Temperature regulation of the mass flow in a filling machine

A technology of temperature control and filling machine, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

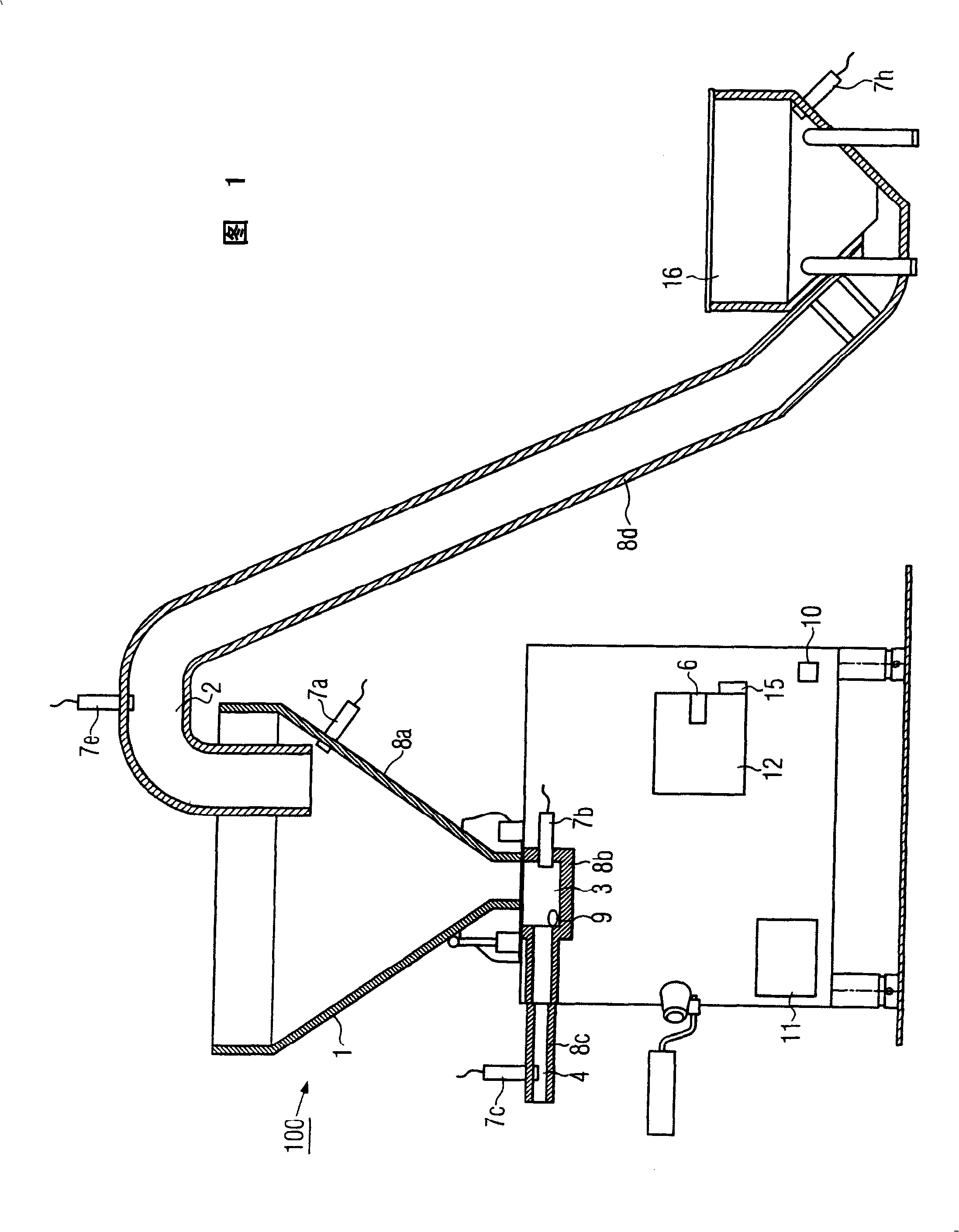

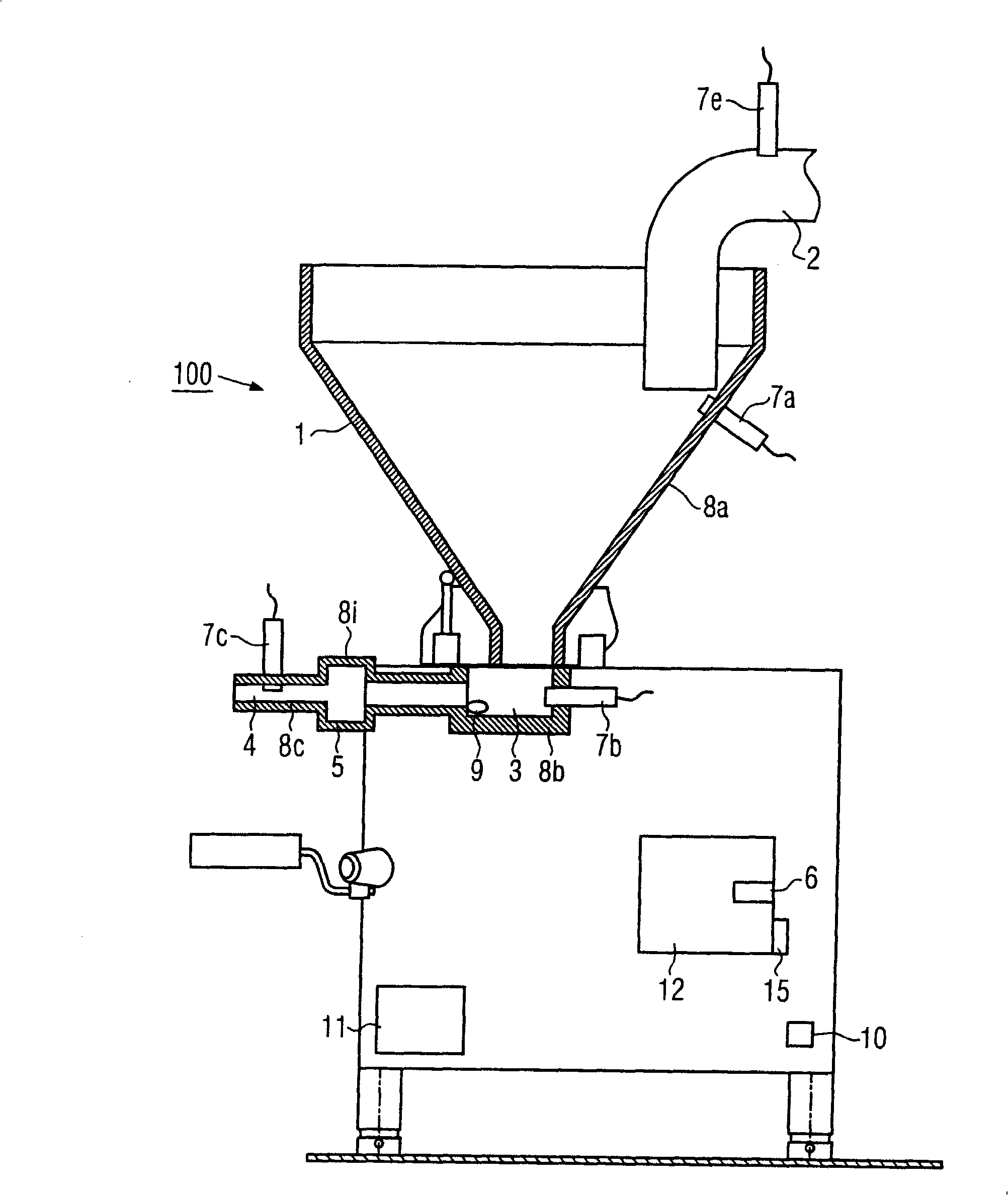

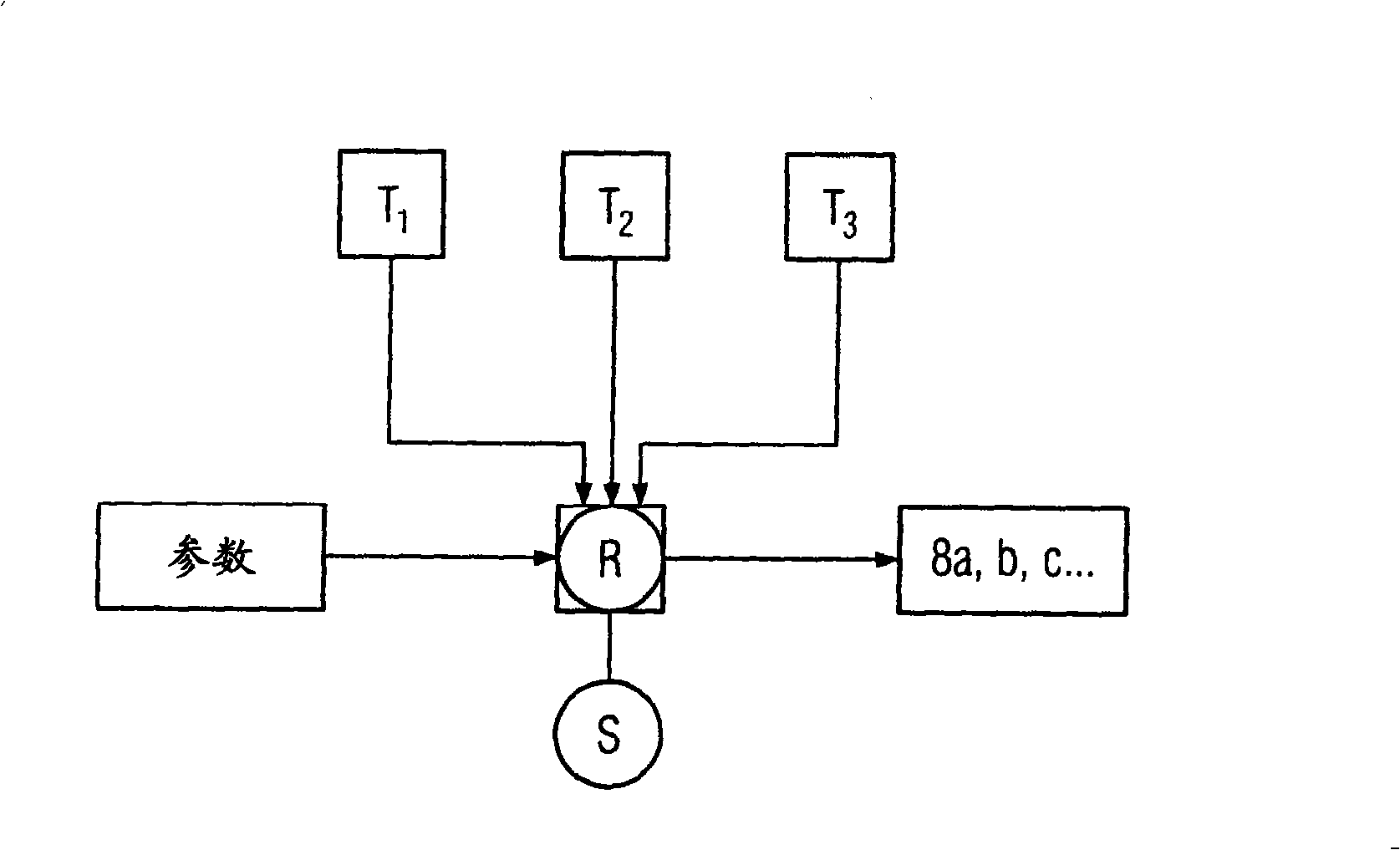

[0030] Figure 1 shows an embodiment of a filling machine 100 of the present invention. The filling machine 100 includes a filling hopper 1, such as a vacuum hopper, in which negative pressure can be generated. In addition, the filling machine 100 comprises a suction pipe 2 , through which a pasty substance, hereinafter also referred to as filling, can be fed into the filling hopper 1 . The suction tube 2 is part of the suction inlet part for the filling. The previous floor mounted hopper 16 may also be included in the suction inlet assembly. In addition, the filling machine also includes a conveying mechanism 3 arranged at the lower end of the conical filling hopper 1 . In a conventional manner, such a conveying mechanism 3 comprises, for example, a vane pump or a screw pump which extrudes the filling material out of the stuffing hopper 1 in the direction of the filling pipe 4 through which the filling material is squeezed into the sausage casing.

[0031] The filling machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com