Ald reactor

A technology of reactors and reaction chambers, applied in the field of processing substrates, for example, can solve problems such as reactor surface corrosion, reaction chambers that cannot function optimally, and reduce material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

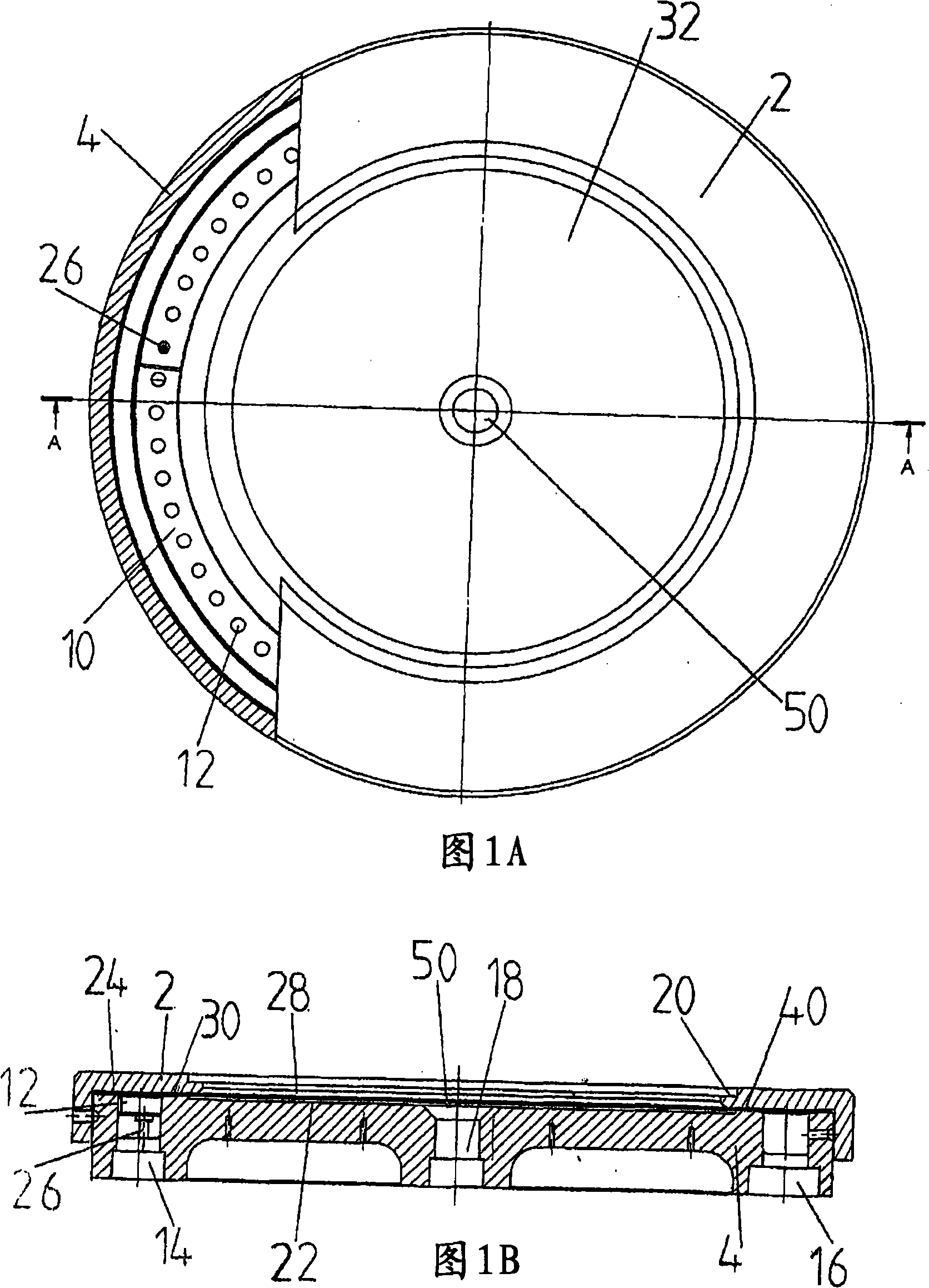

[0011] Figures 1A and 1B show a cylindrical reaction chamber 1 of an ALD reactor according to the invention, comprising a cover plate 2 and a bottom plate 4. The cover plate 2 and the bottom plate 4 define the bottom, top and side walls of the interior portion 28 of the reaction chamber. In the embodiment shown in FIG. 1 , the cover plate 2 is an annular flange-like plate which can be placed and / or fastened tightly over the base plate 4 so as to form the inner part 28 of the reaction chamber. The side walls of the reaction chamber are provided with feed ports 30 and discharge ports 40 through which gas can be fed into and discharged from the inner part 28 of the reaction chamber. Furthermore, the base plate 4 is provided with inlets 12 and 14 along which gas can be supplied to an inlet 30 and an outlet 16 along which gas can be exhausted from the inner part 28 of the reaction chamber through an outlet 40 . There may be one or more inlets 12, 14 and outlets 16. For example, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com