Luminous diode encapsulation method with high efficiency light emitting effect and its packaging structure

A technology of light-emitting diodes and luminous effects, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid-state devices, etc., which can solve problems such as inconvenience, poor light efficiency and loss of light rods, and achieve the effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

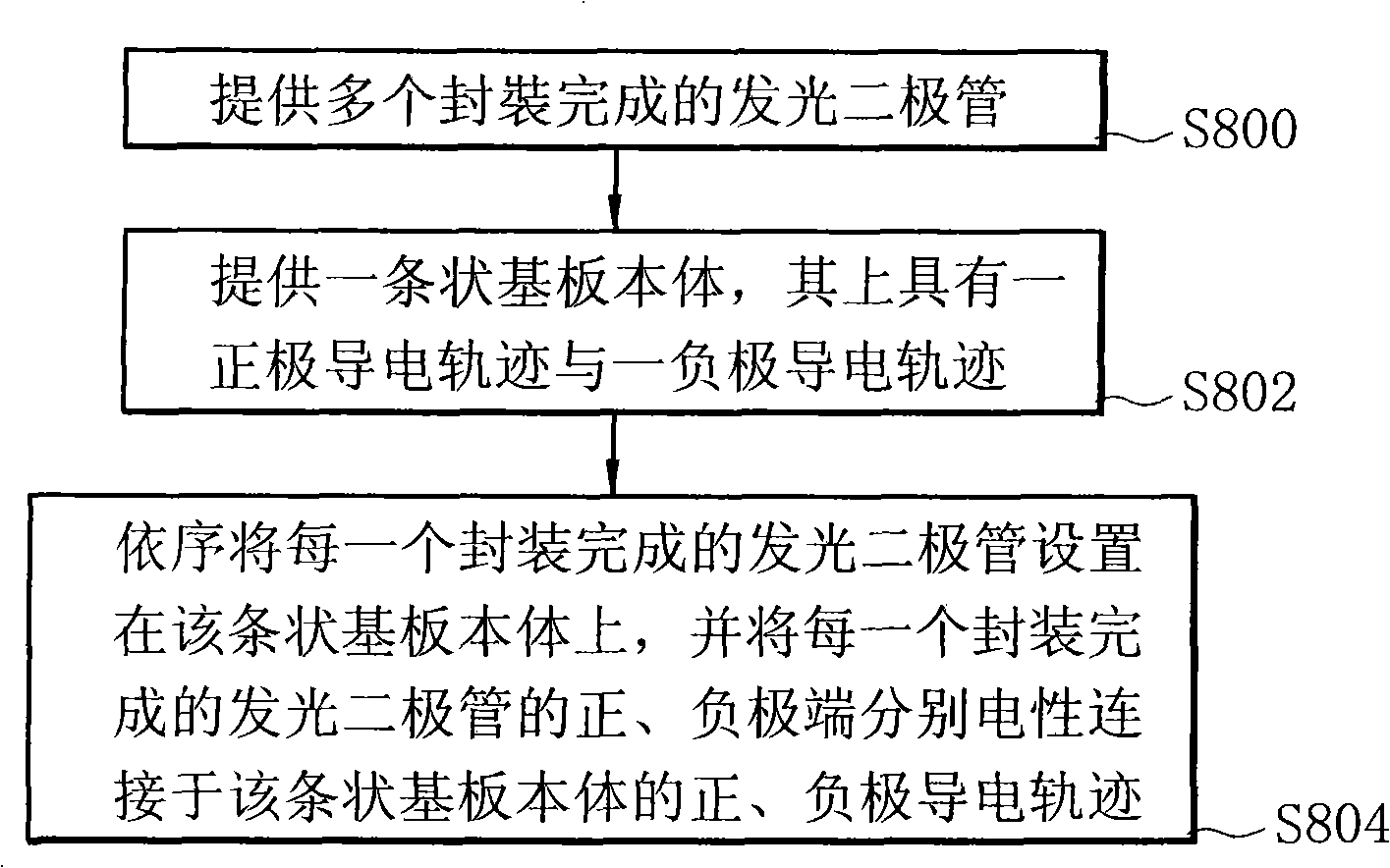

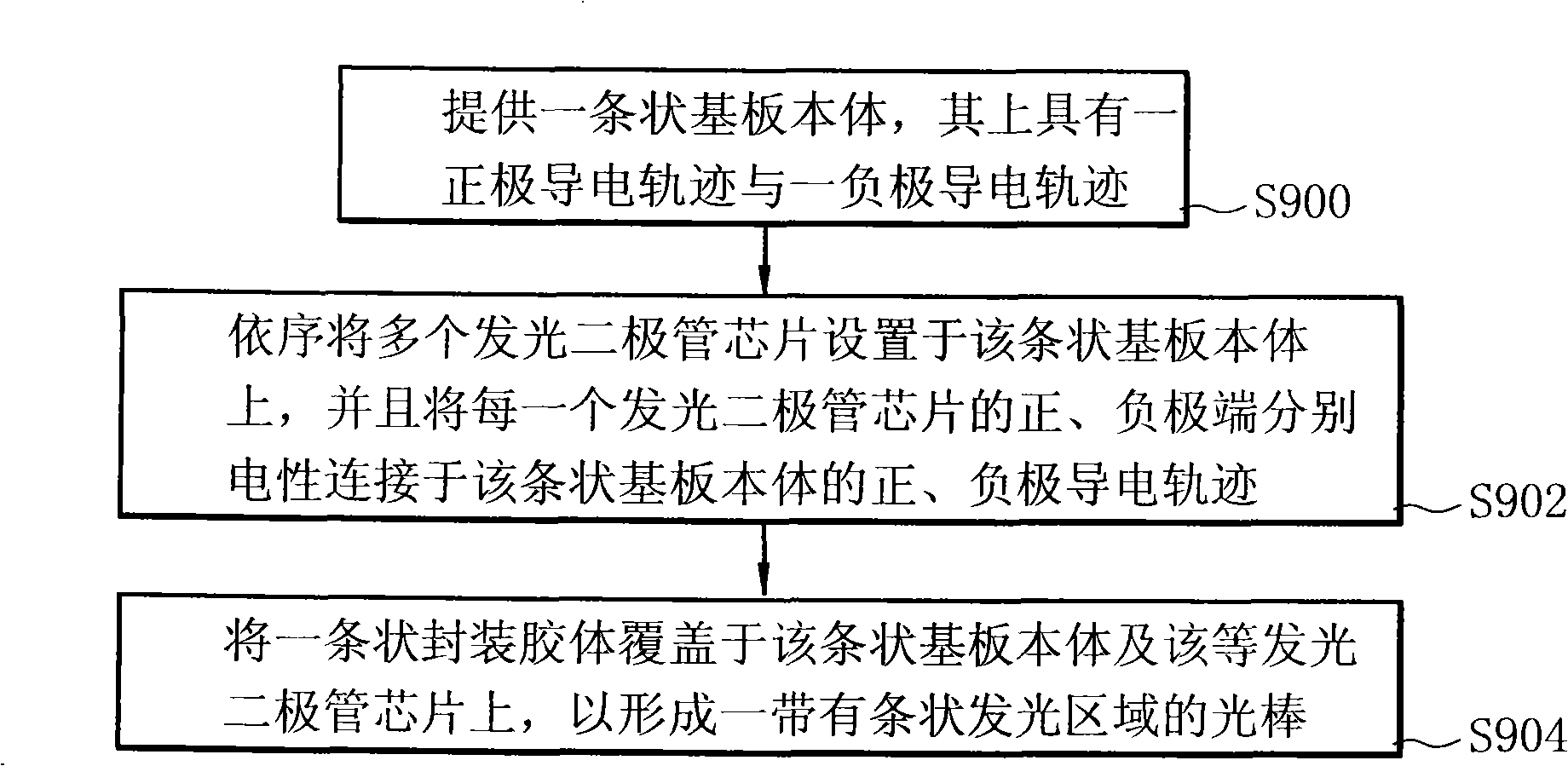

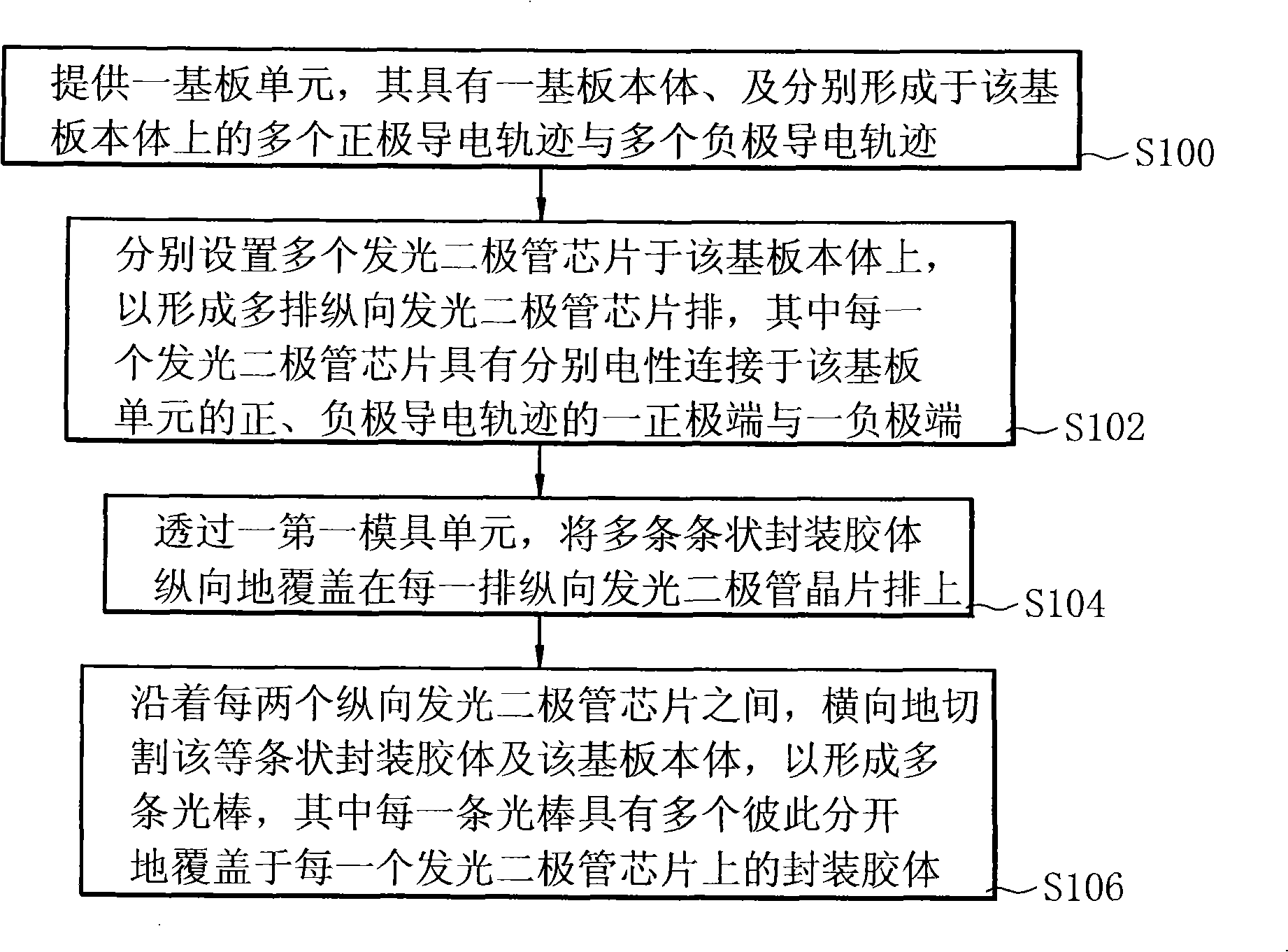

[0063] see image 3 , image 3 a to image 3 d, and image 3 A to image 3 D shows. image 3 It is a flow chart of the first embodiment of the packaging method of the present invention, image 3 a to image 3 d is a schematic diagram of the packaging process of the first embodiment of the packaging structure of the present invention, image 3 A to image 3 D is a schematic cross-sectional view of the packaging process of the first embodiment of the packaging structure of the present invention, respectively. Depend on image 3 It can be seen from the flow chart that the first embodiment of the present invention provides a method for packaging light-emitting diodes with high-efficiency light-emitting effects, which includes the following steps:

[0064] First of all, please cooperate image 3 a and image 3 As shown in A, a substrate unit (substrate unit) 1 is provided, which has a substrate body (substrate body) 10, and a plurality of positive electrode traces (posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com