Soft and hard rubber lap joint structure of air deflector

A technology of air diversion and connection structure, which is applied in the cooling combination arrangement of the power unit, power unit, transportation and packaging, etc. It can solve the problems of easy separation of soft and hard glue, insufficient lap strength, and low service life. Achieve the effects of not easy to separate, long service life and high lap strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

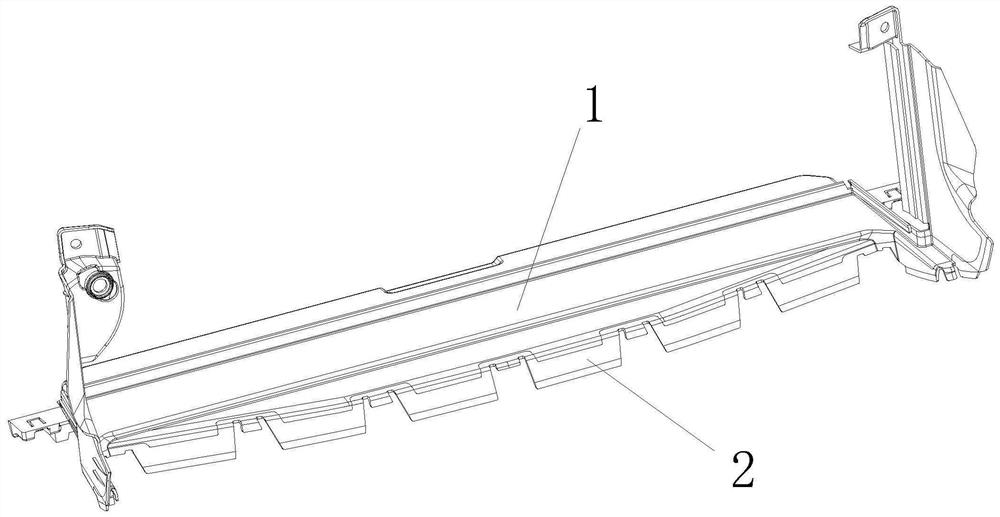

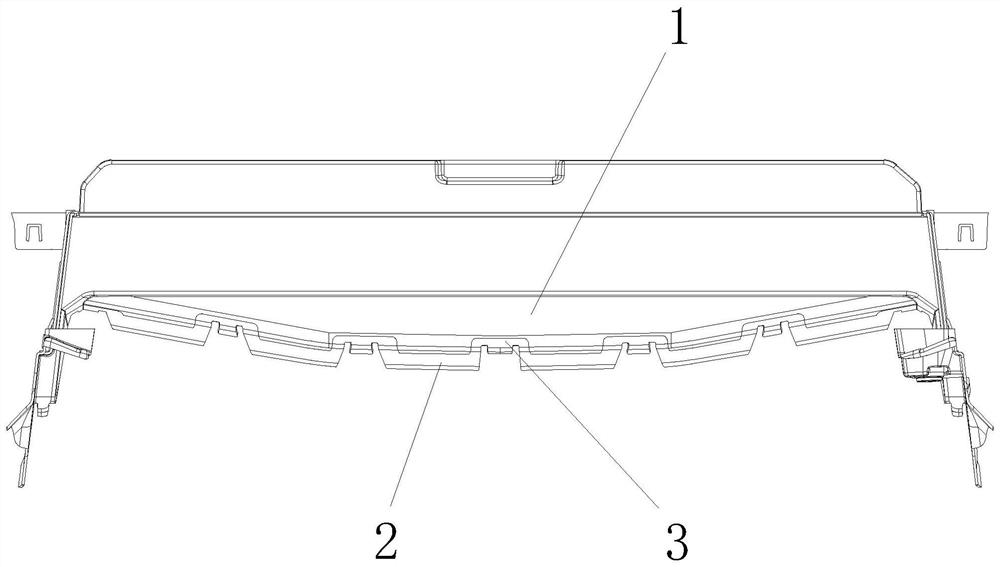

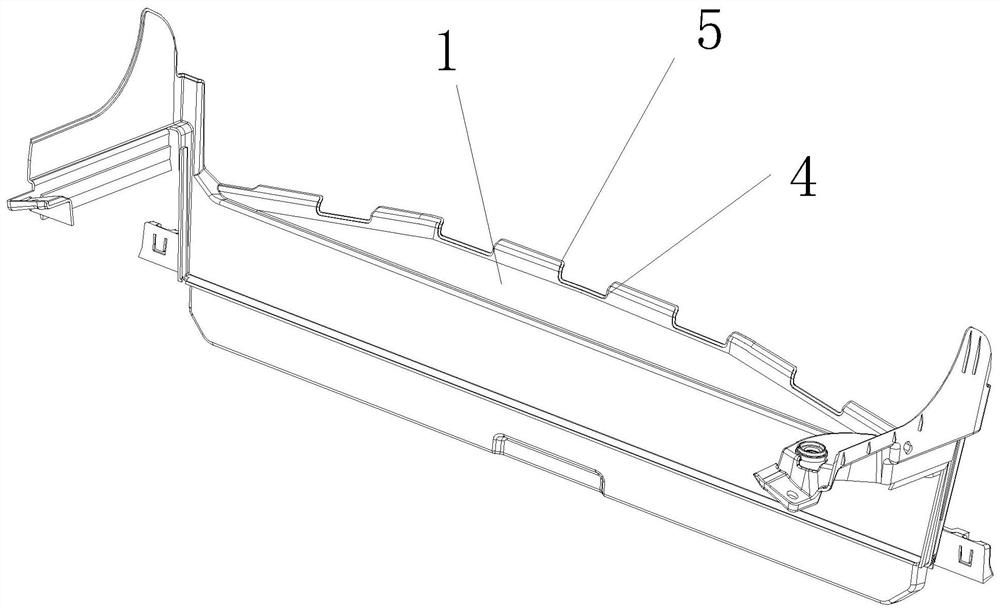

[0022] Such as figure 1 , 2 , 3, an air deflector soft and hard rubber overlapping structure, including a hard rubber layer 1 and a soft rubber layer 2, the soft rubber layer 2 is provided with a plurality of protrusions 3, and the hard rubber layer 1 is correspondingly convex. The riser 3 is provided with a recess 4, the outer edge of the hard rubber layer 1 is provided with a lower connecting plate 5, and the corresponding lower connecting plate 5 on the soft rubber layer 2 is provided with an upper connecting plate 15. During production, the upper connecting plate 15 is connected to the lower connecting plate 5. The connecting plates 5 are overlapped together, the overlapping area is relatively large, and the overlapping strength is high. The convex part 3 on the soft rubber layer 2 is connected with the concave part 4 on the hard rubber layer 1, which can increase the gap between the soft and hard rubber. The adhesive force between them makes the soft rubber layer 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com