High efficiency generator

一种发电机、AC电机的技术,应用在车辆的发电机系统,有源整流器电桥领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following discussion relating to embodiments of the invention employing generator systems comprising active rectifier bridges comprising MOSFET switches is merely exemplary in nature and is not intended to limit the invention or its application or use.

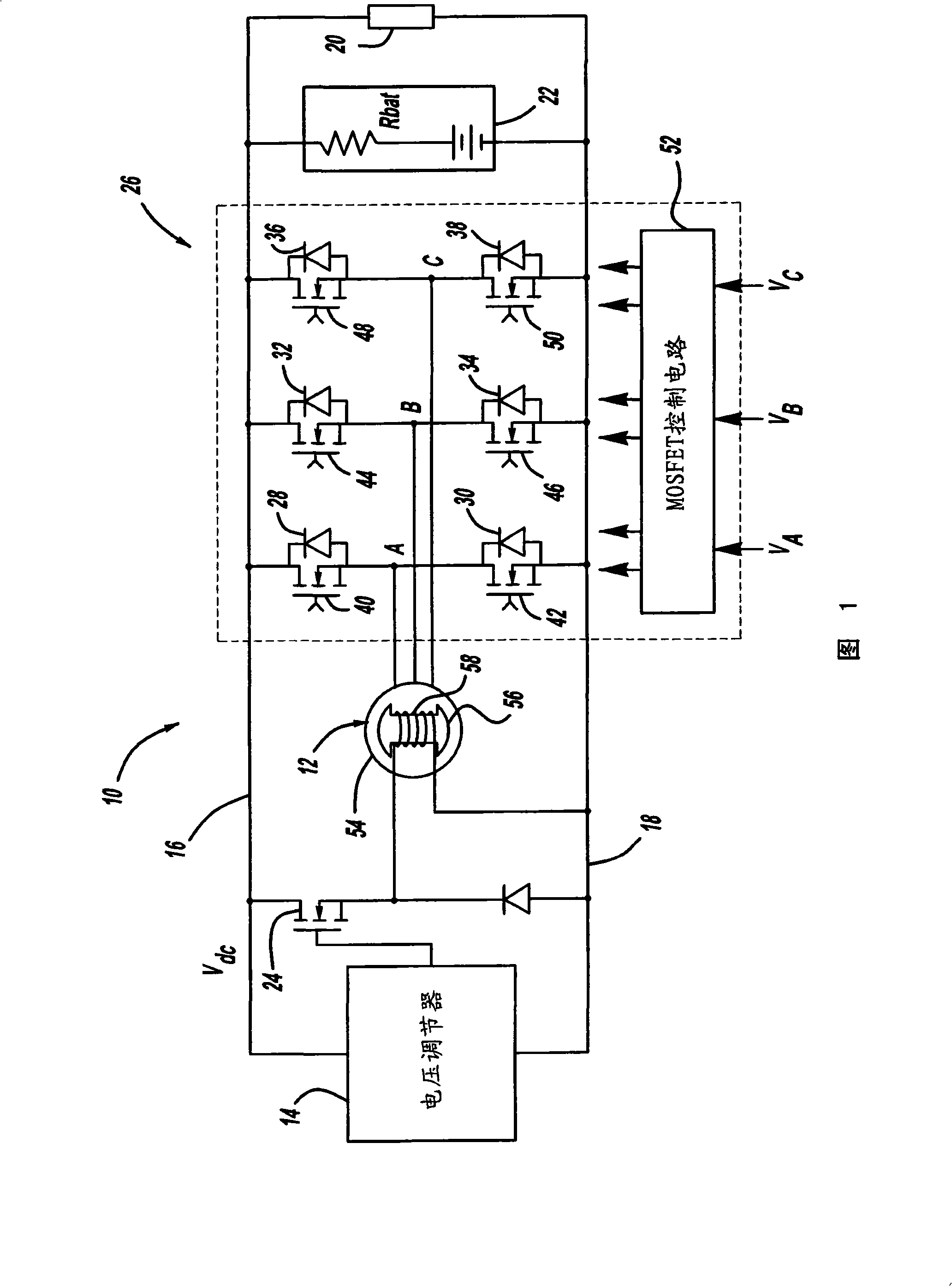

[0012] FIG. 1 is a schematic diagram of a generator system 10 according to an embodiment of the invention. System 10 includes a three-phase wound rotor synchronous electric machine 12 , such as a claw pole electric machine, having field coils 58 on a rotor 56 of electric machine 12 and three-phase AC synchronous armature coils on stator 54 of electric machine 12 . In a non-limiting embodiment, motor 12 is a Lundell motor. Permanent magnets are incorporated in the rotor 56 of the electric machine 12 between the claw poles to provide additional flux to the flux generated by the field coils 58, wherein the total flux is responsible for generating the voltage in the armature coils.

[0013] The system 10 also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com