Gas tank gas supply safety device

A technology for safety devices and gas tanks, applied in gas/liquid distribution and storage, container discharge methods, container filling methods, etc., can solve problems such as gas leakage, waste of gas, and large increase in fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

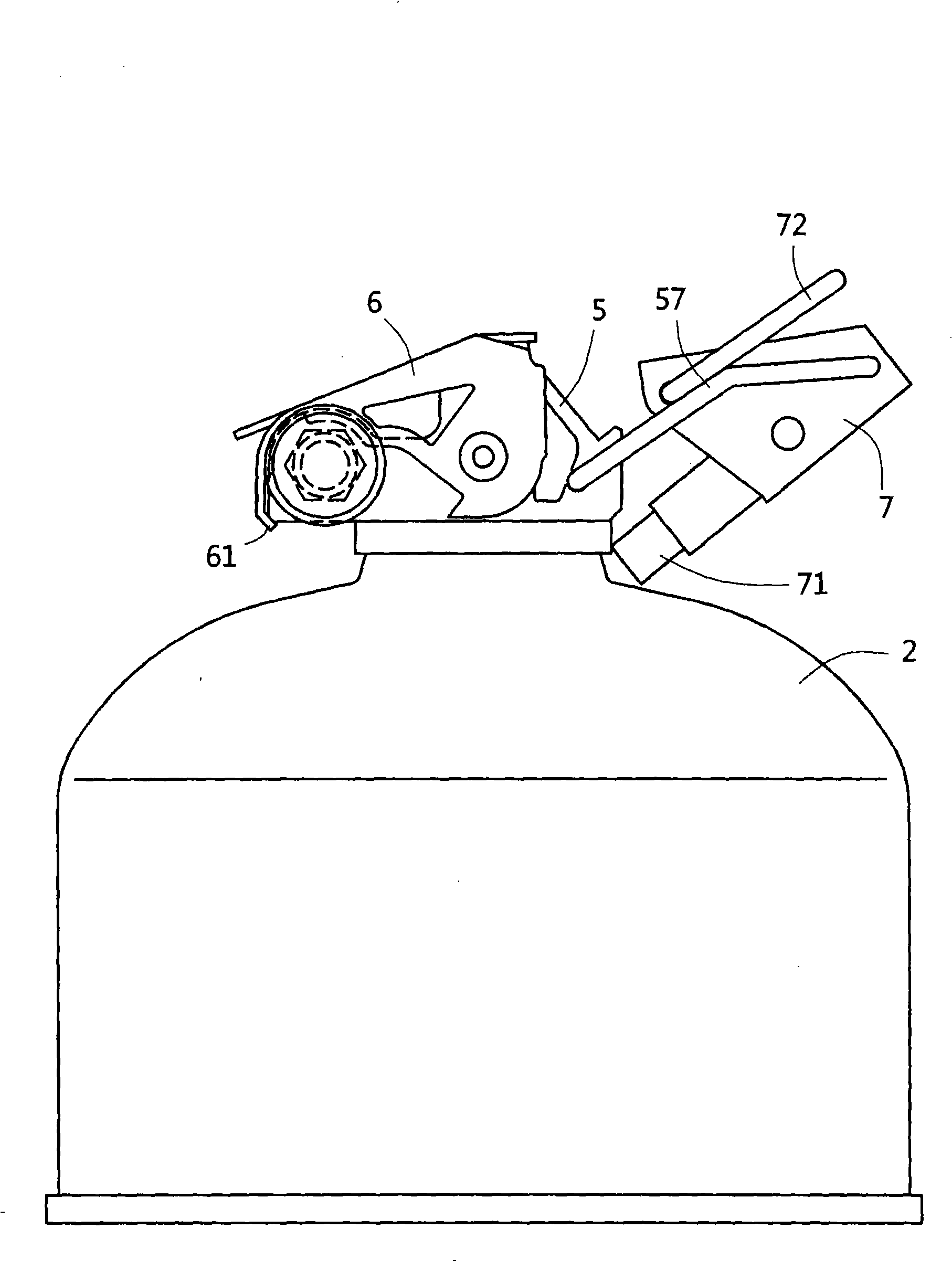

[0023] see image 3 , Figure 4 and Figure 5 As shown, the lower end of a joint 5 is provided with a screw hole 50 which can be screwed with the upper end screw connection part 21 of the gas tank 2, and a needle seat hole 51 and a throttle hole 52 are set in the joint 5, and the needle seat hole 51 A perforation 53 is provided to communicate with the throttle hole 52, and a thimble 54 that can slide up and down is provided in the needle seat hole 51, and the lower end rod 541 of the thimble 54 can push the gas supply nozzle 22 of the gas tank 2, The upper end of the thimble 54 is provided with an arc-shaped push portion 542; in addition, one end of the aforementioned air throttle hole 52 is connected with the gas conduit 31 so that the gas can be supplied to the stove, while the other end of the air throttle hole 52 is screwed. Establish a regulating needle valve 55, make it available to adjust the control of the size of the air supply.

[0024] In addition, a switch eleme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap