Method for producing a fastening arrangement of a fixing dome on a thin-walled component

A technology of thin-walled components and fastening devices, applied in the direction of adhesives, etc., can solve problems such as expensive injection molding tools, tricky and complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

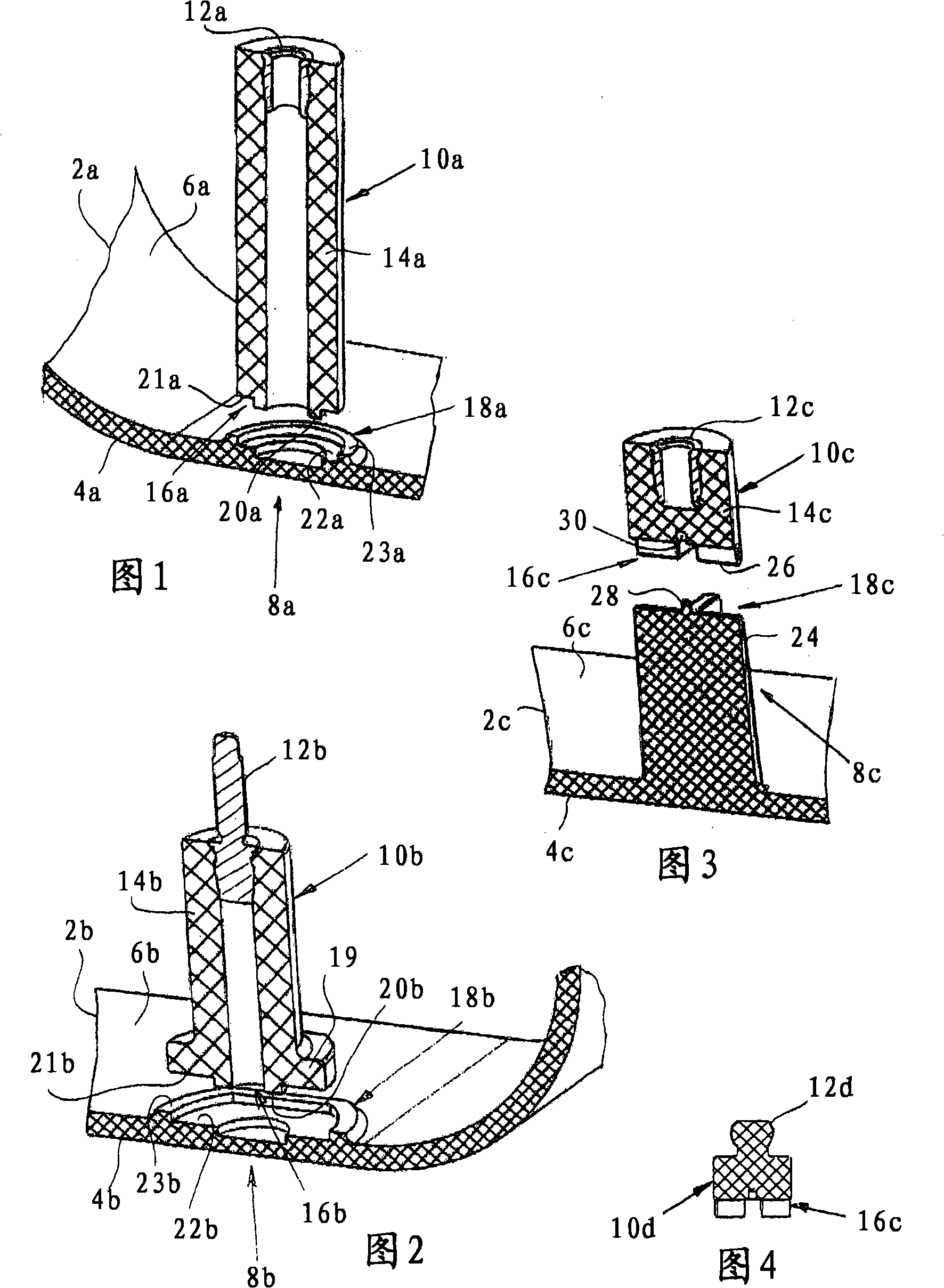

[0022] Figure 1 shows a part of a thin-walled component 2a with a visible side 4a (outer side) and an inner side 6a. A fastening cap 10a with fastening elements 12a in the upper end region is mounted on the inner side 6a of the component 2a in the fastening region 8a.

[0023] In particular, the thin-walled member 2a is a housing, however, as previously stated, other thin-walled members are also conceivable.

[0024] The term "fixing cap" is understood to mean any columnar structure protruding from the inner side 6 a of the component 2 a in the mounted state. In the representative embodiment, the retaining shield 10a is comprised of a sleeve-like body 14a having an annular cylindrical outer surface and an annular cylindrical inner surface. It can be understood that a housing with a large volume or a component with a large surface has a plurality of such fixing caps for fixing or connecting the component 2 a to other components. The geometry as well as the dimensions, especia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com