Two-position control apparatus for superimposed cylinder stocking knitter shuttle

A double-position control and double-needle cylinder technology is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems affecting the quality of socks, missing spandex, and many joints, and achieves low maintenance costs, convenient maintenance, The effect of increasing work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

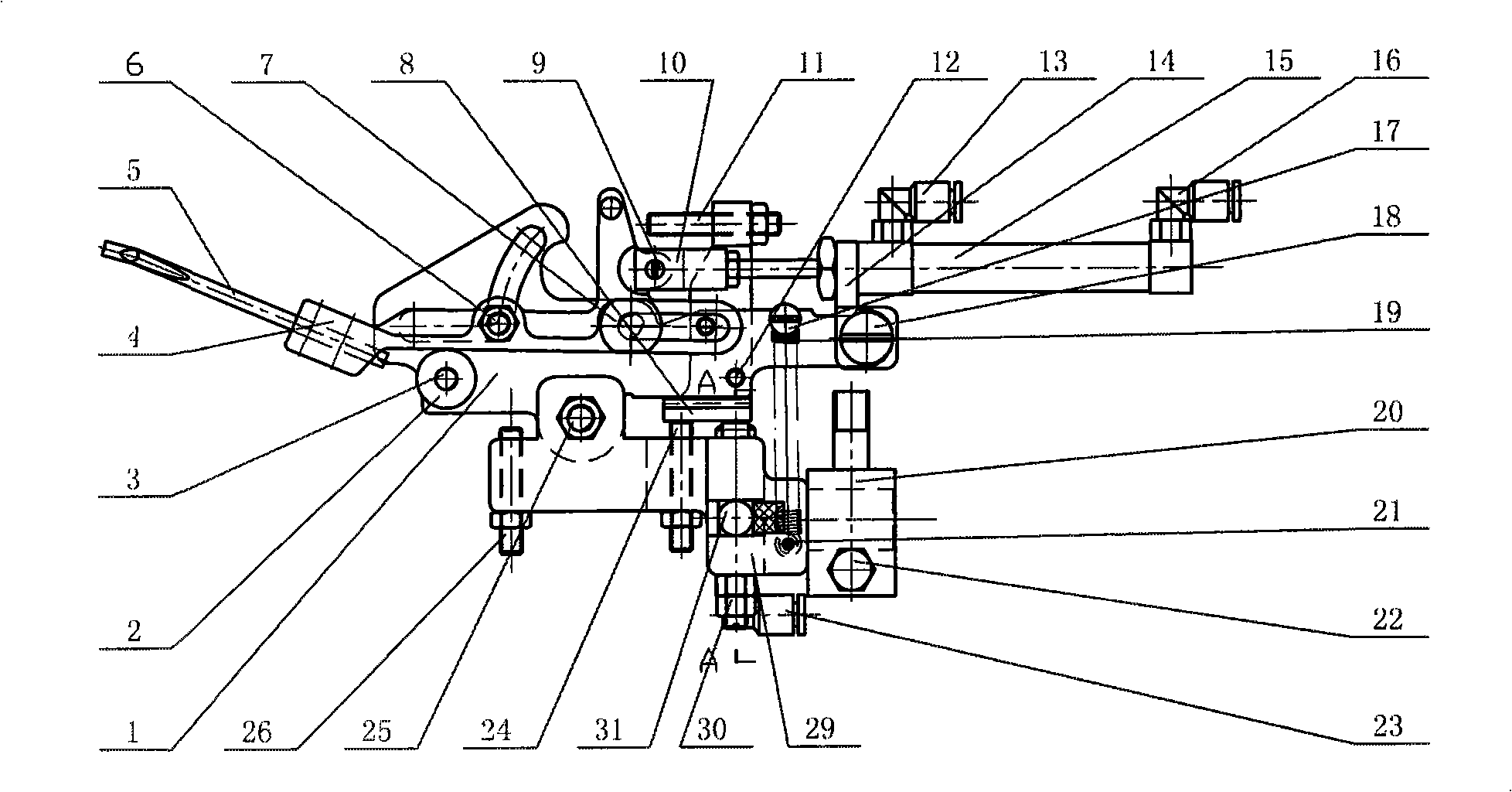

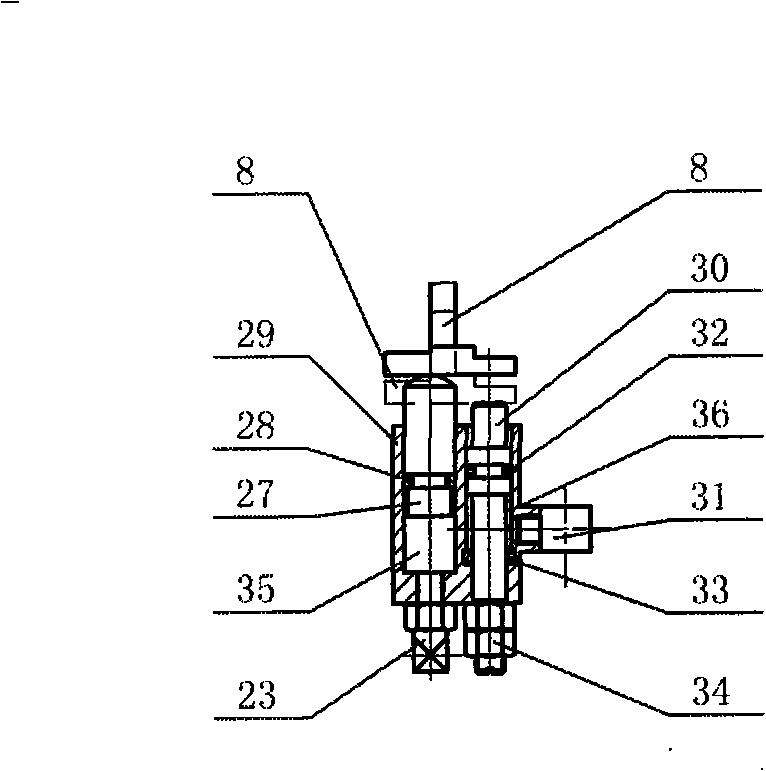

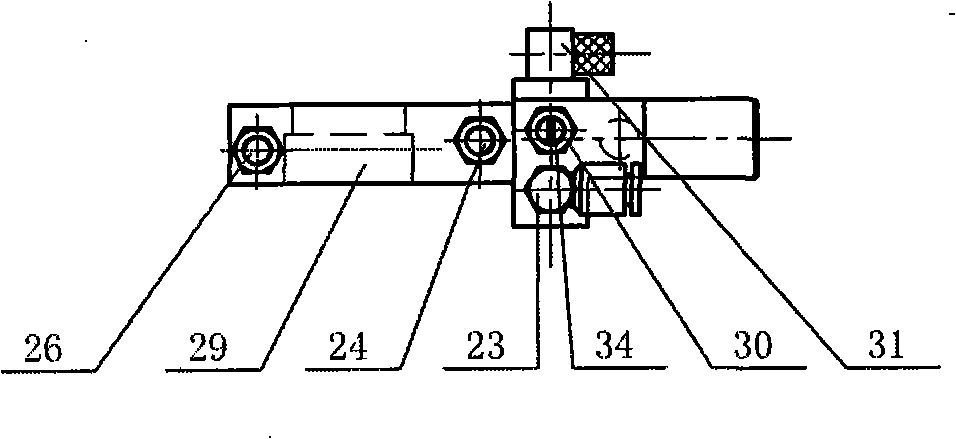

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0016] With reference to accompanying drawing, this two-cylinder hosiery machine shuttle two-position control device comprises fixed block 20, and this fixed block 20 is contained on the machine shuttle seat. The piston seat 29 is fixed on the fixed block 20 by the fixing screw J 22, and the stop screw F 24 and the stop screw G 26 are installed on the piston seat 29 respectively. The shuttle guide plate 1 is movably connected with the piston seat 29 by the axial screw D 25, and the plastic retaining ring 2 is fixed on the shuttle guide plate 1 by the fixing screw H3. The shuttle fixed plate 4 is close to the plastic retaining ring 2, and is movably connected with the shuttle guide plate 1 by the axial screw A 7 . The plastic retaining ring is used for guiding the shuttle fixed plate 4. Shuttle 5 is fixed on the shuttle fixed plate 4. Guide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com