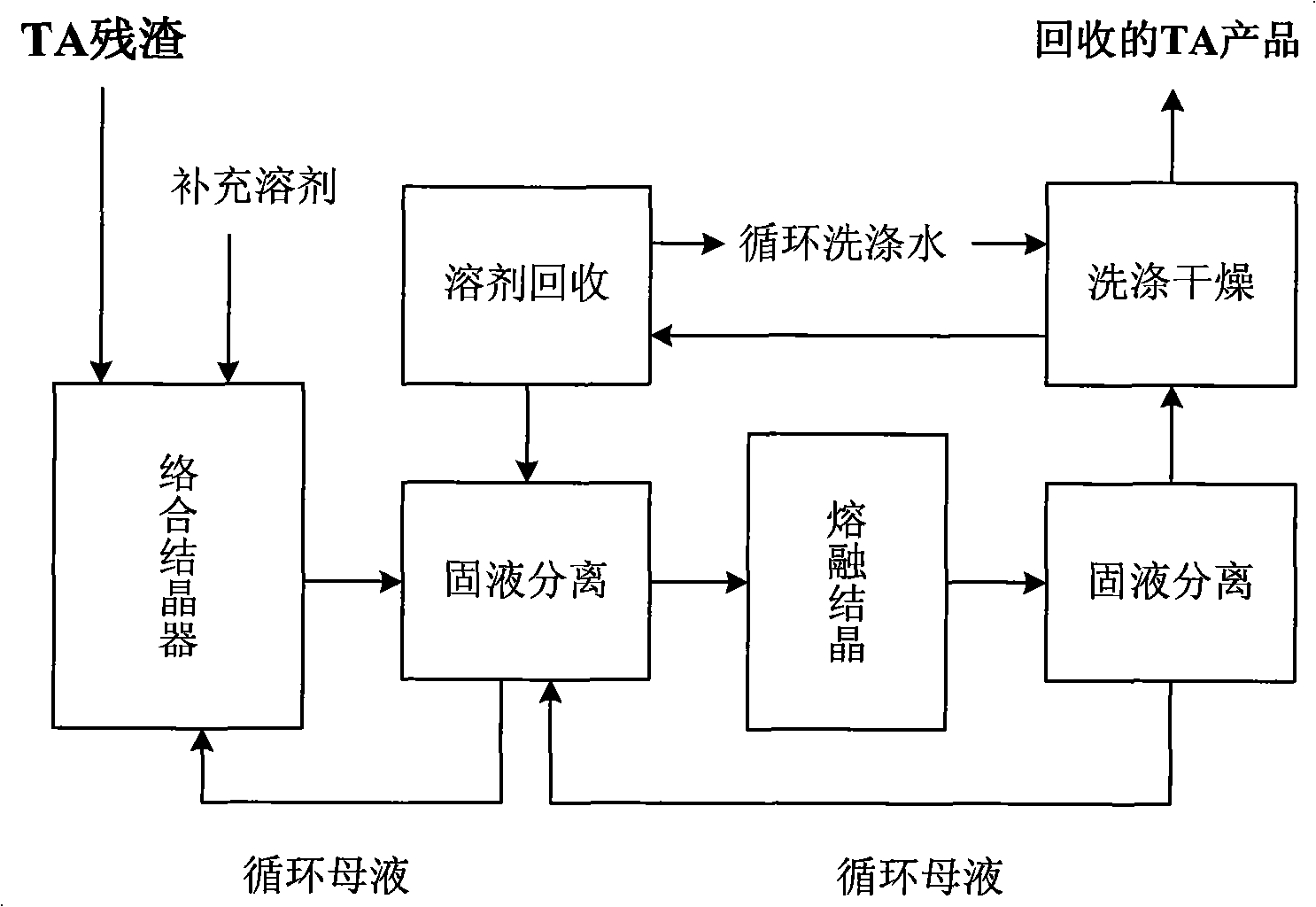

Method for recovering terephthalic acid from coloured terephthalic acid residue by complexation-crystallization

A terephthalic acid and complexing technology, which is applied in the field of recovering terephthalic acid from colored terephthalic acid residues by complex crystallization, can solve problems such as affecting the chromaticity and quality of products, and reduce the discharge of solid wastes. , the effect of protecting the environment and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The TA residue treated in this example comes from the CTA mother liquor impurity removal system, and its main components are: TA (90.15wt%), 4-CBA (4.05wt%), PT (2.44wt%), BA (1.21wt%), IPA (0.75wt%), other components about 1.40wt%, the color index b value of the TA residue is 17.0.

[0032] Put the dry 100.0g colored terephthalic acid solid residue into the complex crystallizer, add 400.0g N, N-dimethylacetamide (DMA), stir and mix; the mixture is in the complex crystallizer at 70°C, After staying for 20 minutes, white TA complex crystals were formed, and the mother liquor also changed from transparent and colorless to yellow. After filtering and washing with a saturated TA complex crystal solution, a white TA complex crystal solid was finally obtained, weighing 117.8 g.

[0033]Using gas chromatography to analyze the mass fraction of solvent DMA in the TA complex crystallization, the mass fraction of DMA is 49.4%, that is, the molecular ratio of DMA and TA is 1.86:1,...

Embodiment 2

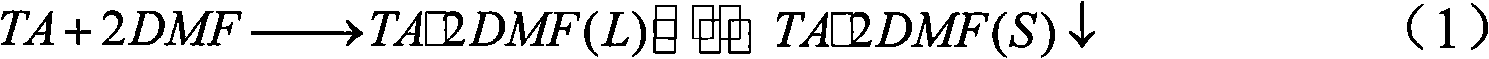

[0035] The treatment of the TA residue was carried out in a similar manner to Example 1. However, the complexing solvent used in this example is an equal mass of N,N-dimethylformamide (DMF), and 102.0 g of DMF complexing crystalline solids of TA were obtained. The mass fraction of solvent DMF in the DMF complex crystal of TA analyzed by gas chromatography is 46.0%, that is, the molecular ratio of DMF and TA is 1.94:1, that is, one TA molecule in the TA complex crystal is combined with about 2 DMF molecular. The crystallization of the complex was vacuum-dried at 120°C to remove the DMF solvent to obtain a TA solid. The impurity content and chromaticity index recovered from TA were analyzed. The relevant analysis data results are compared in Table 1.

Embodiment 3

[0037] The treatment of the TA residue was carried out in a similar manner to Example 1. However, the complex solvent used in this example is an equal mass of N-methylpyrrolidone (NMP), and 88.7 g of NMP complex crystalline solids of TA were obtained. The mass fraction of solvent NMP in the NMP complex crystal of TA analyzed by gas chromatography is 54.2%, that is, the molecular ratio of NMP and TA is 1.98:1, that is, there are about 2 TA molecules combined in the TA complex crystal. NMP molecule. The complex crystallization was vacuum-dried at 120°C to obtain TA solid, and the impurity content and chromaticity index recovered from TA were analyzed, and the relevant analysis data results were compared in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap