Special pneumoelectric linkage plastic-steel belt welding machine for cotton

A technology of plastic-steel belt and welding machine, which is applied in the field of plastic-steel belt welding machine for gas-electric linkage cotton, which can solve the problems of incorrect control of welding and pressure holding time, high pressure and flow requirements, and influence on work effect, so as to improve work effect , good heat dissipation performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

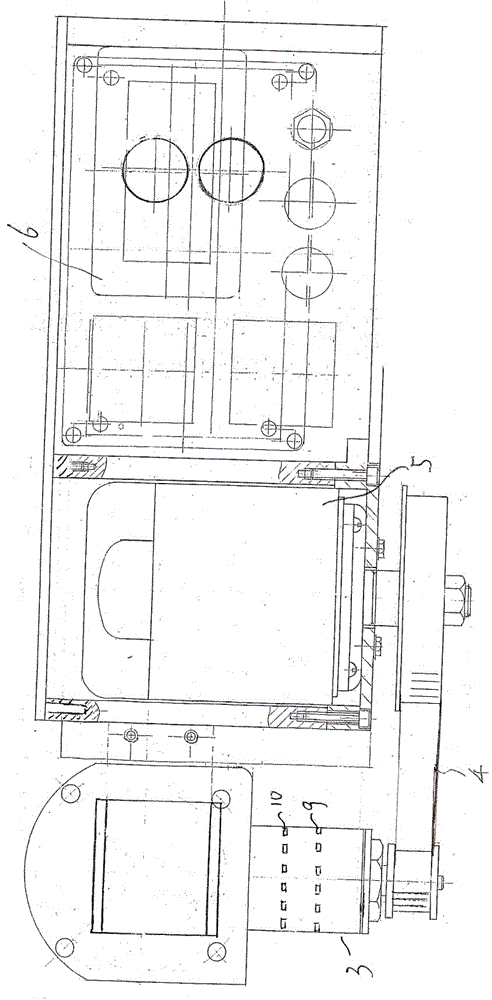

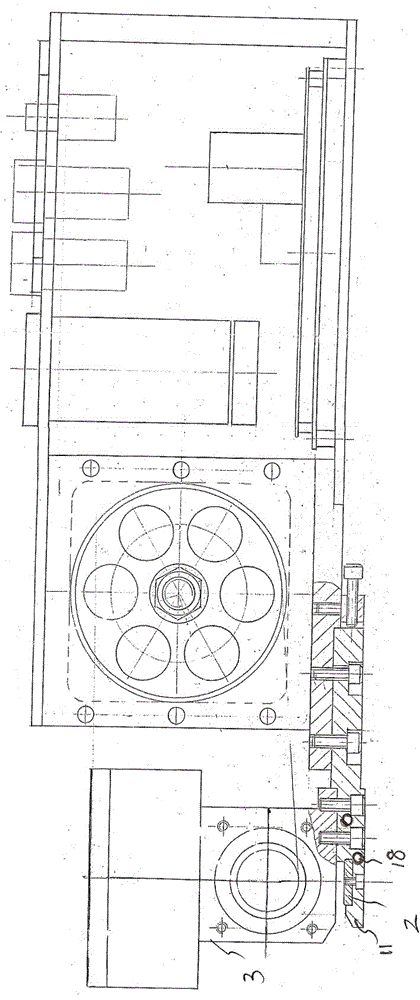

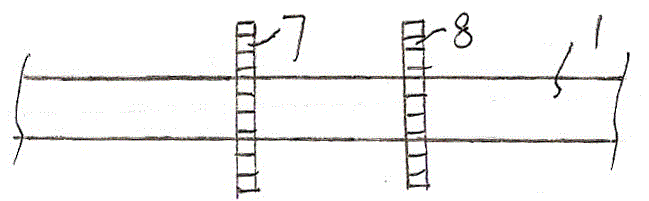

[0021] A special plastic-steel belt welding machine for gas-electric linkage cotton, including an electric transmission shaft 1, a cylinder mechanism, a pressure maintaining mechanism driven by the cylinder mechanism, a friction plate 2, and a bottom plate 11, the friction plate is driven by the electric transmission shaft, the electric transmission shaft, and the cylinder mechanism Installed in the casing 3, the electric transmission shaft is connected with the motor 5 through the synchronous belt mechanism 4, and the motor 5 is connected with the PLC control device 6 which controls the action of the motor and the cylinder mechanism.

[0022] The air cylinder mechanism includes an air pipe connected to the air source, and an air valve controlled by PLC and located outside the casing is arranged on the air pipe, and the air pipe directly communicates with the cylinder in the casing.

[0023] The PLC controller controls the working time of the motor and the air valve.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com