Bolt connection prefabricated assembly quadrangular pyramid space grid structure and manufacturing method thereof

A space grid and prefabricated assembly technology, which is applied in the direction of building structure and construction, can solve the problems of high construction cost, difficult to guarantee welding quality, and long construction period, and solve the problems of heavy welding workload and welding stress and deformation , Reduce the workload of on-site assembly and avoid the effect of false tightening phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

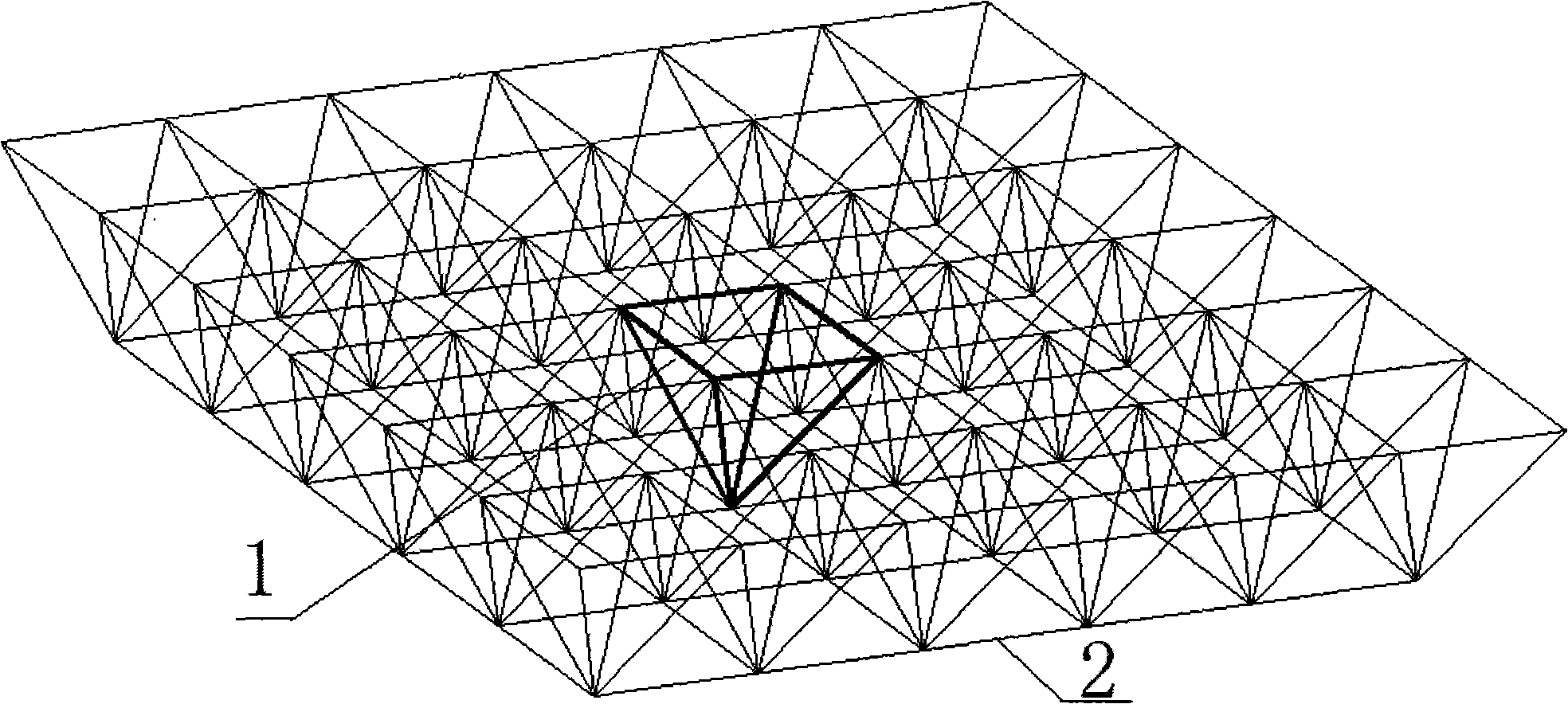

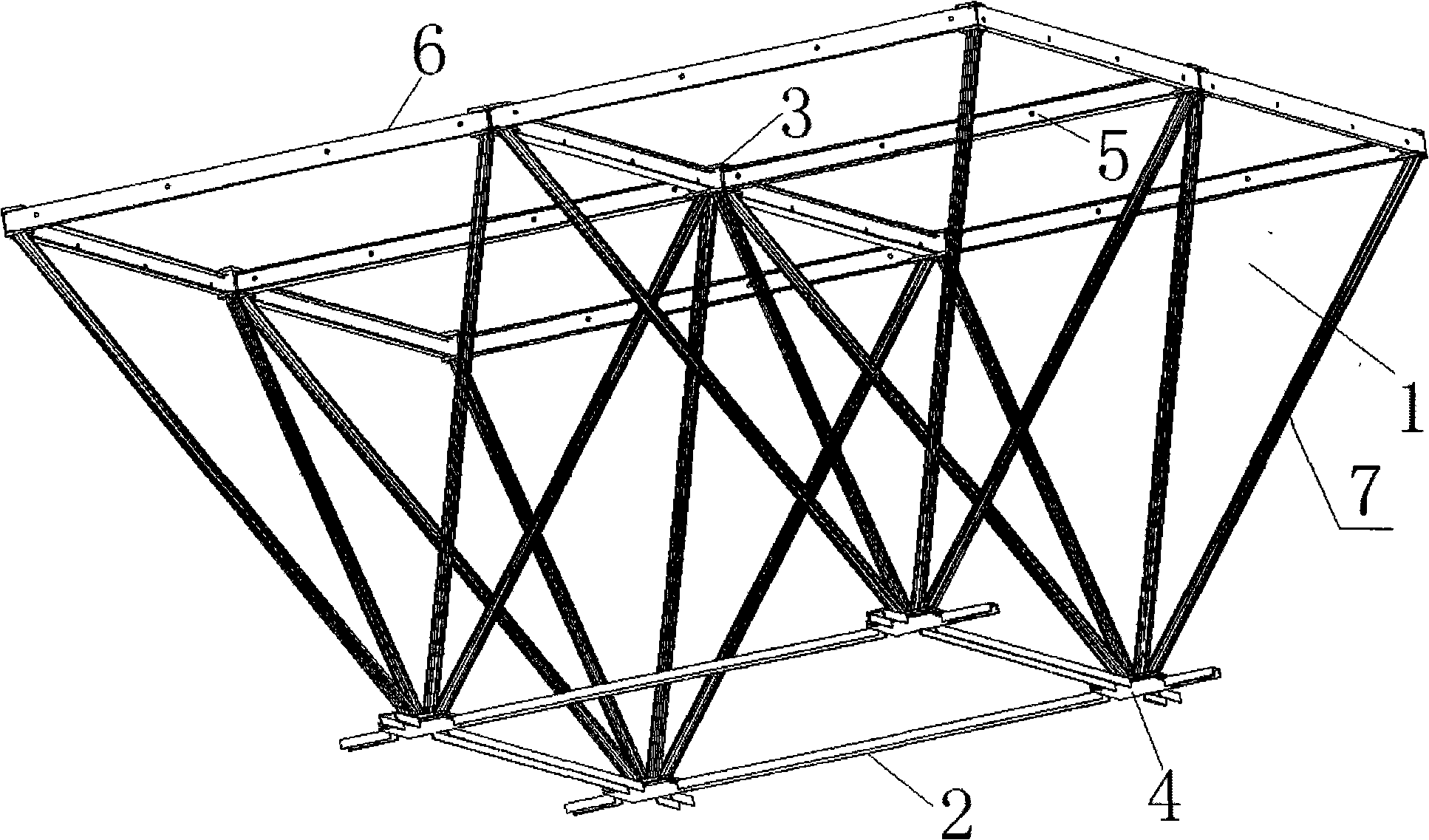

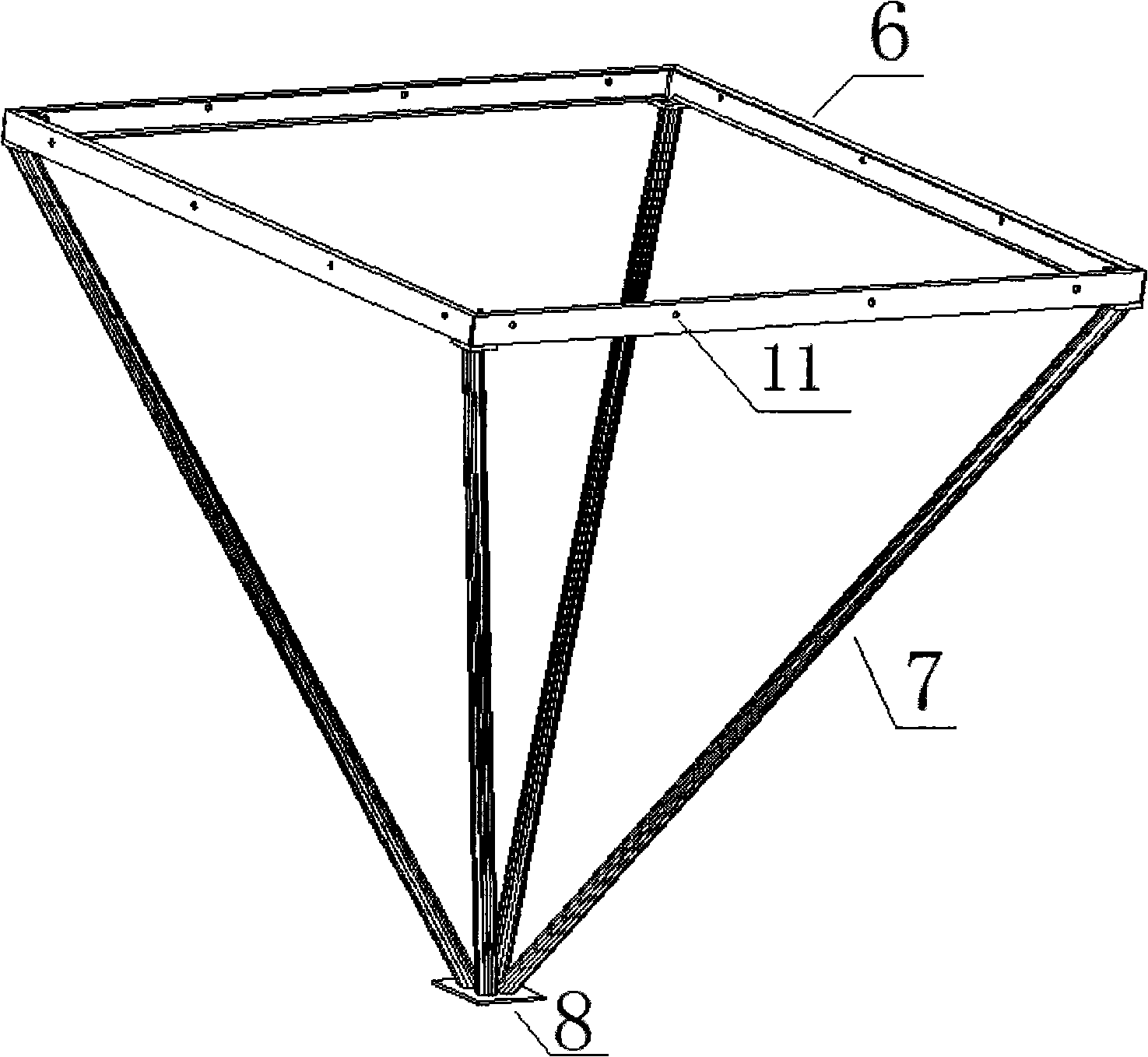

[0034] Such as figure 1 with figure 2 As shown, the bolt connection prefabricated and assembled quadrangular pyramid spatial grid structure includes a quadrangular pyramid module unit 1, a lower chord 2, an upper cover 3, a lower cover 4, and bolts 5. The quadrangular pyramid module unit 1 is prefabricated in the factory, and includes the upper chord 6, the oblique web 7, the web bottom end plate 8, the rib 9, the web top end plate 10, and the reserved bolt holes 11. After being transported to the site, the different quadrangular pyramid module units are connected at the upper chord node by the upper cover plate 3 and the bolt 5, and at the lower chord node by the lower chord 2, the lower cover plate 4 and the bolt 5. The upper chords 6 between the quadrangular pyramid module units 1 are connected by bolts 5. The number of bolts can be set to two or more according to the size of the upper chords. In this embodiment, there are 4, such as image 3 Shown. After the quadrangular pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com