Multi-layer composite seamless overall plastic pipe and process thereof

A multi-layer composite and seamless technology, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of single-layer extruded pipes with single functionality, and achieve the effects of smooth appearance, improved barrier properties, and high lap strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the content of the present invention, the following will be further described in conjunction with specific examples.

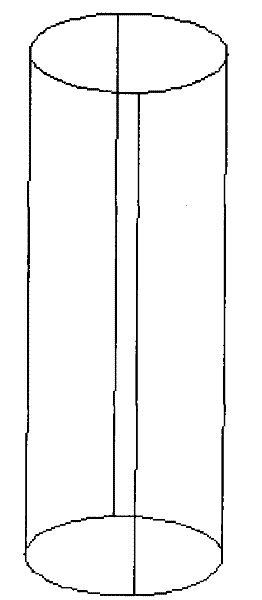

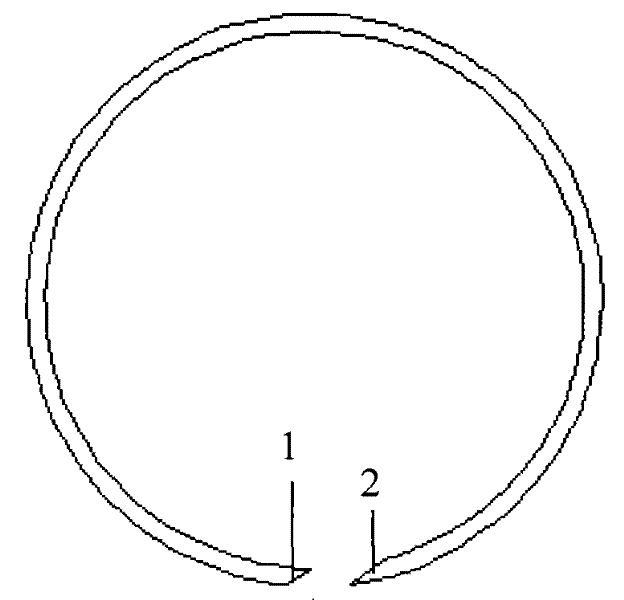

[0025] see Figure 1 to Figure 4 As shown, the multi-layer composite seamless all-plastic pipe of the present invention has a pipe wall including a first end face 1 and a second end face 2, and the first end face 1 and the second end face 2 are completely butted and fixed.

[0026] In a specific embodiment of the present invention, both the first end face 1 and the second end face 2 are inclined end faces, and the inclination angles of the first end face 1 and the second end face 2 are complementary angles to each other.

[0027] In a specific embodiment of the present invention, the first end surface 1 and the second end surface 2 are fixed by welding.

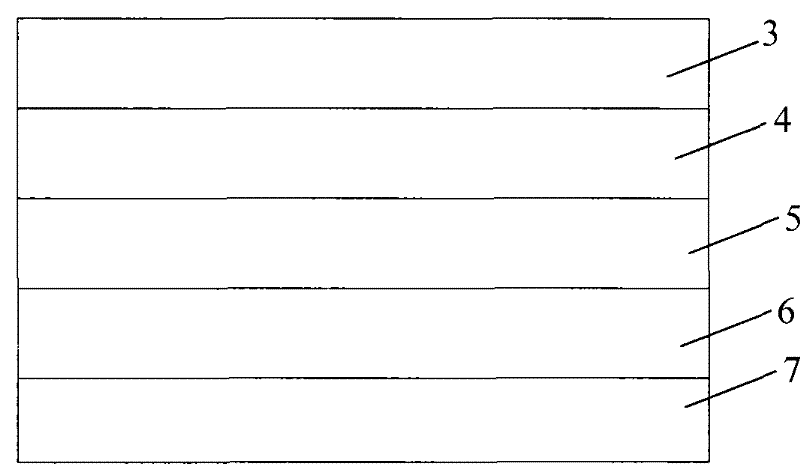

[0028] In a specific embodiment of the present invention, the hierarchical structure of the pipe wall includes a plastic printing layer 3, a first adhesive layer 4, a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com