Device and method for continuously producing a defective-free carrier strip

A carrier tape, error-free technology, applied to record carriers used in machines, cooperating devices, testing sensing devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

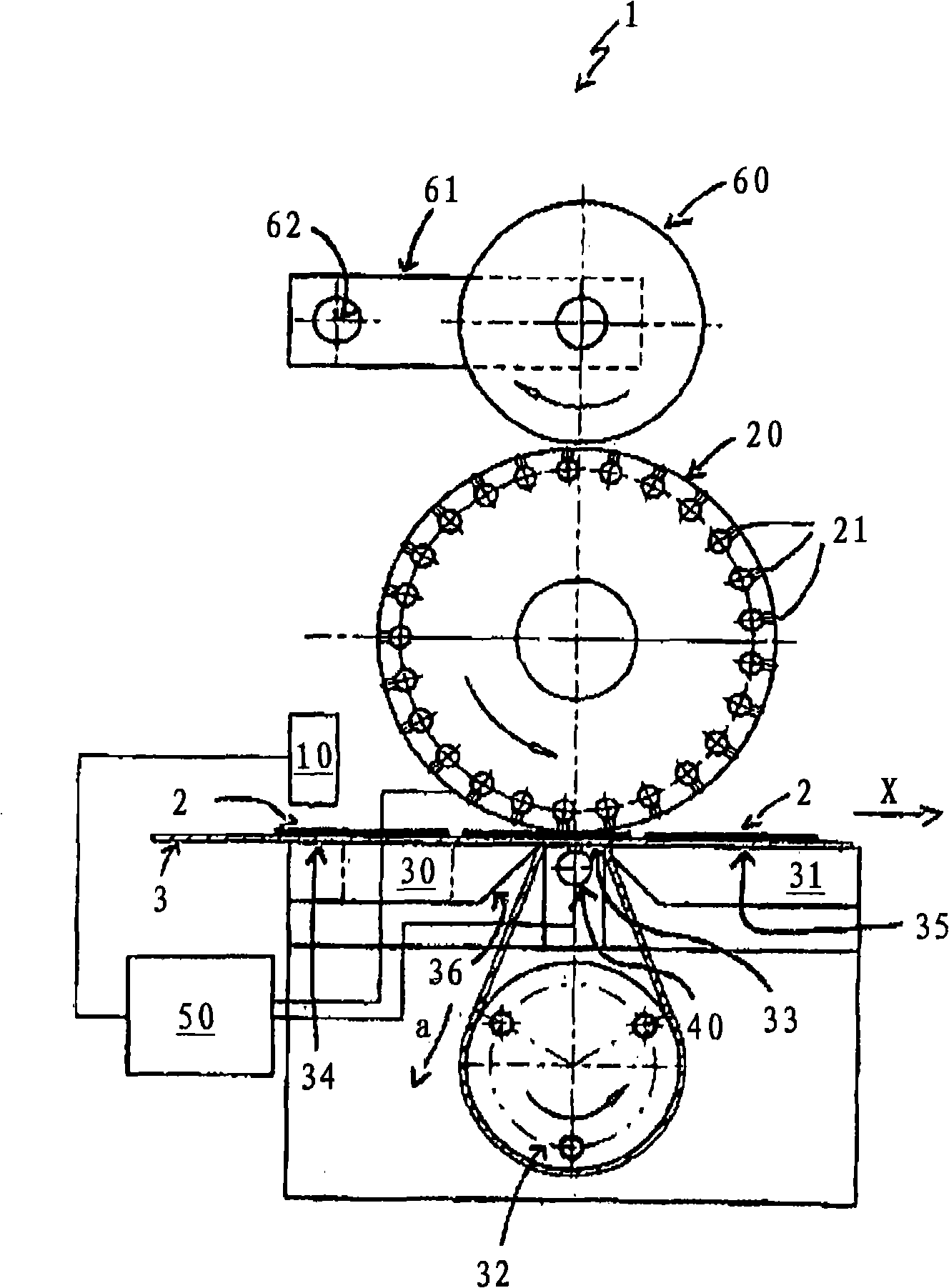

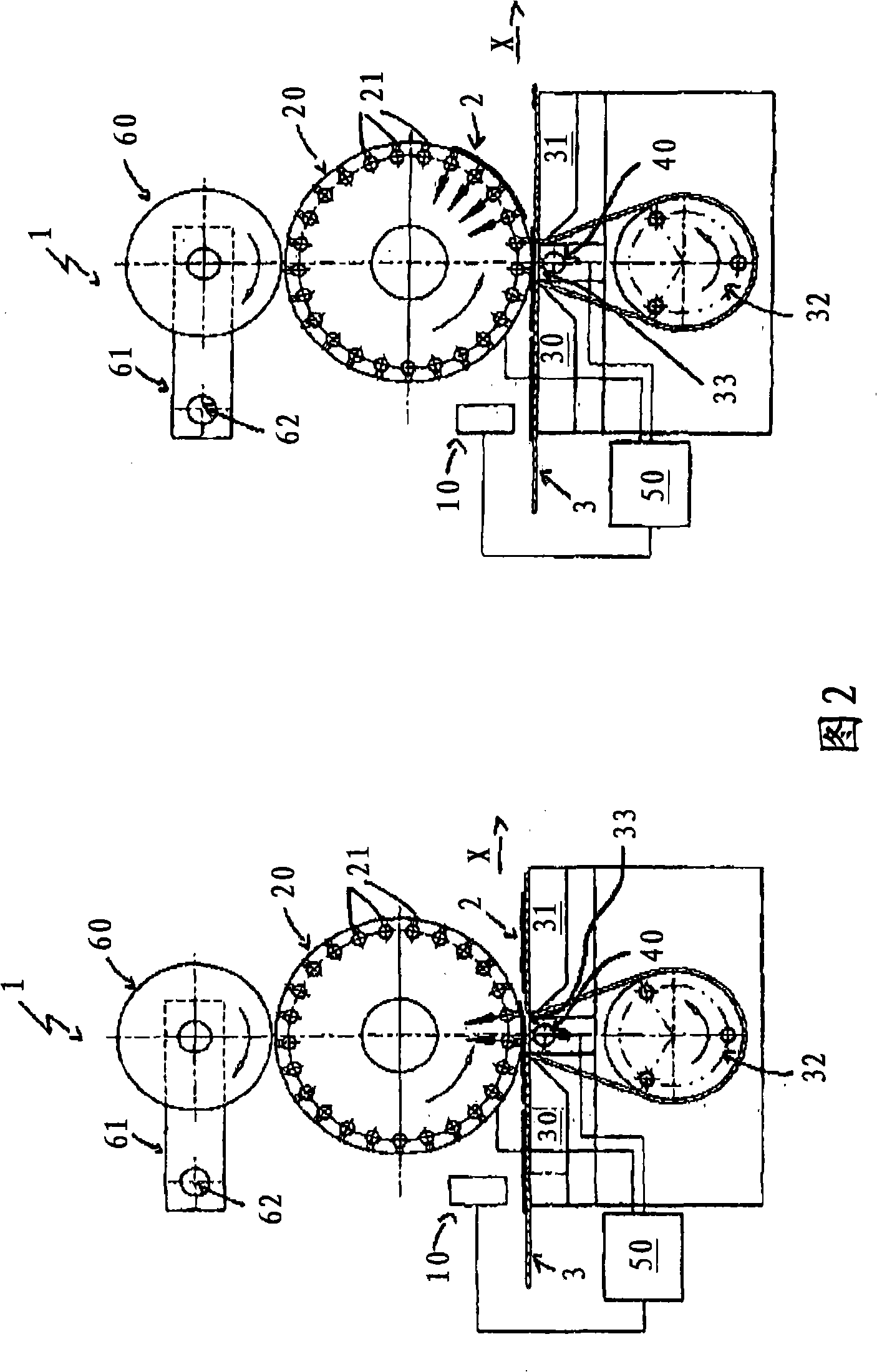

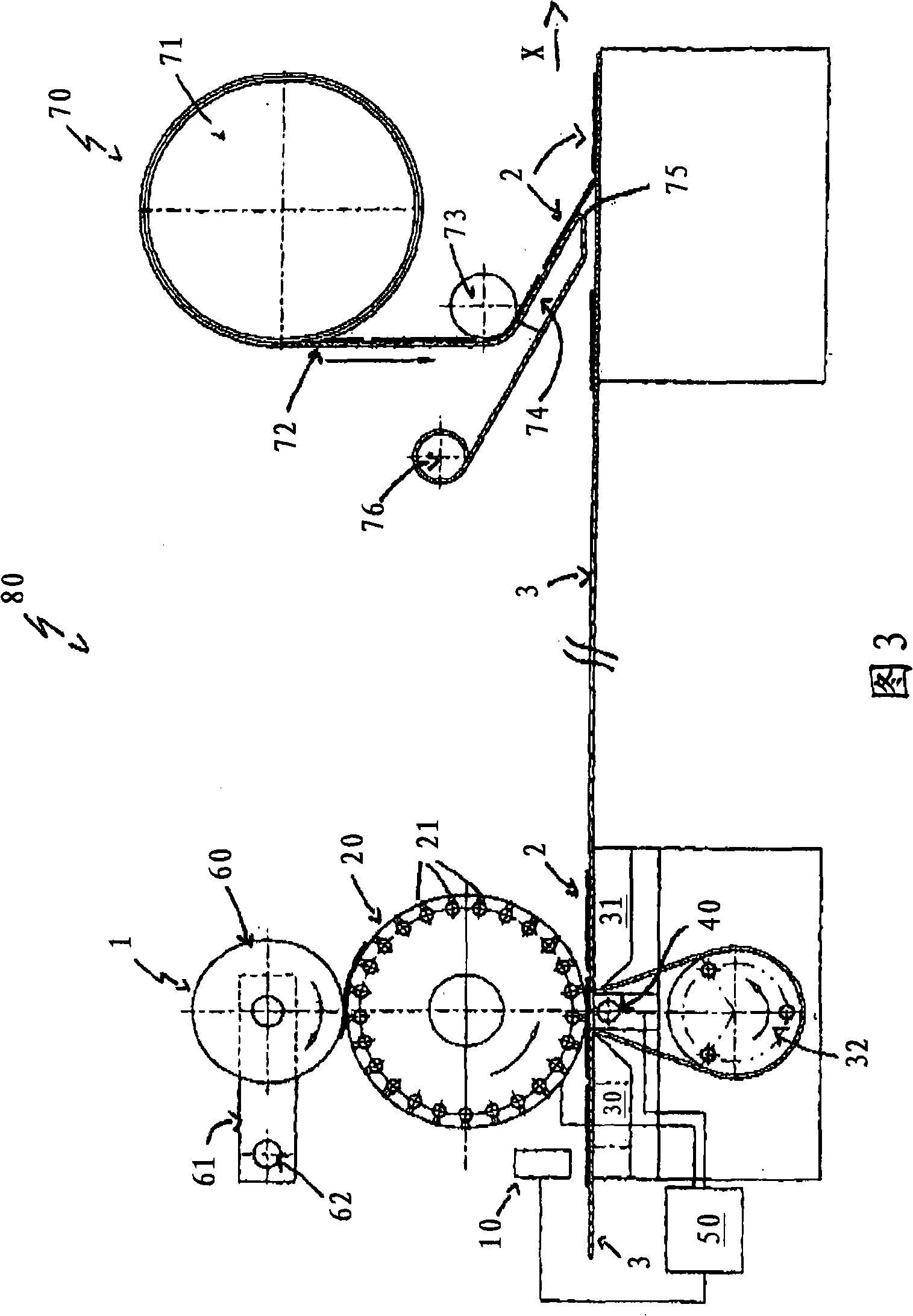

[0027] figure 1 A device 1 is shown for sorting components in the form of faulty transponders from a plurality of transponders 2 which are detachably arranged in a row in succession on a carrier strip 3 at equal distances. The transponder 2 is arranged centrally with respect to the conveying direction X on the carrier strip 3 . Both fault-free and faulty transponders 2 can be arranged on the carrier tape 3 .

[0028] The transponders 2 are designed as flat, flexible film-shaped components and each include a transponder-functional integrated circuit, not shown, which is coupled to a film-shaped antenna. On its side facing the carrier tape 3 , the transponder 2 is equipped with an adhesive layer (not shown), which allows the transponder 2 to be glued to the carrier tape 3 multiple times and released.

[0029]The device 1 comprises a detection device or reading device 10 for detecting transponders 2 with errors; a receiving device in the form of a receiving roller 20 for receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com