Automatic welding process of skewed tube fillet of boiler separator

A technology of separator and cross pipe, which is applied in the field of automatic welding process of boiler separator oblique pipe fillet weld, can solve the problems of easy loss of flux and molten pool, increase the difficulty of control, and affect welding quality, etc., so as to improve labor productivity and Welding quality, avoid downhill welding, reduce the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

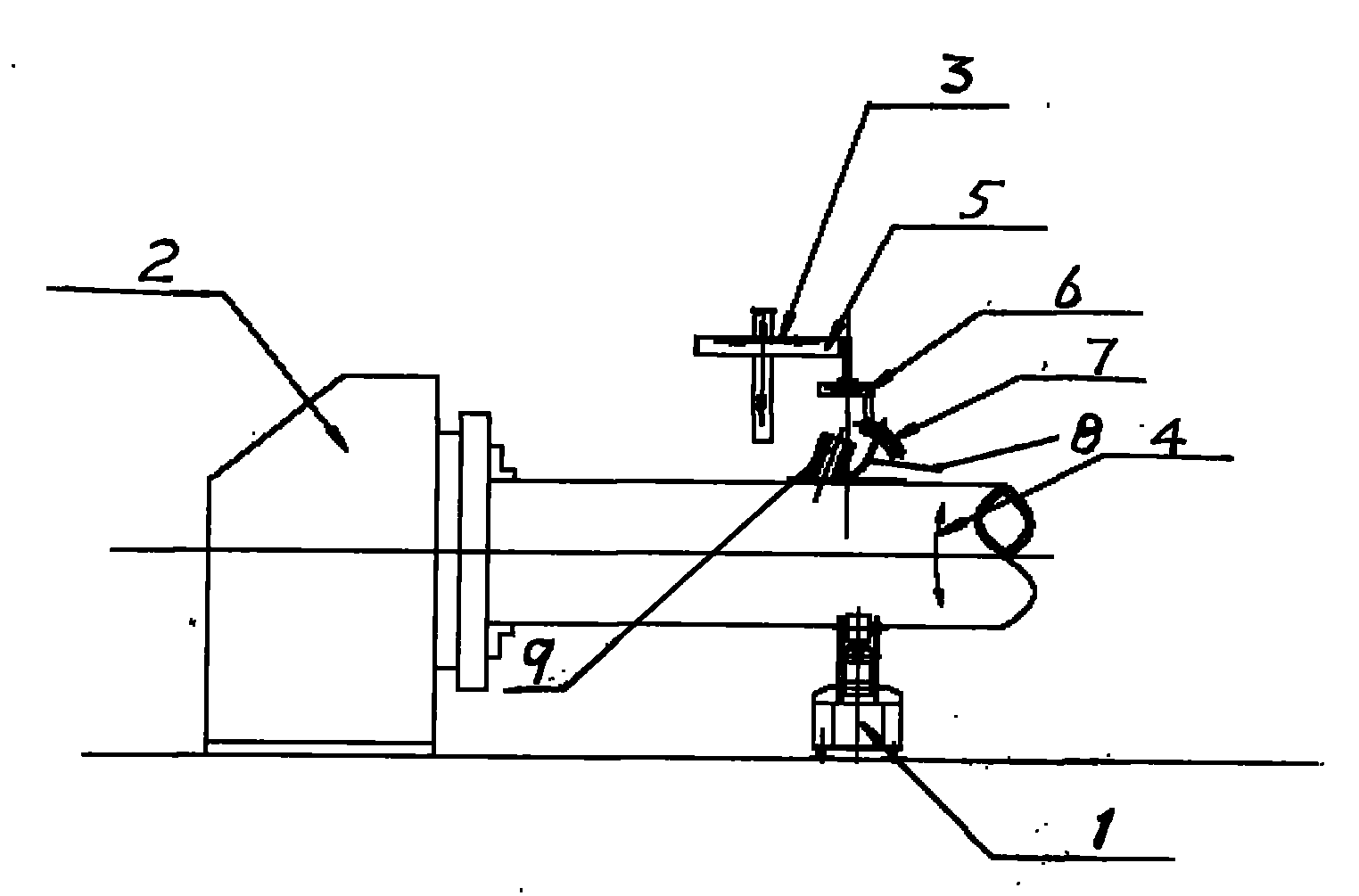

[0026] Such as figure 1 As shown, it is a schematic diagram of the automatic welding process of the fillet weld of the boiler separator oblique pipe, and the submerged arc welding process of the eccentric oblique pipe on the separator is:

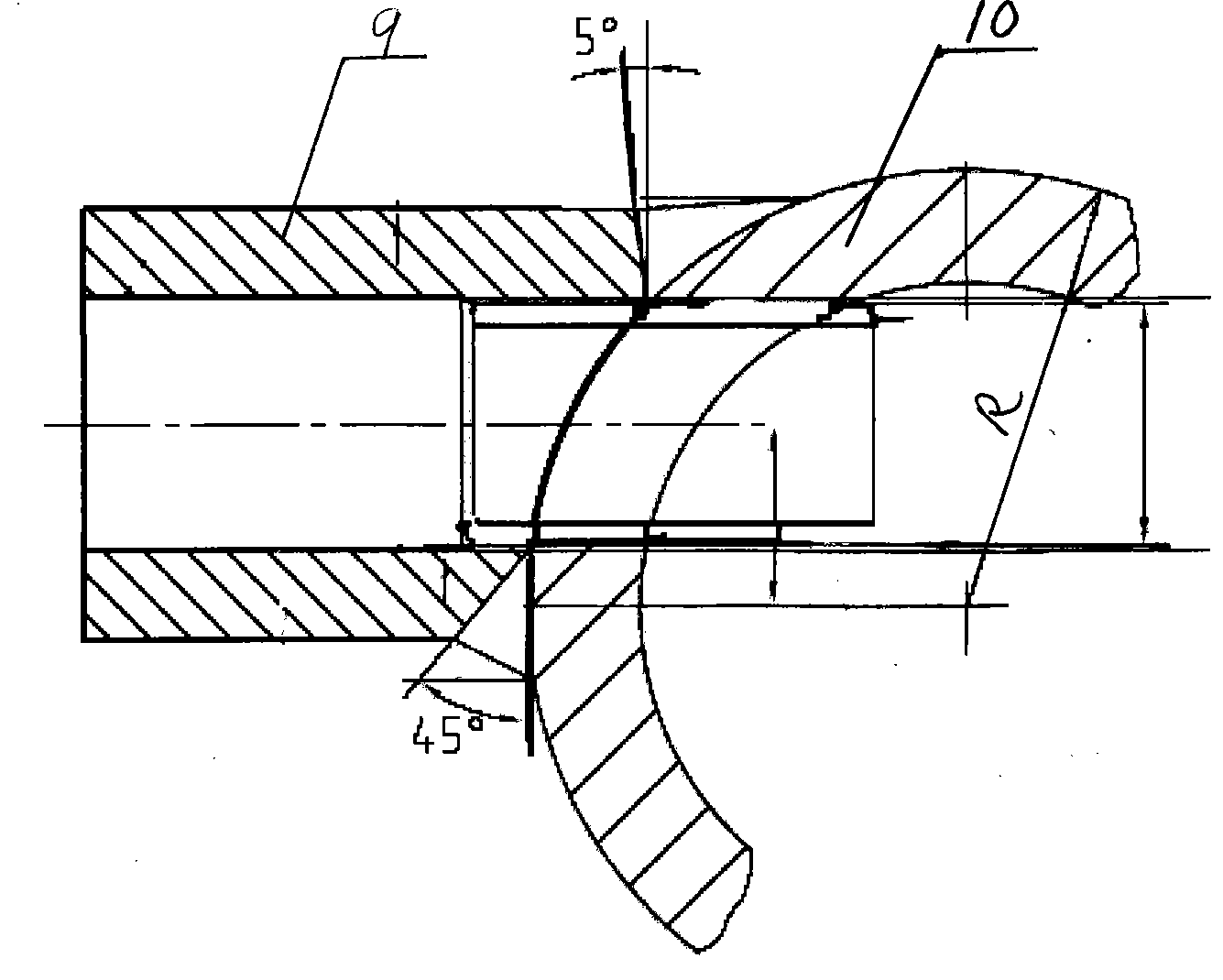

[0027] In the first step, the pipe end of the eccentric skewed pipe 9 adopts a mount-type single V-shaped groove, and the groove angle is a variable angle of 5°-45°, such as figure 2 shown;

[0028] In the second step, one end of the separator 4 is placed on the driven roller frame 1, and the other end is clamped by the power head of the CNC positioner 2;

[0029] In the third step, the processed eccentric skew pipe 9 is fitted with a positioning bush and the separator 4 for positioning and spot welding;

[0030] The fourth step is to put the electric heater into the separator 4 to preheat the welding part before welding, and the preheating temperature before welding is 200°C to 250°C;

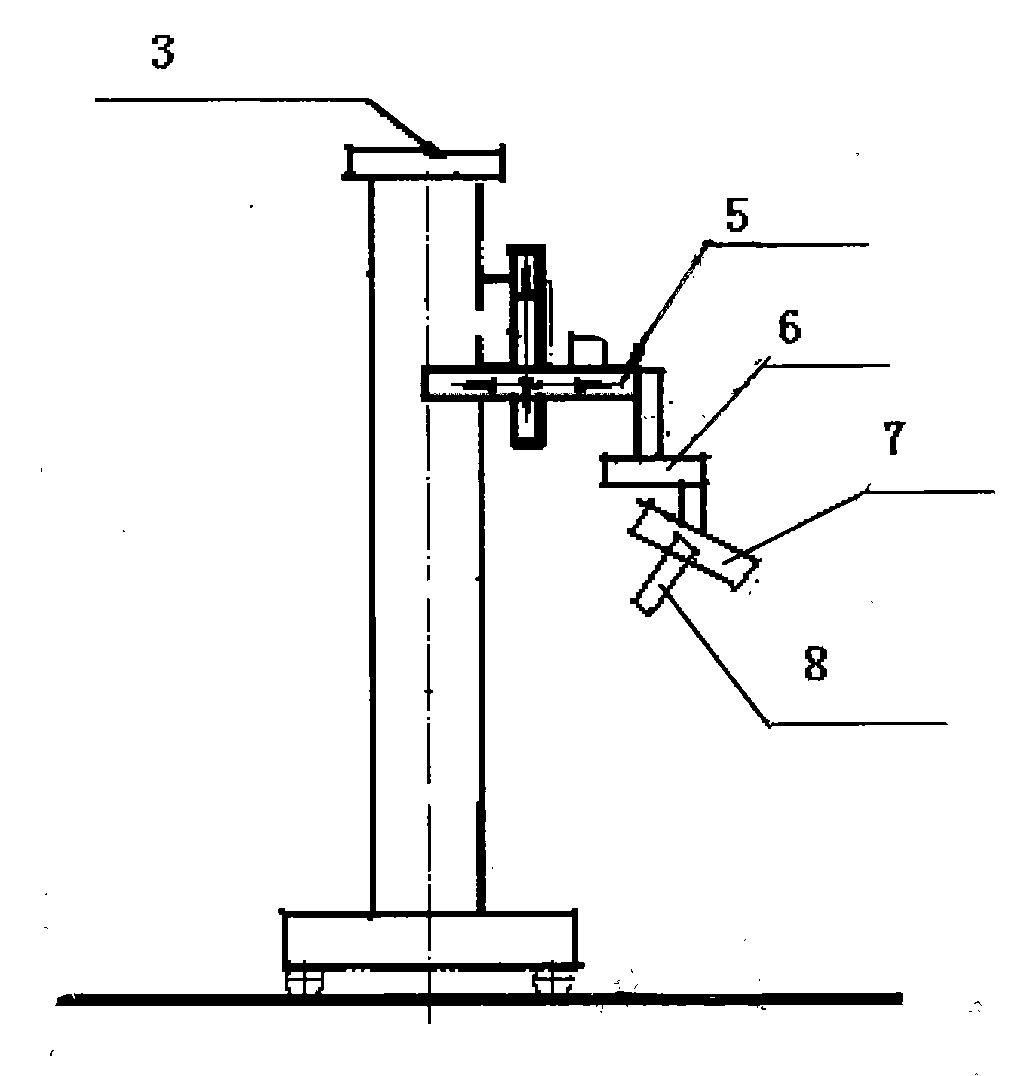

[0031] The fifth step is to move the welding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com