Catalyst for synthesizing polyketone by copolymerization of carbon monooxide and phenyl ethylene

A carbon monoxide and styrene technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic activity and relative molecular mass, and achieve relative The effect of high molecular mass, good catalytic activity and high yield

Inactive Publication Date: 2010-12-01

TIANJIN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The currently used ligand is 2,2'-bipyridine. This catalytic system is used in the process of copolymerization of carbon monoxide and styrene to form polyketones. The catalytic activity and relative molecular weight are not high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

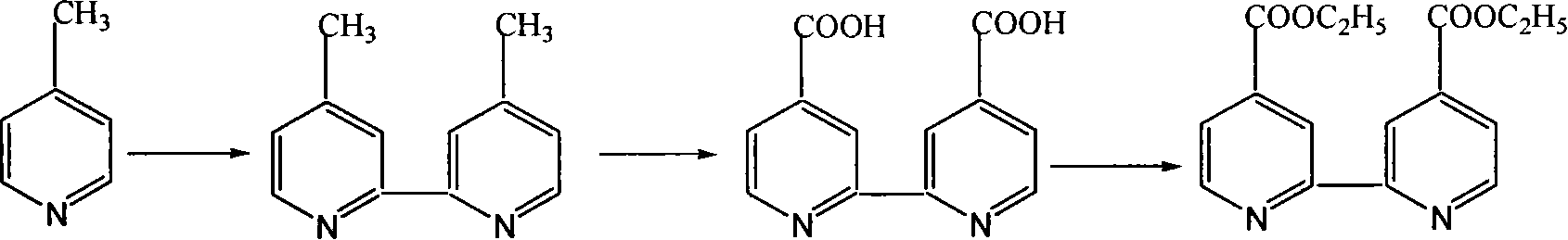

The invention relates to a catalyst used for synthesizing polyketone by copolymerization of carbon monoxide and cinnamene and a method for synthesizing the same. The catalyst comprises palladium acetate, para-benzoquinone, paratoluenesulfonic acid, fluoboric acid or a mixture of the palladium acetate, the para-benzoquinone, the paratoluenesulfonic acid and the fluoboric acid and 4, 4'-dicarboxylic acid carbethoxyl group-2,2'- dipyridyl. In the invention, carbon monoxide and cinnamene are taken as materials, and absolute methanol is taken as a solvent, and under the conditions of a temperatureof between 20 and 80 DEG C and a pressure of between 0.1 and 10Mpa and in the presence of the catalyst, the materials undergo the polymerization reaction for 1 to 3 hours. The catalyst provided by the invention has the advantages of good activity, high yield of the polyketone and high relative molecular mass of the synthesized polyketone; under the condition of the same use level of the main catalyst palladium acetate, the addition of the 4, 4'-dicarboxylic acid carbethoxyl group-2, 2'- dipyridyl can not only improve the activity of the catalyst by 1 to 3 times, but also improve the relative molecular mass of the polyketone by 1 to 2 times.

Description

Catalyst for the copolymerization of carbon monoxide and styrene to polyketones technical field The invention relates to a catalyst for synthesizing polyketones, in particular to a catalyst for preparing polyketones by copolymerizing carbon monoxide and styrene with 4,4'-dicarboxylate-2,2'-bipyridine. Background technique Polyketone is a linear and strictly alternating copolymer prepared by the copolymerization reaction of carbon monoxide (CO) and α-olefin. It has good mechanical properties, solvent resistance, and non-toxic properties. The raw material CO comes from a wide range of sources, reducing the cost compared to most materials synthesized from petroleum. More importantly, the carbonyl group on the main chain of polyketone endows it with unique photodegradation or biodegradation properties. It can slowly degrade into small molecules such as alkenes and CO2, which is of great significance in environmental protection and medical health. In addition, the carbonyl gro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G67/02B01J31/18

Inventor 郭锦棠赵海洋冯亚凯李鹏

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com