Laser holographic open flow film, open flow transfer paper and producing technique thereof

A technology of laser holography and transfer paper, which is applied in the printing process, printing of special varieties of printed matter, packaging paper, etc. It can solve the problems of plate seams, troubles, waste of materials, etc., so as to improve the utilization rate and avoid manual waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] 1) Substrate: PET film: material transparent, flat, uniform thickness, error ≤ ± 10%, no water marks, stains, scratches, light transmittance 91% ~ 93%, its material is polyester material; PET The film thickness is 12-50um, and the length of each roll is about 5000 meters.

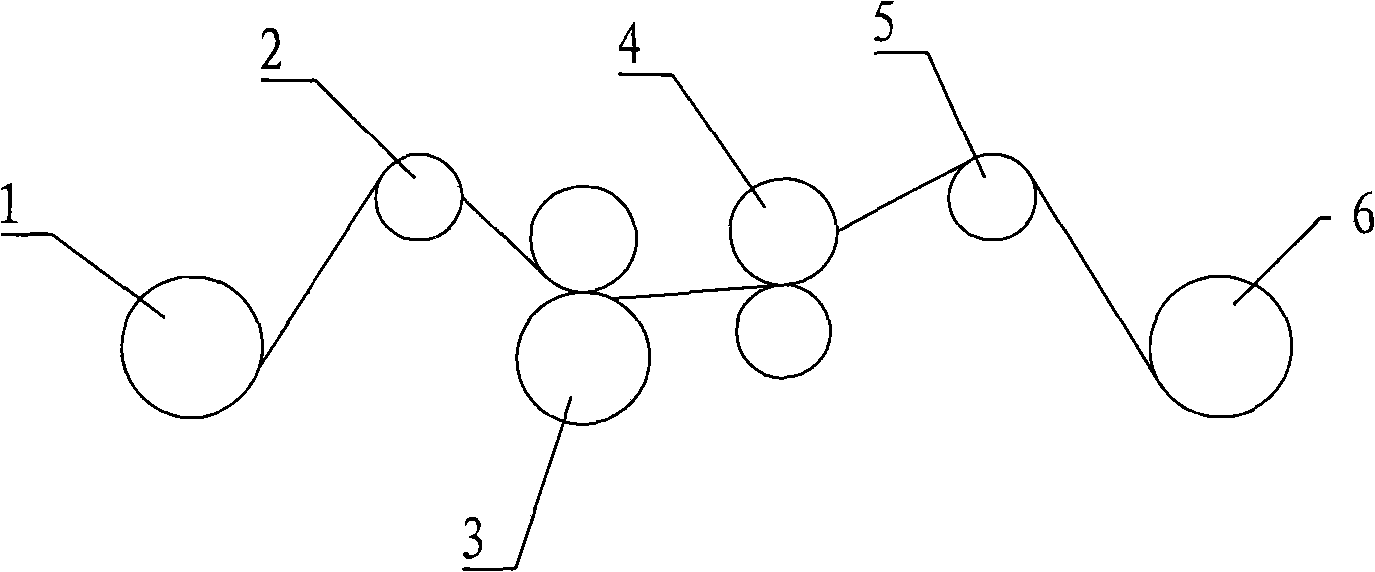

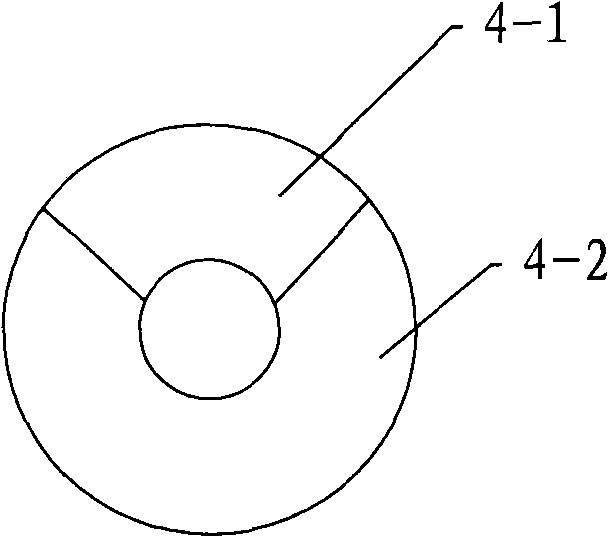

[0029] 2) Equipment: Except for version shaft II4, other equipment and its connection are the same as the prior art. There is a cooling area 4-1 on the plate axis II4, which adopts forced cooling methods, such as water cooling and air cooling, and the temperature of this area is lower than the imaging temperature of the imaging area 4-2.

[0030] 3) Preparation of the anti-counterfeiting holographic smooth film: firstly paste the working plate on the plate axis I 3 and plate axis II4 according to the prior art, the plate seam of the working plate on the plate axis I 3 is at any position, and the plate of the working plate on the plate axis II4 The plate seam is in the cooling area 4-1; according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com