PCB plate clamping apparatus lock catch

A technology of PCB boards and fixtures, which is applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of unfavorable large-scale assembly line production, increase the cost of setting up manufacturing, and low work efficiency, so as to achieve stable and reliable locking state and ensure welding Quality and work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

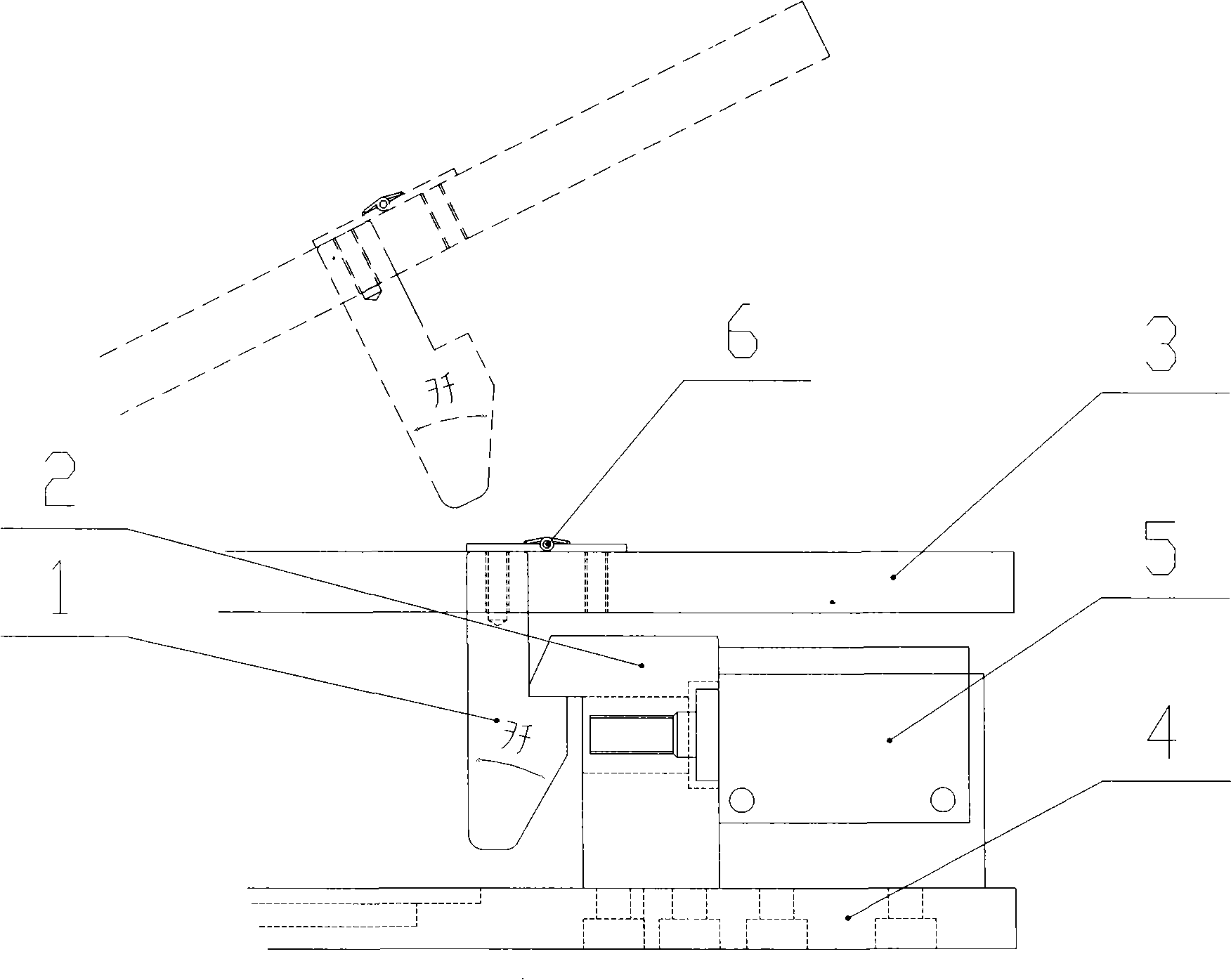

[0011] A PCB board fixture lock as shown in Figure 1 has an upper lock block 1 and a lower lock block 2, and a spring hinge 6 is arranged on the upper pressing plate 3 on the PCB board fixture, and the upper lock block 1 and the spring hinge 6 is fixedly connected to realize the elastic movable connection between the upper locking block 1 and the upper pressing plate 3, and the lower locking block 2 is fixedly connected with the lower pressing plate 4 on the PCB board fixture; When the lower lock block 2 is snapped and locked, the push rod of the cylinder 5 will be offset against the upper lock block 1 when stretching out. The meeting surface of the upper lock block 1 and the lower lock block 2 is an inclined surface, and the inclination angle α of the inclined surface is 30°.

[0012] When in use, after the PCB board is set on the lower pressing plate 4 of the PCB fixture, the upper pressing plate 1 is closed. The surface is an inclined surface, and the upper locking block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com