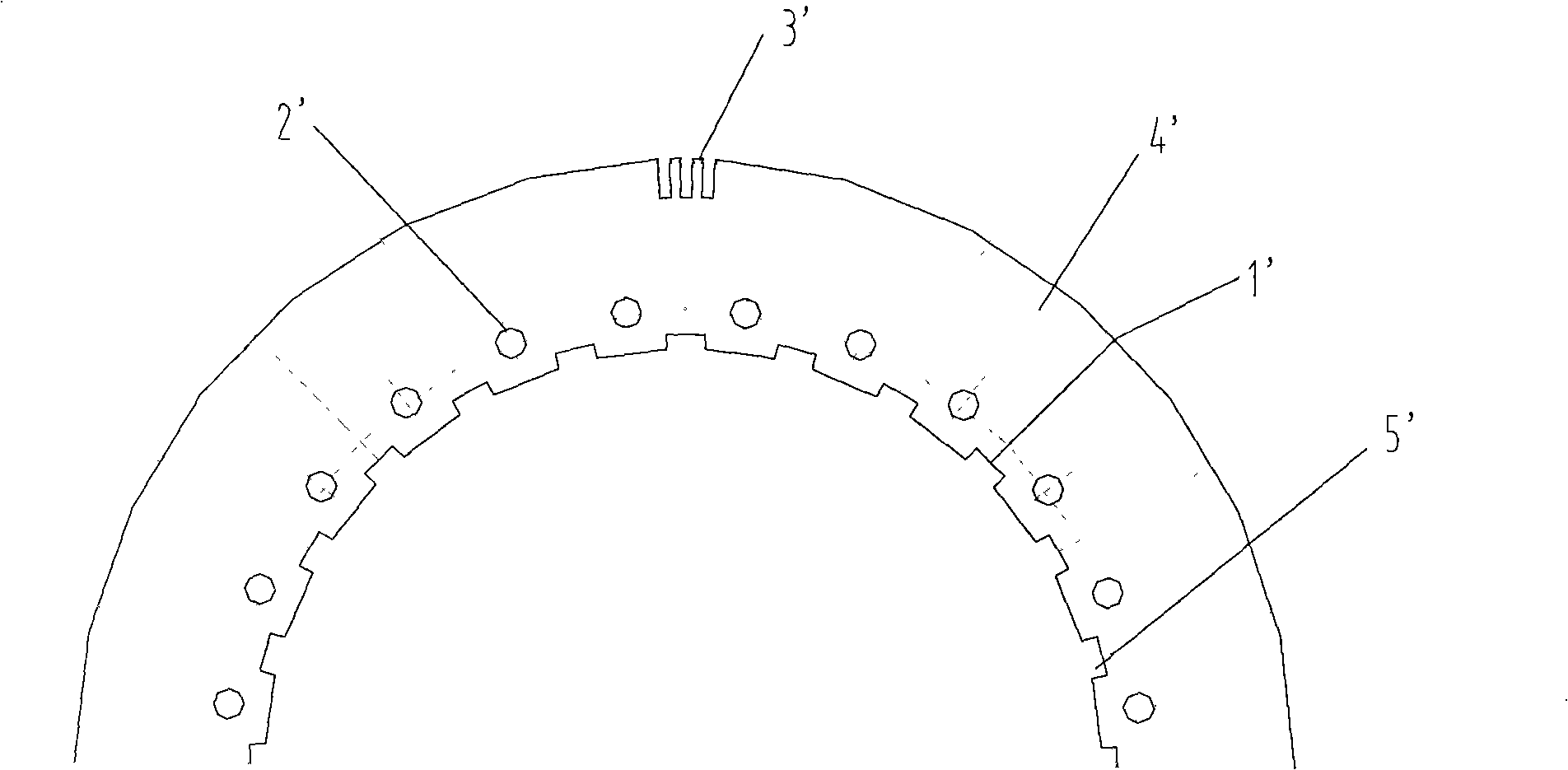

Chaining fanning strip for large-medium type motor and manufacturing method thereof

A manufacturing method and sector-shaped sheet technology, which are applied in the manufacture of stator/rotor body, magnetic circuit shape/pattern/structure, etc., can solve the problems of increased cost, cumbersome manufacturing process, low degree of freedom, etc., and achieve lower die cost and simple operation. , the effect of reducing positioning requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

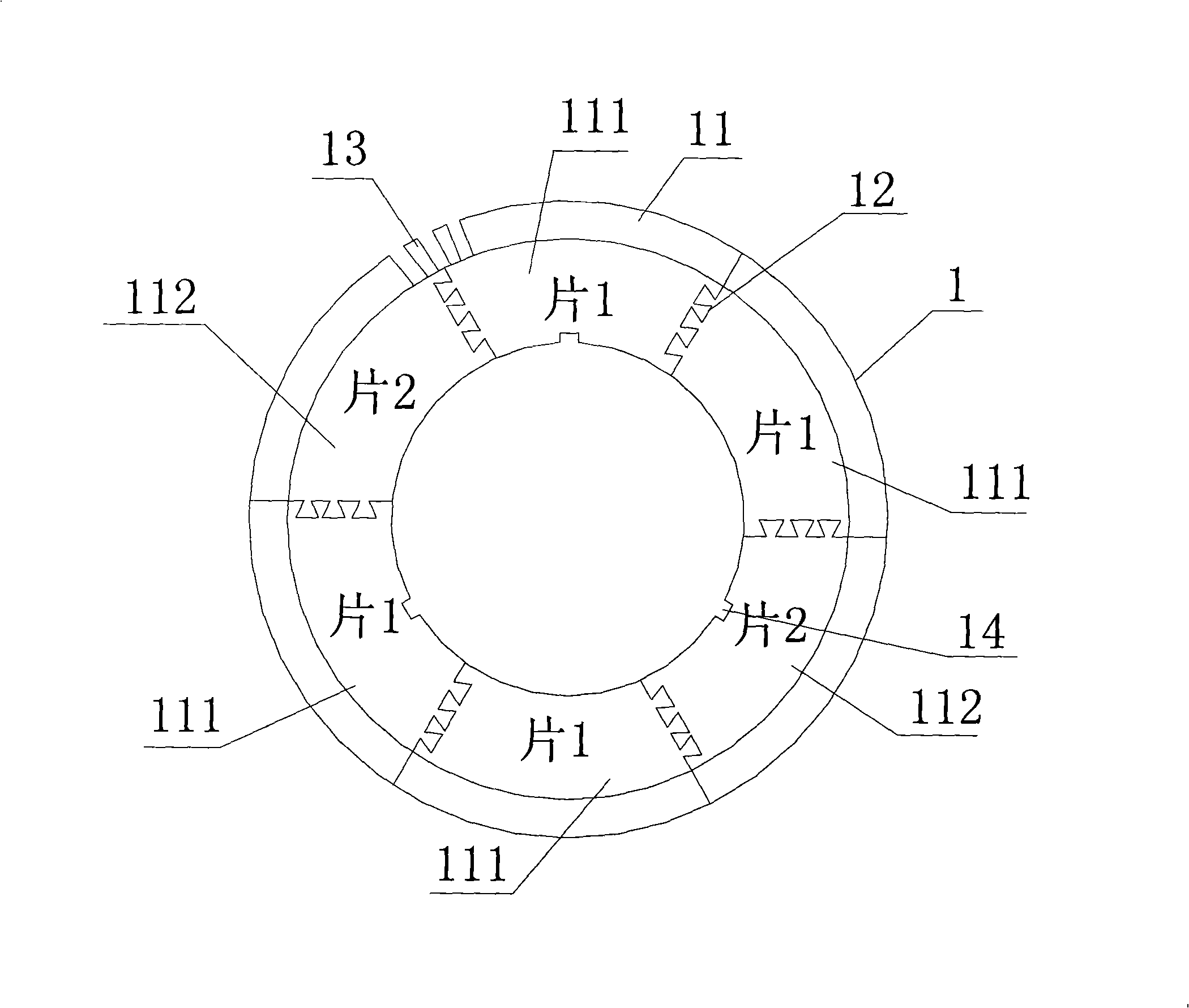

[0019] A large and medium-sized motor link segment of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see figure 2 , which shows one of the present invention, a large and medium-sized motor link segment, which includes several fan-shaped punches 11 that surround a full-circle punch 1, and the outer diameter of the full-circle punch 1 is greater than or equal to 1000mm, there is a seam 12 between every two adjacent sector pieces 11, and the seam 12 is dovetail-shaped.

[0021] In this embodiment, the diameter of the motor punch is 1240mm, and the number of slots is 172. Six sector pieces 11 are used to form a full circular punch 1. Among the six sector pieces, there are four first sector pieces 111 and two The second fan-shaped piece 112 is formed, the first fan-shaped piece 111 has 29 slots, the second fan-shaped piece 112 has 28 slots, and two first fan-shaped pieces 111 are sandwiched between the two second fan-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com