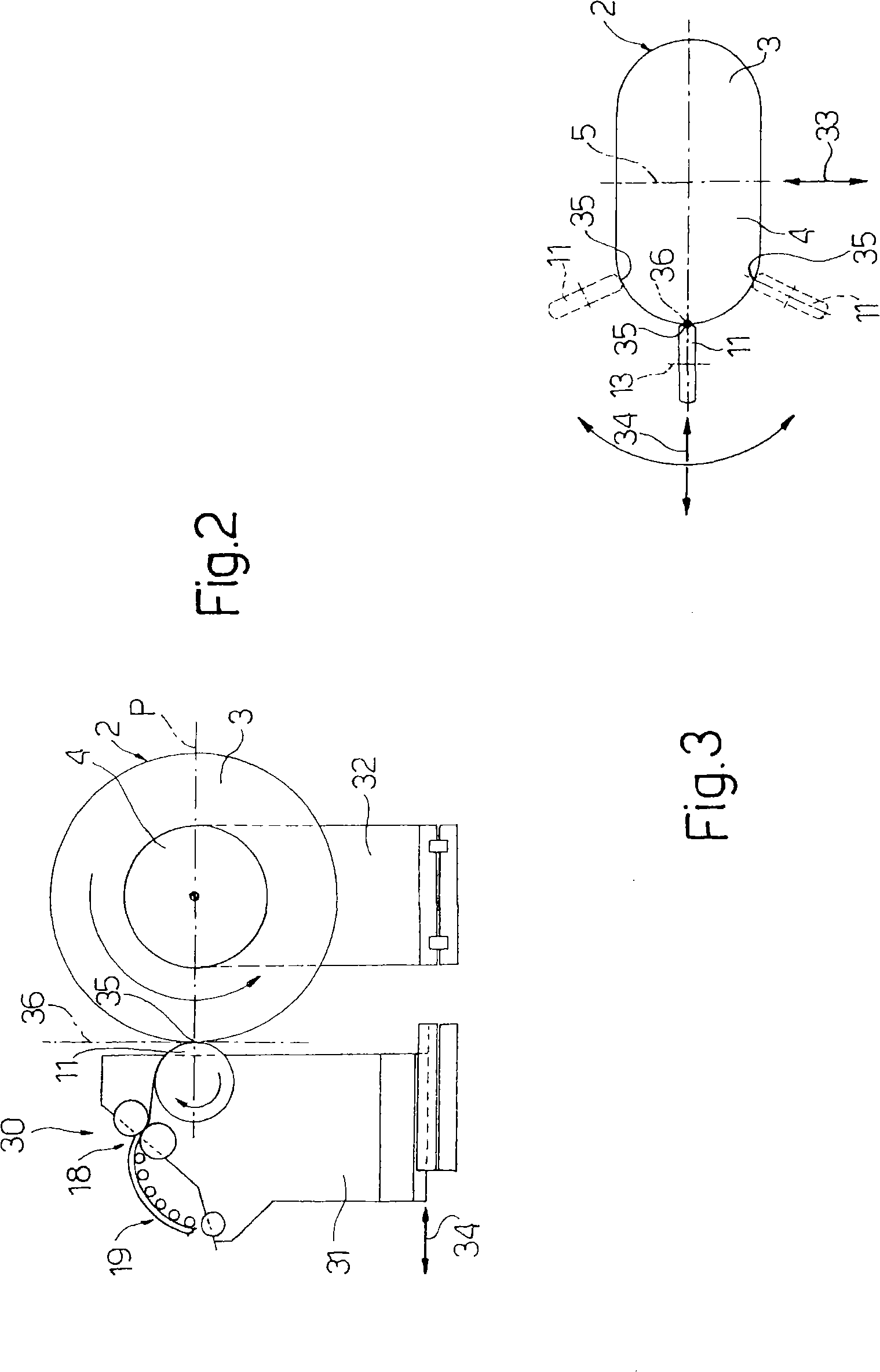

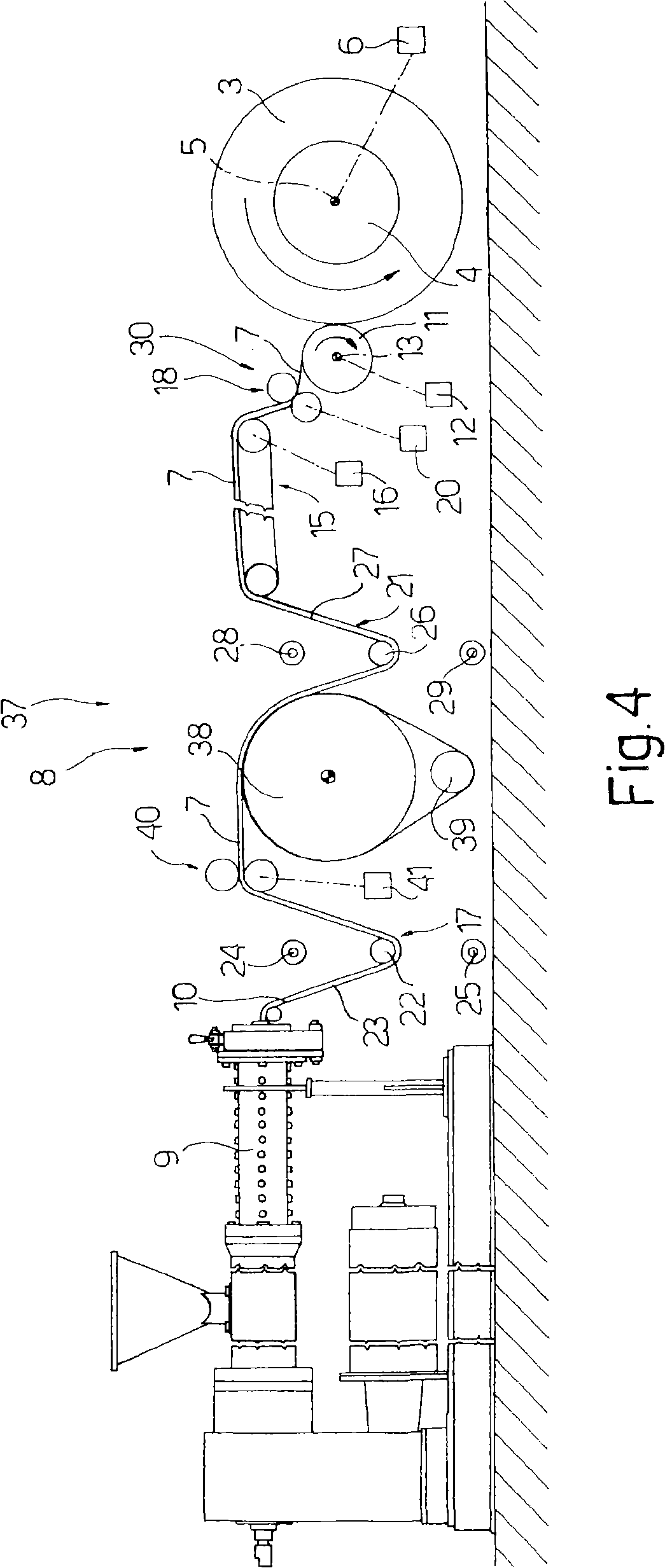

[0016] In FIG. 1, reference numeral 1 denotes the whole of a gluer for thermally gluing the annular surface of the carcass 2, in said related example, the toroid comprises a tire carcass 3 mounted on a mandrel 4, which is connected to The annular surface 2 is coaxial and rotates around the spindle axis 5 driven by the variable speed motor 6 .

[0017] The annular surface 2 is continuously glued to itself by means of a strip 7 of elastic material having a predetermined cross-section, the elastic material being applied to the annular surface by means of a feeder 8 which is a glue applicator 1, comprising a screw extruder 9 for the production of elastomeric material, usually in the form of a circular cross-section strip 10, and a gumming roller 11 arranged in use to contact the annular surface 2 It is tangent to itself and rotates around an axis 13 parallel to the axis 5 driven by the transmission device 12 , and the axis 13 and the axis 5 form a plane P together.

[0018] The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com