Brush head for cleaning silicon chip

A chip and silicon chip technology, applied in the field of chip brush that can improve the efficiency of chip brushing, can solve the problems of silicon chip surface scratches, low particle cleaning efficiency, secondary contamination, etc., to improve particle removal rate and reduce secondary contamination. Less contamination and less scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

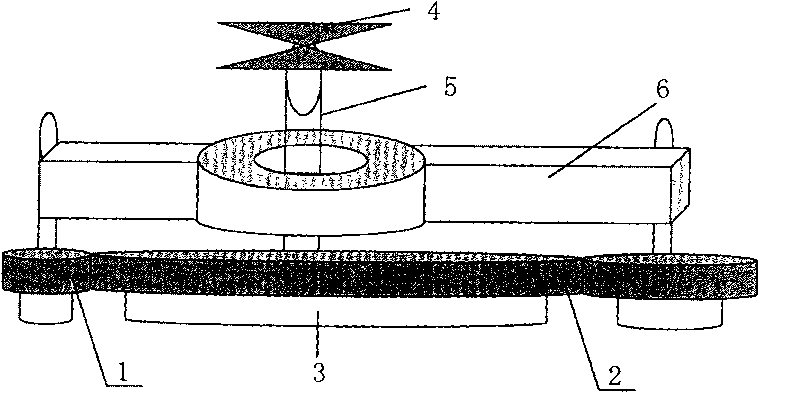

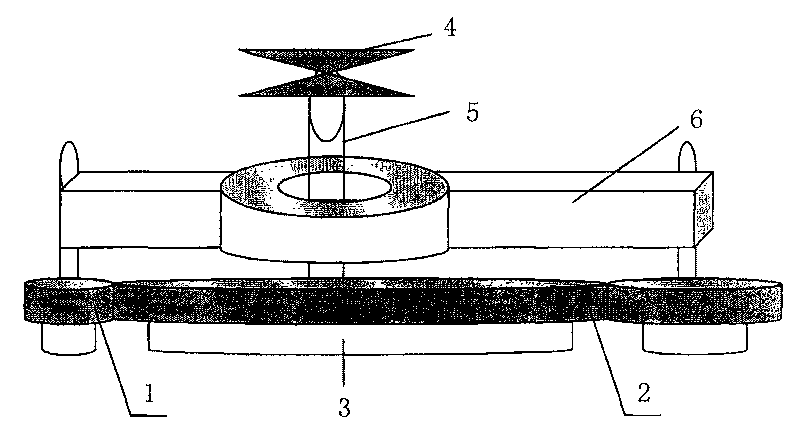

[0008] The brush chip head for cleaning silicon wafers of the present invention includes a plurality of brushes, and the brushes can be driven by the brush driving mechanism to rotate at different speeds. The planetary gear can be used to make the brush produce different speeds.

[0009] As shown in the drawings, in one embodiment of the present invention, the brush drive mechanism includes a planetary gear 1, a power gear 2, a motor 4, a bearing 5, and a connector bracket 6, and the power gear 2 is connected to the motor through the bearing 5 4, and the motor 4 drives the power gear 2, the planetary gear 1 and the power gear 2 are connected in a meshing manner, and relatively rotated under the drive of the power gear 2, and the connector bracket 6 is used for The planetary gear 1 is fixedly connected, and brushes 3 are arranged under the rotating shafts of the planetary gear 1 and the power gear 2, and the vertical pressure and position of each brush 3 on the silicon chip can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com