Electric valve

An electric valve and valve core technology, which is applied to lift valves, balance valves, valve devices, etc., can solve the problems of noise, processing and assembly errors, partial wear of the valve seat portion 72b, etc., and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the electric valve according to the present invention will be described with reference to the drawings.

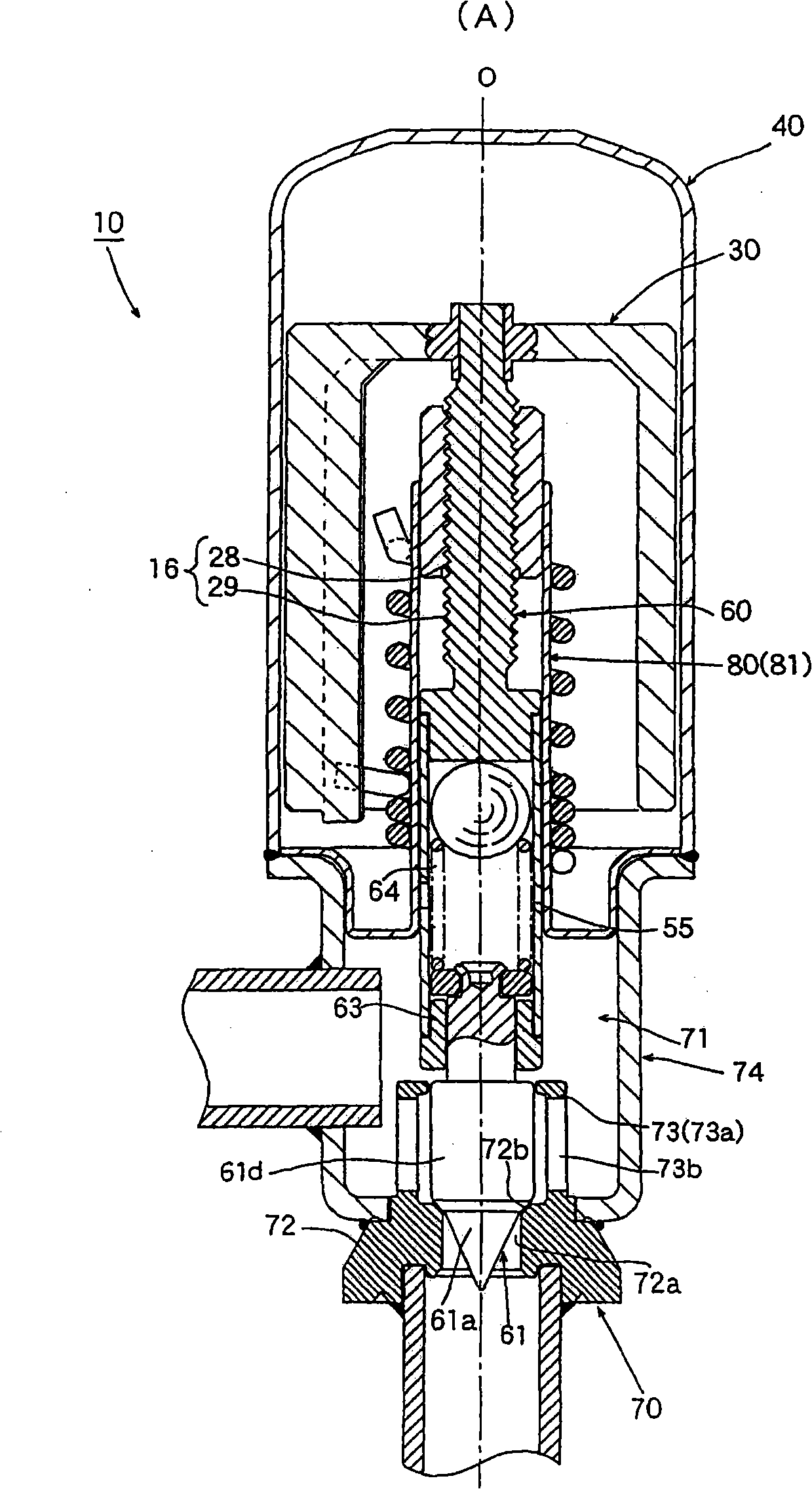

[0019] figure 1 It is a figure which shows one embodiment of the electric valve of this invention.

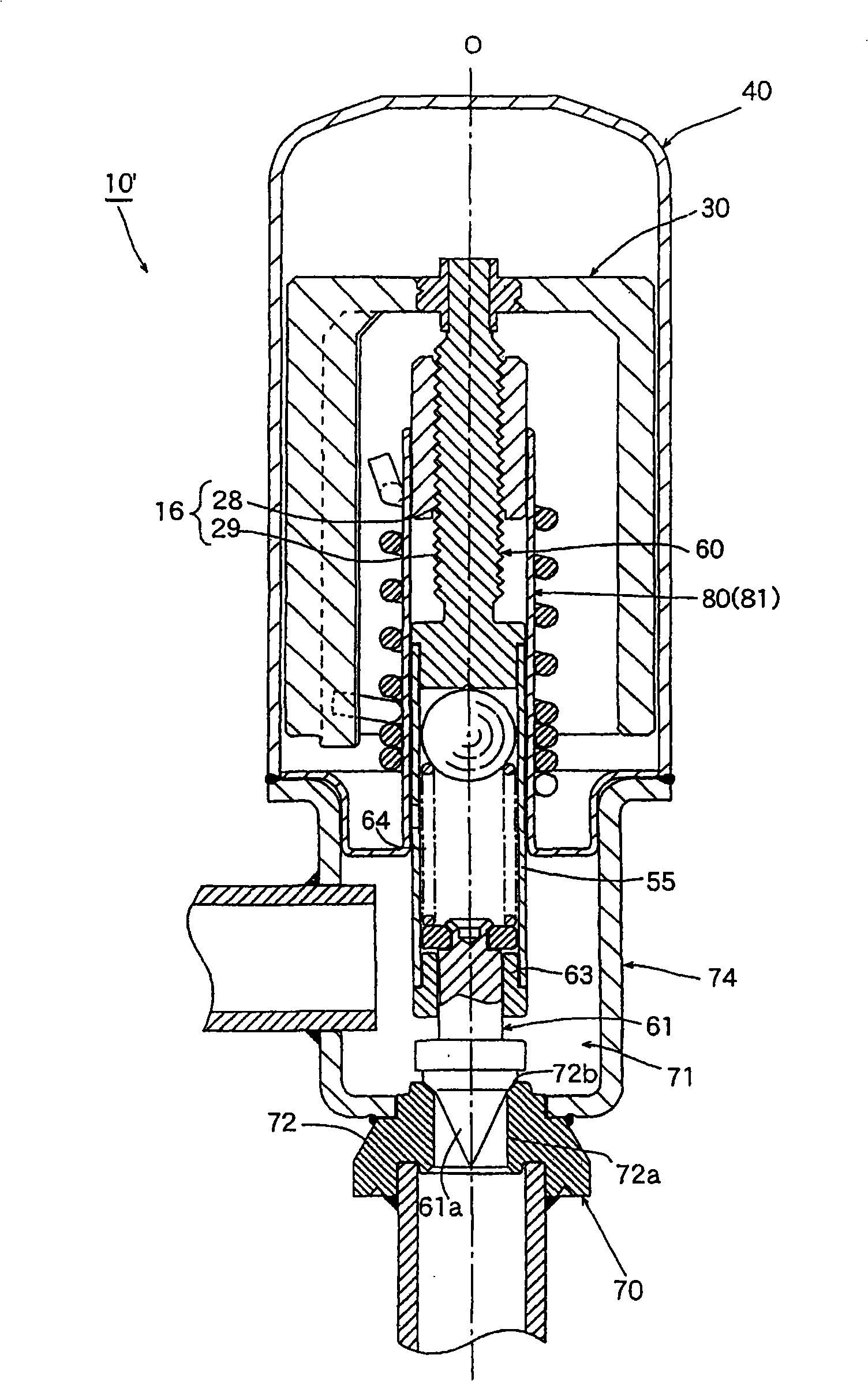

[0020] figure 1 The parts other than the valve body 70 and the spool 61 of the electric valve 10 shown are the same as those mentioned above figure 2 The electric valve 10' shown has substantially the same structure. Here, the same structure and the same functional parts are marked with common symbols and repeated descriptions are omitted. The following description focuses on the differences.

[0021] figure 1 In the electric valve 10 shown, the valve body 70 includes: a valve chamber forming part 74, which is made of a stamped part and forms a valve chamber 71 for fluid to flow in and out; a valve seat part 72, which is made of a cutting part and has a The valve seat portion 72b is in contact with and separated from the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com