Lens array and method of making same

a microlens array and optical lens technology, applied in the field of microlens arrays and optical lenses, can solve the problems of reducing the light collection efficiency of the array, reducing the resolution with which the photosensitive resin can be patterned, and increasing the color distortion with time, so as to improve the reliability or useful life of the microlens, improve the sensor sensitivity, and be easy to fabricate and less expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

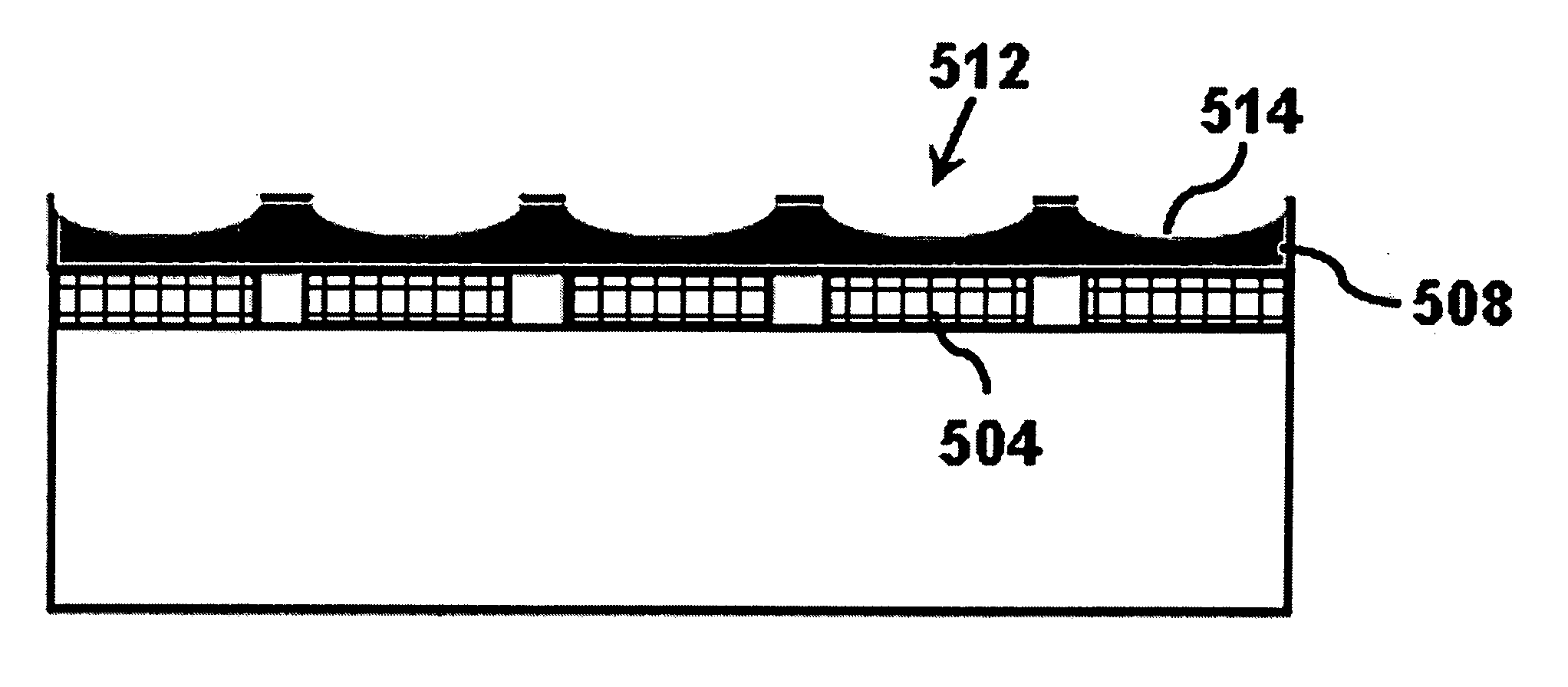

[0029]FIG. 4 is a flowchart illustrating a method 400 in accordance with an embodiment of the present invention for fabricating a microlens array or a non-spherical lens. A substrate is first provided in step 402, where the substrate may include an array of CMOS or CCD sensors. The sensor array may be any suitable size, ranging from small screen applications to large display devices. A dielectric layer is then deposited on the substrate in step 404. A patterning layer, such as a spin-on photoresist or other photosensitive material, is deposited on the dielectric layer in step 406. Selected portions of the patterning layer are removed, such as by conventional photolithography processing, in step 408. The removed portions expose areas of the dielectric layer where the microlenses or non-spherical lenses are to be formed. With embodiments having a sensor array, the exposed areas correspond to locations of individual sensor elements.

[0030] In step 410, the exposed portions of the diele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com