Backlight module group and its optical plate

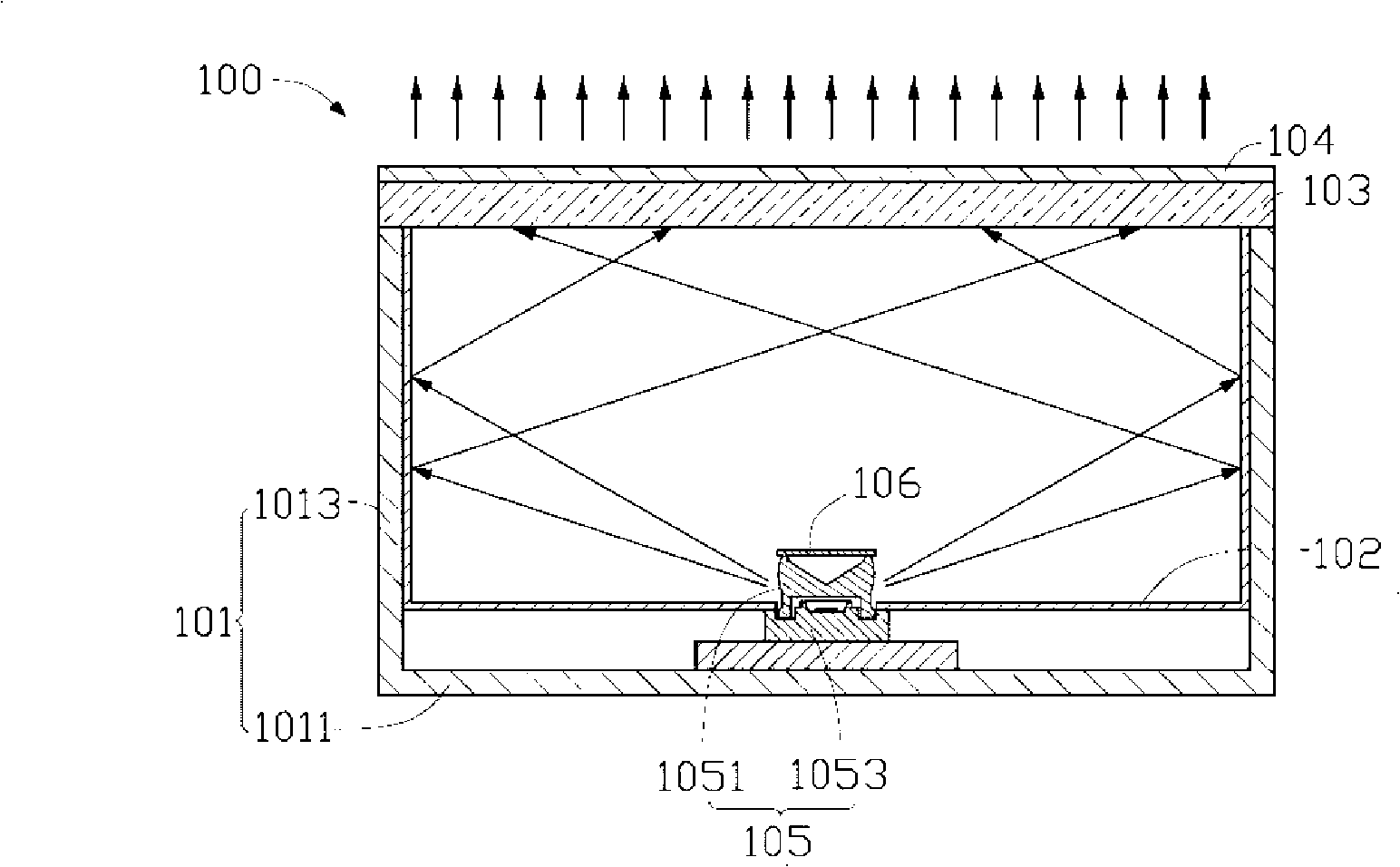

A technology of backlight module and optical plate, applied in optics, optical elements, nonlinear optics, etc., can solve the problem of uneven light output of backlight module 100, and achieve the effect of improving light output uniformity and light output uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The backlight module and its optical plate of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

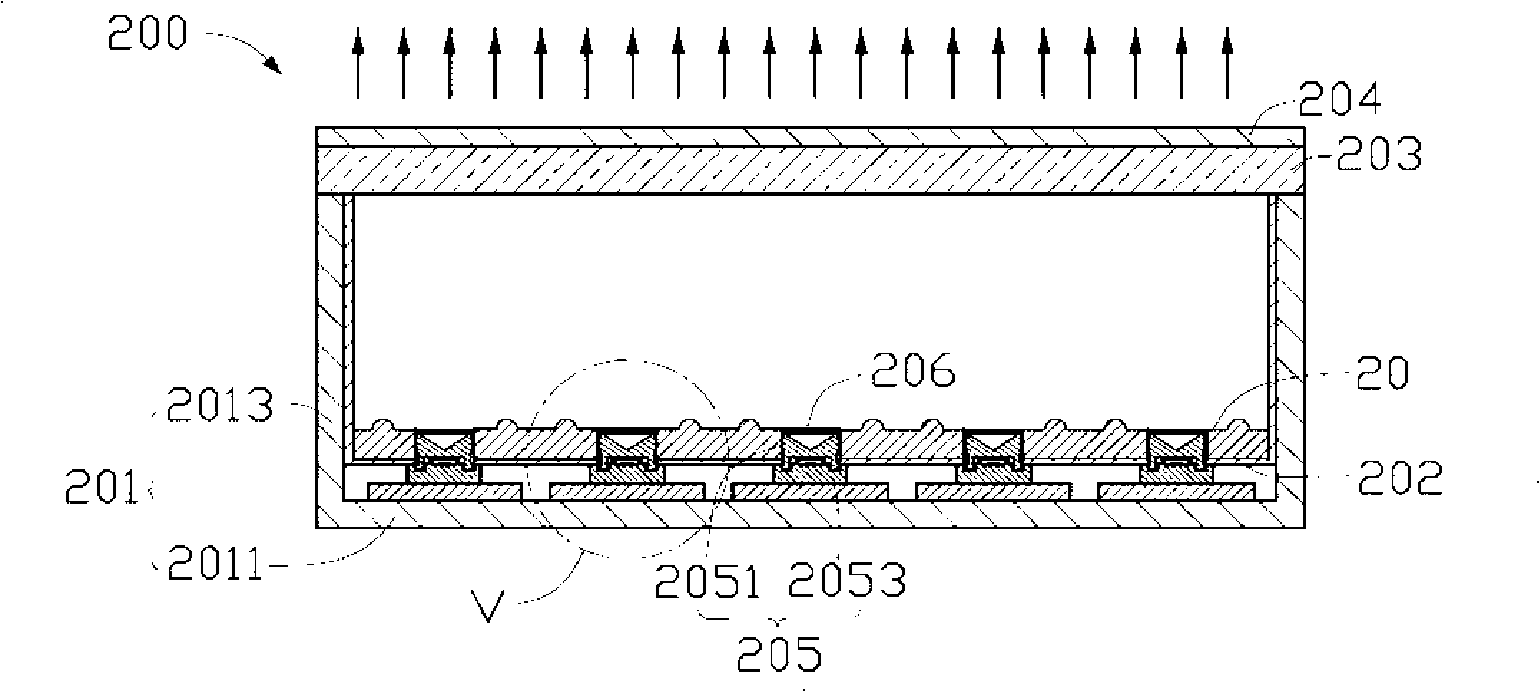

[0021] See figure 2 , The backlight module 200 of the first preferred embodiment of the present invention is shown, which includes a frame 201, a diffusion plate 203, a plurality of point light sources 205, an optical plate 20 and a reflective sheet 206. The frame 201 includes a bottom plate 2011 and four sidewalls 2013 vertically extending from the edge of the bottom plate 2011 to one side thereof. The four side walls 2013 are connected to each other and form a cavity (not shown in the figure) together with the bottom plate 2011 for accommodating the point light source 205 and the optical plate 20. The diffusion plate 203 is disposed on the top of the side walls 2013.

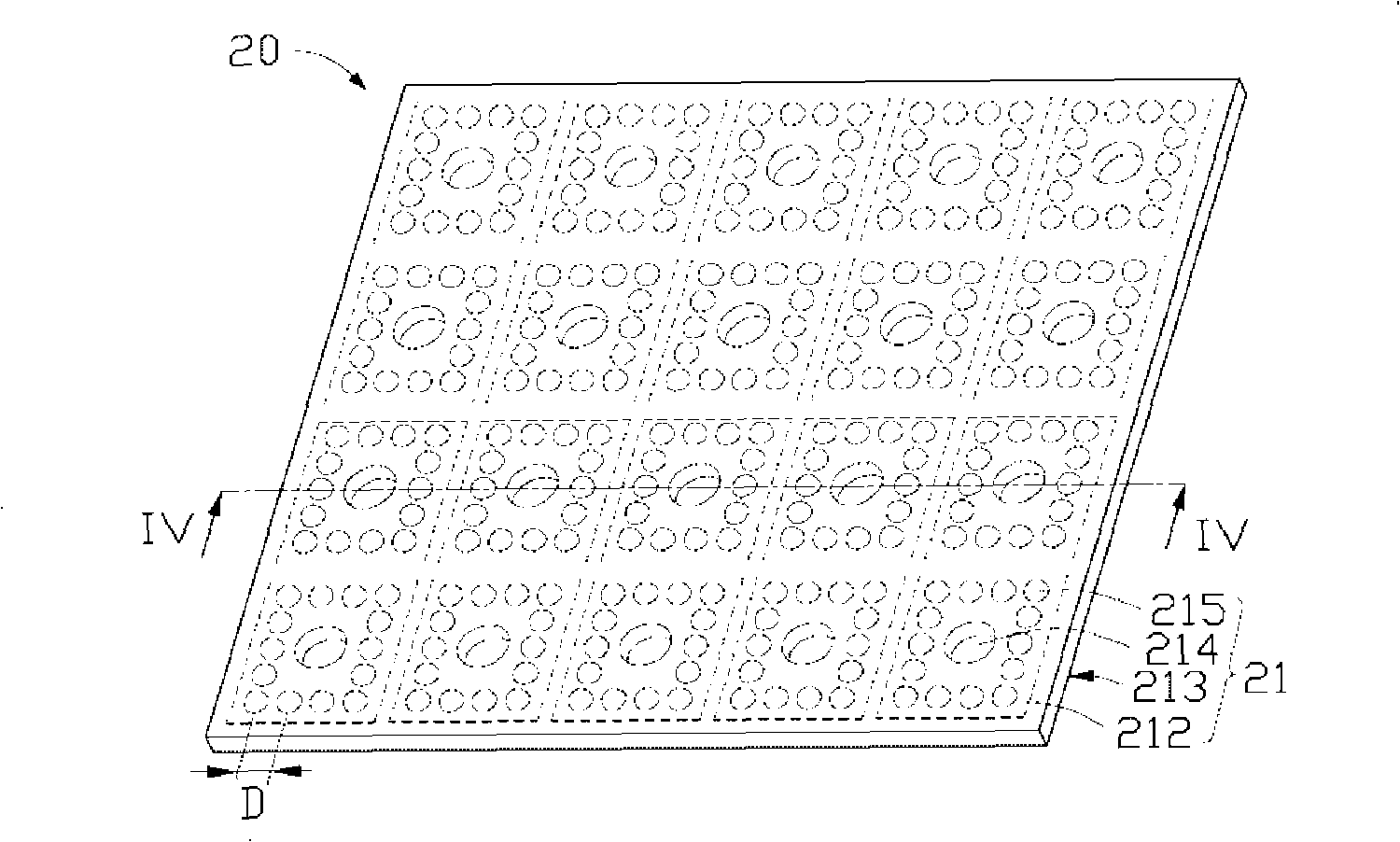

[0022] See also image 3 versus Figure 4 The optical plate 20 has a square shape and includes a plurality of optical plate units 21 arranged clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spherical radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com