Electric resistance type touch screen and method of manufacture

A manufacturing method and technology of touch screen, applied in the direction of electric digital data processing, instrument, input/output process of data processing, etc., can solve problems such as greatly reduced aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

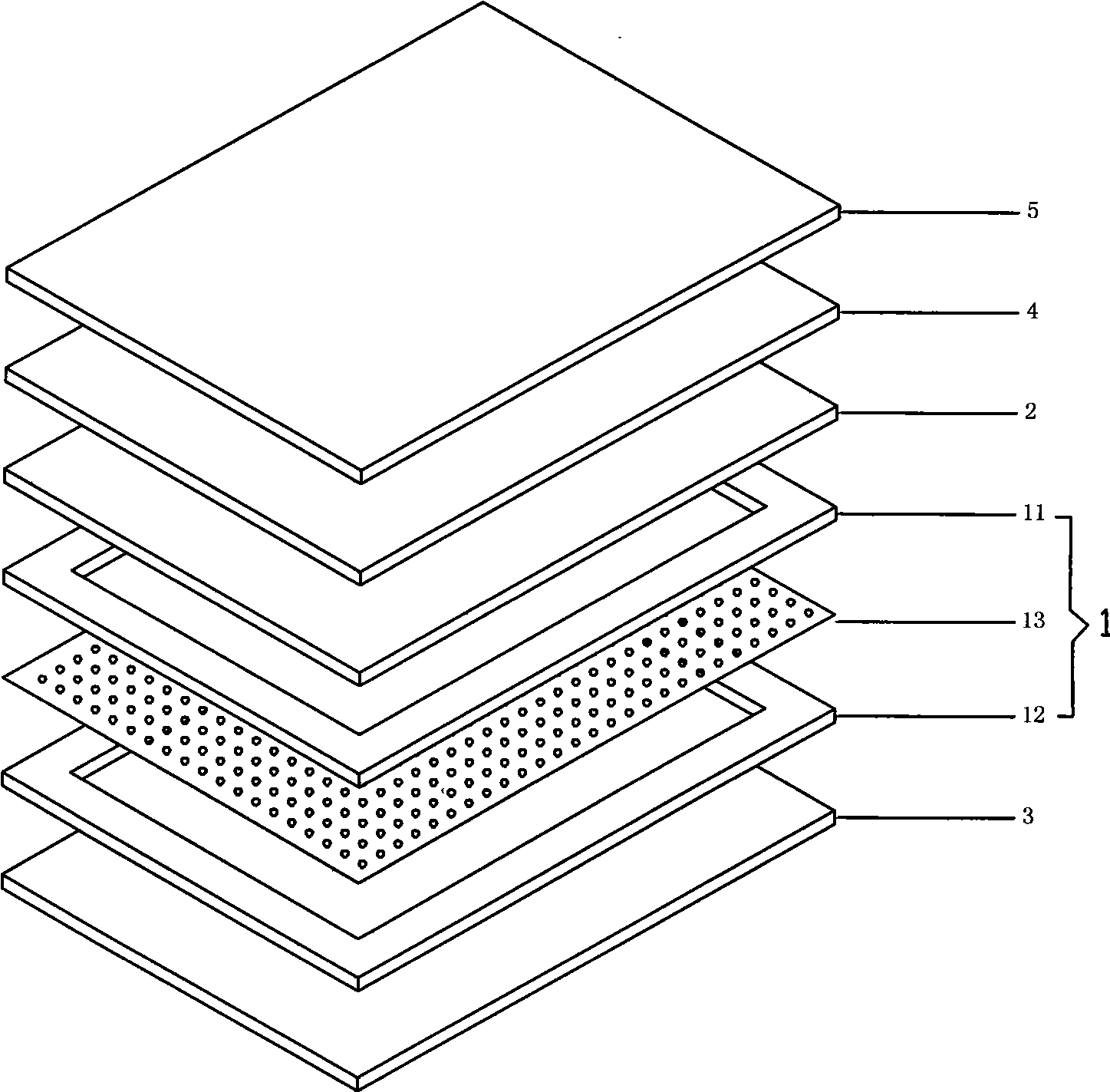

[0026] refer to figure 1 , which is a three-dimensional exploded view of an embodiment of the touch screen provided by the present invention; as shown in the figure, this embodiment mainly includes the following layers of structure:

[0027] circuit layer 1;

[0028] The upper line ITO film 2 attached to the upper surface of the circuit layer;

[0029] A lower conductive printed circuit (Print Circuit, PC) board 3 attached to the lower surface of the circuit layer.

[0030] During specific implementation, the circuit layer specifically includes:

[0031] On-line circuit layer 11;

[0032] Offline circuit layer 12;

[0033] The isolation layer 13 is arranged between the upper line circuit layer and the lower line circuit layer.

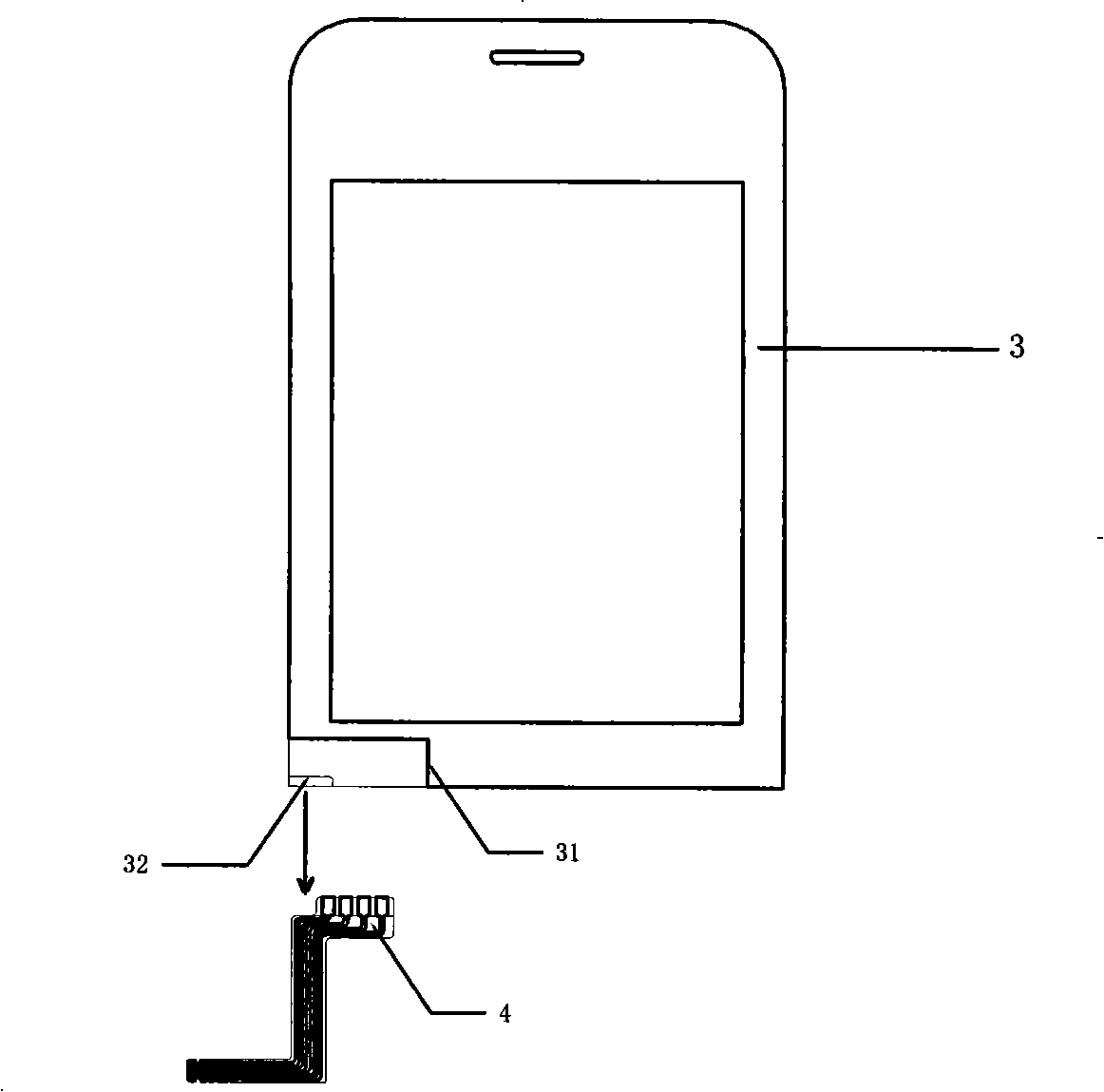

[0034] Wherein, a flexible printed circuit 4 (FlexiblePrinted Circuit, FPC) provided with leads is also drawn out from the circuit layer 1 ( figure 1 not shown, refer to figure 2 ).

[0035] In addition, the upper layer of the ITO film on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com