Highly effective radiation LED lamps

A technology of LED lamps and LED light sources, applied in lighting and heating equipment, parts of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of difficult heat dissipation of LED lamps, insufficient luminous brightness of single-chip LEDs, and poor effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

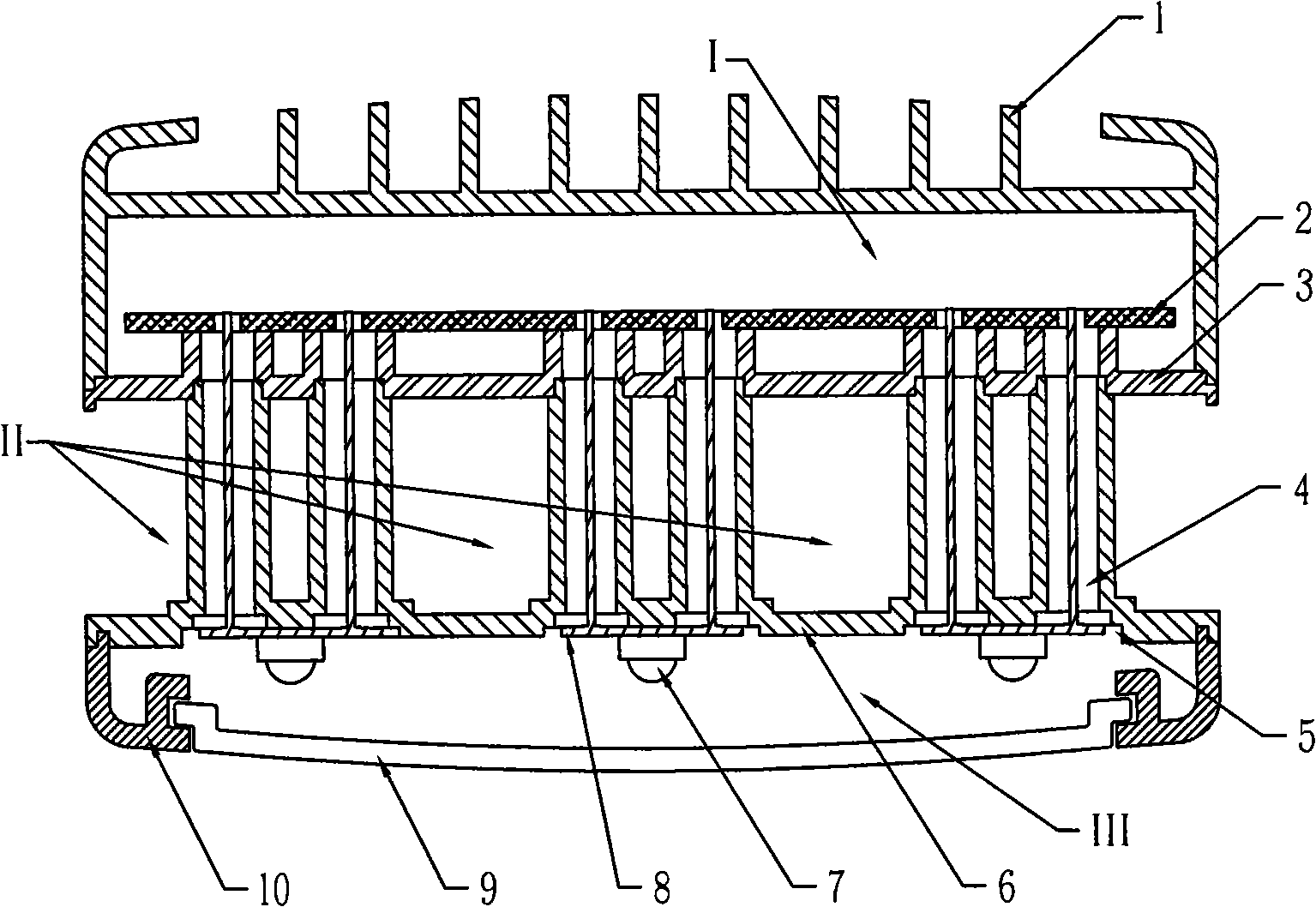

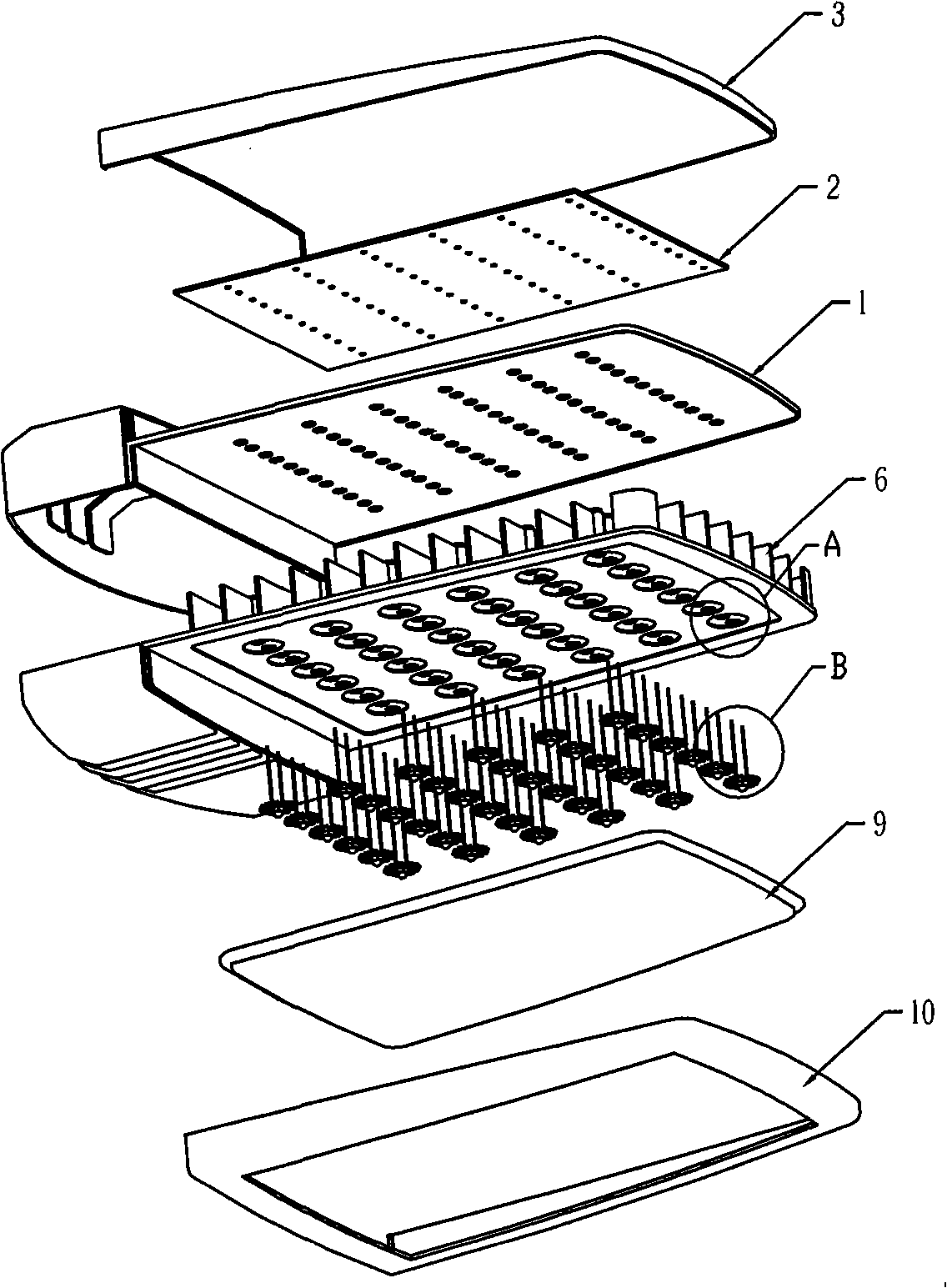

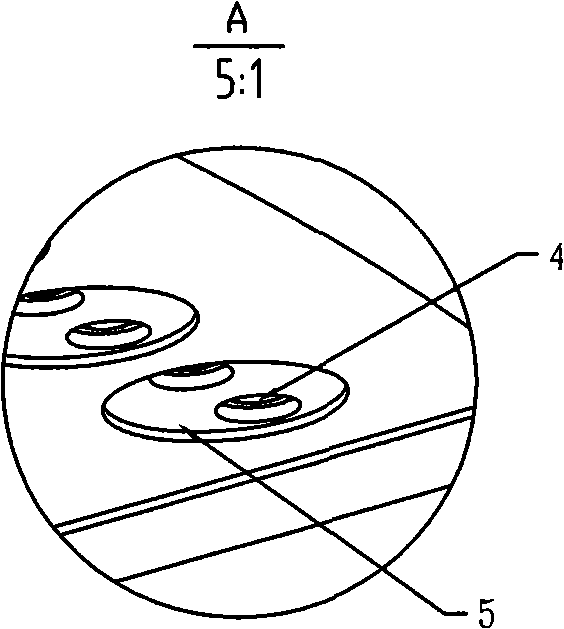

[0036] Example 1, such as figure 2 , as shown in Figure 3. The lamp head of the LED street lamp is long, and the lower surface of the open heat sink 6 is arranged with multiple LED light sources and lenses 7 along the vertical and horizontal directions; each LED light source and lens 7 are attached to the lower surface of the open heat sink 6 through the LED substrate 8. In the accommodation hole 5, the LED light source and lens 7 wires pass through the LED wire hole 4 to realize circuit connection with the PCB circuit board and corresponding electronic components 2, and most of the heat generated by the LED light source 7 is directly conducted to the open heat sink 6. From the surface to the upper part of the open heat sink 6, there are many grid-like heat conduction ribs arranged in a row. Since the open heat dissipation cavity part (II) of the lamp is directly exposed to the outside air, the natural wind from the outside passes through the upper part of the open heat sink ...

Embodiment 2

[0037] Example 2, such as Figure 4shown. LED tunnel light, the lower surface of the open heat sink 6 is arranged with a plurality of LED light sources and lenses 7 along the vertical and horizontal directions; each LED light source and lens 7 is attached to the LED accommodating hole 5 on the lower surface of the open heat sink 6 through the LED substrate 8 Inside, the wires of the LED light source and the lens 7 pass through the LED wire perforation 4 to realize circuit connection with the PCB circuit board and corresponding electronic components 2, and most of the heat generated by the LED light source 7 is directly conducted to the lower surface of the open radiator 6 until the open radiator 6 is opened. There are many grid-like heat conduction ribs on the upper part of the heat sink 6. Since the open heat dissipation cavity part (II) of the lamp is directly exposed to the outside air, the natural wind from the outside passes through the upper part of the open heat sink 6....

Embodiment 3

[0038] Embodiment 3, as shown in Figure 5. For LED spotlights, a plurality of LED light sources and lenses 7 are respectively arranged on the lower surface of the open heat sink 6 along the vertical and horizontal directions; each LED light source and lens 7 are attached to the LED accommodating hole 5 on the lower surface of the open heat sink 6 through the LED substrate 8 Inside, the wires of the LED light source and the lens 7 pass through the LED wire perforation 4 to realize circuit connection with the PCB circuit board and corresponding electronic components 2, and most of the heat generated by the LED light source 7 is directly conducted to the lower surface of the open radiator 6 until the open radiator 6 is opened. There are many grid-like heat conduction ribs on the upper part of the heat sink 6. Since the open heat dissipation cavity part (II) of the lamp is directly exposed to the outside air, the natural wind from the outside passes through the upper part of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com