Automatic doffing system

An automatic doffing and doffing technology, applied in textiles and papermaking, etc., can solve the problems of long doffing time, production efficiency, unsuitable for roving frame upgrades, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

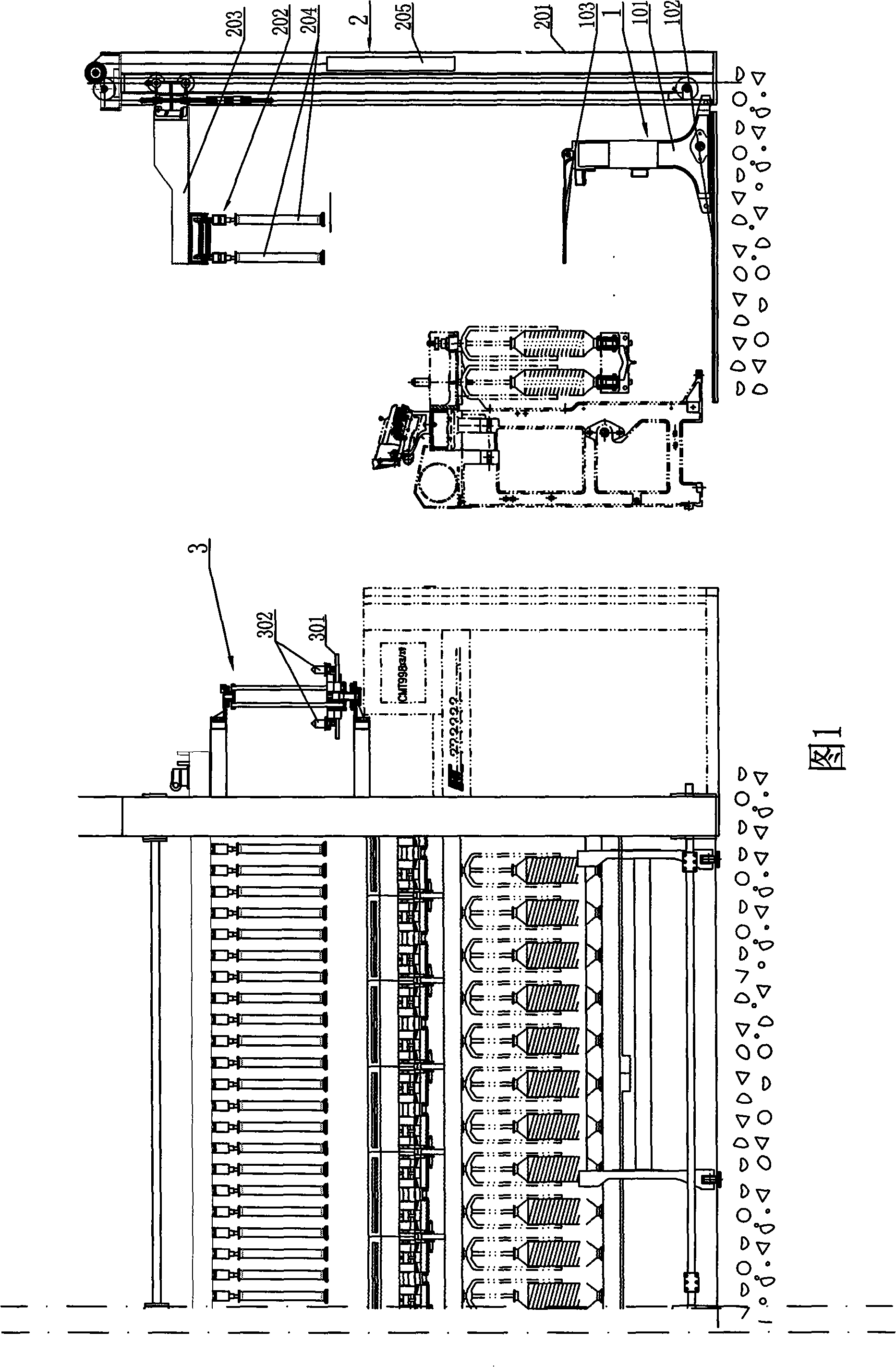

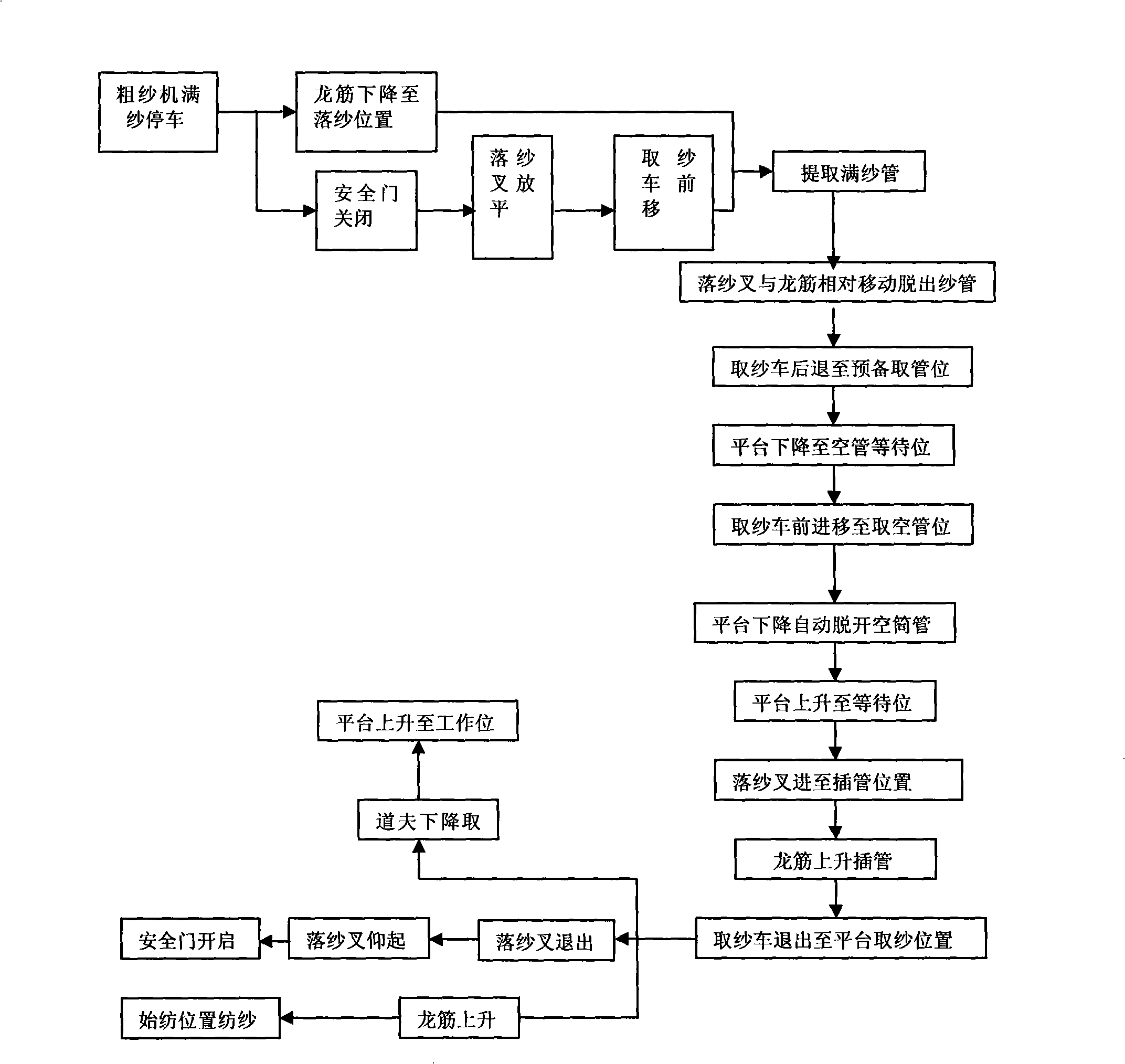

[0016] See Figure 1 and figure 2 , an automatic doffing system, including a yarn taking vehicle cover 1, a lifting platform cover 2, and a manipulator cover 3 for converting empty bobbins and full bobbins. When doffing, the take-up car in the take-up car set carries the doffing fork that is consistent with the number of spindles of the roving frame and moves forward to the designated position of the full bobbin, and the doffing fork removes the corresponding full bobbins respectively. Then the yarn-taking car moves to the designated position and waits to receive the following empty bobbins; the platform of the lifting platform lowers and delivers the empty bobbins with the same quantity as the number of spindles of the roving frame to the yarn-taking car. The doffing fork uses its front fork to pick up the corresponding empty bobbins, and the empty bobbins are transferred to the take-up car, and the take-up car moves forward to send the empty bobbin to the designated position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com