Method and system for automatically making sub batch plan for steel-smelting continuous casting furnace

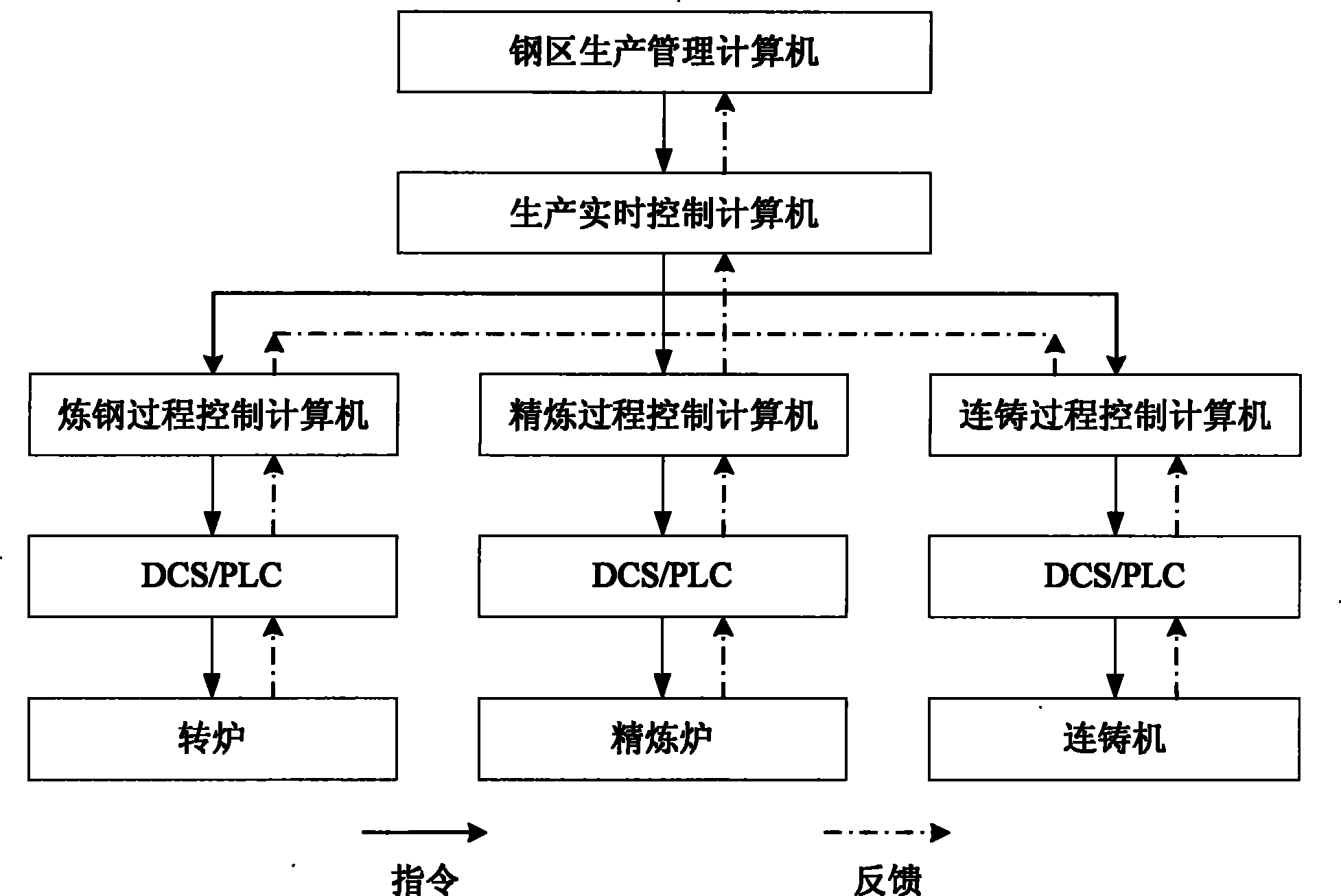

A continuous casting furnace, planning technology, applied in the direction of total factory control, total factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

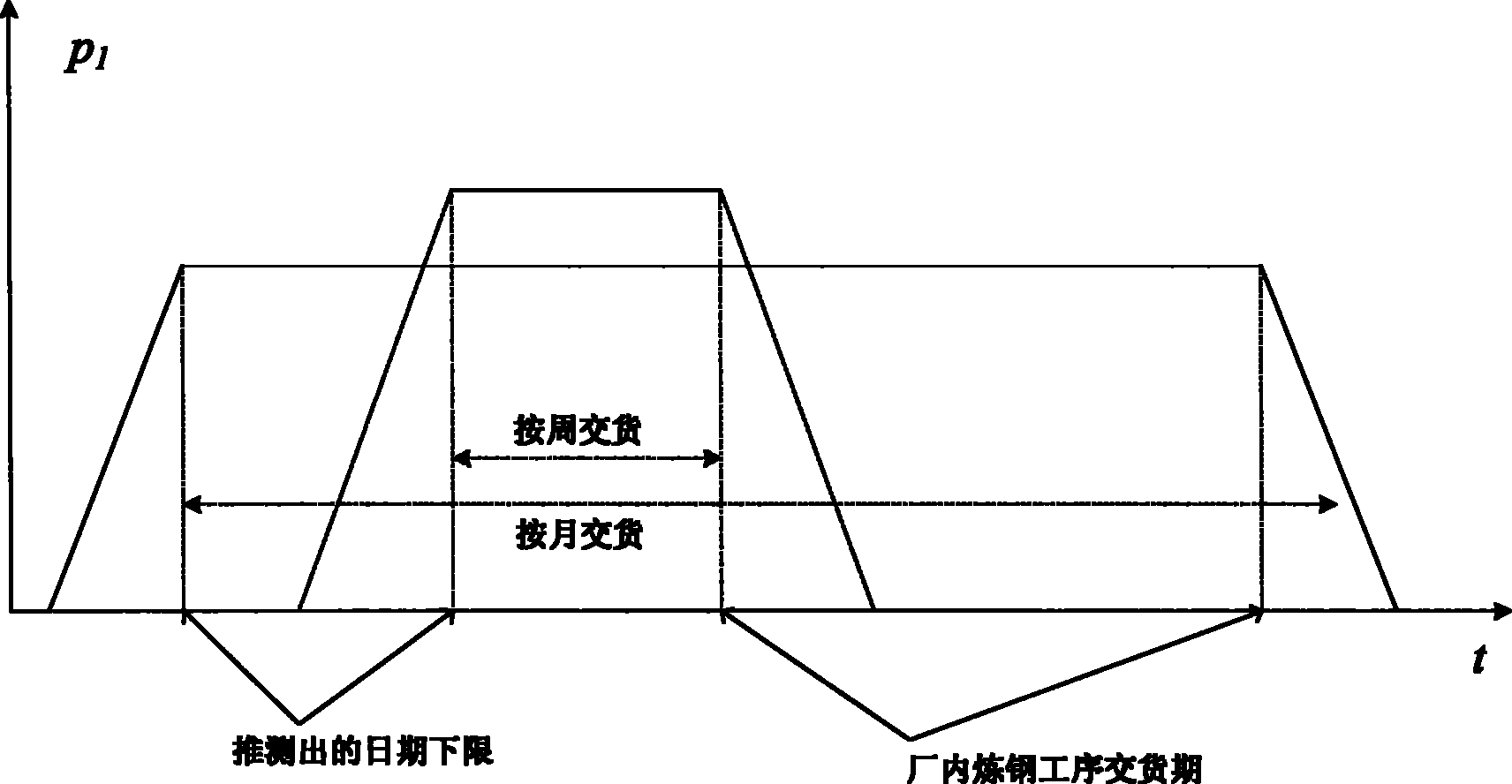

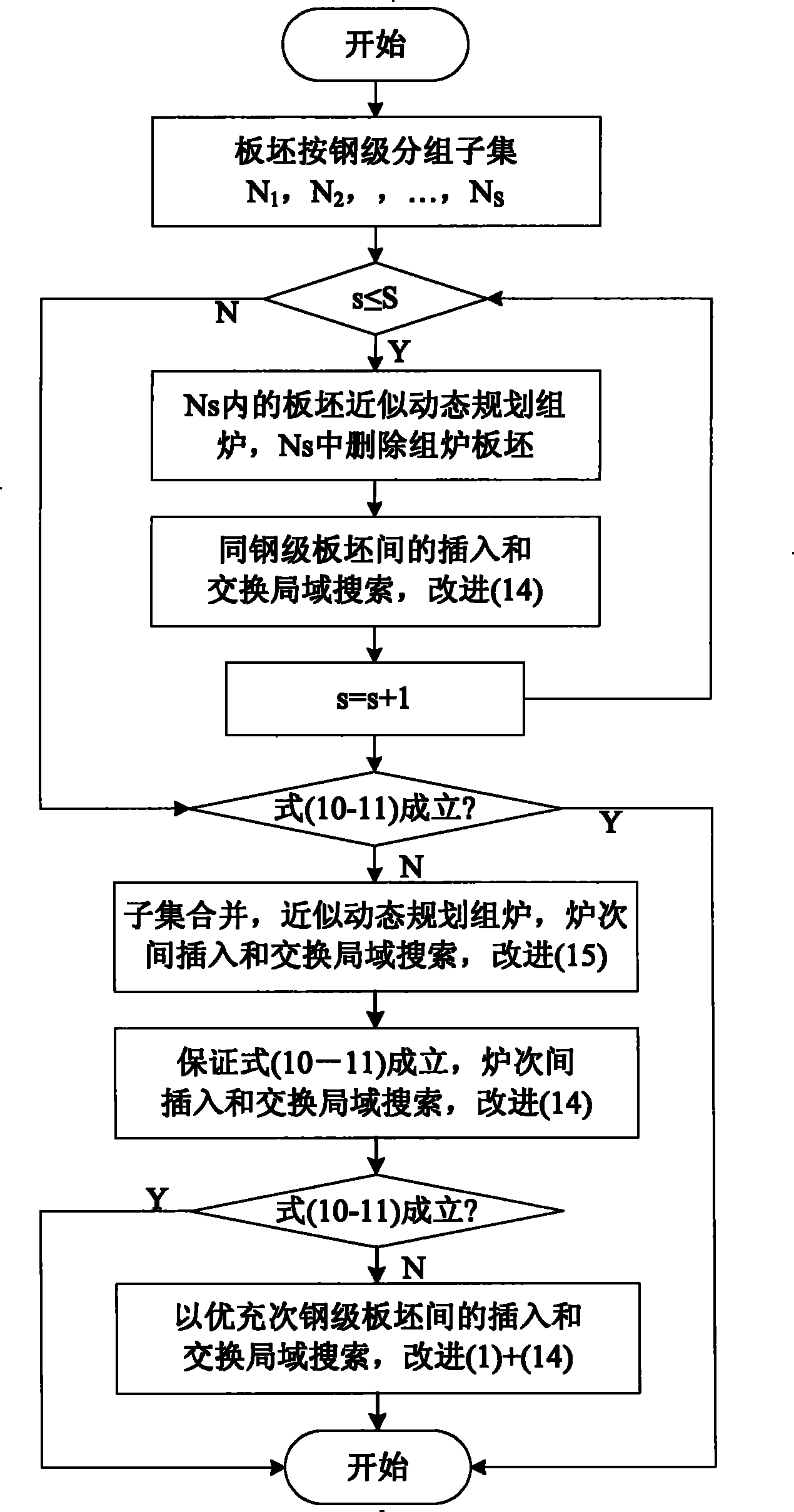

Method used

Image

Examples

Embodiment Construction

[0118] The embodiment of the present invention is a steelworks of a large iron and steel enterprise. The steelmaking plant has two converters, one RH refining furnace, and two continuous casting machines. The daily production capacity of the converter is about 65 furnaces, and the daily production capacity of RH refining is about 30 furnaces. The smelting capacity of the converter is 300 tons, and the width adjustment rule of the continuous casting machine is positive "Y" width adjustment (that is, from wide to narrow), each time the width adjustment range is 50mm and 100mm, and the molten steel of one heat is only It is allowed to adjust the width once, and the maximum (minimum) setting width of the continuous casting machine is 1450mm (900MM). The slabs produced by continuous casting are then sent to the hot rolling workshop for rolling into coils. The lateral pressure of the slabs according to different hardness groups is [50mm, 250mm].

[0119] The specific implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com