Roll bending device

A technology of bending rolls and installation positions, applied in the direction of counter pressure devices, metal rolling, manufacturing tools, etc., can solve problems such as weak supports, achieve simple design, reliable design, and avoid high load effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

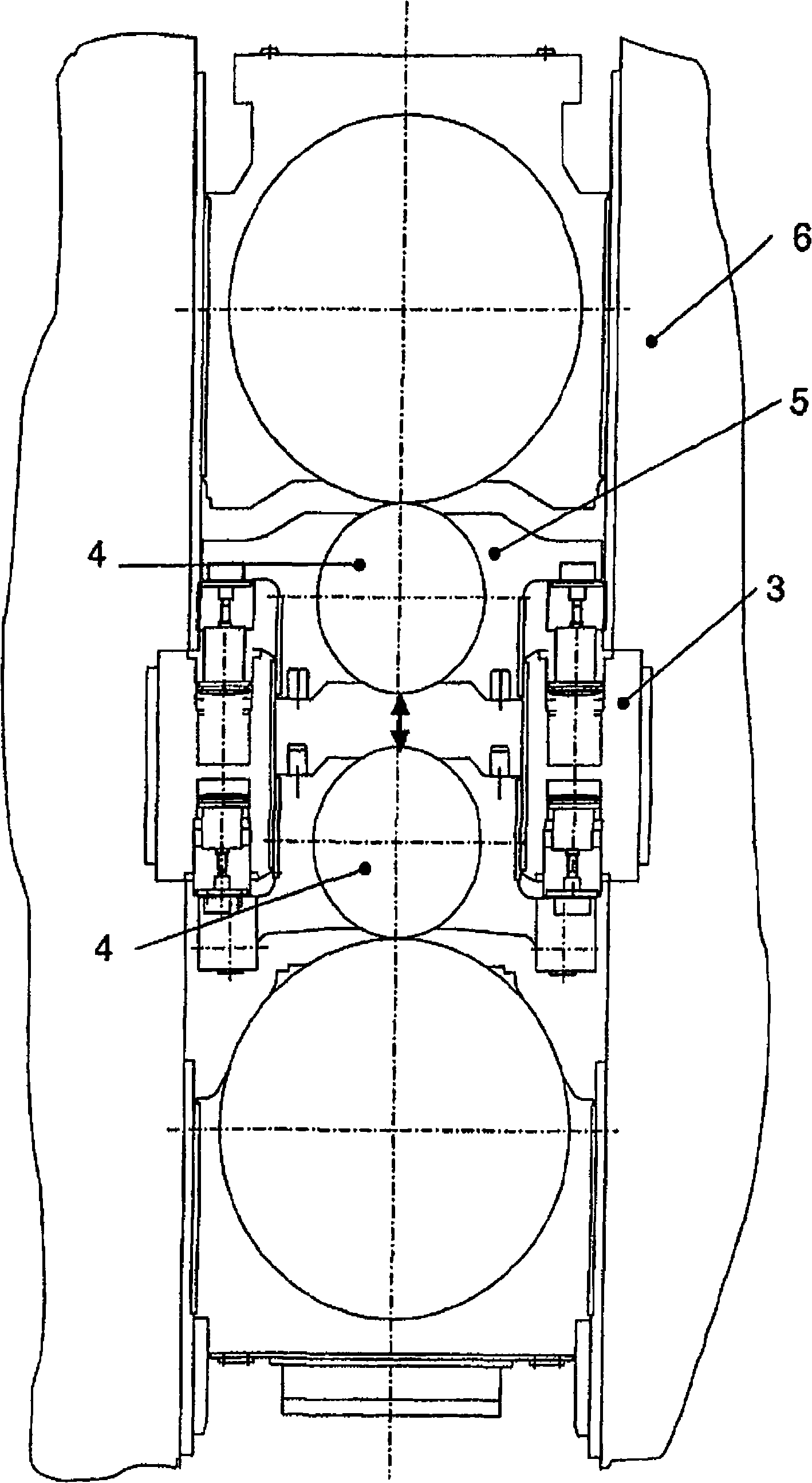

[0038] figure 1 The rolling stand shown is known from the prior art. The bending block is fixed to the roll stand frame 6 and is acting against the roll chock 5 to allow the roll 4 to bend. Especially when rolling or rolling thick materials with a large roll distance, the contact length between the roll chocks 5 at the bending block 3 is small, so that the roll chocks 5 are particularly in the presence of lateral loads. Insufficient and possible damage. This can lead to serious injury or substantially increased maintenance effort.

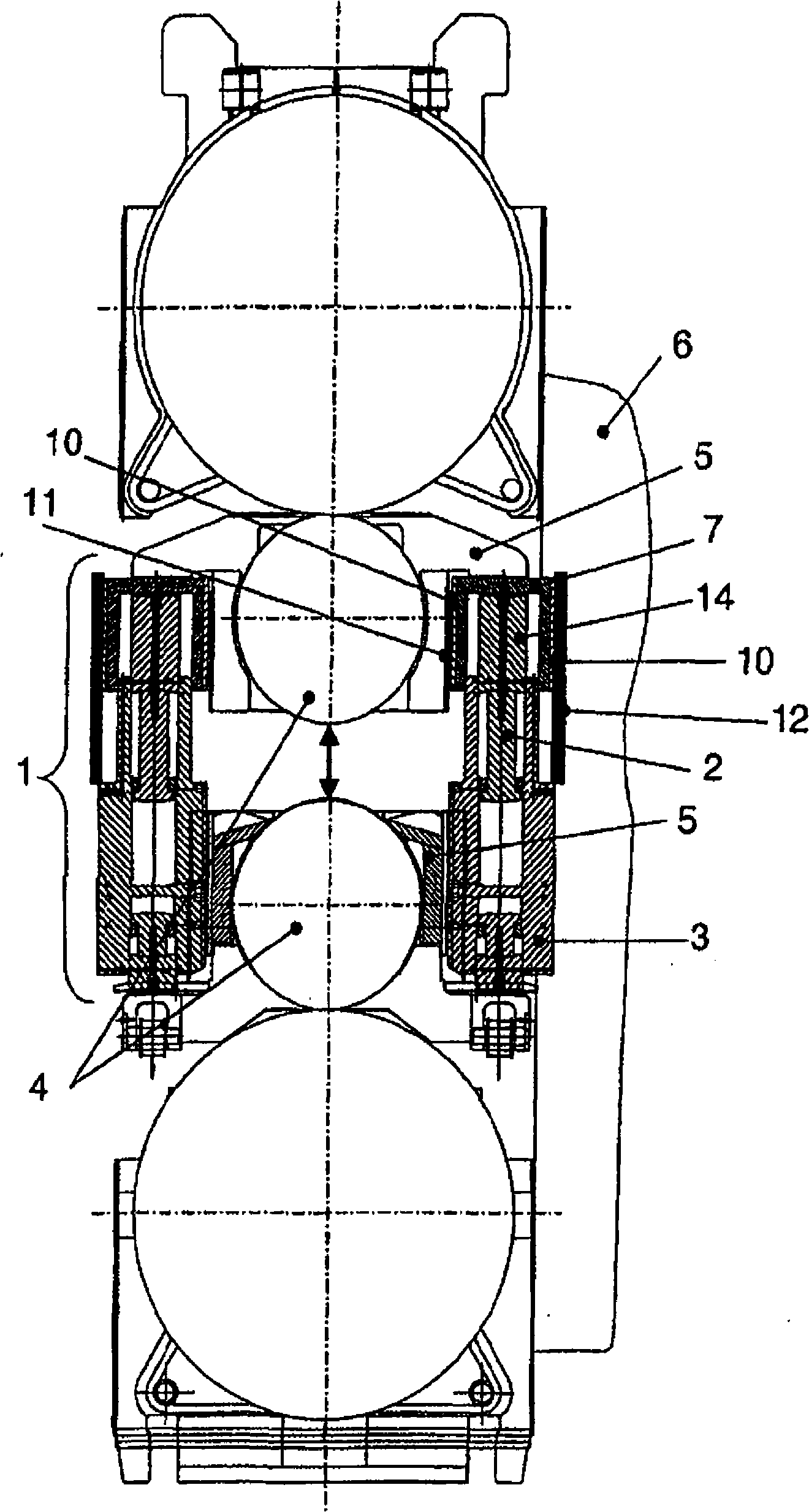

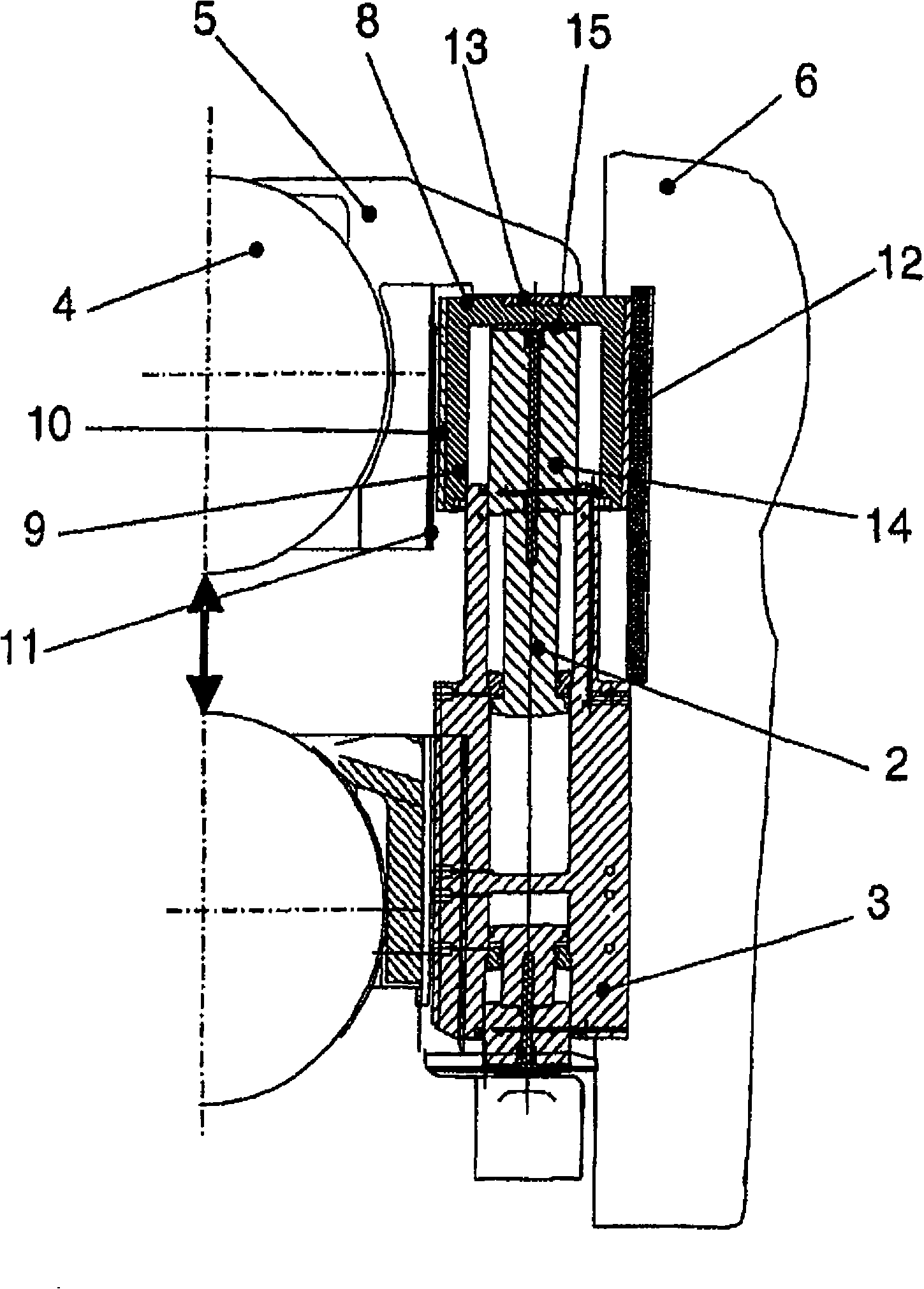

[0039] figure 2 A 4-high rolling stand with a bending device according to the invention is shown. The bending block 3 is fixable to the roll stand frame 6 and comprises at least one piston 2 generating the bending force. The bending force is transmitted to the roll chock 5 through the thrust piece 14 and the extension piece 7 . A thrust member 14 is connected to the piston 2 . The extension can move up and down together with the thrust memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com