Reactor pressure vessel material irradiation control sample well type storing device

A technology for preservation devices and pressure vessels, applied in storage devices, transportation and packaging, nuclear engineering, etc., can solve the problems of difficult to achieve ideal results, high cost, difficult to control the temperature and humidity of the hot chamber, and achieve easy inspection and good radioactivity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

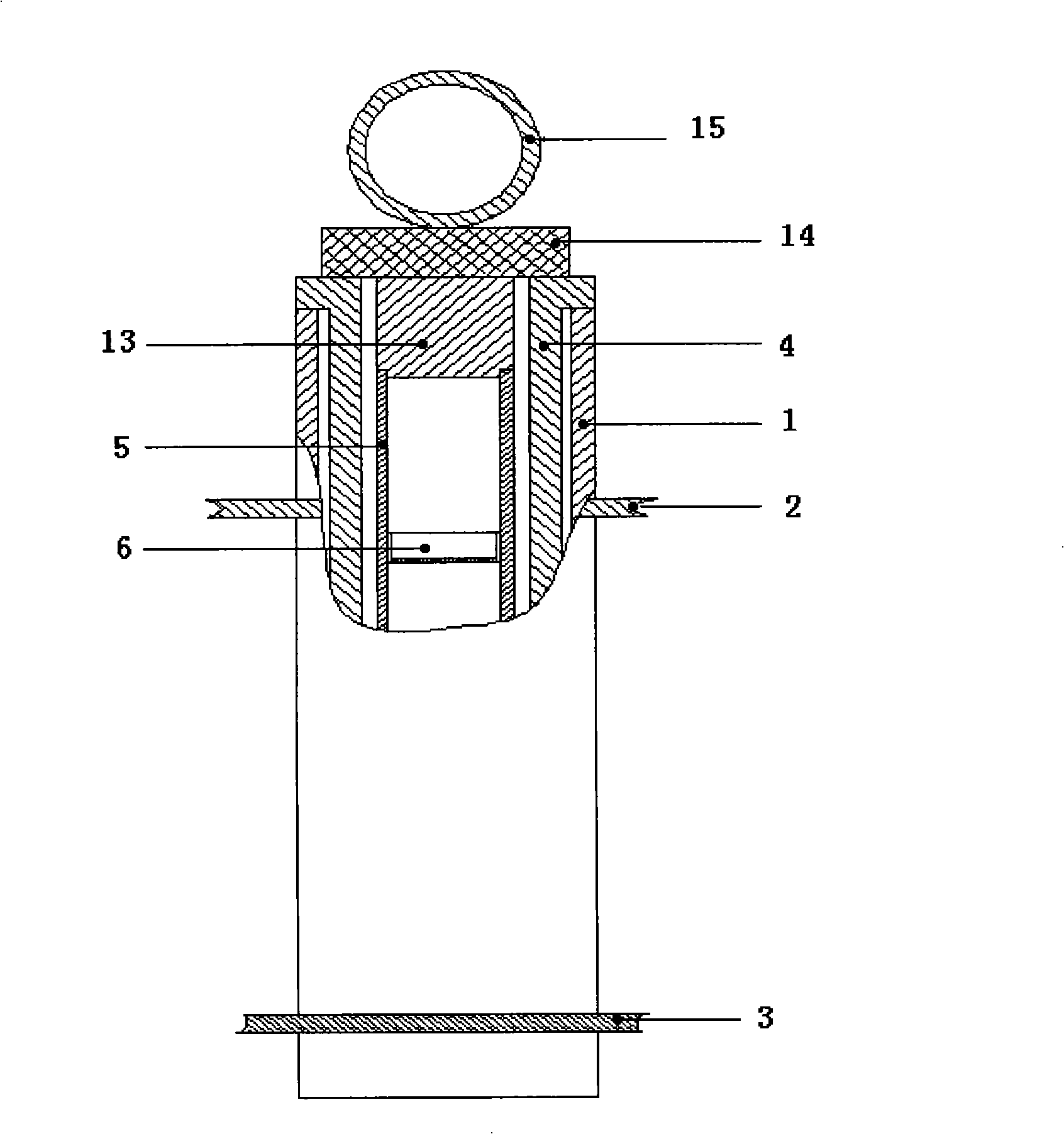

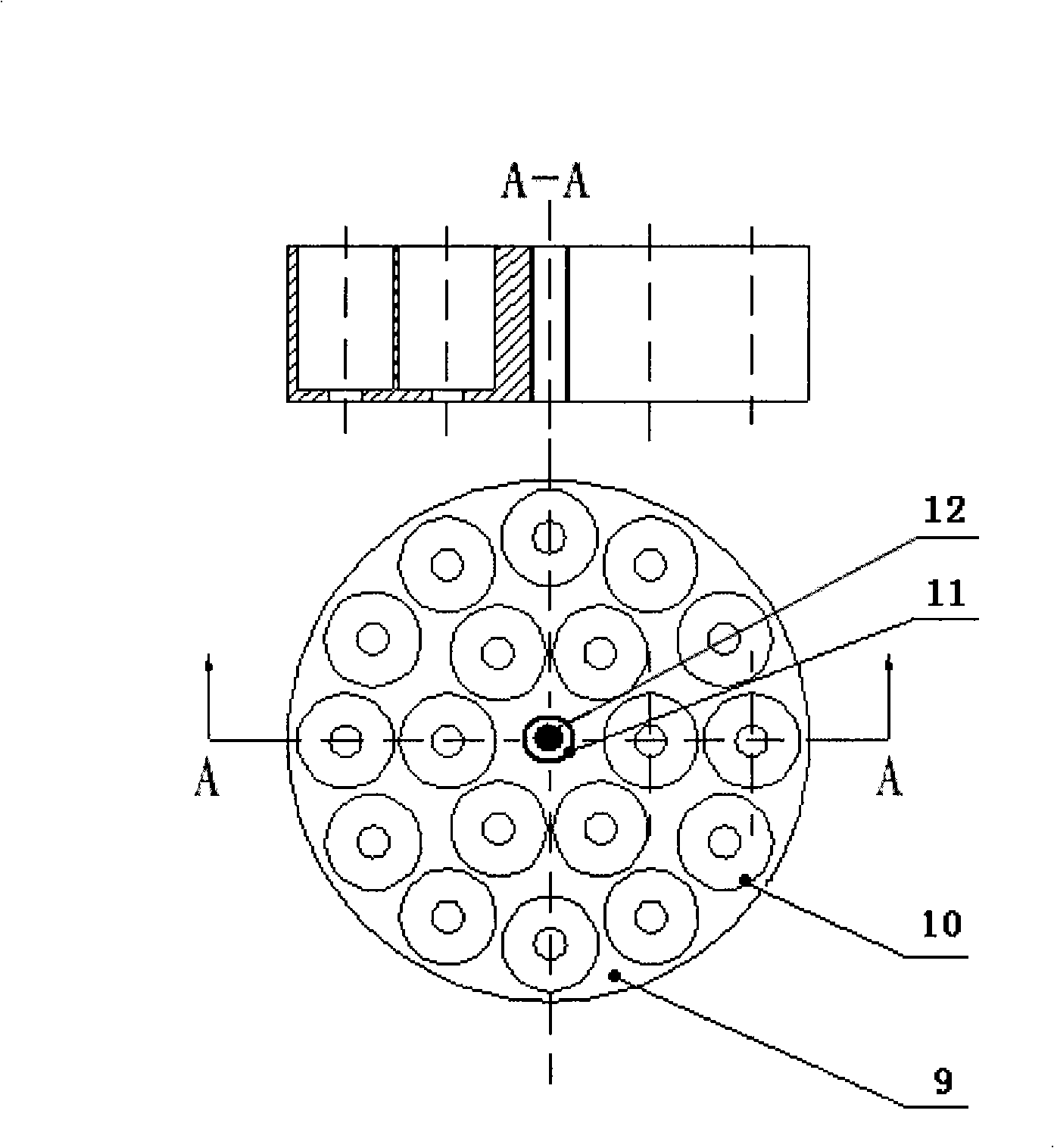

[0021] Such as figure 1 As shown, the present invention includes a carbon steel pipe 1 fixed with an upper steel plate 2 and a lower steel plate 3 and welded at the bottom, and a stainless steel liner pipe 4 welded at the bottom is placed in the carbon steel pipe 1 as the storage well wall, and the liner pipe 4. It is filled with benzyl silicone oil as a storage medium. Leakage must be checked before use to prevent leakage of the storage medium. The storage grid 5 is placed in the liner pipe 4 and immersed in the preservation medium. In order to increase the space utilization rate of the storage well, the storage grid 5 has five layers; the storage grid 5 is welded with a tray 6, and the tray 6 Place sample box 9 on it; also weld a cylindrical stainless steel shielding block 13 on the top of storage grid 5, be welded with storage well cover 14 on the top of shielding block 13, be welded with suspension ring 15 on the well cover 14.

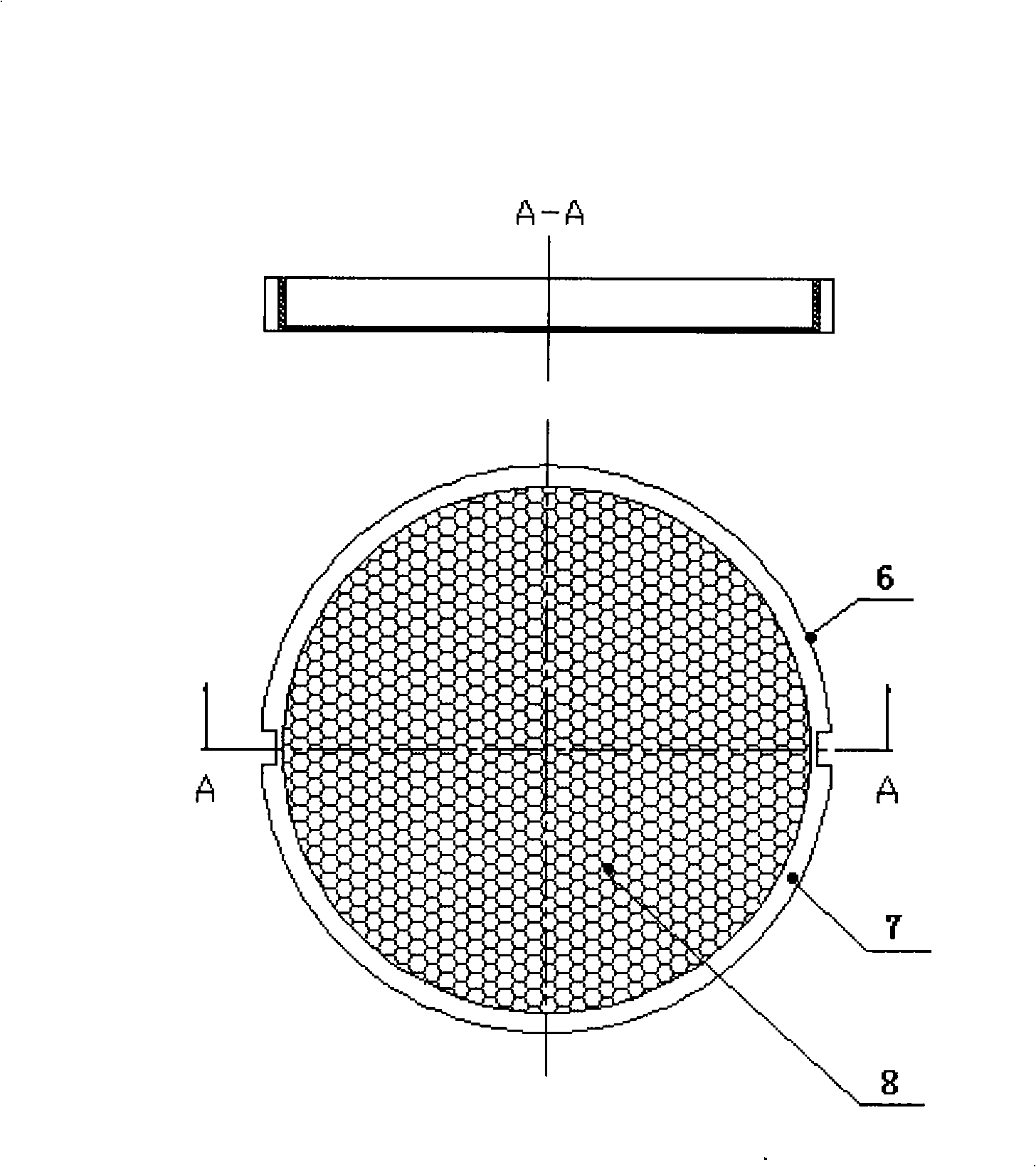

[0022] Tray 6 as figure 2 As shown, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com