Gin pole turnover mechanism

A technology of a turning mechanism and a four-bar linkage mechanism, which is applied in drilling equipment, earth-moving drilling, supporting devices, etc., can solve the problems of inability to reduce the transportation height, the limitation of mechanical height, and the increase of transportation costs, and can shorten the forward tilt to the horizontal state. time, lower transportation height, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

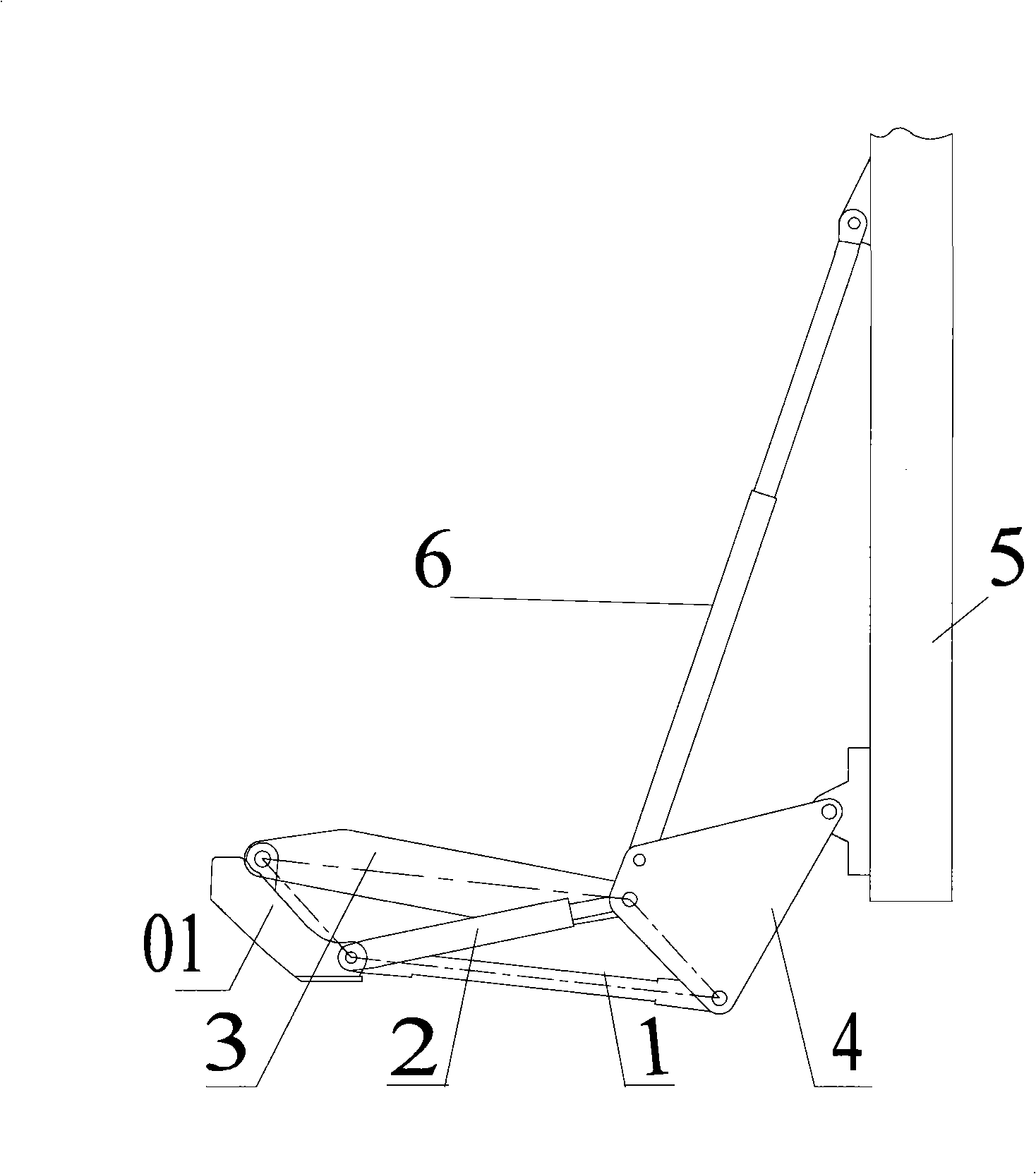

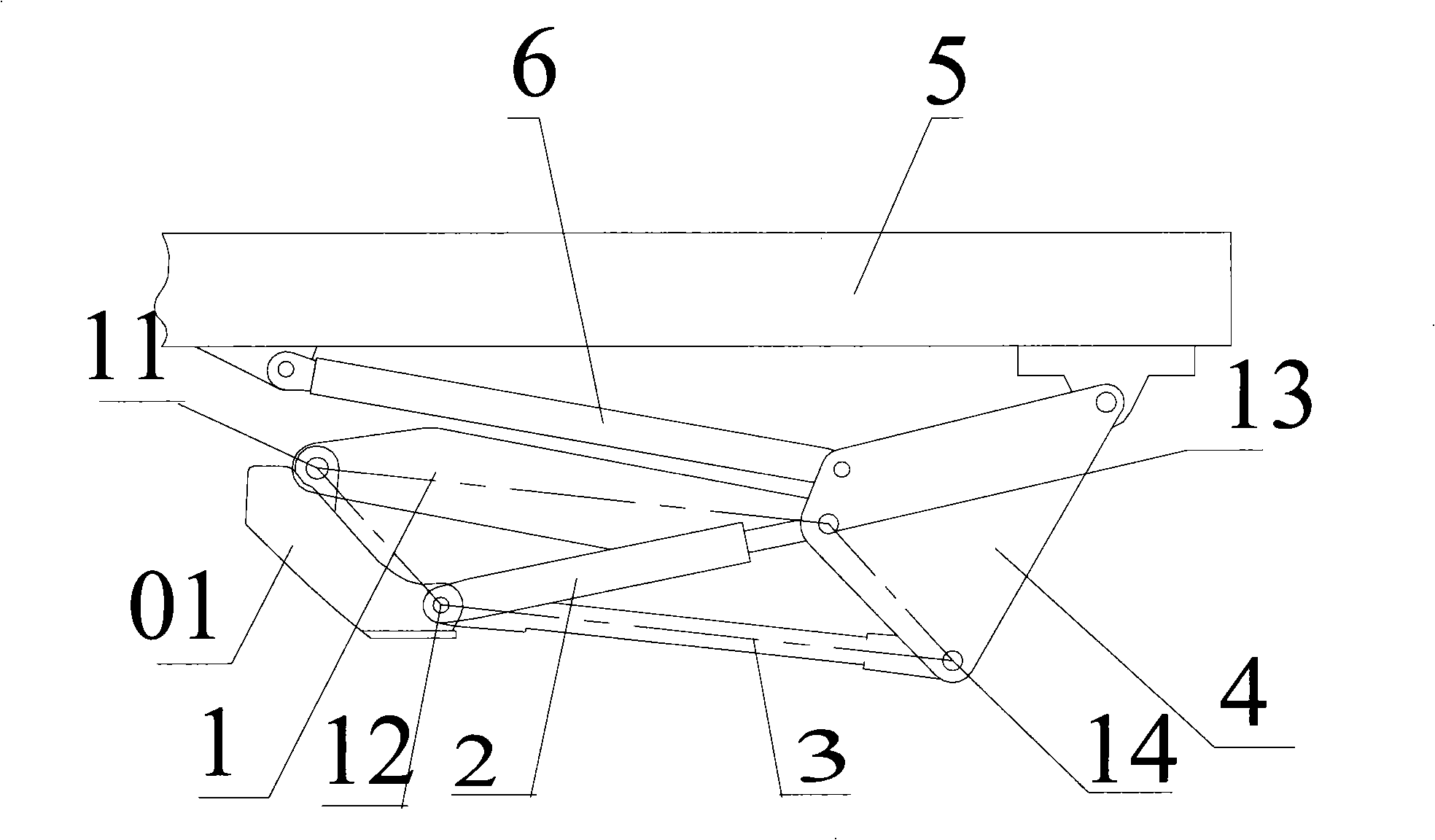

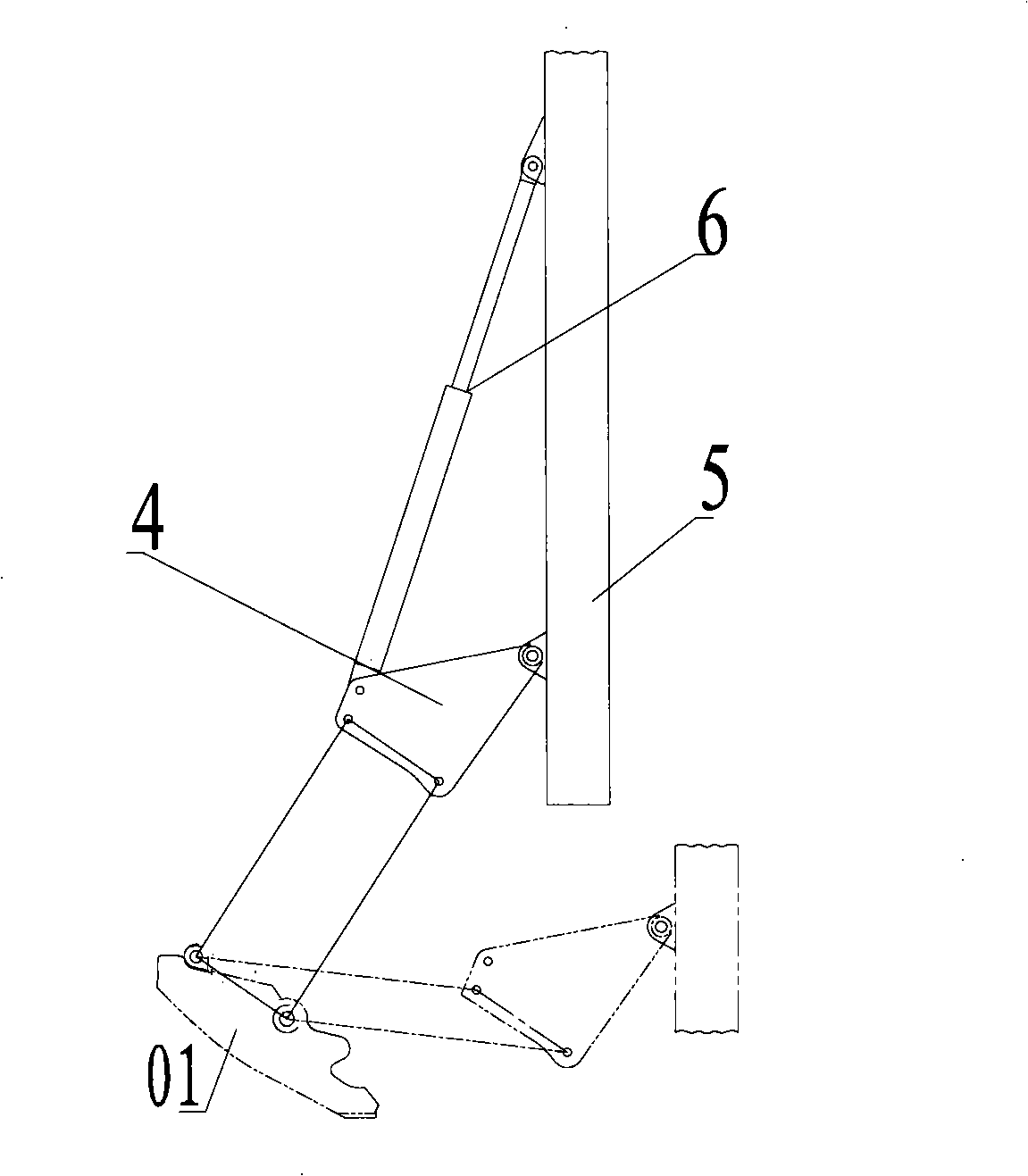

[0058] In the mast turning mechanism provided in Embodiment 1, by changing the corresponding position of the four-bar linkage mechanism, the two ends of the hypotenuse of the triangular bracket are relatively rotated, and then the mast can be tilted forward to a horizontal state with the cooperation of other structures, reducing the load of the pile machine. transport height. Such as Figure 4 As shown, the mast turning mechanism in this example includes a chassis 01 , a boom 1 , a luffing cylinder 2 , a support rod 3 , a tripod 4 , a luffing cylinder 7 , a connecting rod 8 , a mast 5 and a mast cylinder 6 .

[0059] One end of the connecting rod 8 is hinged to the chassis 01 through the second hinge shaft 12, and the other end forms a detachable hinge with the chassis 01 through the movable hinge shaft 18. Because both ends of the connecting rod 8 are hinged to the chassis 01, the connecting rod 8 is opposite to the chassis 01. fixed. One end of the support rod 3 and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com