Vibration type convey

A conveying device, a vibrating technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of adjusting vibration characteristics, damage, piezoelectric body of the vibration body, etc., to improve stability and durability, Improve transmission efficiency and reduce the effect of violent movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

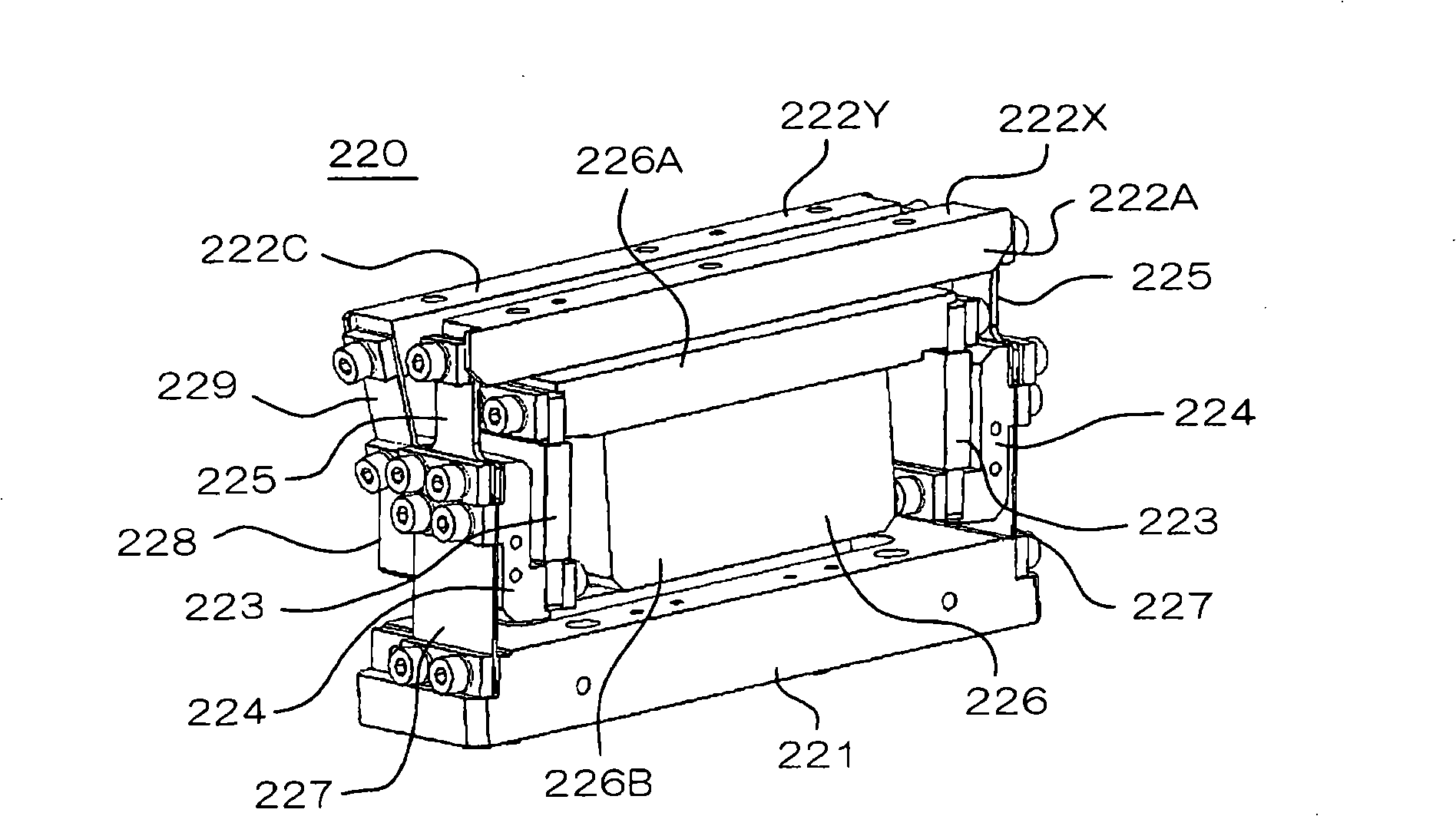

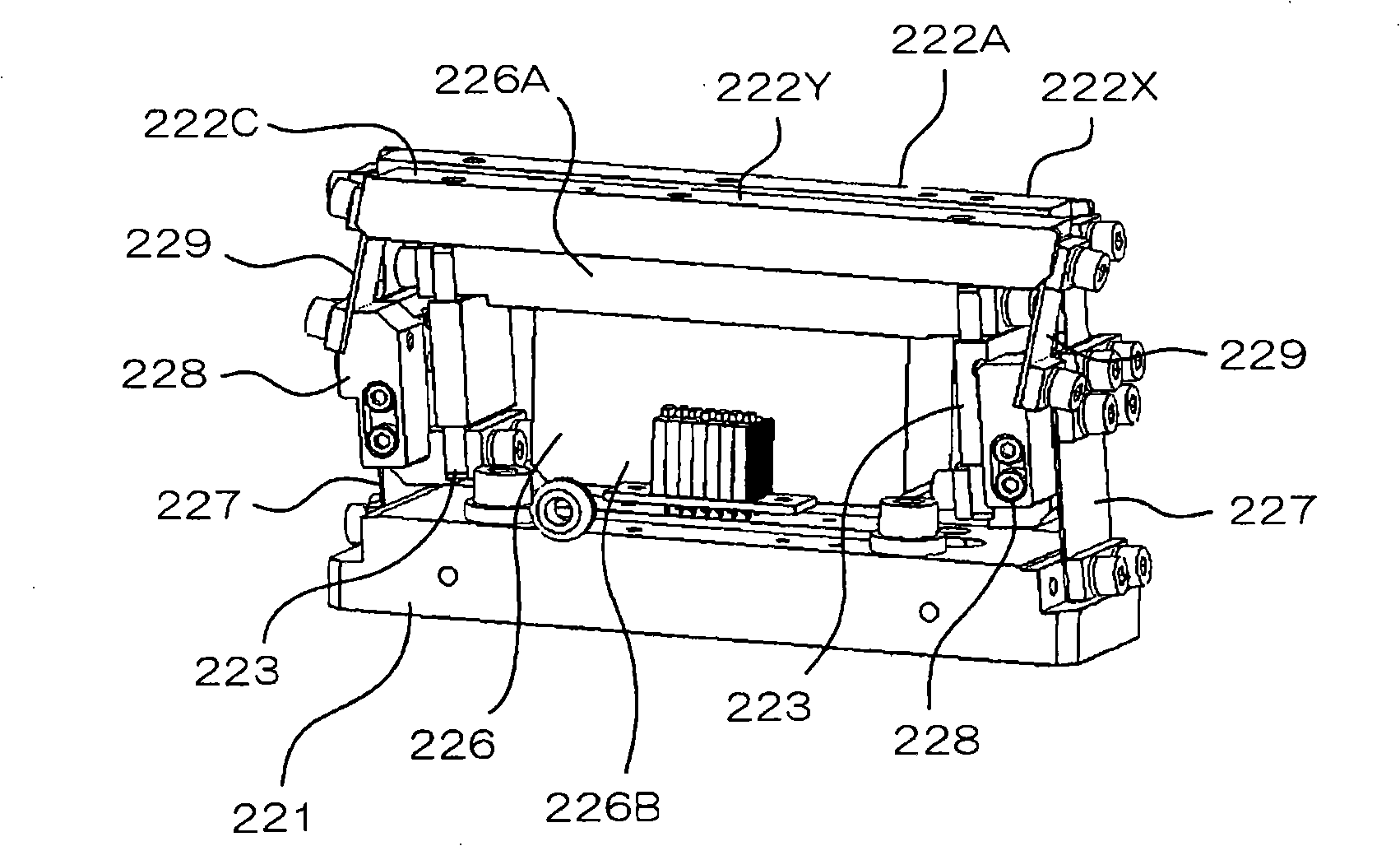

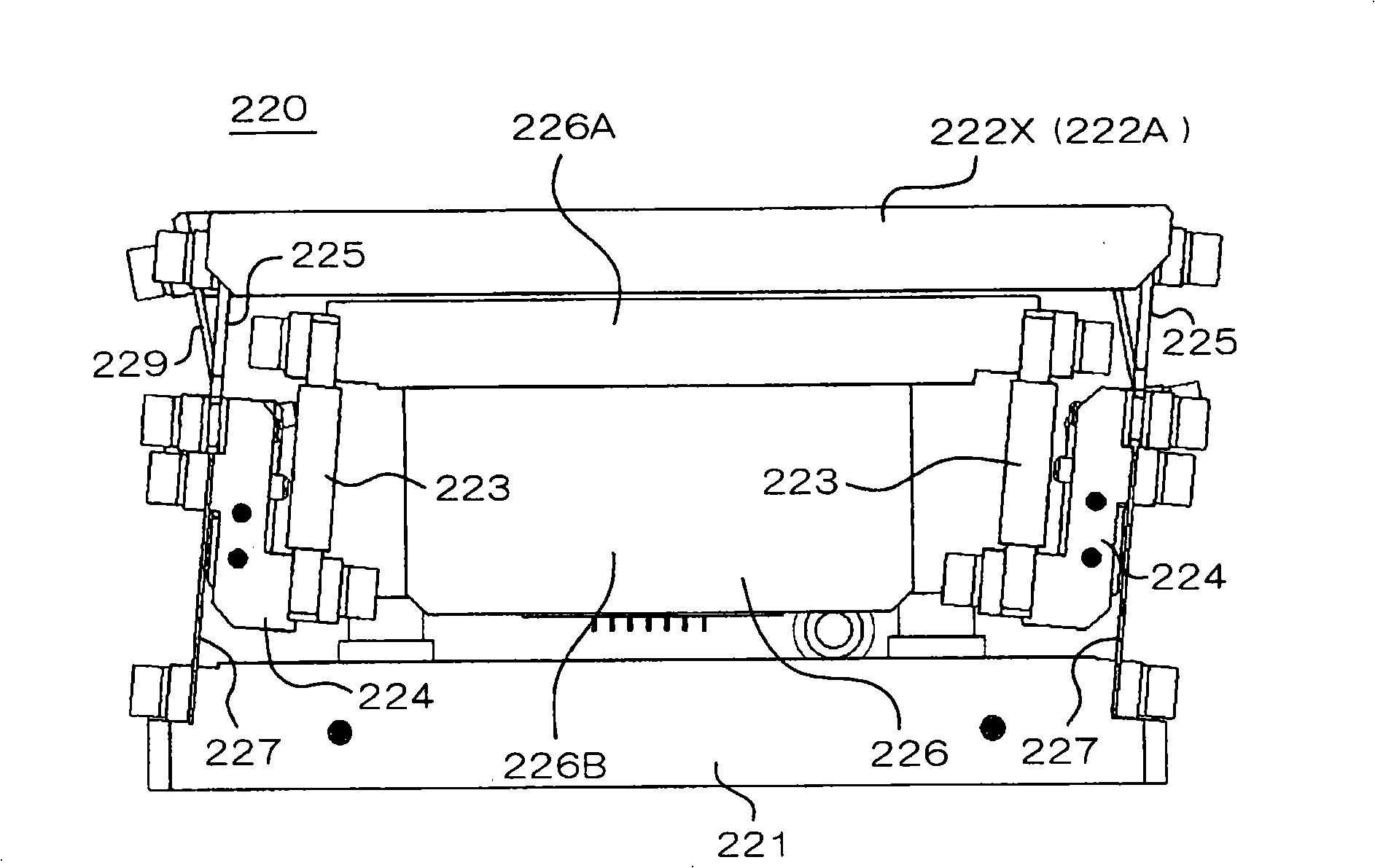

[0031] Embodiments of the present invention will be described below together with illustrated examples. figure 1 It is a schematic front side perspective view of the vibrating conveying device 220 according to this embodiment in a state where the conveying block 221B serving as a constituent part of the first conveying body and the conveying block 222B serving as a constituent part of the second conveying body are removed, figure 2 It is the rear side perspective view, image 3 is the front view, Figure 4 is the rear view, Figure 5 is the right side view, Image 6 It is a schematic plan view of a configuration example of a vibrating conveyor.

[0032] The vibratory conveying device 220 of the present embodiment has a base 221 and a first conveying body 222X (refer to Image 6 . Depend on figure 1 with figure 2 shown in slot 222A and Image 6shown conveying block 222B), the vibrating body 223 for vibrating the first conveying body 222X, the connecting member 224 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com