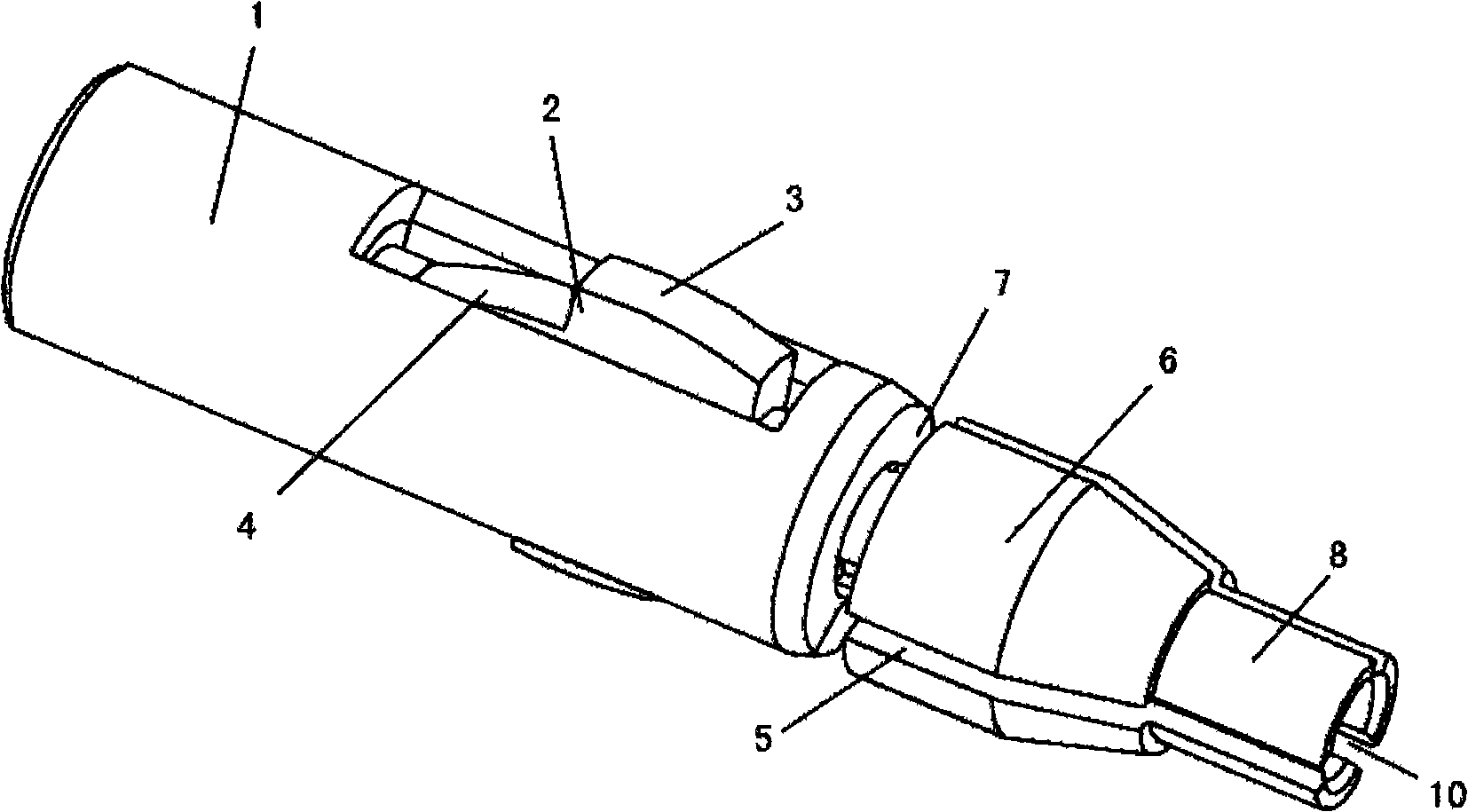

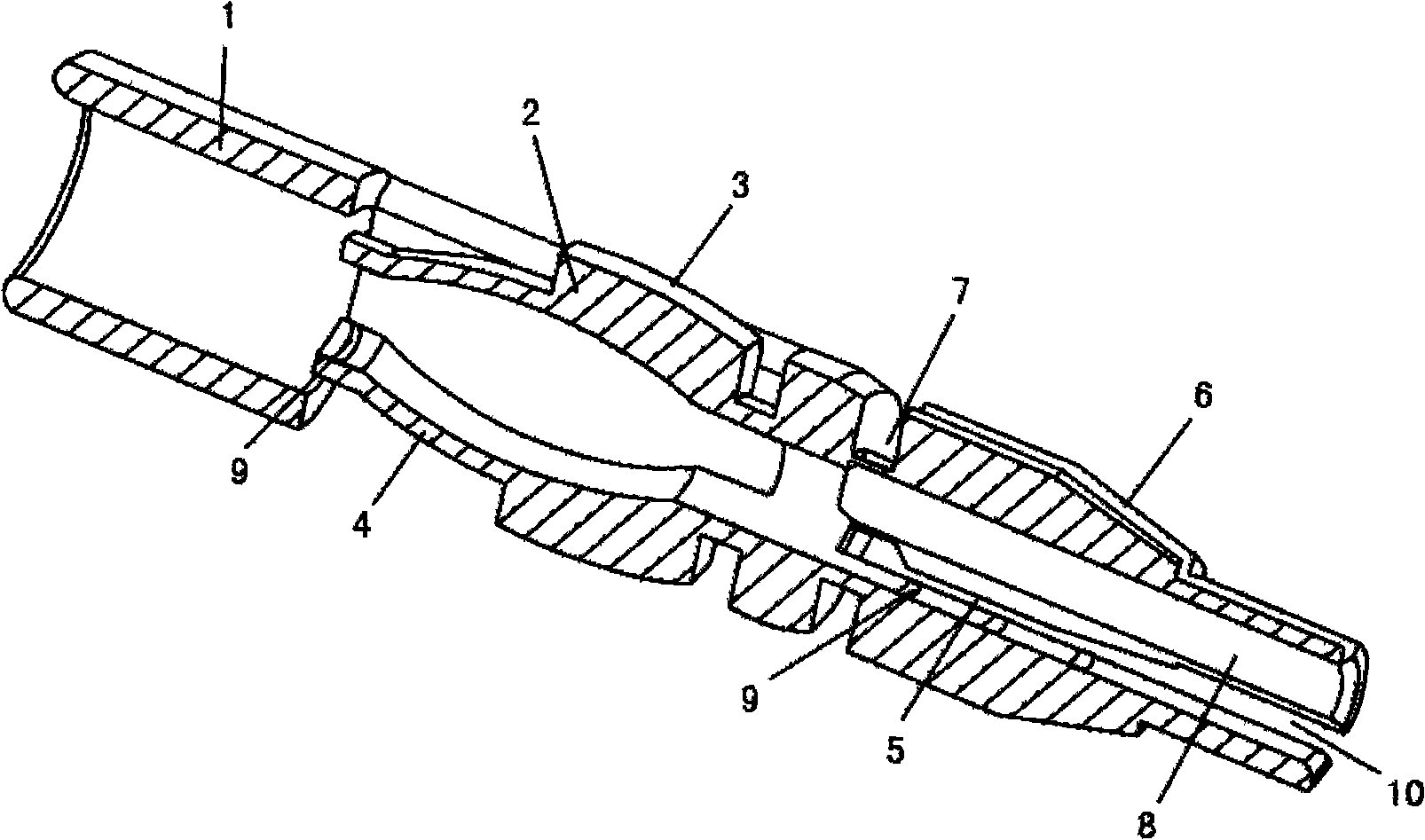

Clamping head for optical fibre splicer

An optical fiber splicer and collet technology, which is applied to the coupling of optical waveguides and other directions, can solve the problems of complicated operation, insufficient protection of bare fibers, and long splicing operation time, so as to achieve the effect of reliable bonding and multiple protection.

Inactive Publication Date: 2008-10-15

JIANGSU UNIKIT OPTICAL TECH

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the installation of optical fiber cables for optical fiber connection sub-products mainly uses special tools to push the bare fiber by pressing the bent optical fiber sheath, so as to ensure the bonding of the optical fiber surface, and then rely on the single-point clamping device set in the sleeve Tight, the special tool cannot guarantee sufficient bonding force of the optical fiber, especially when the surface of the bare fiber is defective, it is even more difficult to ensure the true bonding of the fiber surface, and it cannot effectively prevent the rotation of the optical fiber cable. When an accidental force is applied during installation or use, it cannot fully protect bare fiber

There is also a collet used for optical fiber connectors, which is provided with an equal-tapered helical surface on the surface of the locking head of the collet cylinder. Although this structure has reliable performance and automatic anti-rotation, it is complicated to operate during the splicing process. Long operation time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a collet used for a splice, comprising a cylindrical body provided with an optical fiber line hole, one end of the cylindrical body is provided with at least two locking heads divided by a lock groove, while the other end is provided with at least one spatula, the upper end face of the body of the spatula is an arch surface which can be extended by pressure, and the arch surface is higher than the external surface of the cylindrical body. Compared with the prior art, the collet has at least one spatula arranged on the front end of the cylindrical body, the upper end face of the body of the spatula is the arch surface which can be extended by the pressure, and the arch surface is higher than the external surface of the cylindrical body. When installed, an optical fiber line passes through the optical fiber line hole; an ejector sleeve of an optical-fiber junction group is pushed, when the ejector sleeve is pushed to the position of the spatula, the back arch surface of the spatula is pressed down; as the spatula head of the spatula is closely attached to the surface of the optical fiber line, and the arch surface of the body of the spatula is pressed to extend, so that the optical fiber line is pushed forward automatically, thereby guaranteeing the joint of fiber surfaces is powerful and reliable.

Description

Collets for fiber optic splices technical field The invention relates to a component for an optical fiber connector, in particular to a chuck for an optical fiber connector. Background technique At present, the installation of optical fiber cables for optical fiber connection sub-products mainly uses special tools to push the bare fiber by pressing the bent optical fiber sheath, so as to ensure the bonding of the optical fiber surface, and then rely on the single-point clamping device set in the sleeve Tight, the special tool cannot guarantee sufficient bonding force of the optical fiber, especially when the surface of the bare fiber is defective, it is even more difficult to ensure the true bonding of the fiber surface, and it cannot effectively prevent the rotation of the optical fiber cable. When an accidental force is applied during installation or use, it cannot Fully protect bare fibers. There is also a collet used for optical fiber connectors, which is provided wit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B6/38

Inventor 吕根良黄金安

Owner JIANGSU UNIKIT OPTICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com