Plug-in device for electrical connection

A plug-in device and electrical connection technology, applied in the direction of contact parts, etc., can solve the problems of large contact area, easy to loose, not strong enough, etc., and achieve the effect of overcoming small force, not easy to loose, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

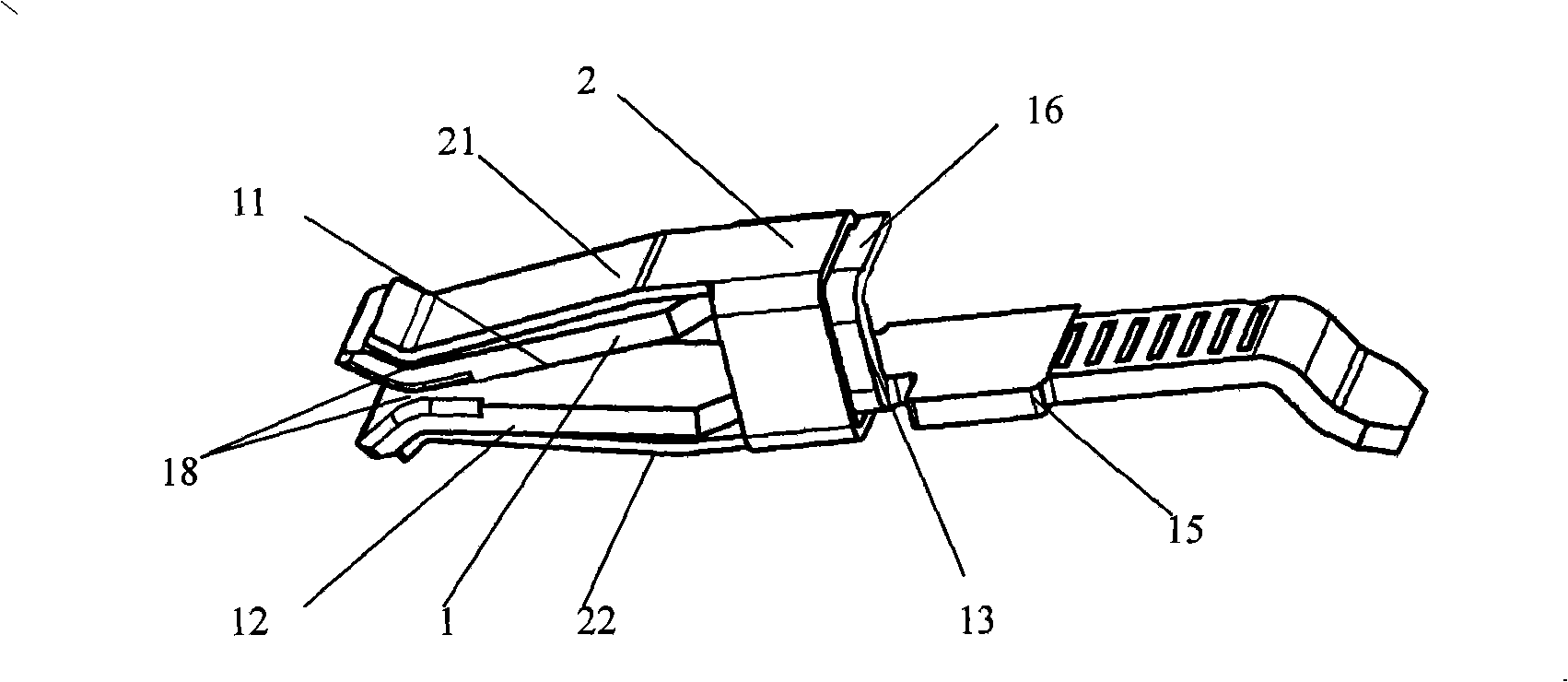

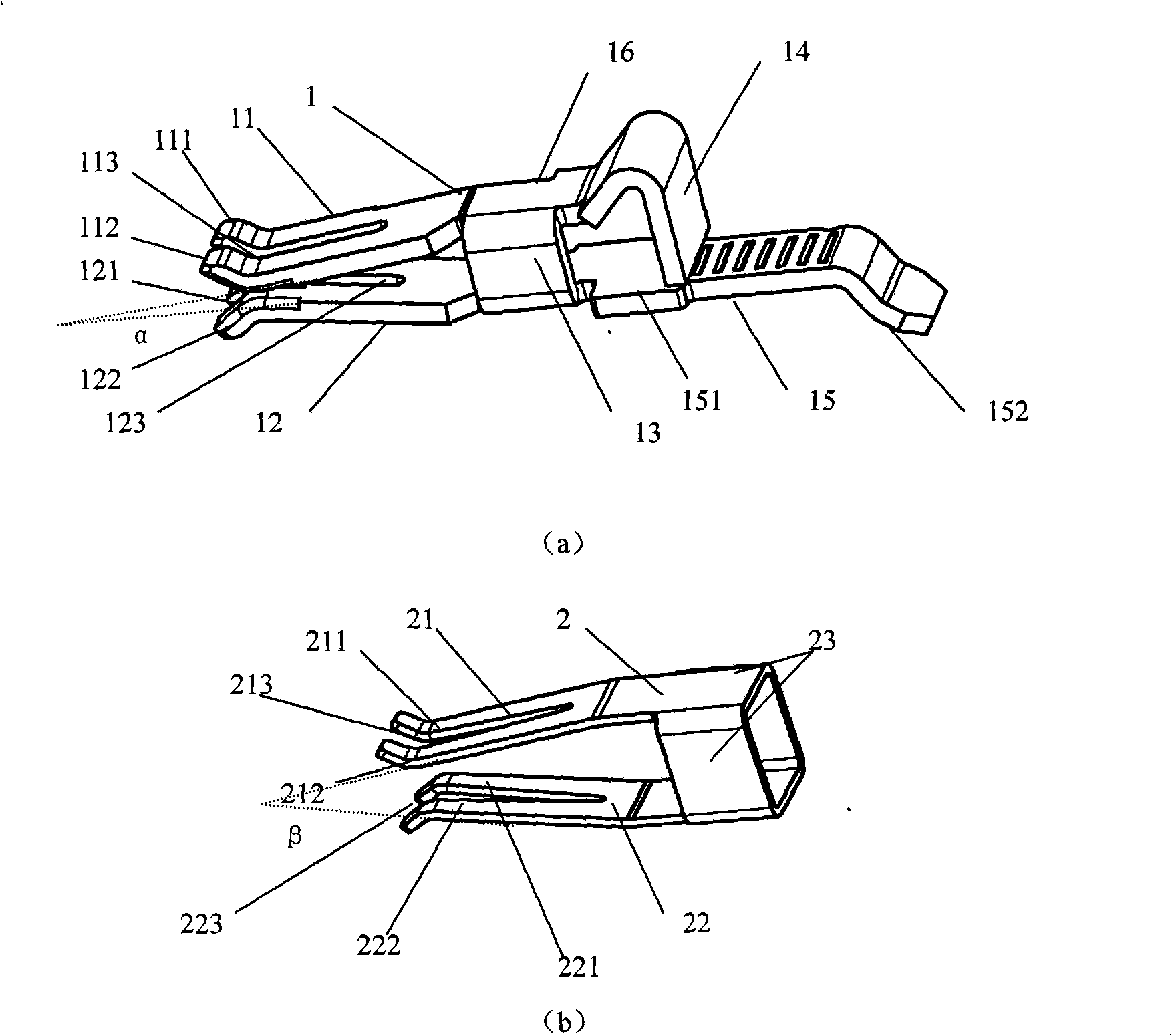

[0017] Embodiment 1: as figure 1 As shown, the plug-in device for electrical connection in this embodiment includes a metal piece 1 and a spring steel sheet 2 surrounding the outer periphery of the metal piece 1, wherein the metal piece 1 includes two opposite elastic side legs 11, 12, two The elastic side legs 11, 12 are connected by laths 13; the spring steel sheet 2 includes two opposite clip side parts 21, 22, and one end of the two clip side parts 21, 22 is connected by a cladding ring piece 23; the cladding ring piece 23 is corresponding to the position of the lath 13, and is coated on the tail portion 16 of the metal part 1 where the lath 13 is located. The other ends of the two clamping side portions 21, 22 and the outer sides of the contact portions 18 of the two elastic side legs 11, 12 are respectively Contact, the two clip side parts 21, 22 are straight shapes, such as Figure 5 As shown, the two clip side portions 21, 22 can also be curved. The tail portion 16 o...

Embodiment 2

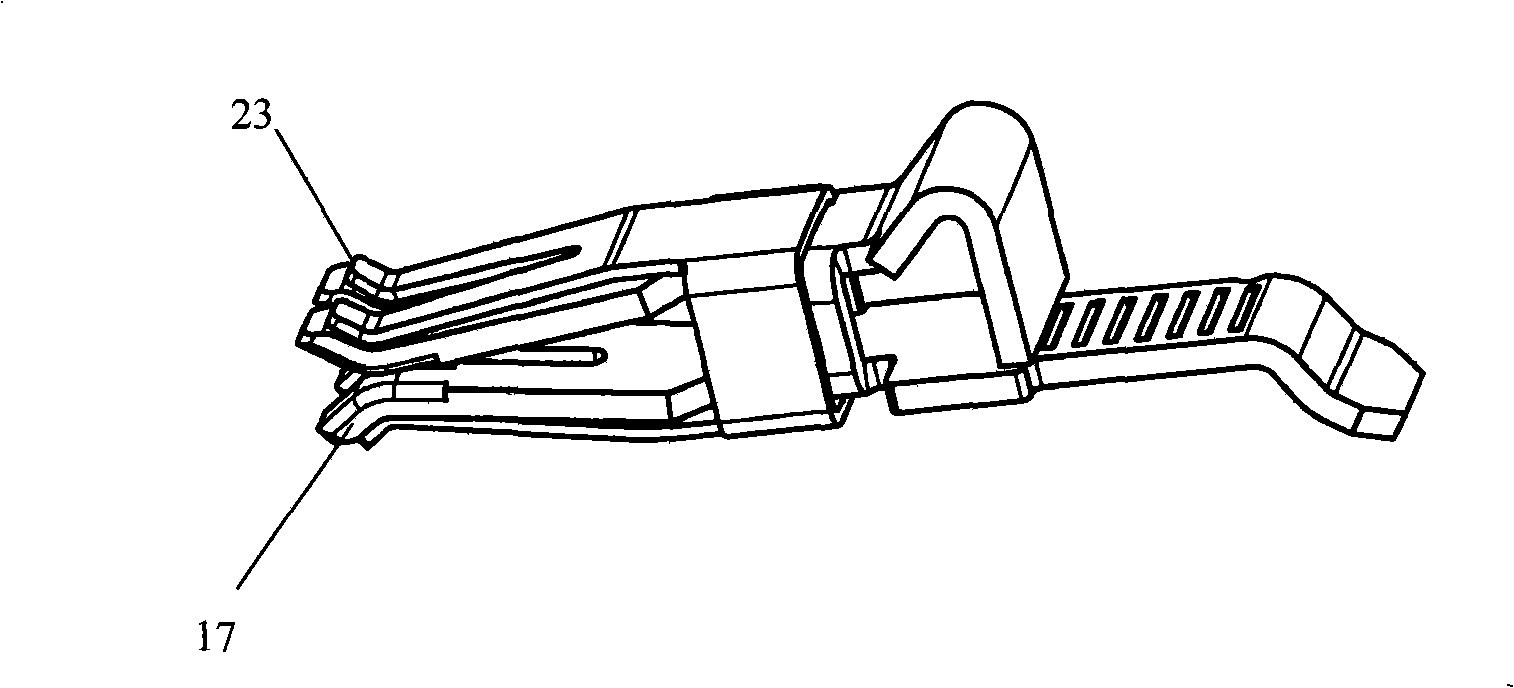

[0018] Embodiment 2: as figure 2 , image 3 As shown, the plug-in device for electrical connection in this embodiment includes a metal piece 1 and a spring steel sheet 2 surrounding the outer periphery of the metal piece 1, wherein the metal piece 1 includes two opposite elastic side legs 11, 12, two The elastic side legs 11, 12 are connected by laths 13; the spring steel sheet 2 includes two opposite clip side parts 21, 22, and one end of the two clip side parts 21, 22 is connected by a cladding ring piece 23; the cladding ring piece 23 is corresponding to the position of the lath 13, and is coated on the tail portion 16 of the metal part 1 where the lath 13 is located. The other ends of the two clamping side portions 21, 22 and the outer sides of the contact portions 18 of the two elastic side legs 11, 12 are respectively Contact, the two clip side parts 21, 22 are straight shapes, such as Figure 5 As shown, the two clip side portions 21, 22 can also be curved. The elas...

Embodiment 3

[0020] Embodiment 3: as Figure 4 As shown, the plug-in device for electrical connection in this embodiment has basically the same structure as that in Embodiment 2, except that the plug-in device in this embodiment does not have a bent portion 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com