Patents

Literature

45results about How to "Reduce maximum power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

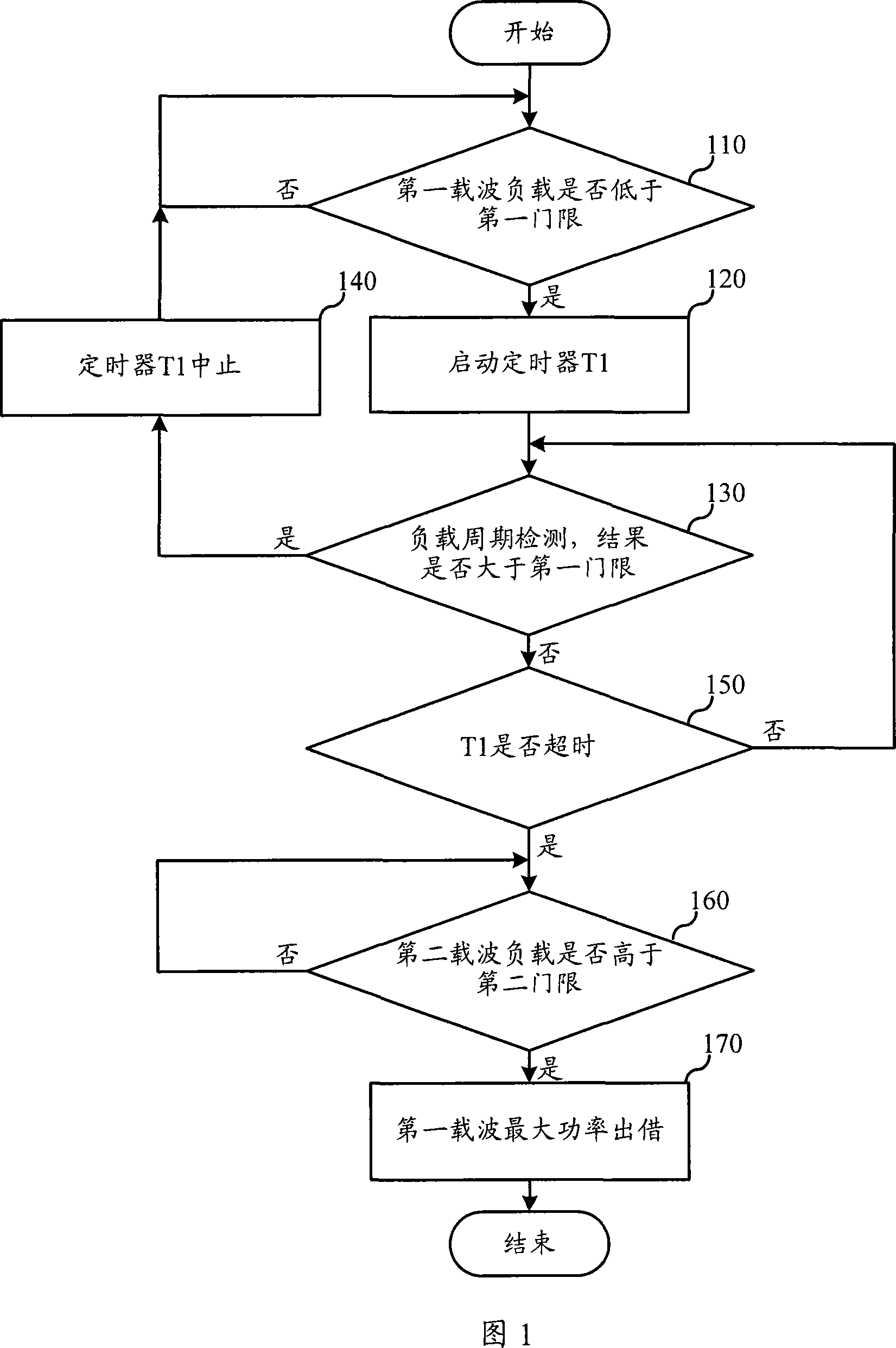

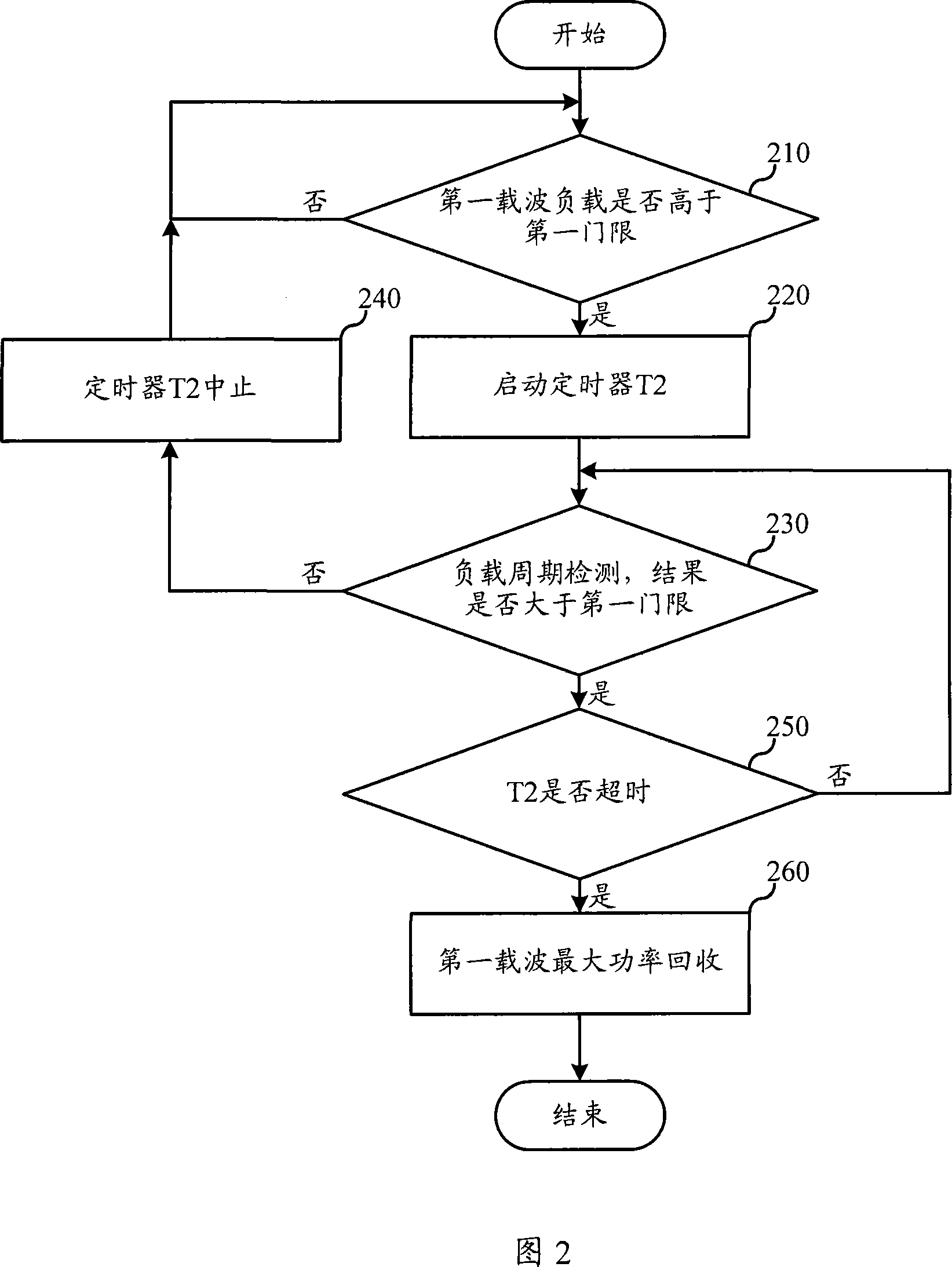

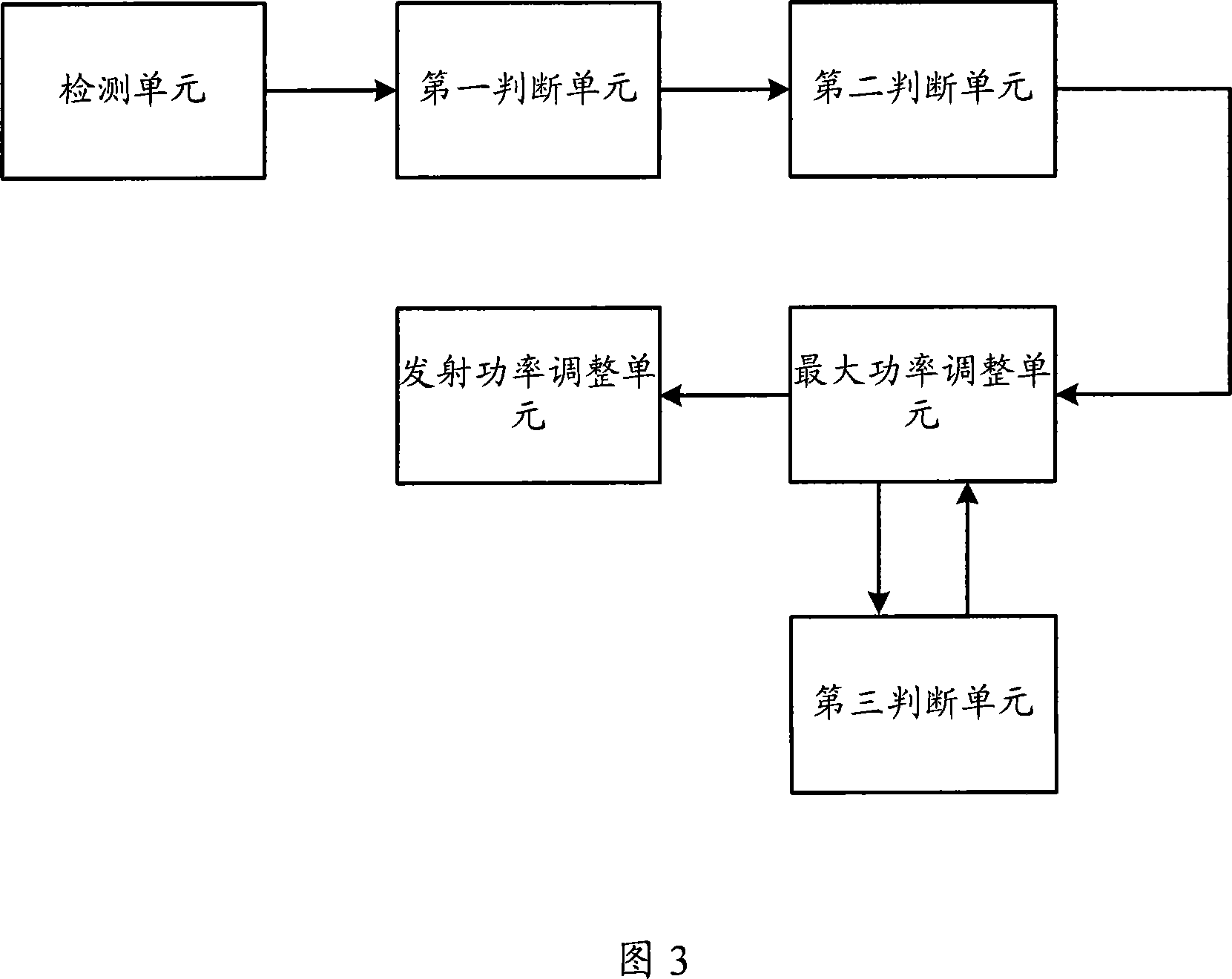

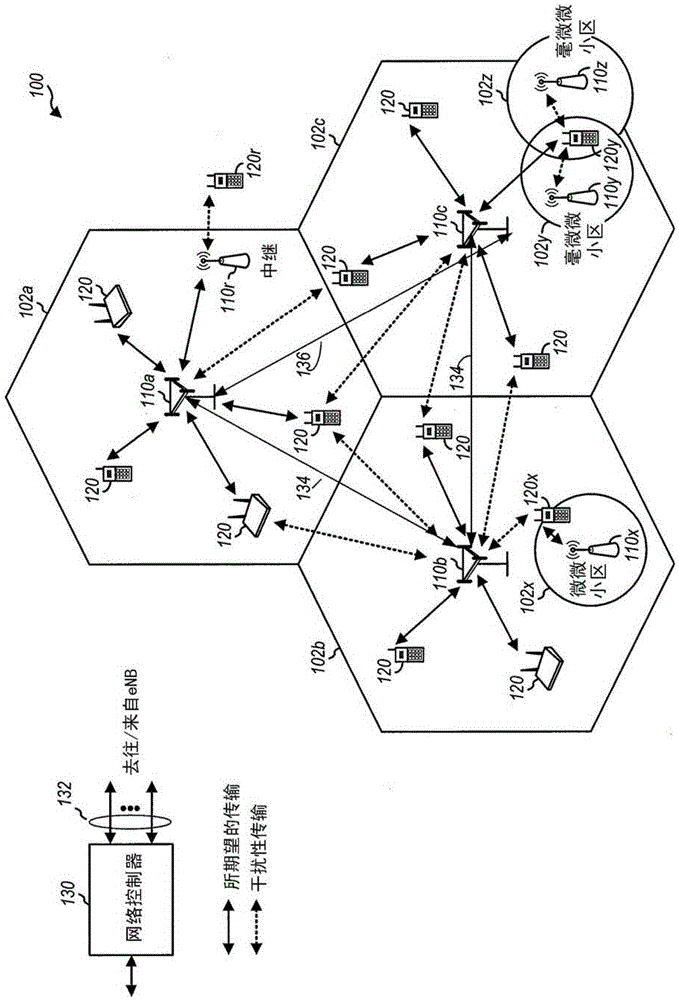

Intercarrier power distribution method and system in a same power amplification

ActiveCN101083496AReduce maximum powerIncrease maximum powerEnergy efficient ICTTransmission control/equalisingDistribution methodLow load

The invention relates to the wireless communication field, disclosing a method and system of power distribuiton between carriers in the same power amplifier, solving the problem that loads between carriers are unbalanced. On the condition that a power amplifier simultaneously bears at least two carriers in the same sector, if one carrier is in low load state for long, reducing its maximum power and lending the reduced power to at least one other carrier; before lending, able to judge whether loads of other carriers are in over load state, lending the reduced power to other carriers in over load state; if the first carrier is in heavy load state for long after lending, taking back the lent power.

Owner:HUAWEI TECH CO LTD

Method and apparatus for specific absorption rate backoff in power headroom report

Uplink transmission power adjustment is provided by a mobile device receiving an uplink transmission grant from a serving base station. The mobile device determines a maximum power reduction for uplink transmissions and a SAR-related power reduction. The mobile device compares these values and adjusts transmission power according to the SAR- related power reduction in response to the SAR-related power reduction exceeding the maximum power reduction. A power headroom report is generated when the determined SAR-related power reduction exceeds a previous SAR-related power reduction. This power headroom report is transmitted from the mobile device to the serving base station under various conditions.

Owner:QUALCOMM INC

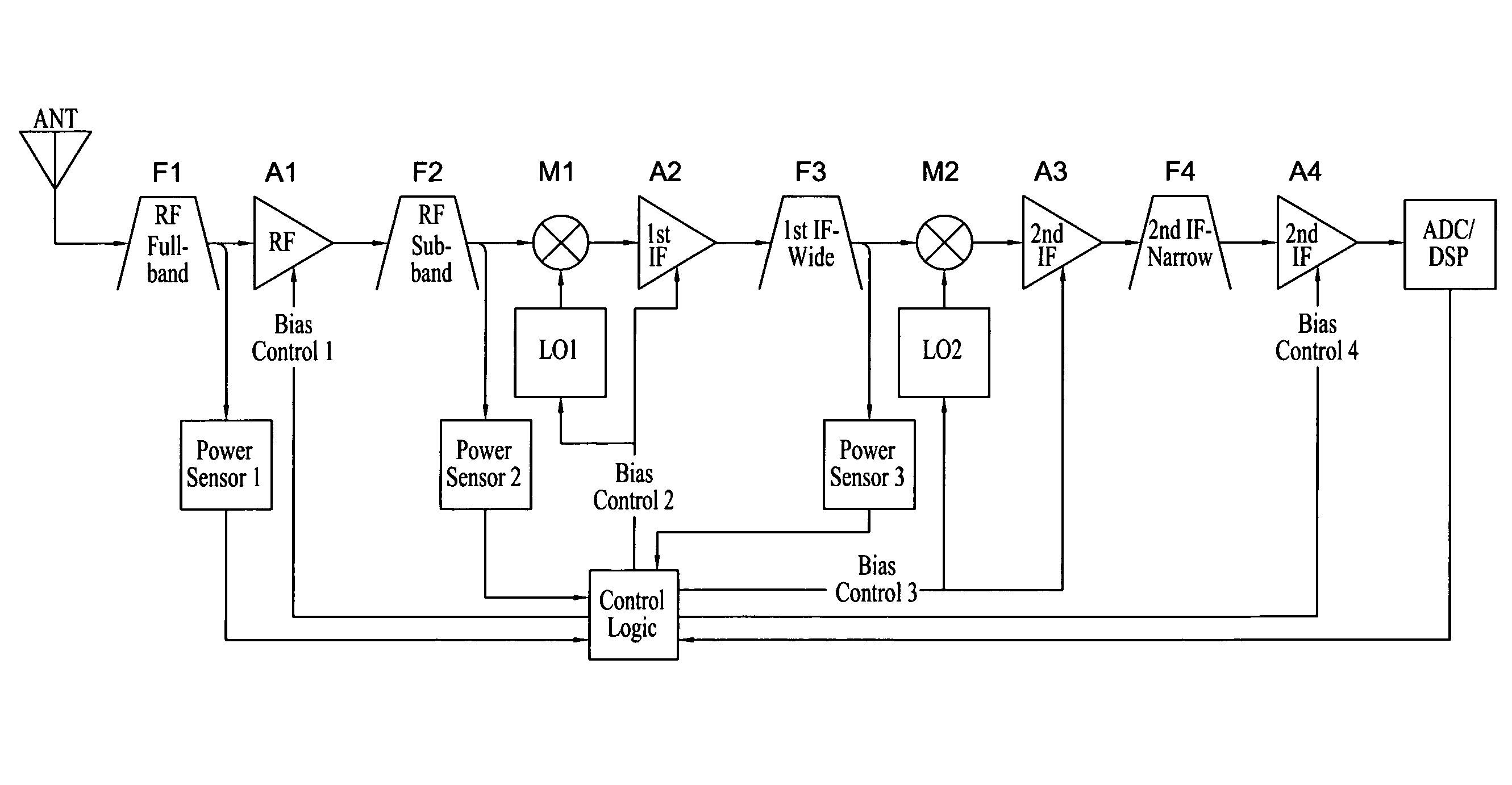

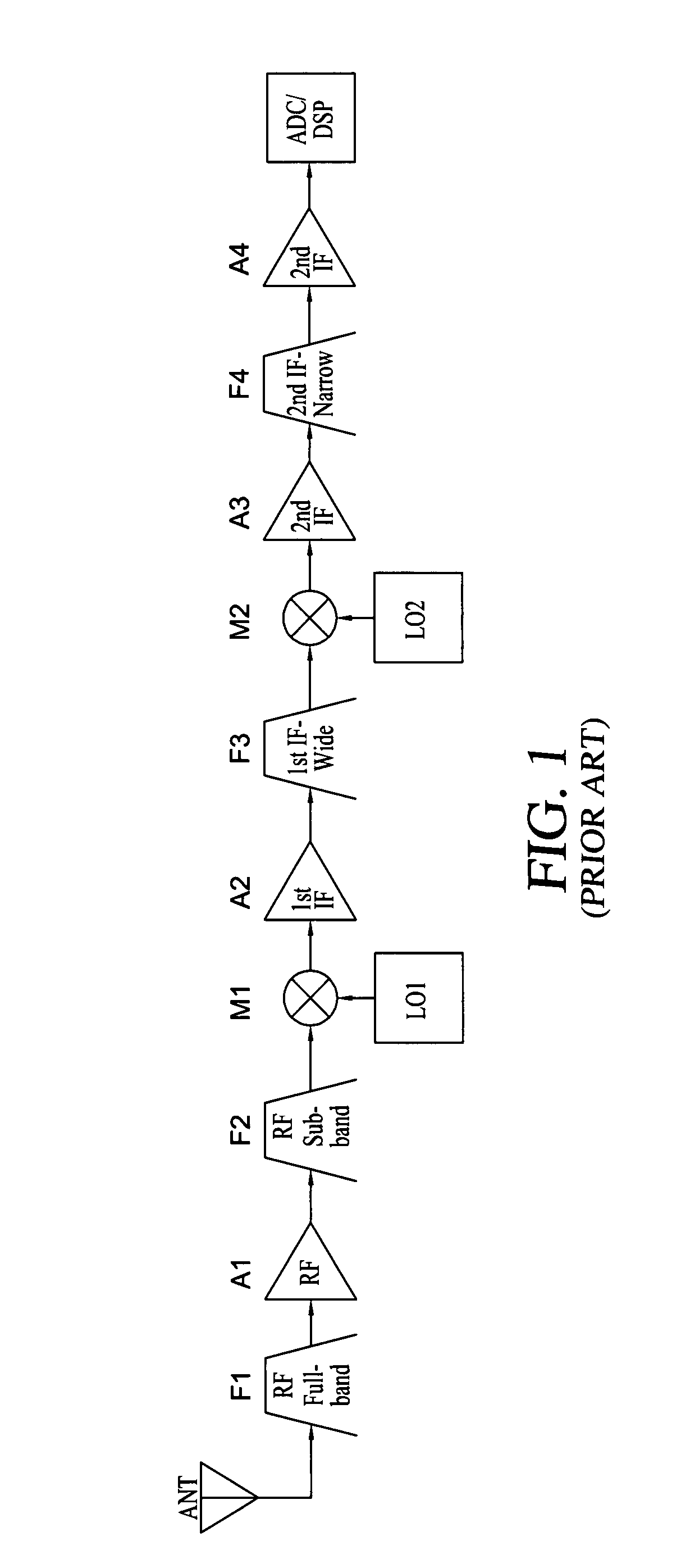

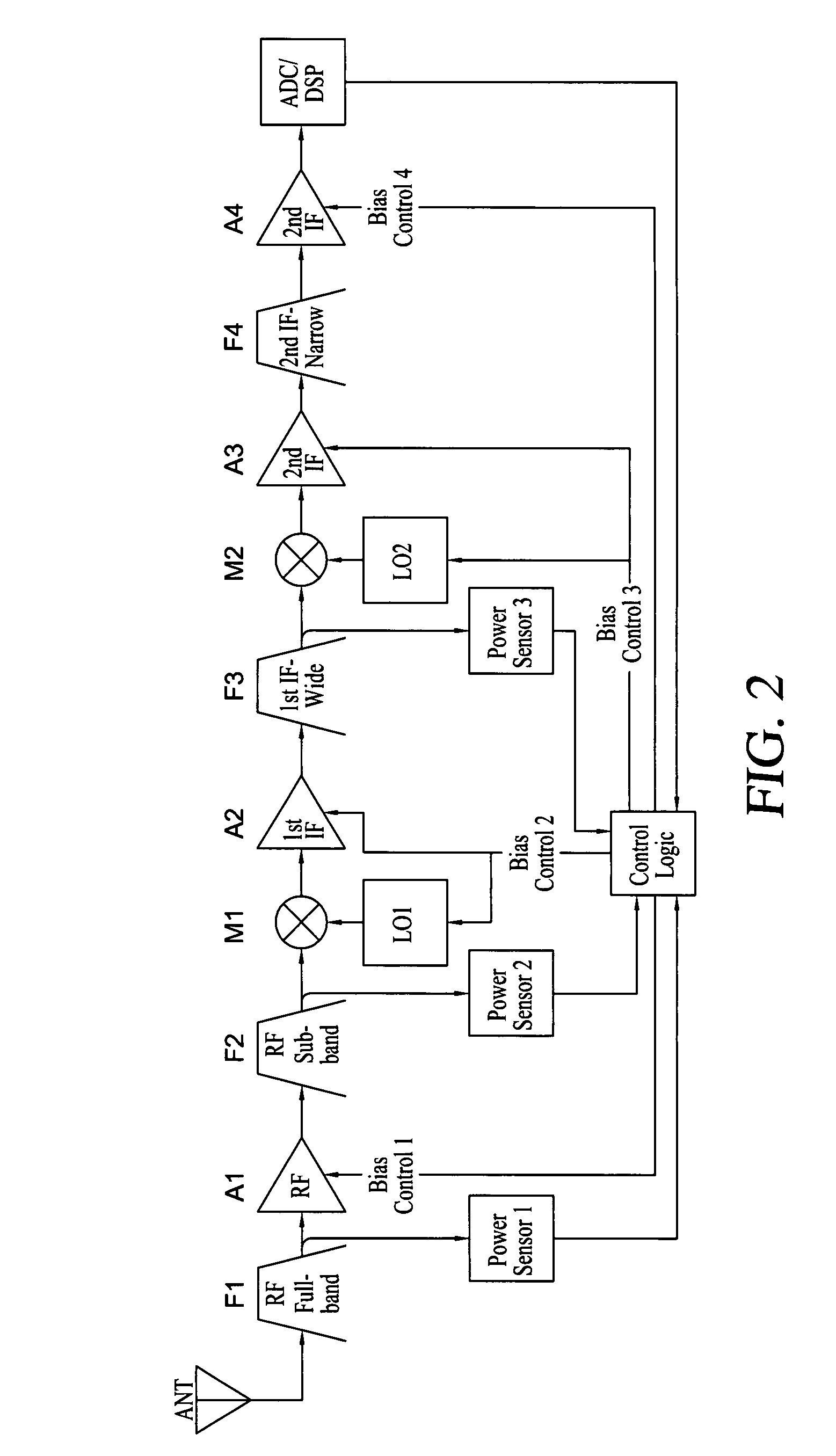

RF receiver utilizing dynamic power management

ActiveUS7639998B1Reduce power consumptionReduce thermal loadRadio transmissionAmplifier detailsPower sensorDigital signal processing

A radio frequency (RF) receiver utilizing dynamic power management for administration of power consumption. The RF receiver includes an RF antenna, an RF full band filter, an RF amplifier, an RF sub-band filter, a first local oscillator, an RF mixer, a first IF amplifier, an IF wide band filter, a second local oscillator, an IF mixer, two secondary IF amplifiers, an IF narrow band filter, a digital signal processing subsystem, three power sensors, and a control logic subsystem. Based on its location in the system, each power sensor has a unique threshold setting that is set just below a total RF power level where desired signal degradation might occur. The control logic subsystem utilizes outputs of the power sensors to detect a total RF power present due to interfering signals plus a desired signal within an entire bandwidth present at each stage and dynamically manages power by adjusting bias of each stage accordingly via its bias control outputs.

Owner:ROCKWELL COLLINS INC

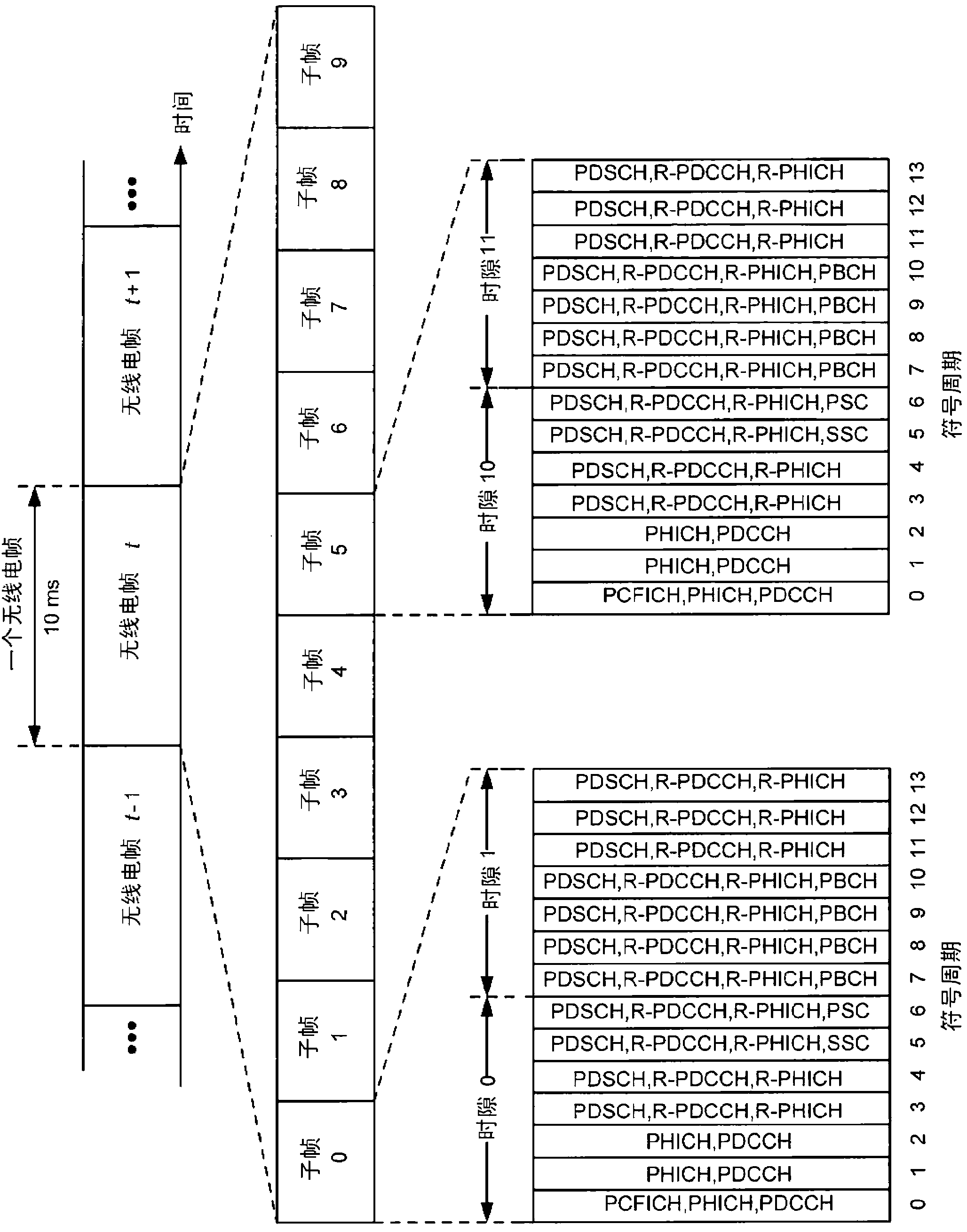

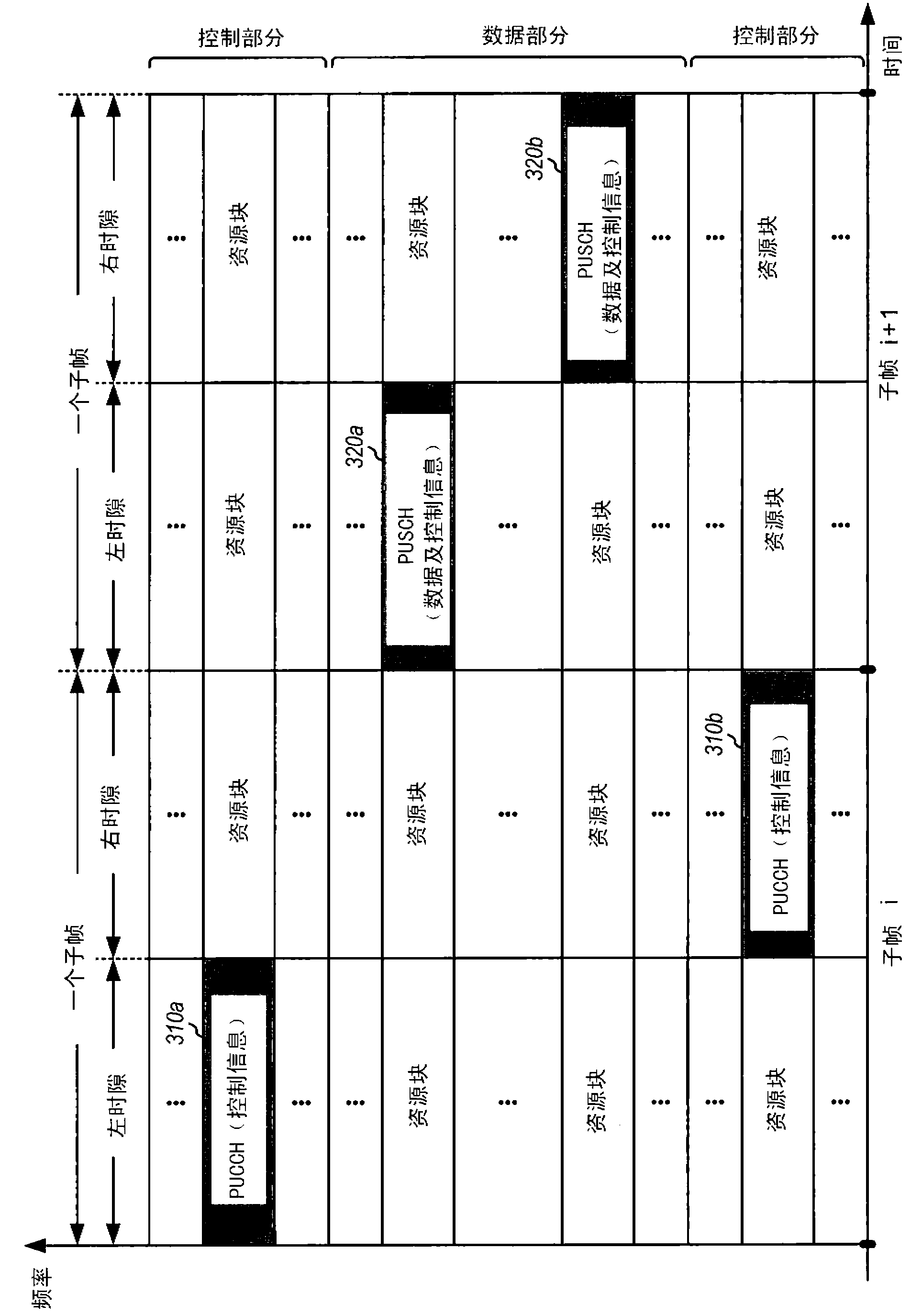

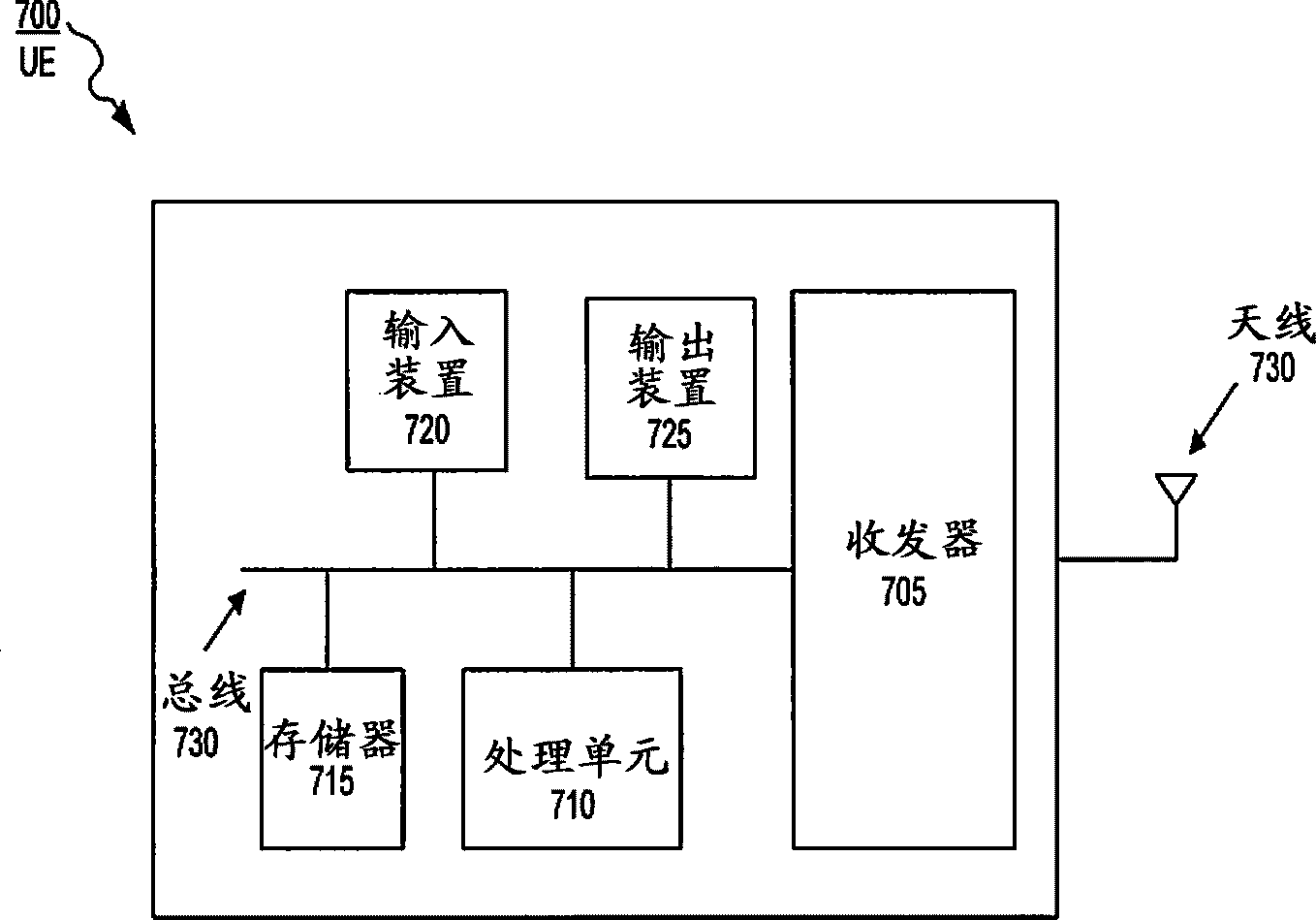

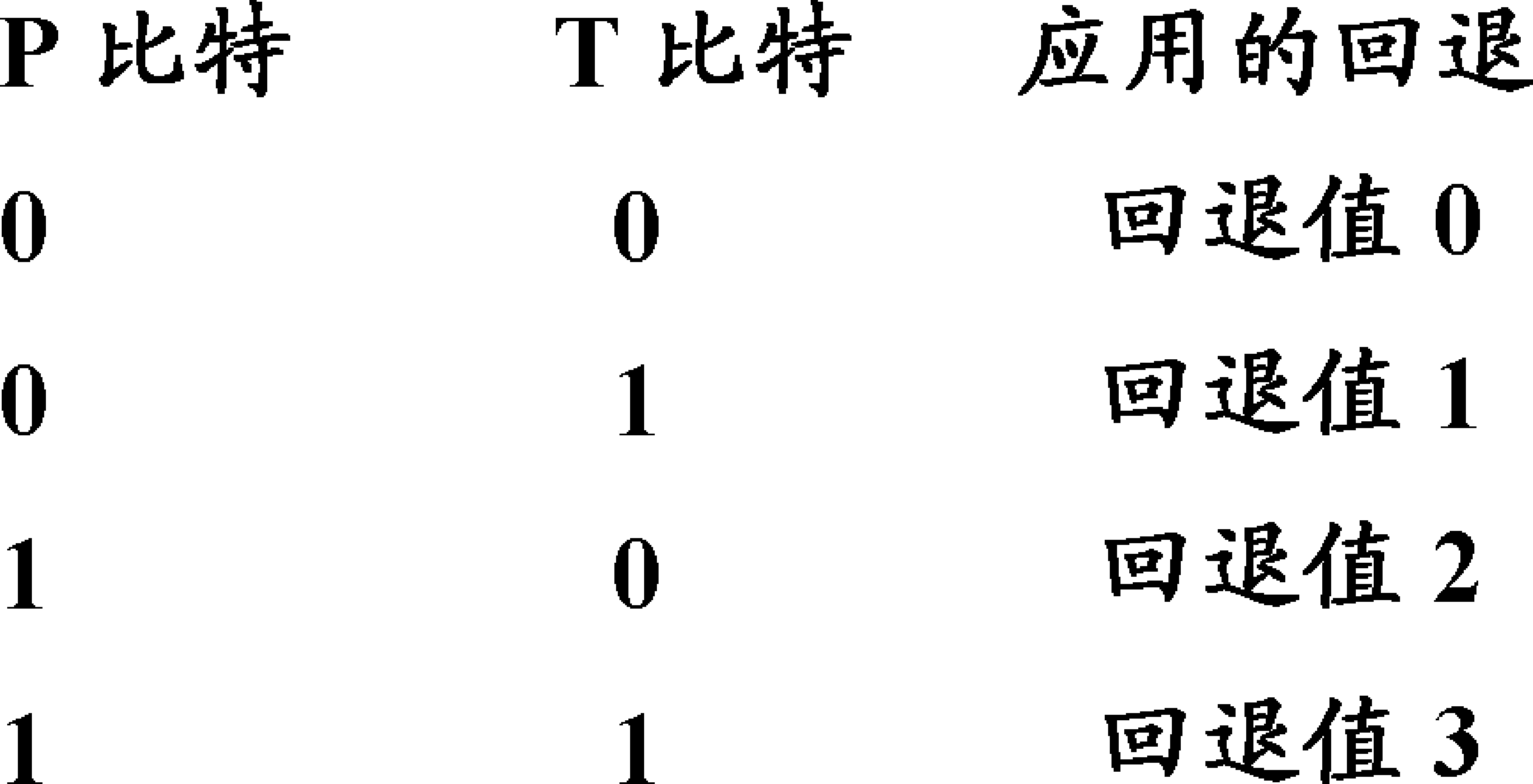

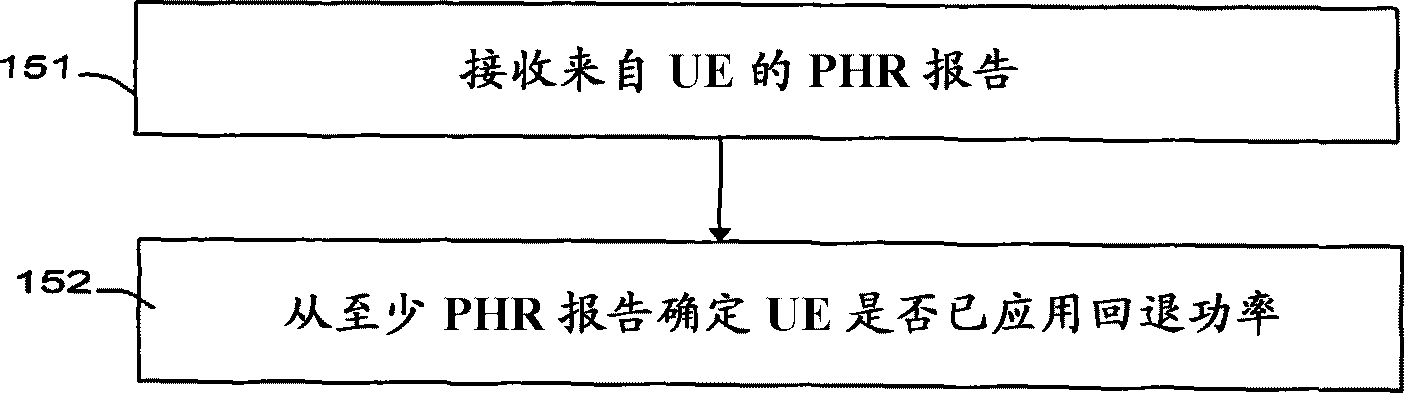

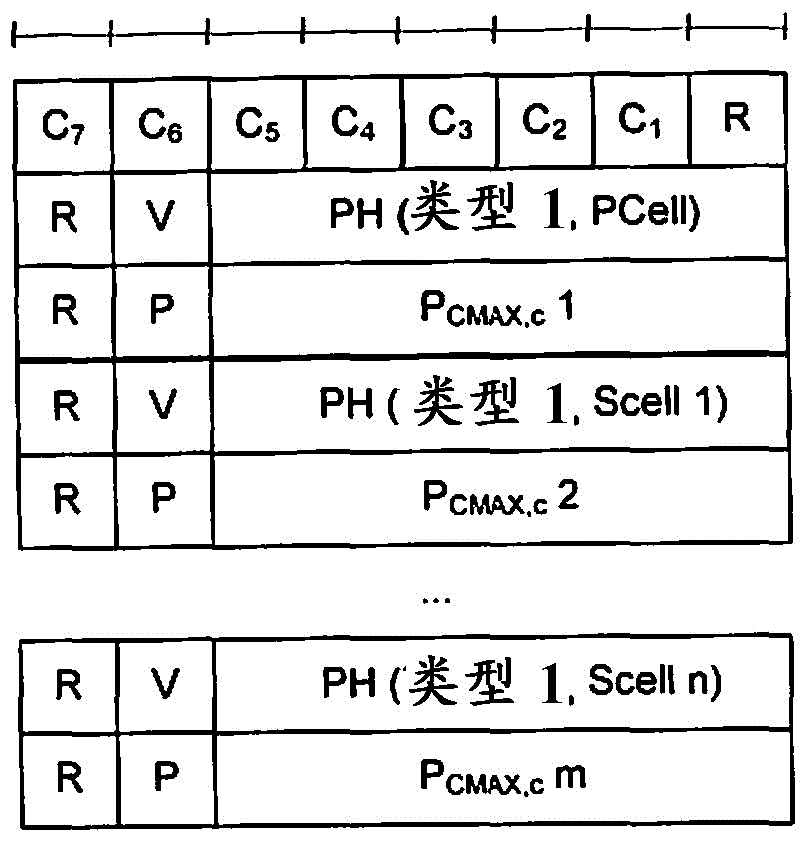

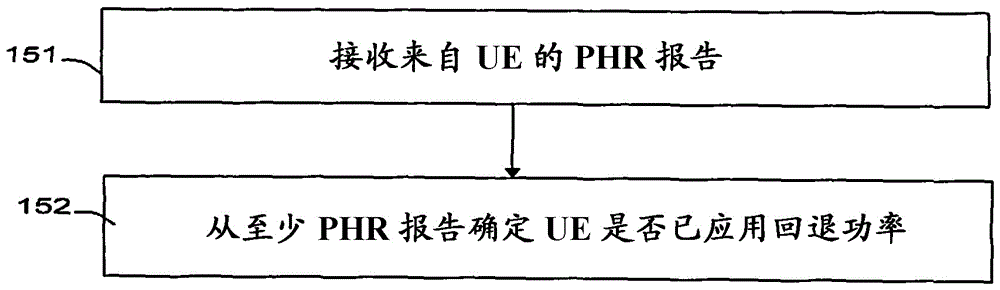

Methods and apparatuses for enabling power back-ff indication in phr in a telecommunications system

ActiveCN103270799AImprove adaptabilityOptimize schedulingPower managementRadio Base StationUser equipment

The exemplary embodiments describe a method for use in a user equipment (700), a method for use in a radio base station (600); a user equipment (700) and a radio base station (600). According to the exemplary embodiments, the user equipment (700) is configured to decide on application or not of a power reduction and to indicate it decision in a power headroom report intended for transmission to the radio base station (600). The radio base station (600) is configured to receive the power headroom report and based on the indicated information in the received power headroom report, the base station in made aware of an additional or special power backoff (e.g. to fulfill SAR requirements) has been applied and thereby able to distinguish it from normal power backoff or power reduction.

Owner:TELEFON AB LM ERICSSON (PUBL)

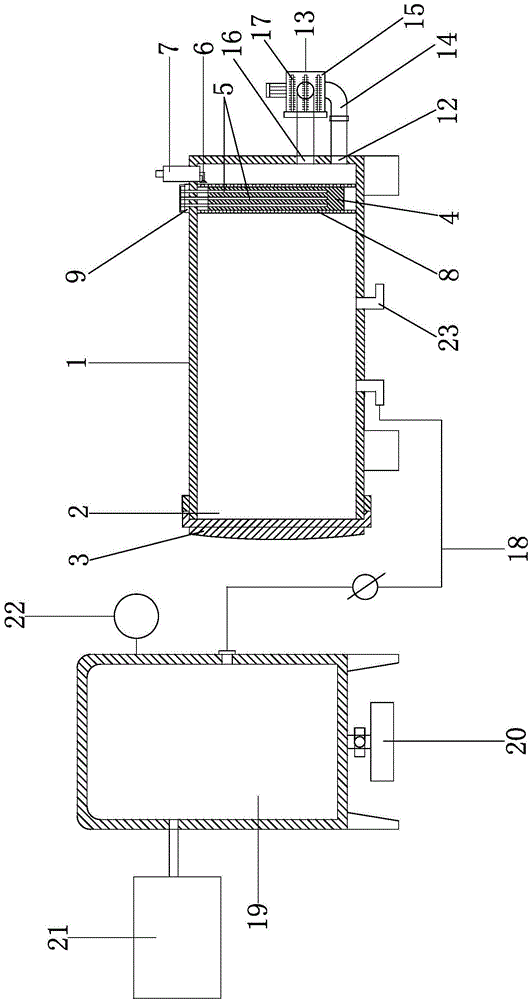

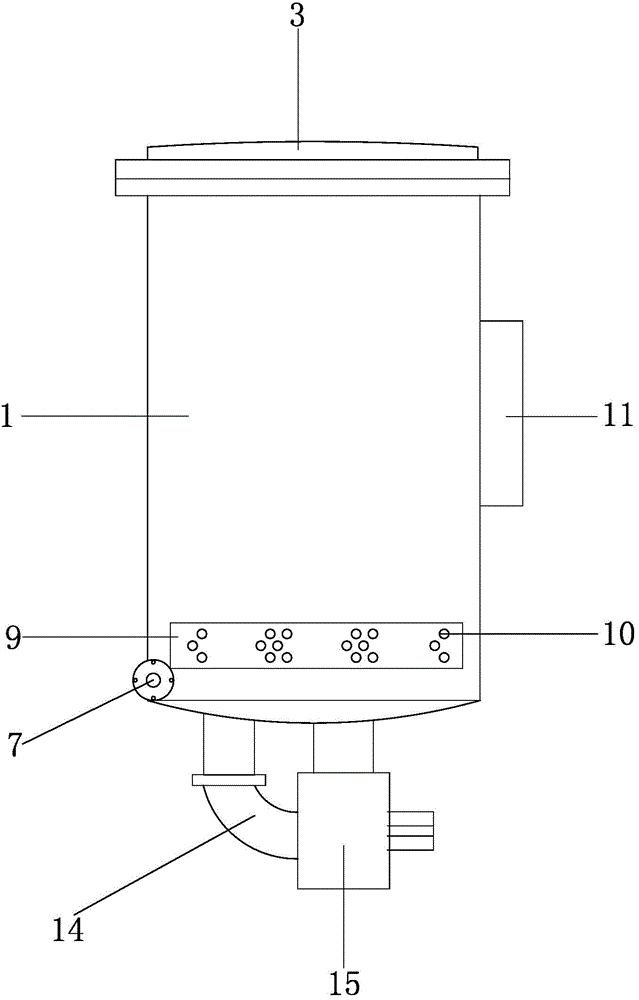

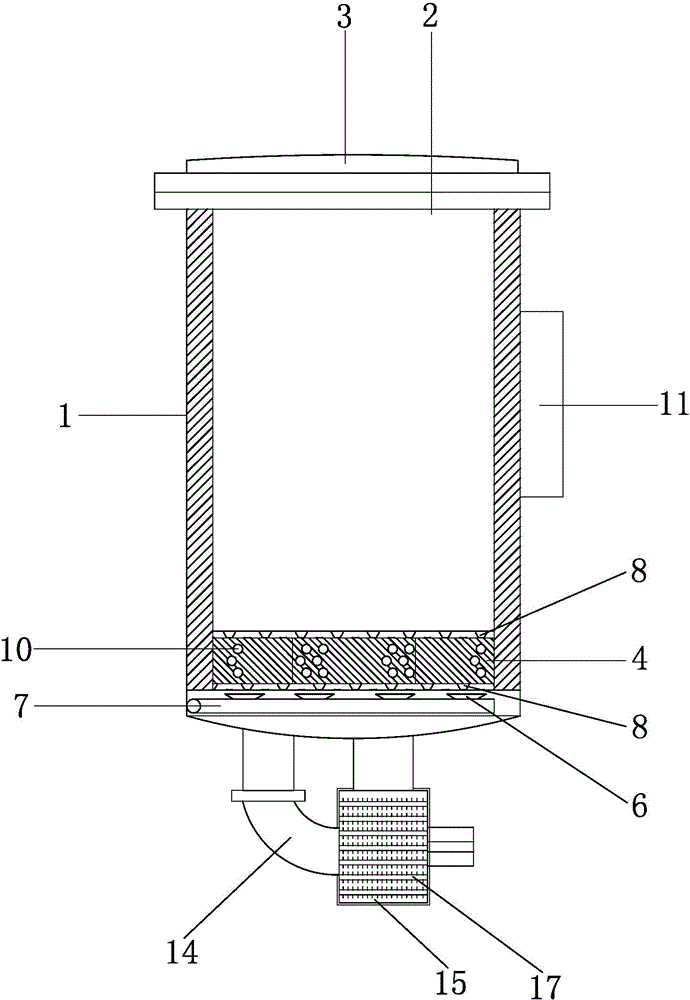

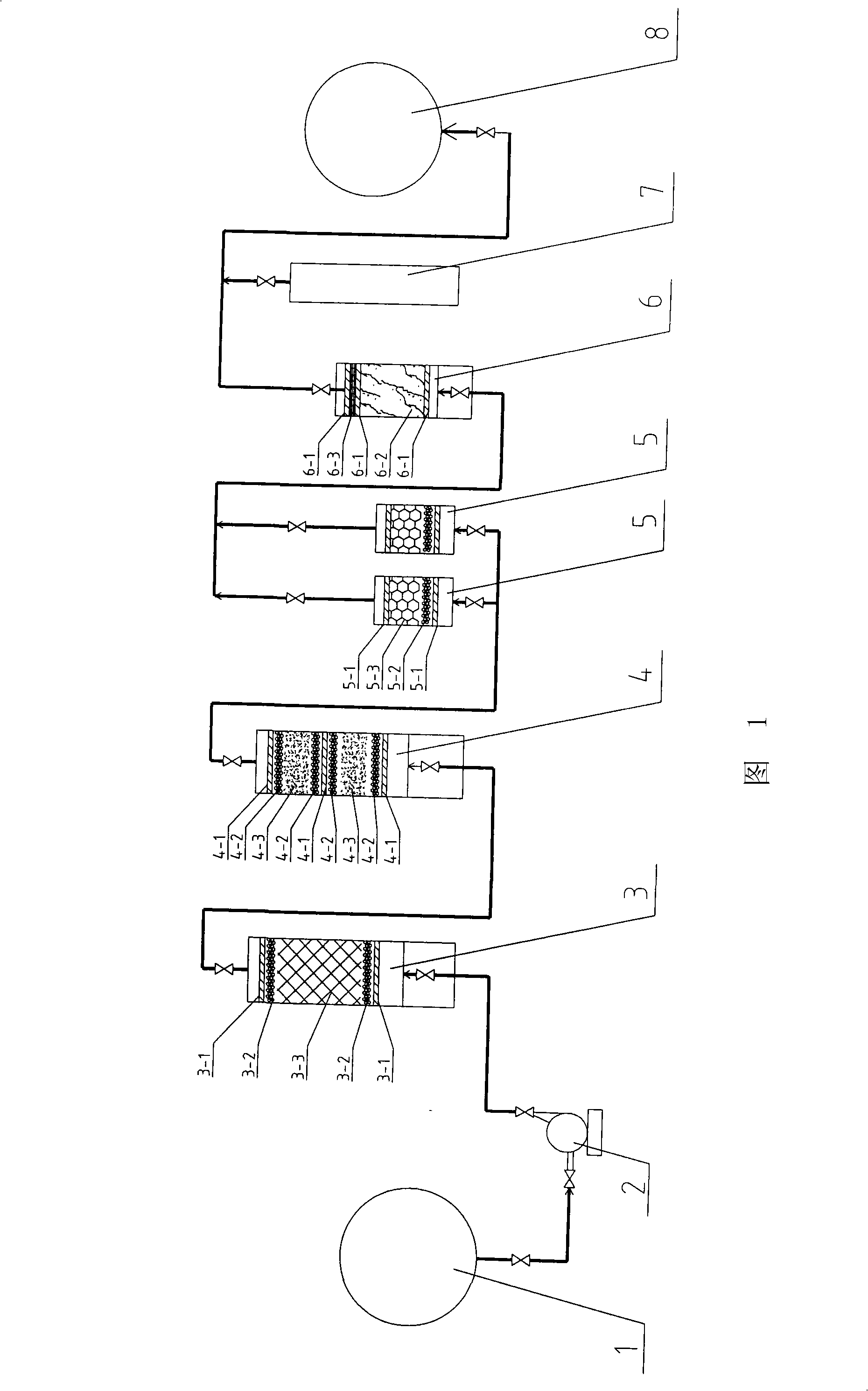

Stream setting machine

ActiveCN104593979AEfficient conversionImprove evaporation efficiencyTextile treatment containersHeating/cooling textile fabricsEngineeringVacuum pump

The invention provides a stream setting machine, and belongs to the technical field of a setting machine. The stream setting machine solves the problems that the heating speed of the existing structure is slow, the steam quantity cannot be easily controlled, the whole machine size is bulky and the existing structure does not have heat storage function, and the like. The stream setting machine is characterized in that a sealed cap is arranged at the open end of the front side of a tank body, a high temperature heat storage plate is arranged in the tank body, a heating pipe is detachably arranged in the high temperature heat storage plate, a plurality of spray headers that can spray water to the high temperature heat storage plate are arranged on one side of the high temperature heat storage plate, spray headers are all connected to a water inlet pipeline; a circulating heating mechanism is arranged at the rear end of the tank body, a vacuum tank that the interior is in a negative pressure condition is connected with the tank body by a pressure relief control pipeline, a condensate water collecting tank is arranged on the bottom of the vacuum tank, a vacuum pump is connected with the vacuum tank, and a pressure gauge is installed on the vacuum pump. The stream setting machine has the advantages that the steam can be effectively converted, the heat in the tank body is uniform, the setted objects can be dried fast, and the usage of power shortage areas can be met.

Owner:TIANTAI COUNTY MINGTONG MACHINERY

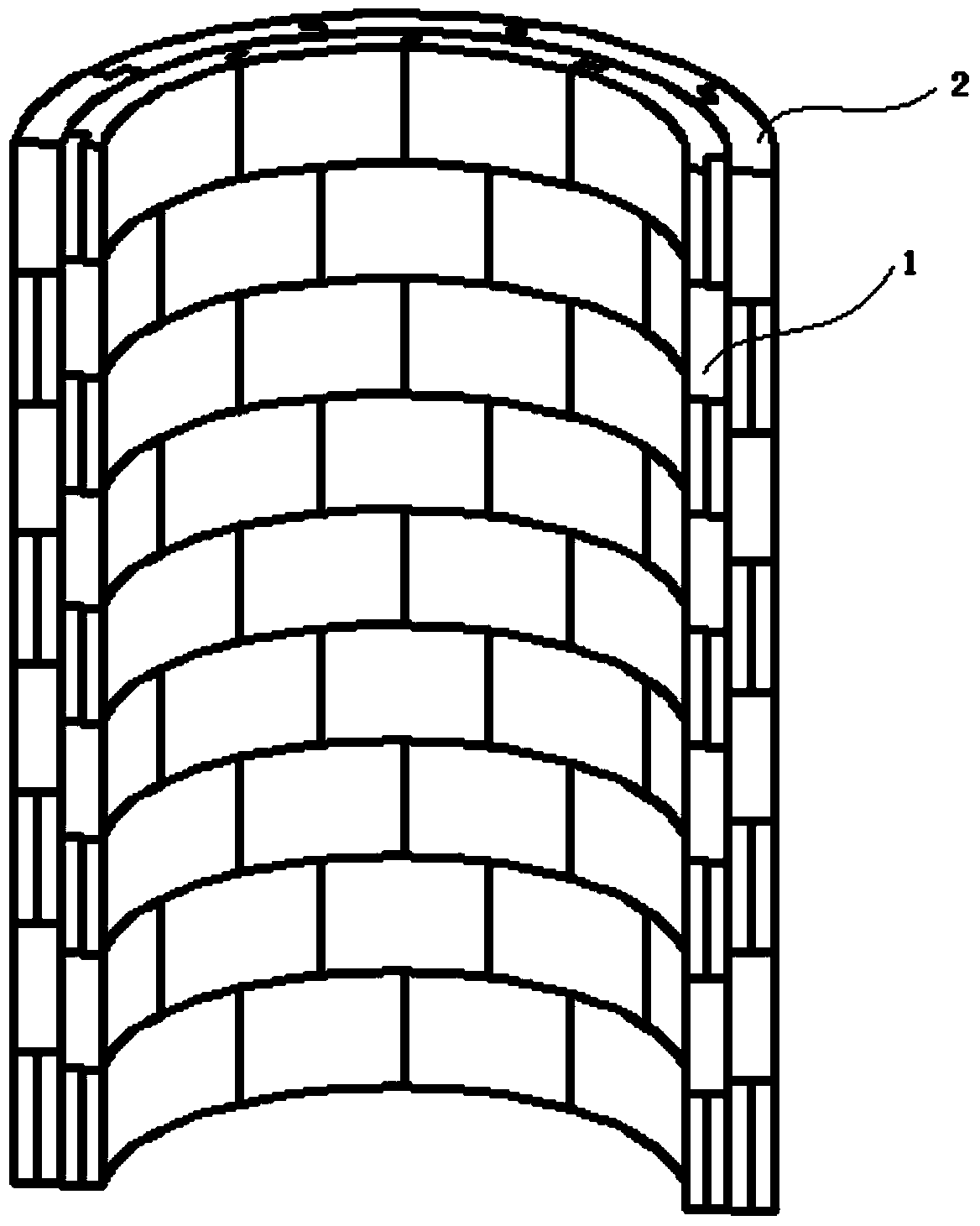

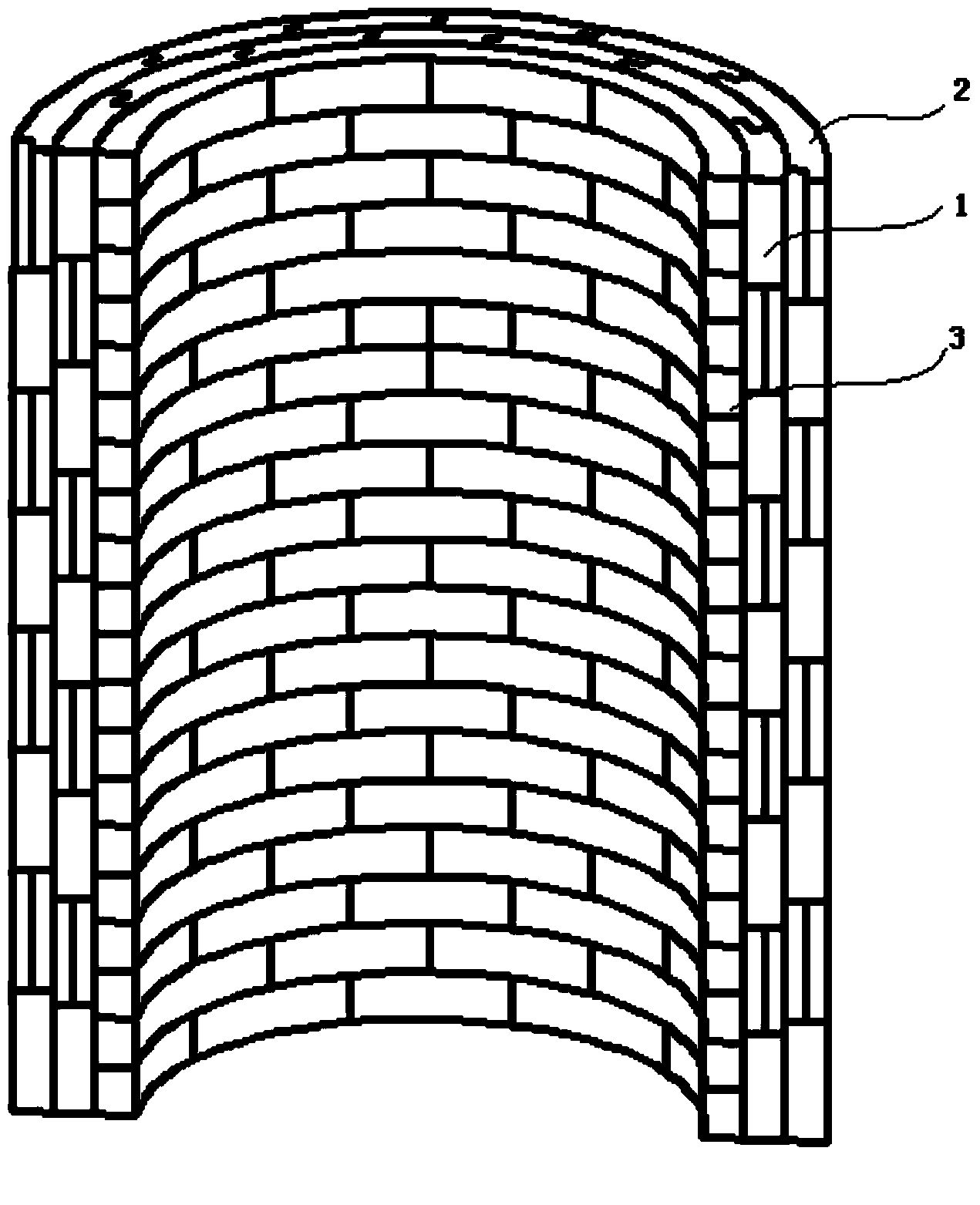

Sapphire crystal growing furnace side screen and preparation method thereof

InactiveCN104073878AReduce maximum powerReduce power consumptionAfter-treatment apparatusPolycrystalline material growthFiberboardSapphire

The invention discloses a sapphire crystal growing furnace side screen. The drum-shaped growing furnace side screen comprises an inner screen and an outer screen connected with the inner screen, wherein the inner screen and the outer screen are both assembled by a plurality of zirconia fiberboards. The invention further discloses a preparation method for the sapphire crystal growing furnace side screen. The growing furnace side screen reduces electrical consumption, lowers the peak power of long crystal, saves energy by above 40%, and is favorable in stability; the zirconia fiberboards are free of volatilization in a high-temperature state, favorable in vacuum degree and stability of the temperature gradient of the thermal field, and assembled by the same arc-shaped zirconia fiberboards in a staggered joint manner; the zirconia fiberboards can be independently replaced when damaged, the entire heat-insulating side screen is not needed to be replaced, and the manufacturing cost of sapphire crystal is effectively lowered.

Owner:南京理工宇龙新材料科技股份有限公司

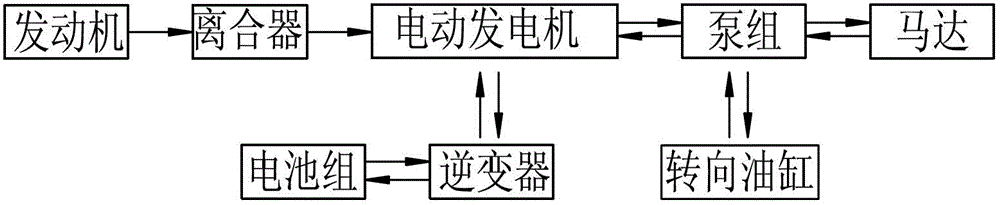

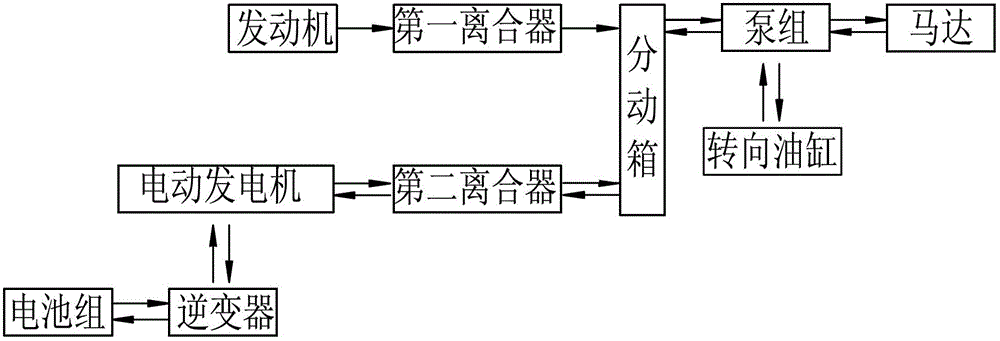

Transport vehicle for hybrid power engineering

InactiveCN103144527AReduce power consumptionReduce fuel consumptionGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingClutchElectric generator

The invention relates to a transport vehicle for the hybrid power engineering. The transport vehicle comprises a transmission system, a hydraulic drive system, a hydraulic steering system, a hydraulic wet-type braking system and a micro electrical control system, wherein the transmission system comprises an engine, a first clutch connected with engine, a motor-generator connected with the first clutch, a pump set connected with the motor-generator, an inverter connected with the motor-generator, a battery pack connected with the inverter and a motor and a steering oil cylinder which are driven by the pump set. According to the transport vehicle for the hybrid power engineering, a power source adopts oil and electricity hybrid power, air pollution is reduced greatly, the oil consumption is reduced greatly, exhaust emission and environmental pollution are reduced, the whole energy consumption is reduced, service lives of components of a break system are prolonged, and the operation security of the vehicle is improved.

Owner:SUZHOU DAFANG SPECIAL VEHICLE

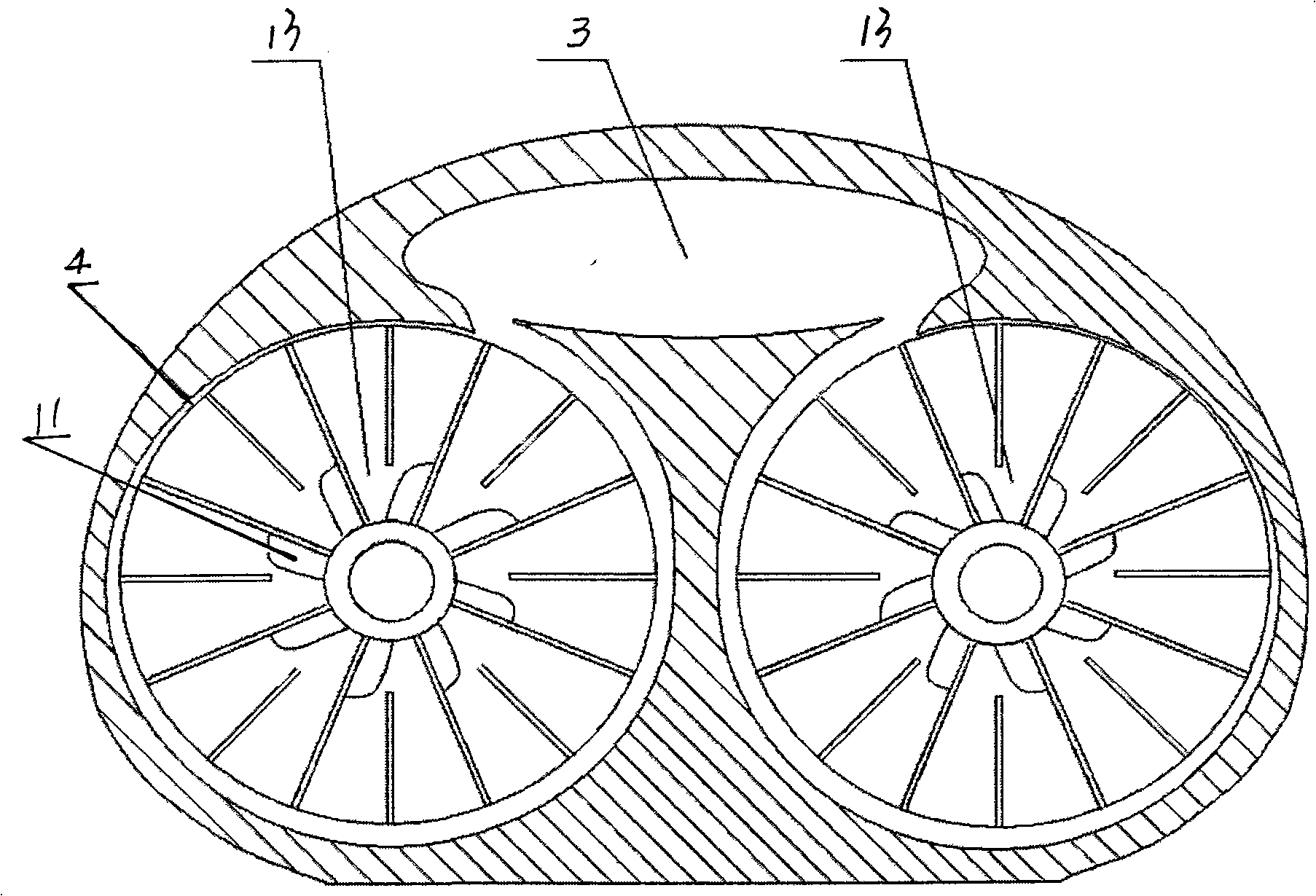

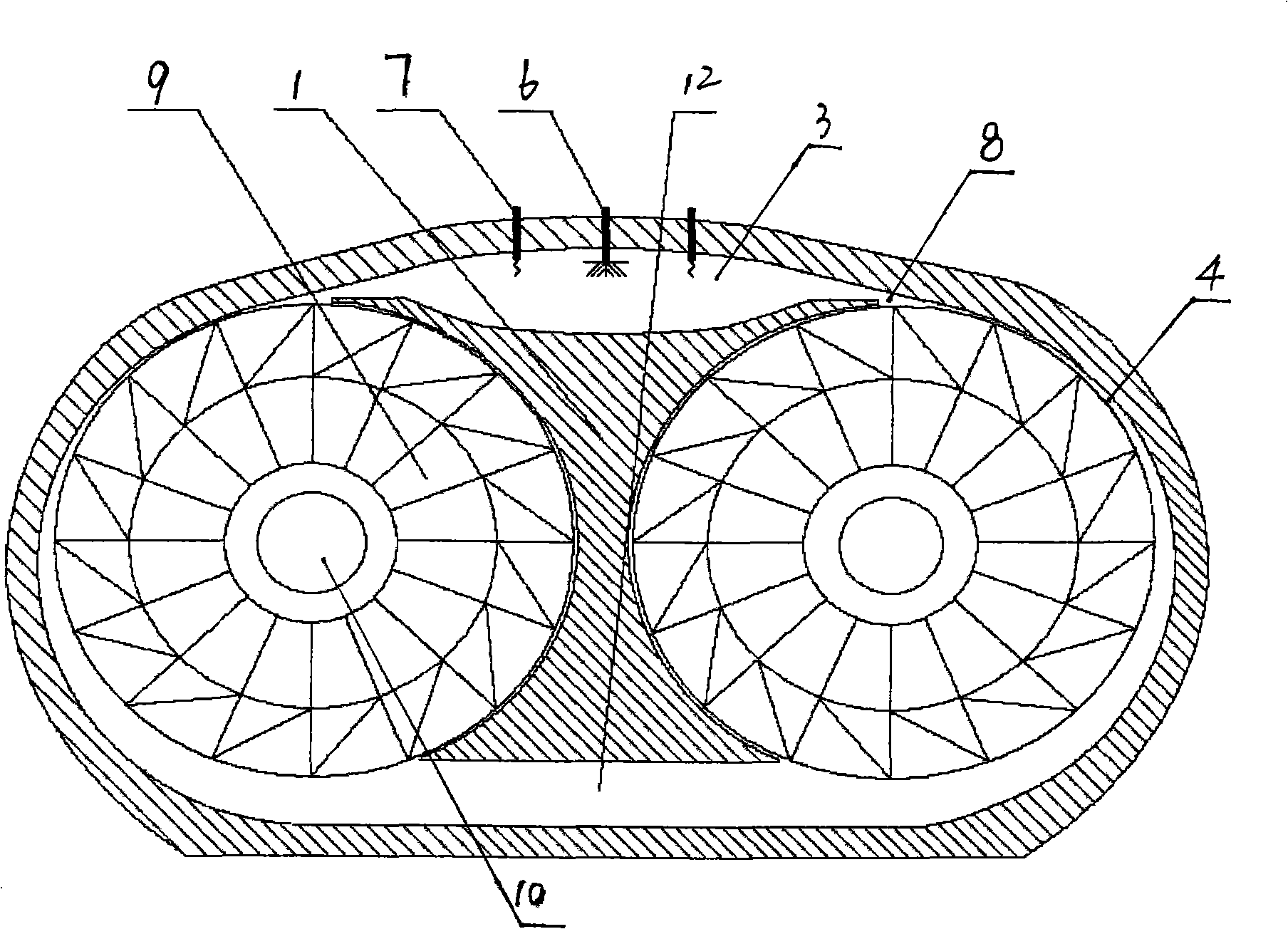

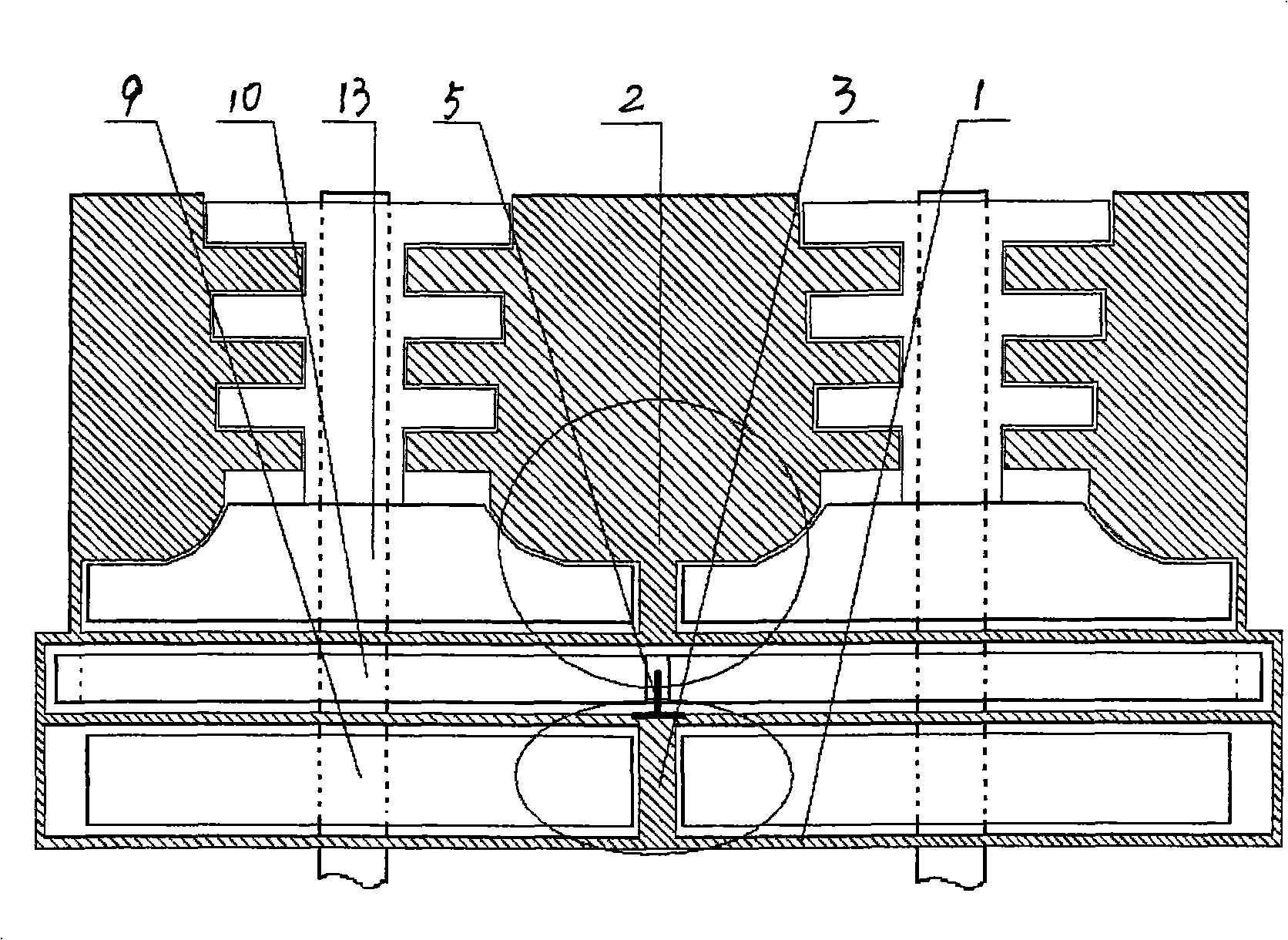

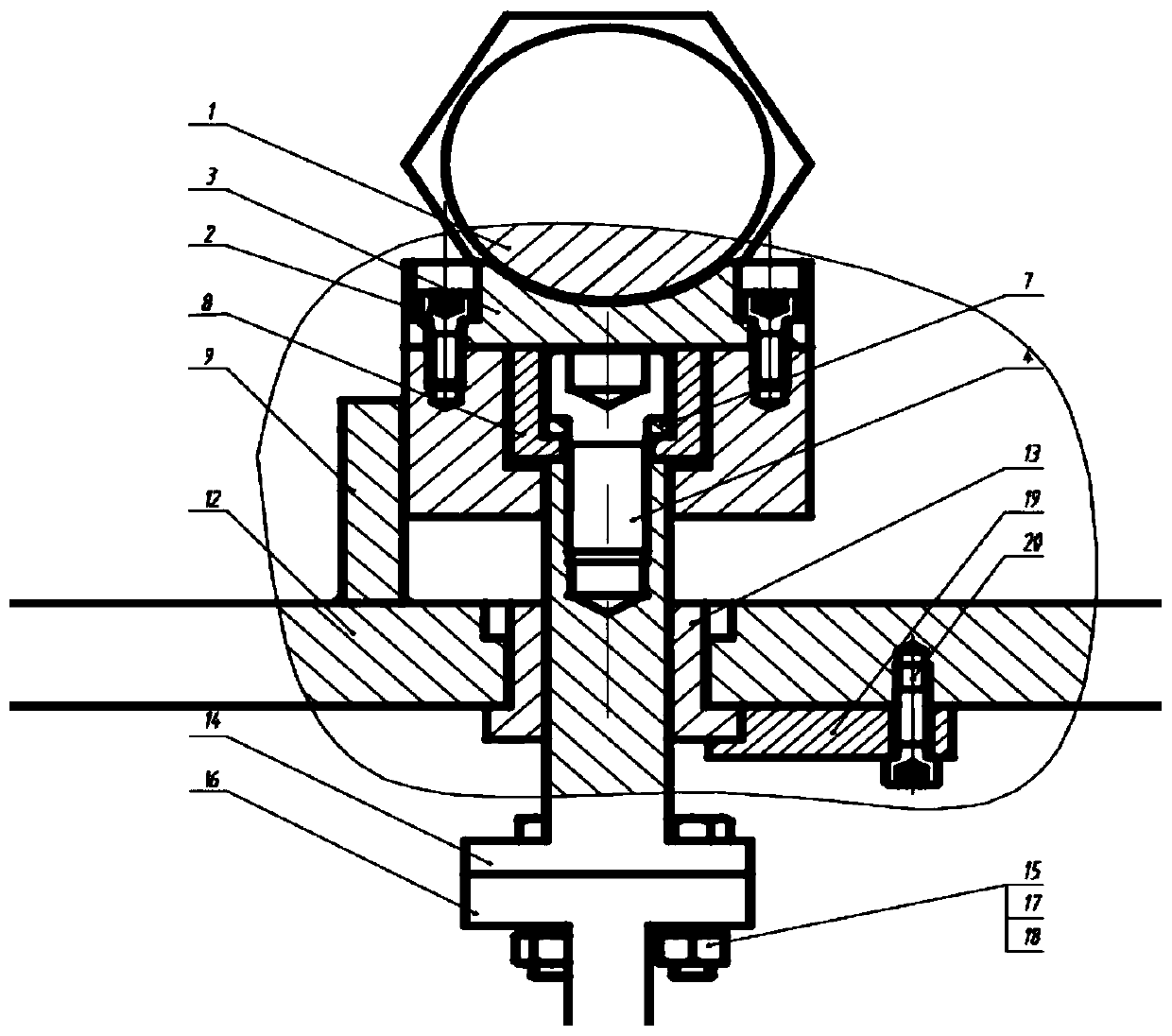

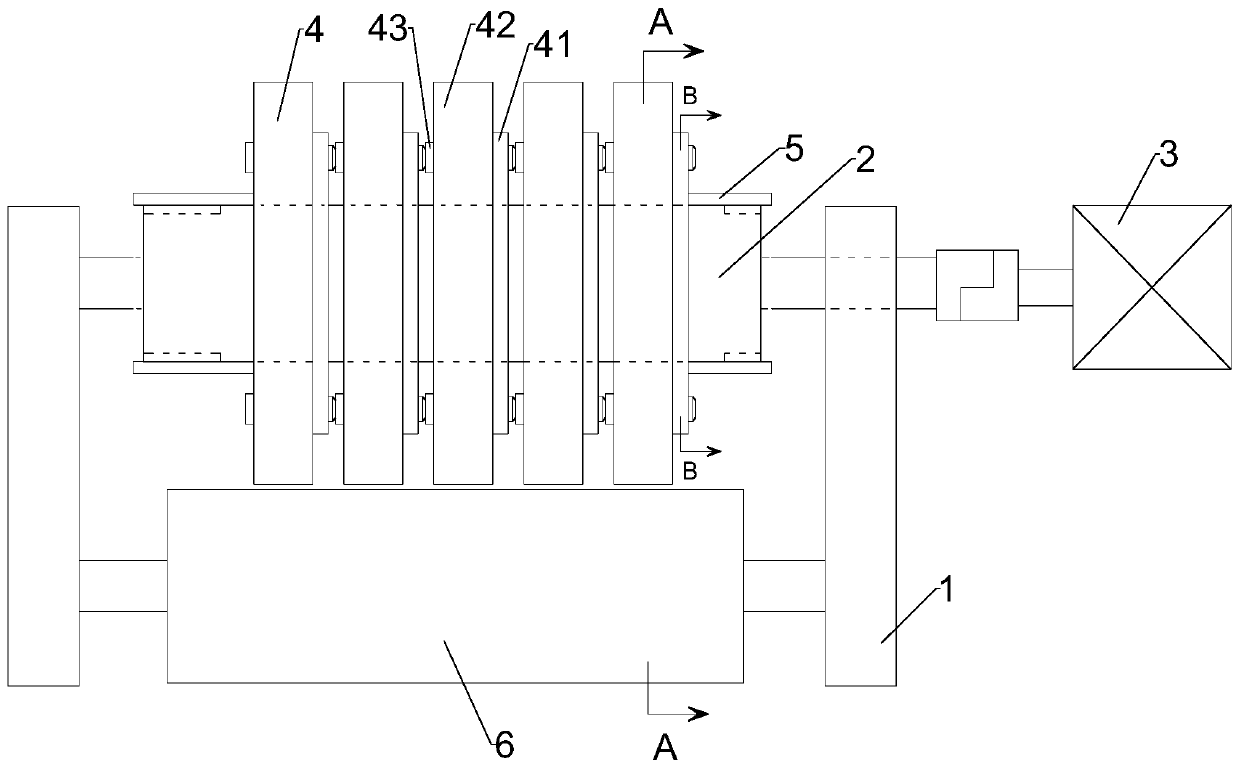

Radial power rotor engine

InactiveCN101526012AImprove low-speed performanceImprove airtightnessRotary piston enginesCombustion chamberReady to use

The invention discloses a radial power rotor engine which has a structure that a compressed air surge chamber (2), a combustion chamber (3) and a rotor chamber (4) are formed in an engine shell (1), wherein an air compressor (13) is communicated with the combustion chamber (3) through the compressed air surge chamber (2) and a one-way valve (5), the combustion chamber (3) is connected with a fuel-injection apparatus (6) and a timing ignition device (7), and a puff port (8) of the combustion chamber (3) is communicated with the rotor chamber (4); the rotor chamber (4) is internally provided with a rotor (9) which consists of a rotor shaft (10) and rotor vanes (11), the rotor vanes (11) are homocentrically and circularly distributed on the rotor shaft (10) which is arranged on the engine shell (1), and the rotor shaft (10) is provided with the air compressor (13). The invention has the advantages of simple structure, few parts, easy manufacture, stable property and simple maintenance and can use various fuels.

Owner:席伟

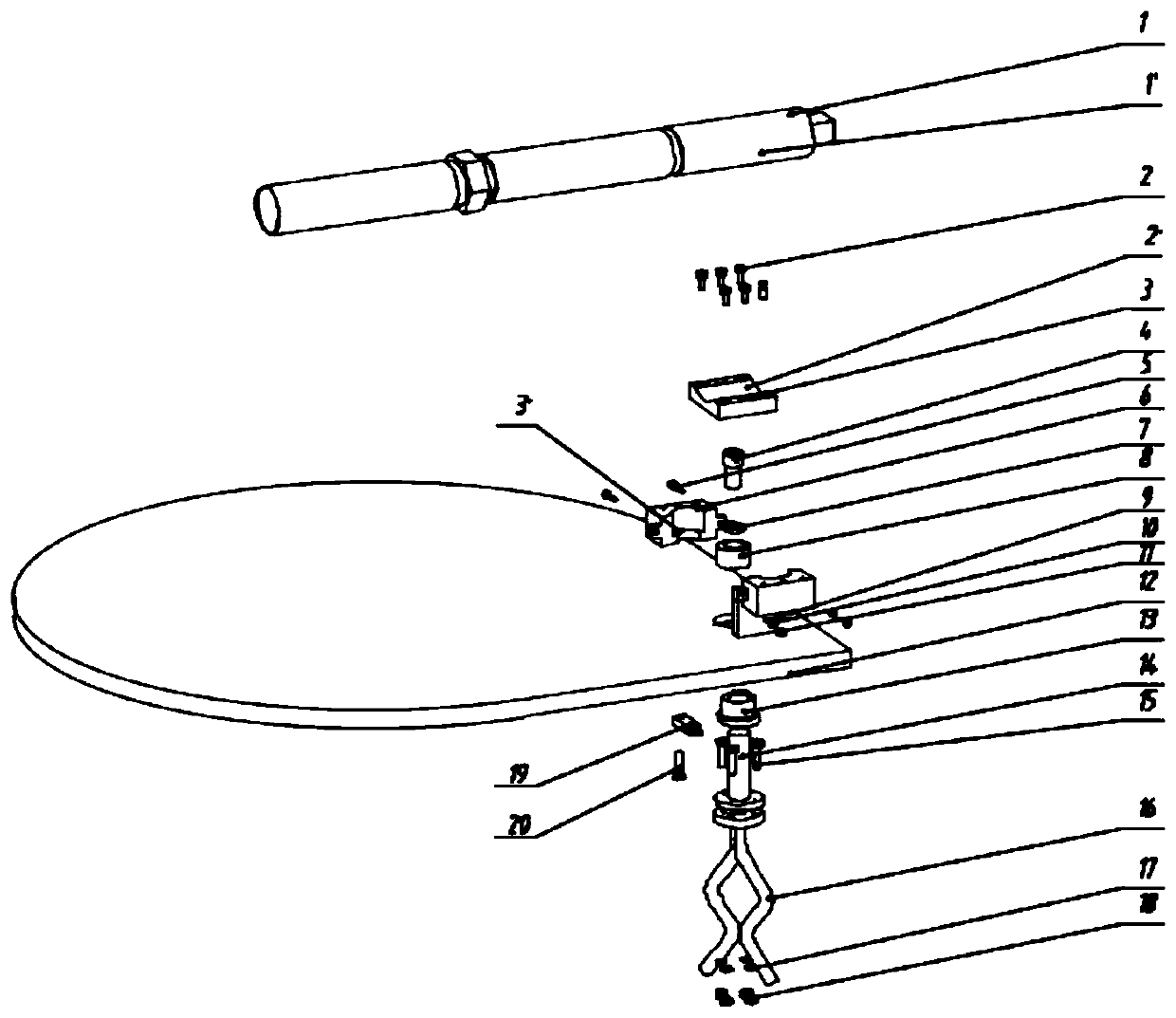

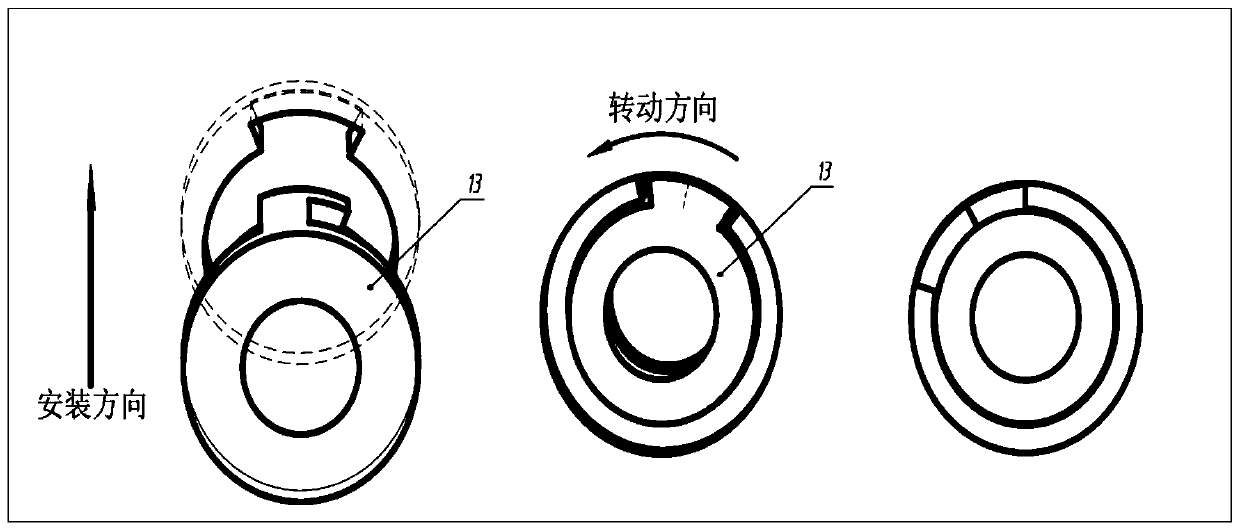

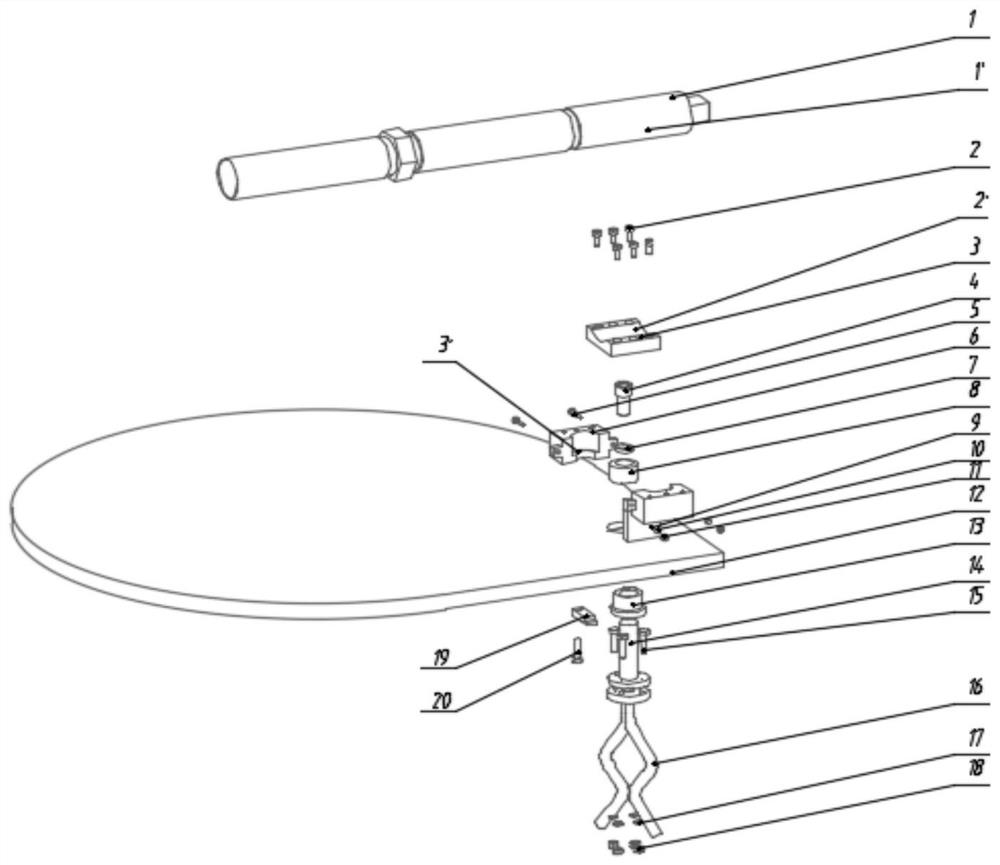

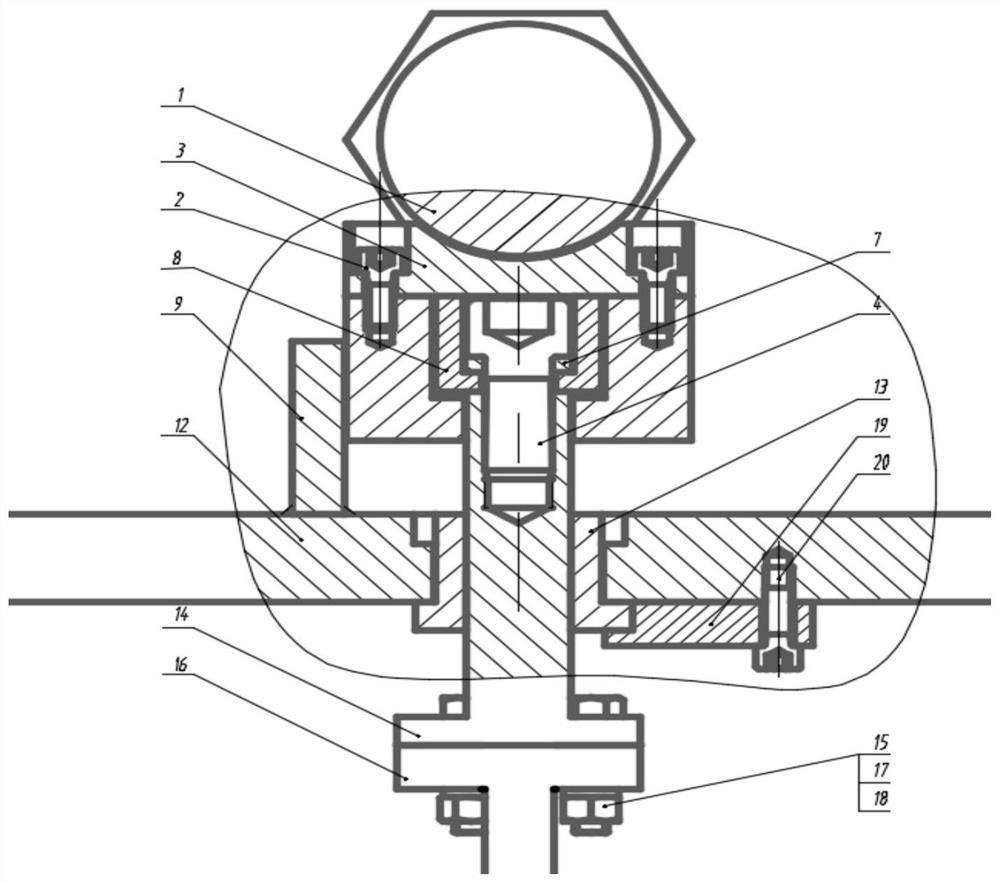

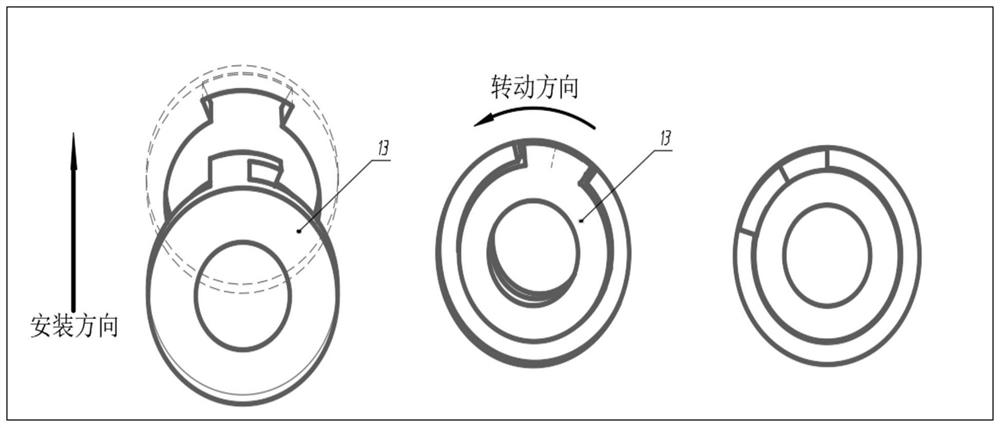

Friction type anti-loosening structure of underwater clamp connector

The invention provides a friction type anti-loosening structure of an underwater clamp connector. The friction type anti-loosening structure comprises a clamp handle, a clamp handle fixing plate, a clamp handle rotating block, a threaded rod, a threaded sleeve, a torsion joint, a guide plate and a pressing plate. Reticulated knurling is arranged on the contact surfaces of the clamping handle and aclose bolt of the clamp connector, so that the friction coefficient of the clamping handle and the close bolt is increased; a lug is arranged outside the threaded sleeve and capable of limiting the circumferential direction and the axial movement of the threaded sleeve through being assembled and rotated by a certain angle with a shell plate of the connector, so that the linear movement of the threaded rod is ensured; when the threaded sleeve and the threaded rod are rusted and cannot be screwed off, a remote control robot carries a manipulator to axially pull the threaded rod out of one sideof a pressing plate of the shell plate, wherein the pressing plate plays a limiting role, and the pressing plate can be pulled off so that a locking device and the close bolt can be separated; the guide plate is used for limiting the rotation of the clamp handle; and the torsion joint is provided with an interface combined with a torsion wrench, and a ROV carries the torsion wrench to realize therotation of the threaded rod, so that the pressure of the clamp handle and the close bolt is provided, and the anti-loosening purpose is finally realized.

Owner:HARBIN ENG UNIV

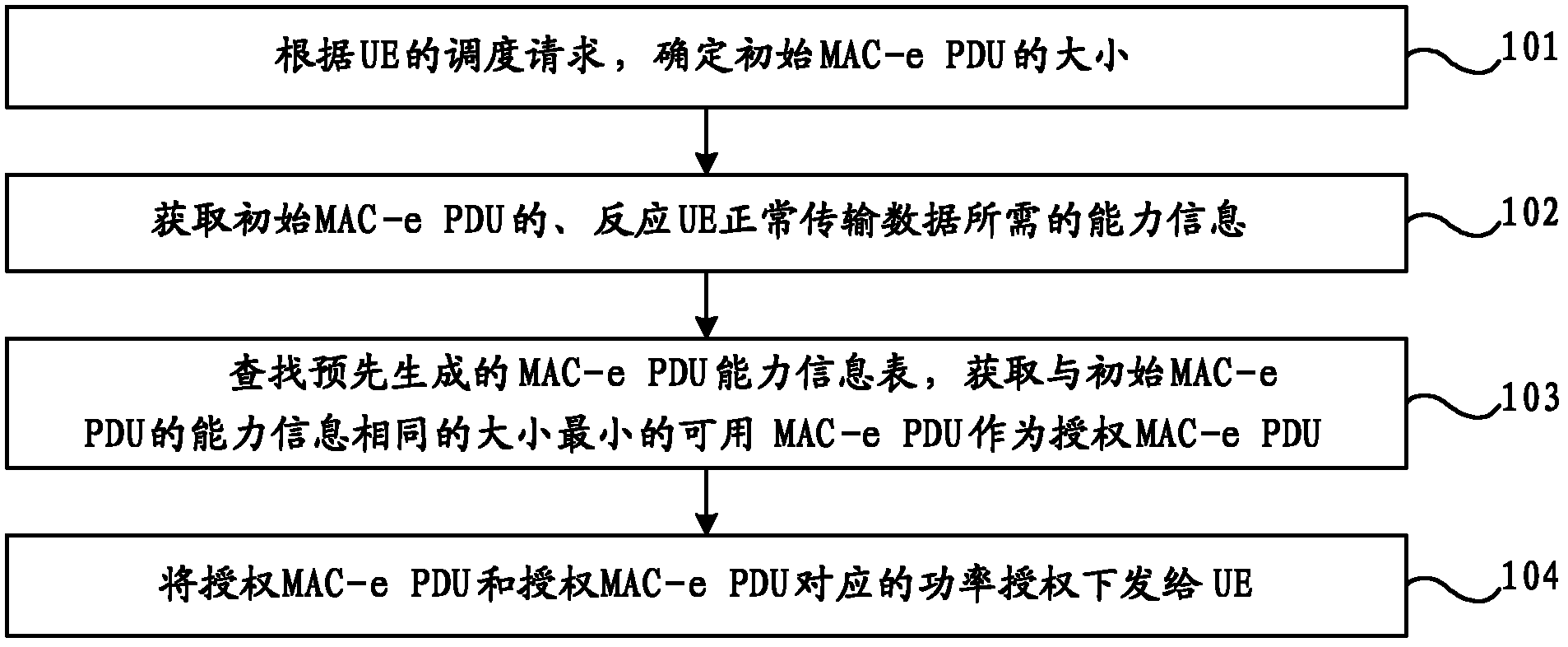

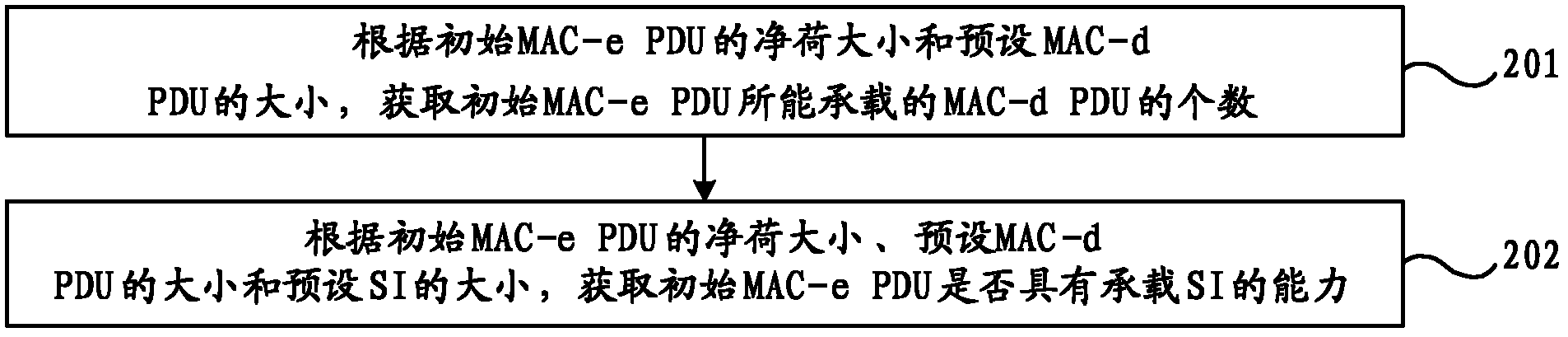

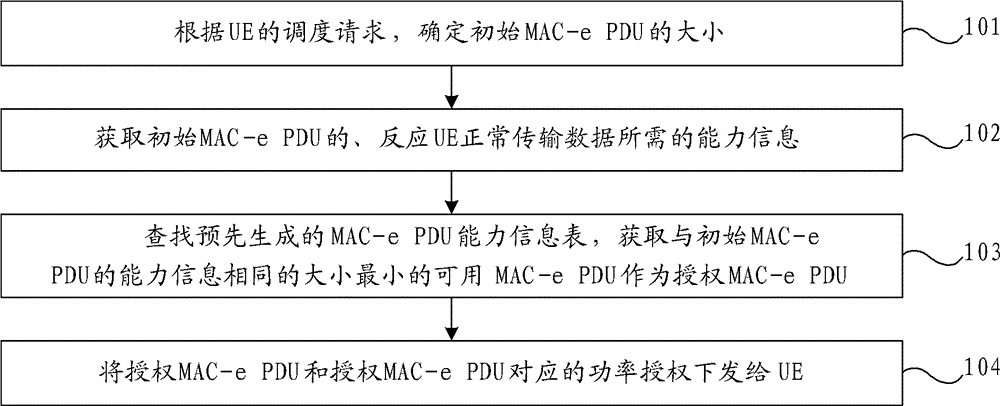

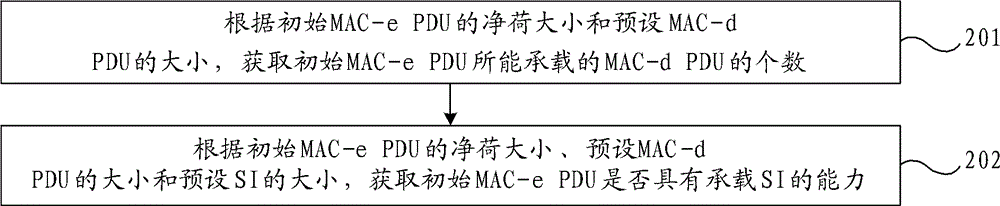

Method and device for resource authorization

InactiveCN102869094AGuaranteed normal uploadGuaranteed to upload data normallyWireless communicationAuthorizationOperating system

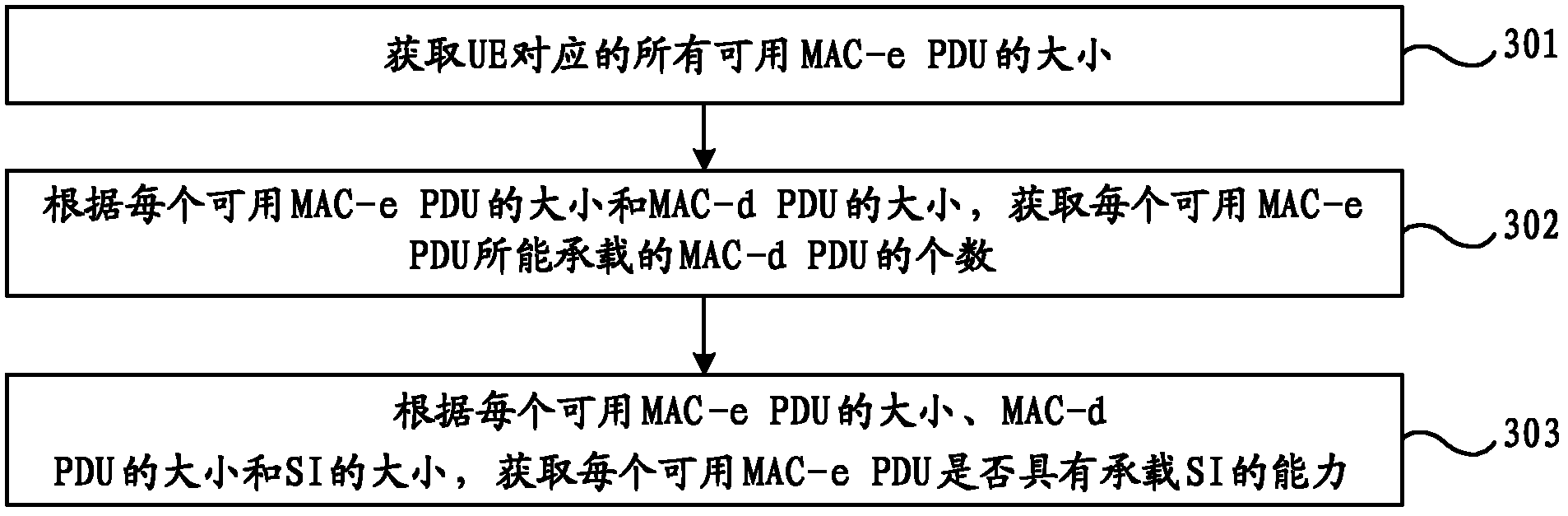

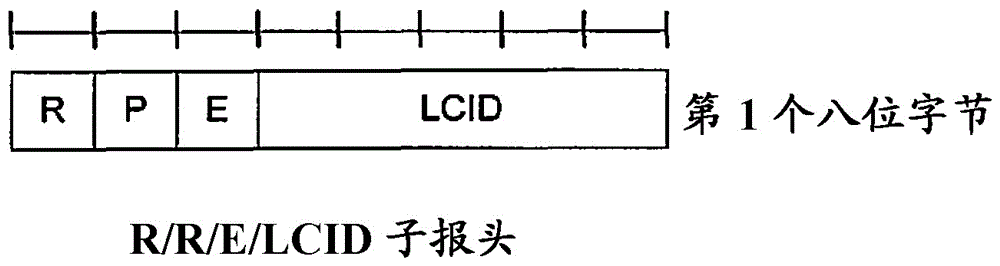

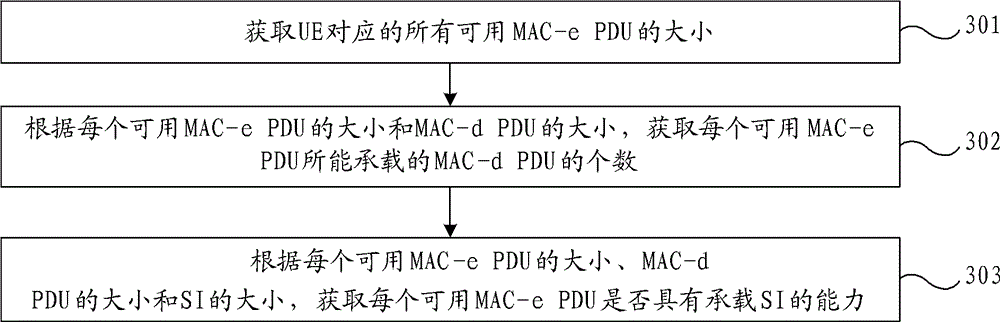

The invention provides a method and a device for resource authorization. The method includes the steps: determining the size of an initial MAC-e PDU (protocol data unit) according to a scheduling request of a user terminal; acquiring capacity information of the initial MAC-e PDU; inquiring a pre-generated MAC-e PDU capacity information sheet and acquiring the minimum usable MAC-e PDU with capacity information as same as that of the initial MAC-e PDU as an authorized MAC-e PDU; including the sizes of all usable MAC-e PDUs and the capacity information of each usable MAC-e PDU in the MAC-e PDU capacity information sheet; and issuing the authorized MAC-e PDU and power authorization corresponding to the authorized MAC-e PDU to the user terminal. By the aid of the technical scheme, the power of UE (unified equipment) can be more reasonably authorized, MAC-e PDU resources can be more reasonably distributed, and waste of the MAC-e PDU resources and power resources is decreased.

Owner:TD TECH COMM TECH LTD

Methods and apparatuses for enabling power back-off indication in phr in a telecommunications system

ActiveCN105939538AImprove adaptabilityOptimize schedulingPower managementRadio Base StationUser equipment

Owner:TELEFON AB LM ERICSSON (PUBL)

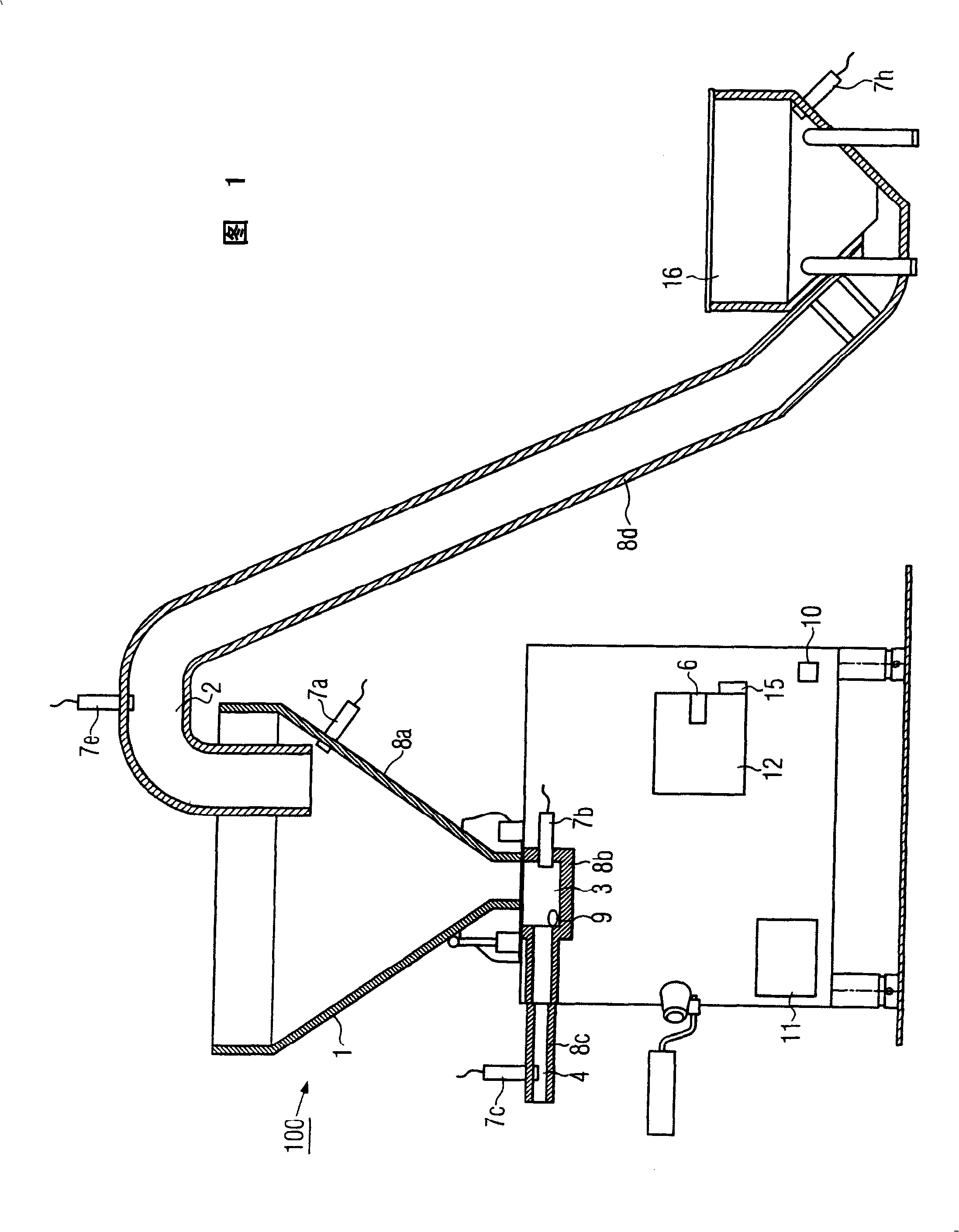

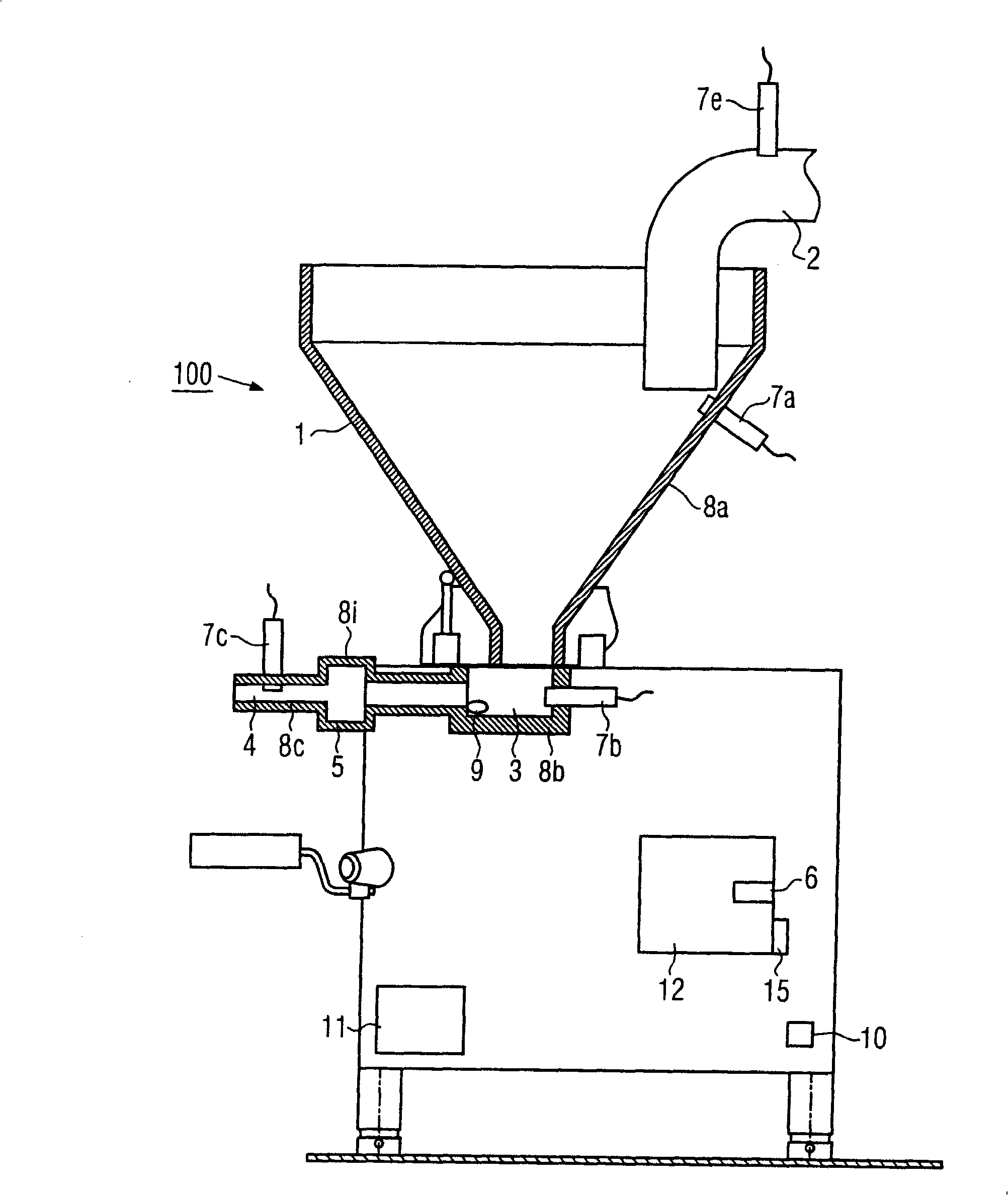

Temperature regulation of the mass flow in a filling machine

ActiveCN101313691ACompensation for temperature effectsIncrease production capacityTemperatue controlSausage filling/stuffing machinesTemperature control

The method involves passing a mass flow over multiple regions of a filling machine (100). Temperature of the mass flow or of components flowing through the mass flow is measured within the regions of the filling machine. The temperature of the mass flow is controlled to a predetermined temperature by a heating / cooling device based on the measured temperature. The temperature is measured within a region of a filling hopper (1) or an intake region (2) and adjacent to a conveying system (3). An independent claim is also included for a filling machine comprising a filling machine.

Owner:ALBERT HANDTMANN MASCHFABRICK

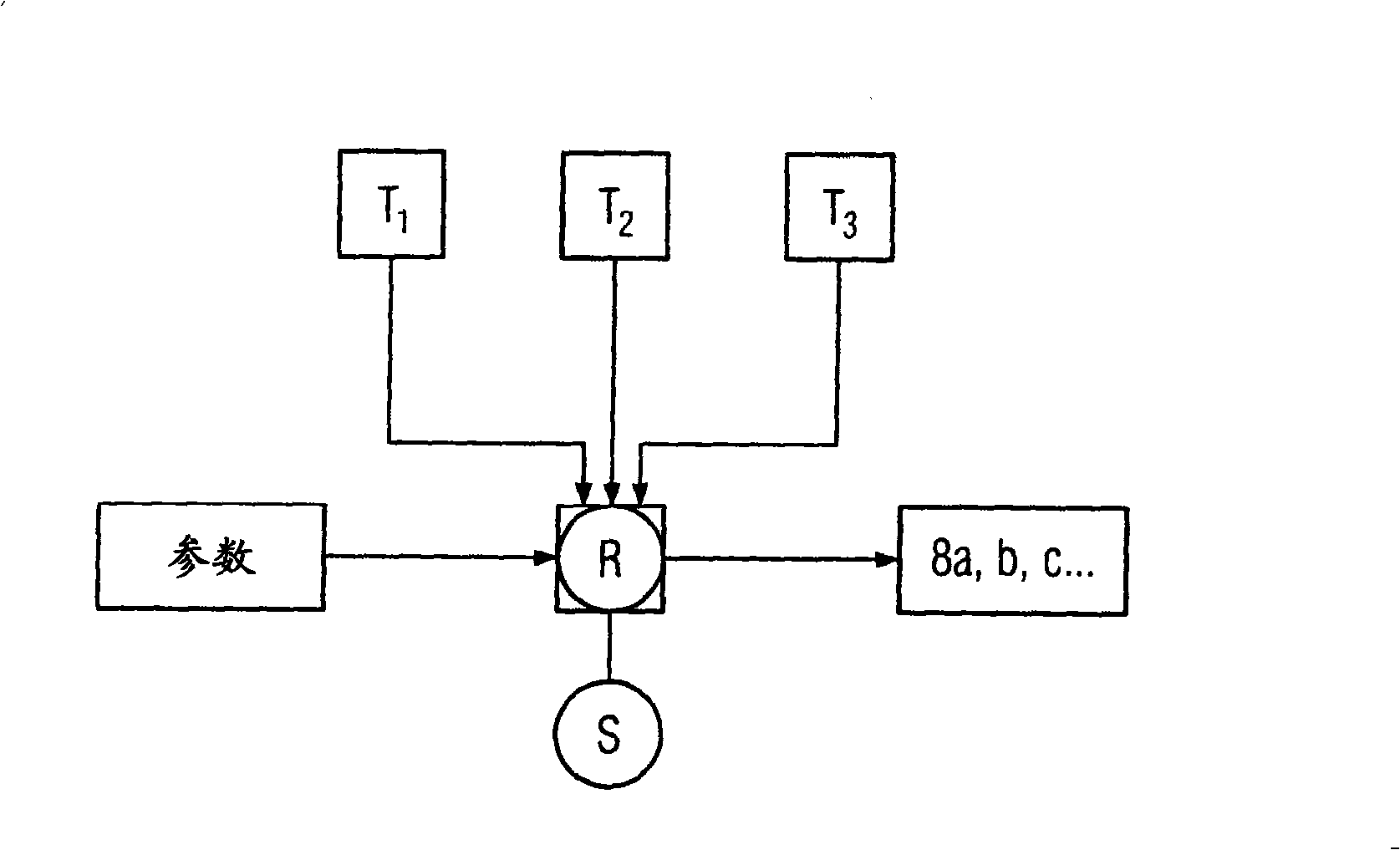

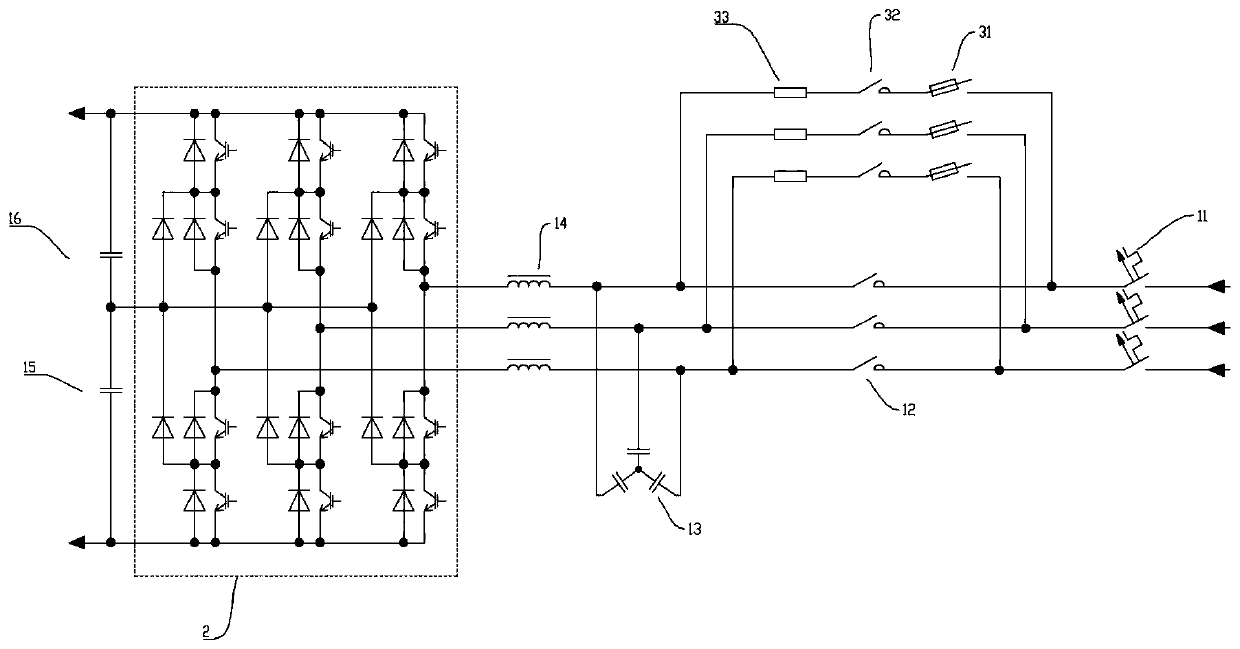

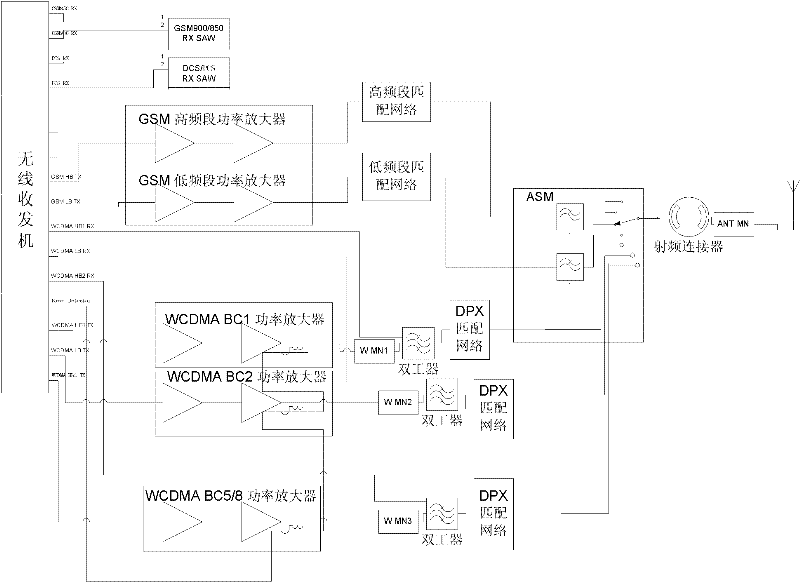

Three-level wind power converter soft start circuit and control method

PendingCN110932331AAvoid damageRelieve pressureAc-dc conversion without reversalEfficient power electronics conversionConvertersCapacitance

The invention relates to the technical field of three-level converters of wind generating sets, in particular to a three-level wind power converter soft start circuit. The main loop power supply inputis connected with a converter controller U and a main loop protection switch Q; a main loop grid-connected switch KM2, a filter reactor L, an alternating-current filter capacitor C and a three-levelpower module M1 are sequentially connected in the direction from the main loop protection switch Q to the direct-current bus, a positive bus capacitor C1 and a negative bus capacitor C2 are arranged at the two ends of the main loop protection switch Q, and the converter controller U is connected with the three-level power module M1; a charging alternating-current protection fuse FU1 is connected in the direction from the power distribution source to the direct-current bus side, and a charging contactor KM1, a charging resistor R1, a double-split transformer T1, a rectifier bridge V1, a rectifier bridge V2 and a charging direct-current fuse FU2 are connected in the direction from the charging alternating-current protection fuse FU1 to the direct-current bus side. According to the invention,surge impact of the power supply on the DC capacitor and the AC filter capacitor of the bus can be reduced, damage to related devices due to surge current is avoided, and soft start of the system isrealized.

Owner:天津瑞源电气有限公司

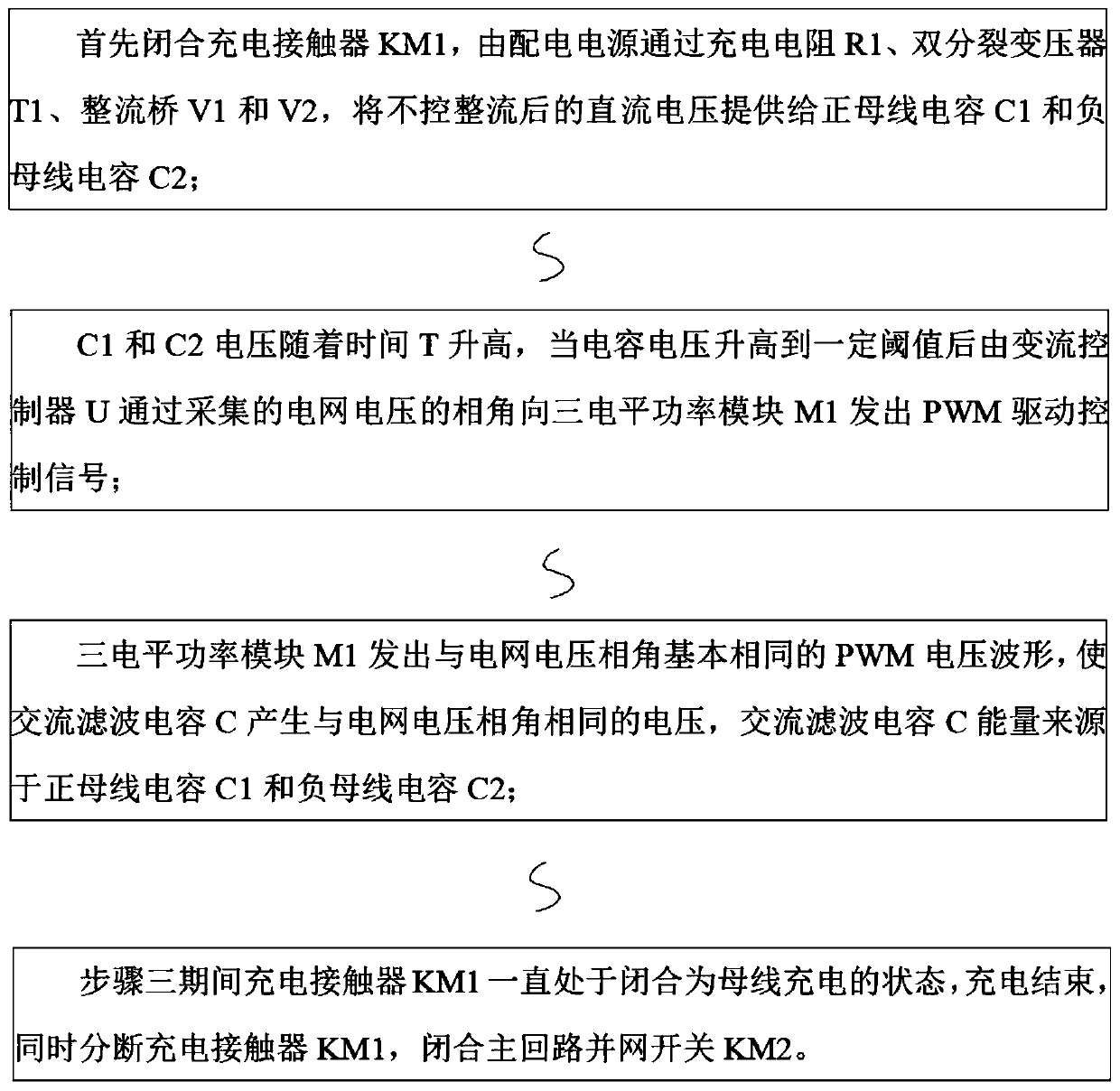

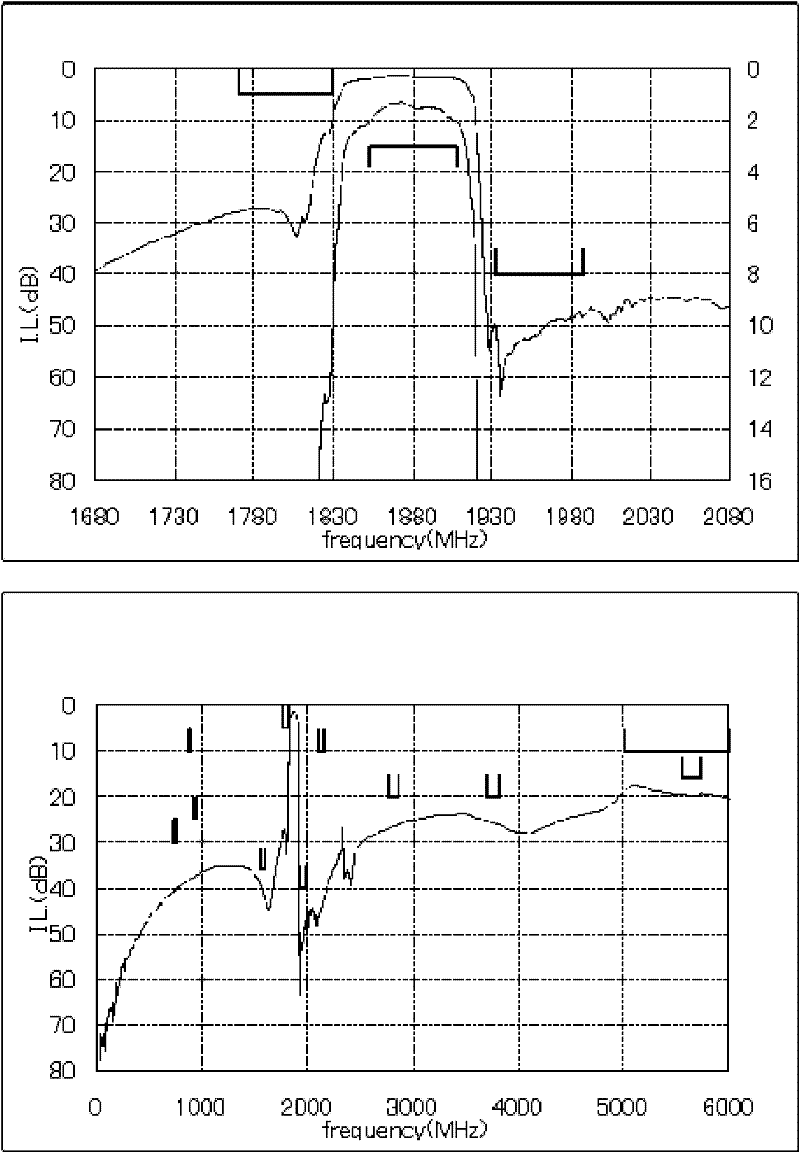

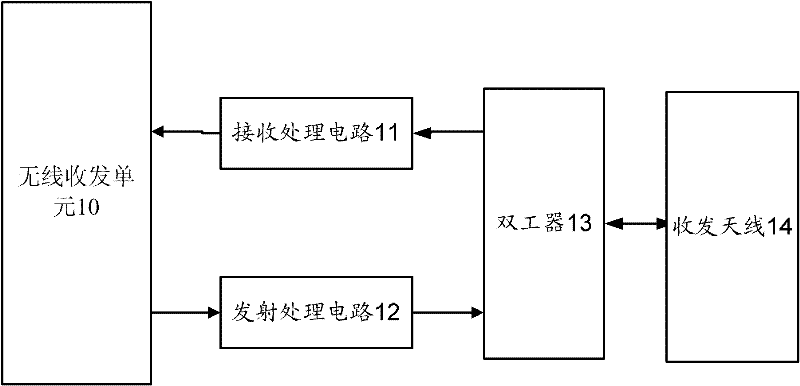

Wireless communication transceiver system

InactiveCN102523012AReduce maximum powerReduce heat dissipationEnergy efficient ICTTransmissionAudio power amplifierTransceiver

The invention discloses a wireless communication transceiver system. The wireless communication transceiver system comprises a wireless transceiver unit, a receiving processing unit, a sending processing unit, a duplexer and a transceiver antenna, wherein both the receiving processing circuit and the sending processing circuit are connected with the duplexer; and the duplexer is connected with the transceiver antenna to receive and send the wireless signal; a sending access of the duplexer is a low-pass filter which can improve insertion loss, so that the power consumption is saved, simultaneously, the maximum power to be output by a power amplifier in the receiving processing circuit and the sending processing circuit is reduced, thus the terminal heat dissipation is reduced.

Owner:JIEKAI COMM TECH SHANGHAI CO LTD

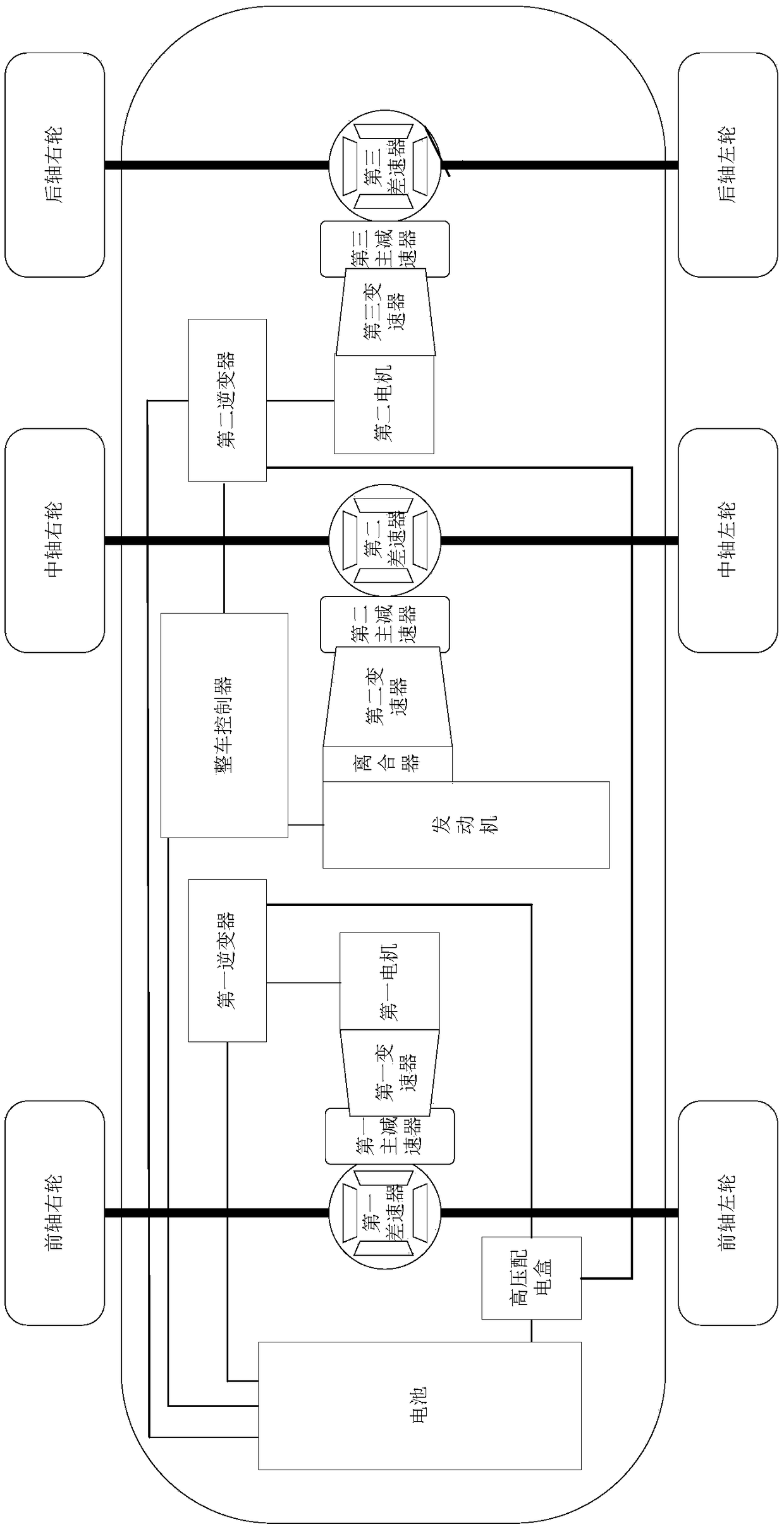

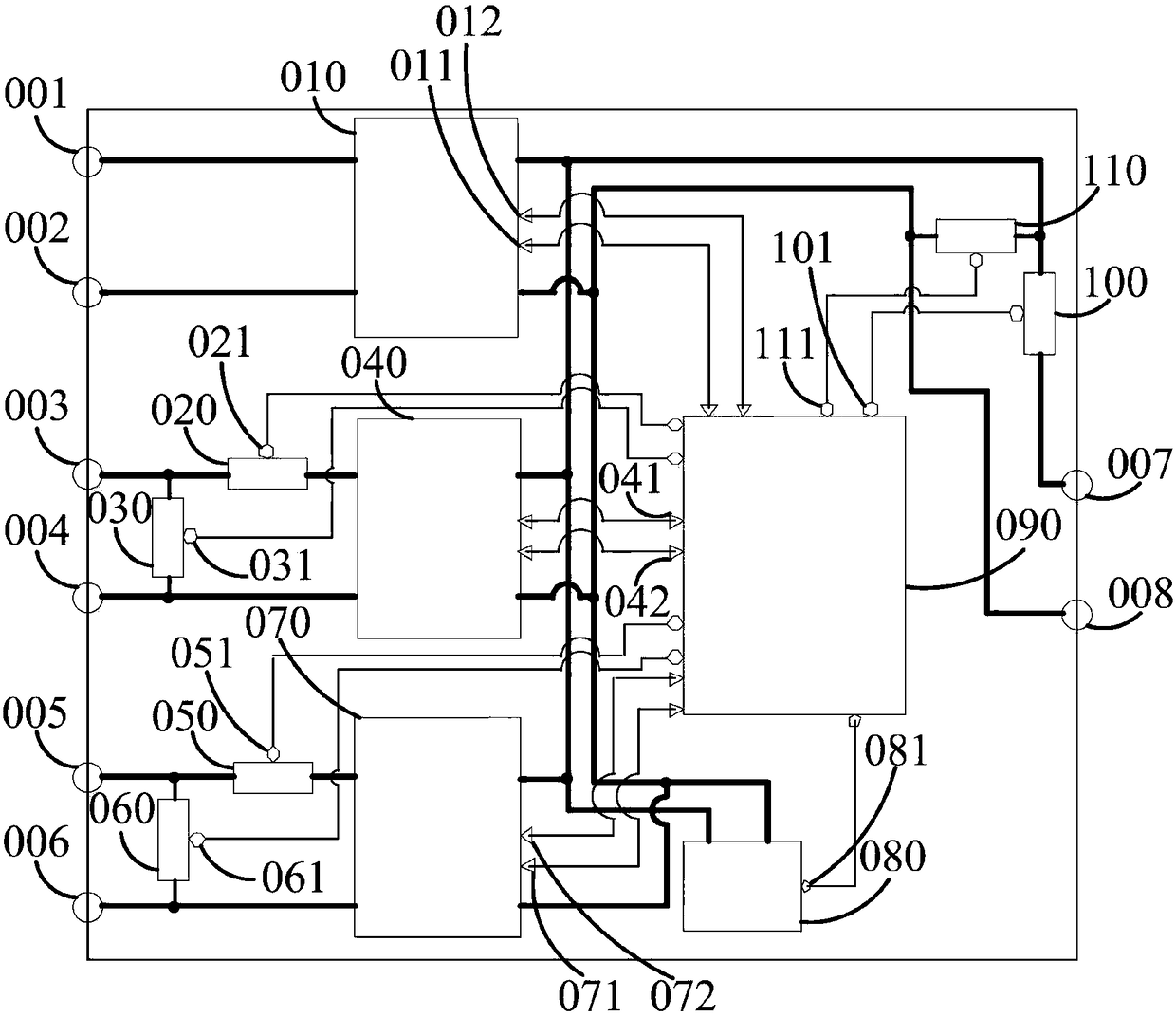

Distributed three-shaft driving hybrid power system

InactiveCN108528201AOptimal working pointReduce maximum powerHybrid vehiclesGas pressure propulsion mountingReduction driveShaft mining

The invention relates to a distributed three-shaft driving hybrid power system. The system comprises an engine power assembly, a first motor power assembly, a second motor power assembly, a battery and a whole vehicle controller; the output end of the engine is sequentially connected with a second variator, a second main reducer and a second differential; the output end of a first motor is connected with a first differential through a first variator and a first main reducer; the output end of a second motor is connected with a third differential through a third variator and a third main reducer; the engine drives a center shaft, a front shaft is driven by the first motor and a rear shaft is driven by the second motor; a pure electric front-and-rear shaft driving mode, an engine center shaft driving mode, a full-time six-wheel driving mode, a braking energy recovery mode and a parking charging mode are achieved by the whole vehicle. The power system is mainly applied to large three-shaft mining self-unloading vehicles, the performance is safe and reliable, the motors or the engine separately or cooperatively operate in perspective efficient intervals, the efficiency of the power system is improved, and the energy utilization rate is improved.

Owner:WUHAN UNIV OF TECH

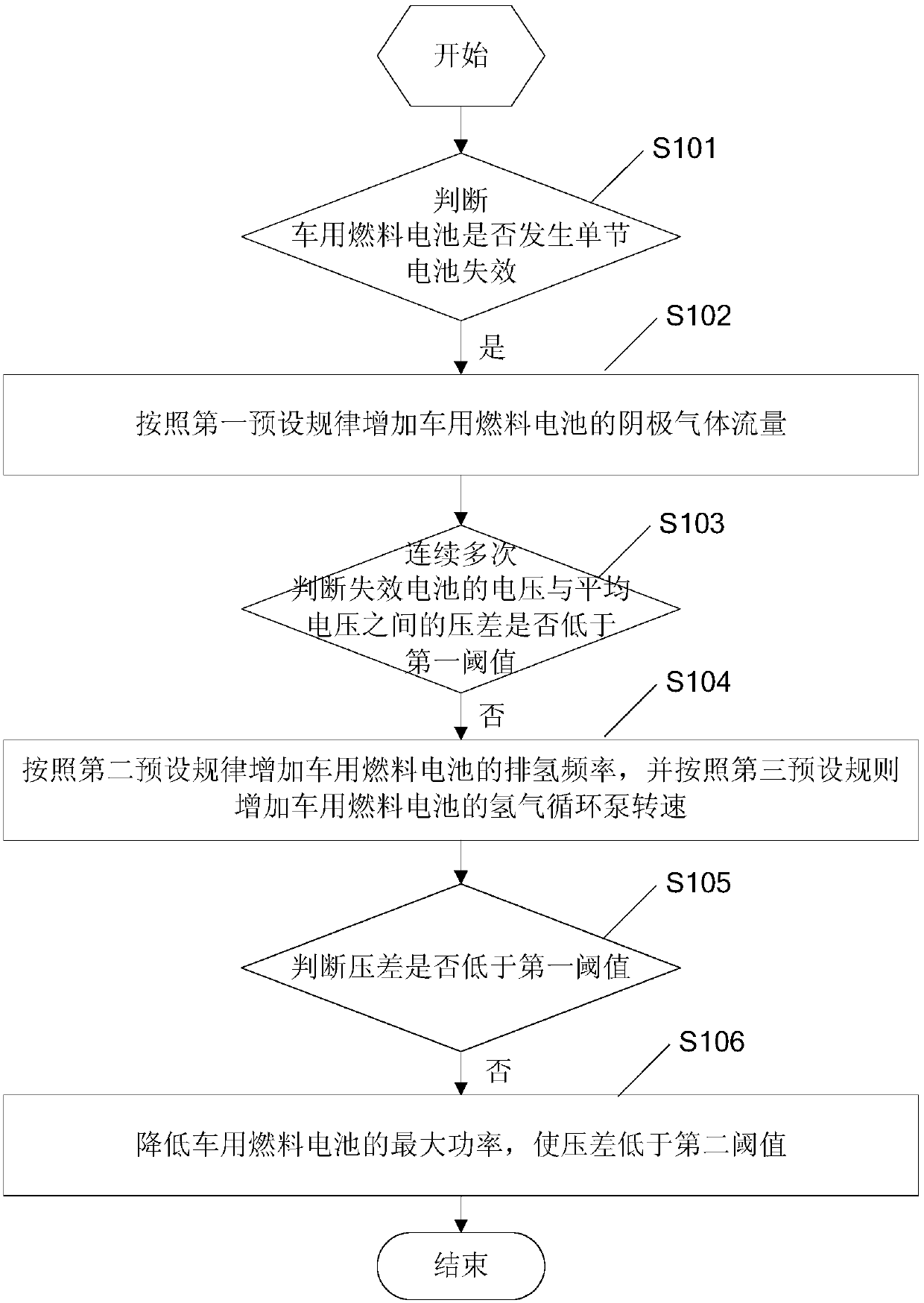

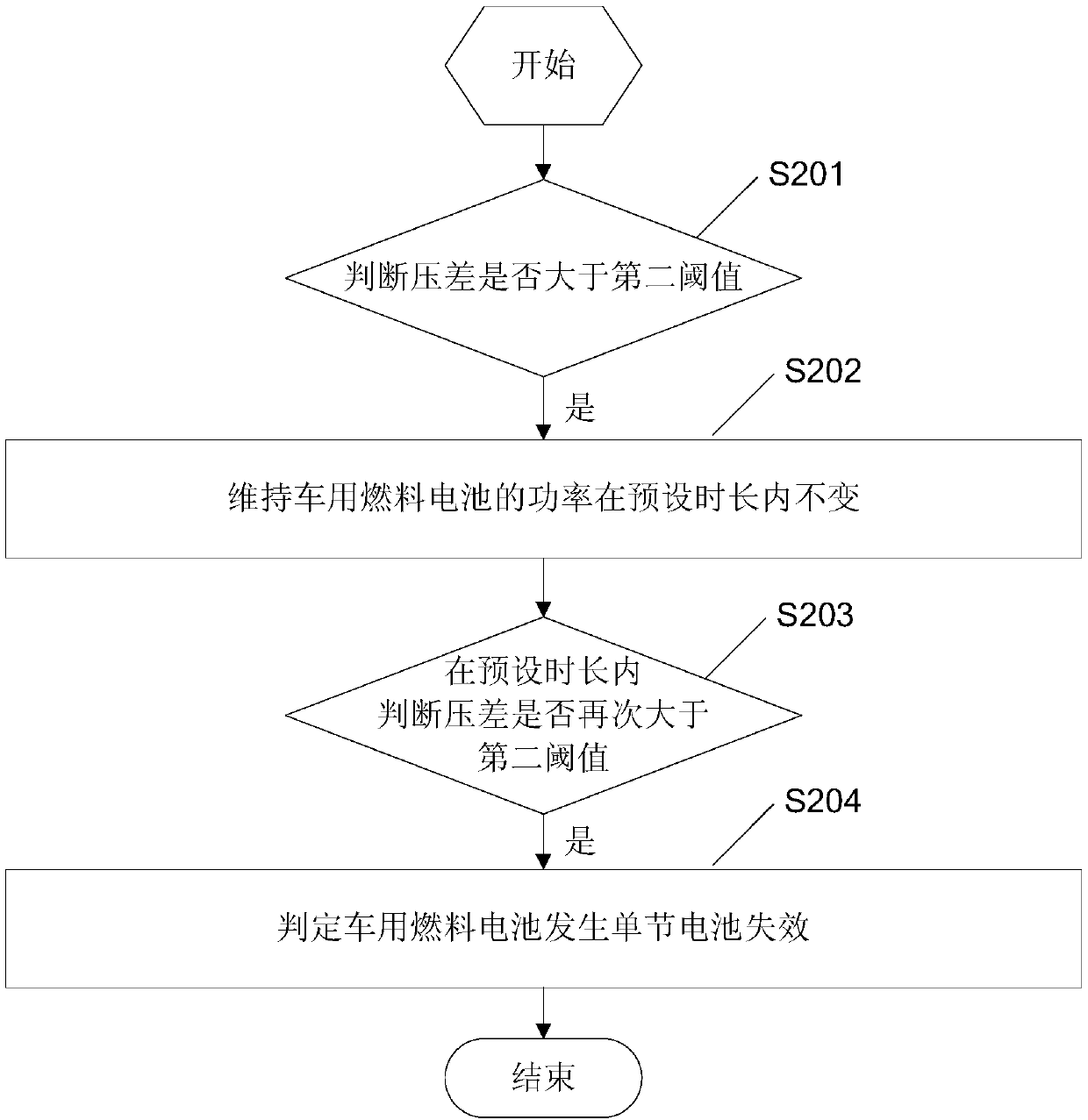

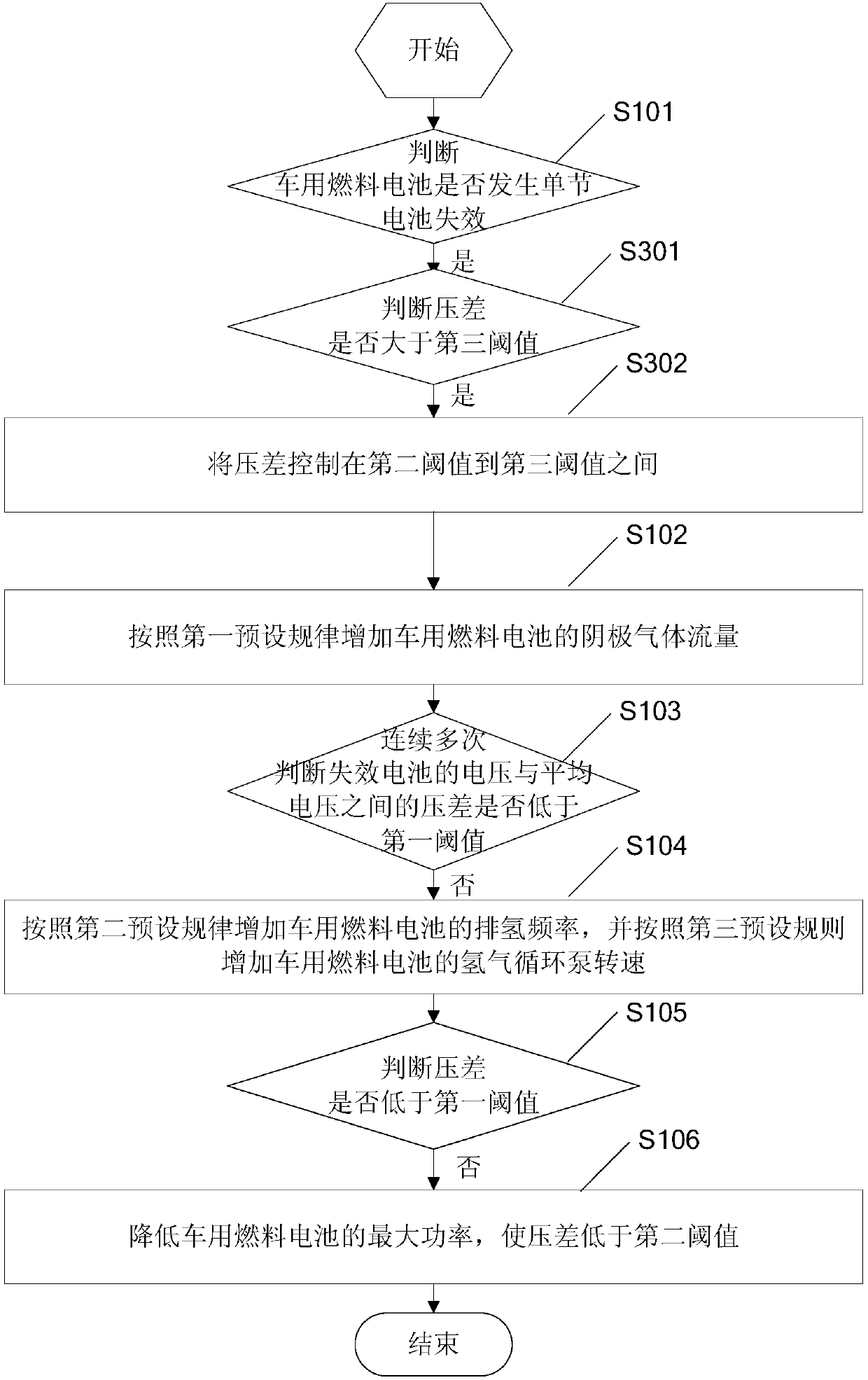

Single battery failure control method for vehicle fuel cell and controller

ActiveCN109638320AMaintain uniformityNo loss of vehicle powerMotive system fuel cellsEngineeringCirculating pump

The invention provides a single-cell failure control method for a vehicle fuel cell and a controller. By increasing the gas flow, the hydrogen discharging frequency and the rotating speed of the hydrogen circulating pump, the voltage of the failure battery can be recovered in time as much as possible, and if the voltage of the failure battery cannot be recovered in time, the differential voltage between the voltage of the failure battery and the average voltage of the vehicle fuel cell can be controlled to be lower than a second threshold value at least. According to the method, by keeping theuniformity of the fuel cell stack, the influence on the service life of the fuel cell stack caused by too low voltage of a failure cell is prevented, and the fuel cell stack can continue to operate reliably without losing the power of the whole vehicle.

Owner:SHANGHAI HYDROGEN PROPULSION TECH CO LTD

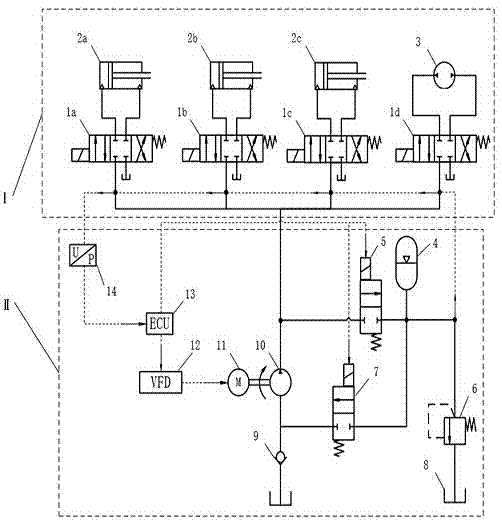

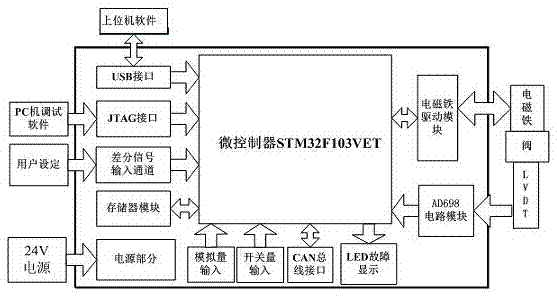

Quick response power system for engineering machinery

ActiveCN105442658AReduce maximum powerReduce noiseSoil-shifting machines/dredgersPower control systemHydraulic pump

The invention belongs to the technical field of power control systems for engineering machinery, and discloses a quick response power system for the engineering machinery. The quick response power system comprises an executing mechanism and a power quick response unit; the executing mechanism is composed of an oil cylinder, a work hydraulic pump, three three-position four-way reversing valves and three hydraulic cylinders; the power quick response unit is composed of an energy accumulator, a first solenoid reversing valve, a safety valve, a second solenoid reversing valve, an oil cylinder, a one-way valve, a power hydraulic pump, an electromotor, a motor frequency converter, a control unit and a pressure sensor. According to the invention, the rotation speed of the hydraulic pumps can be timely, quickly and efficiently regulated according to the specific change conditions of the pressure of hydraulic components, the energy utilization rate can be increased, and the rated power provided by a hydraulic machinery power system, namely the rated power of the electromotor can be lowered.

Owner:山西华固天成建筑工程有限公司

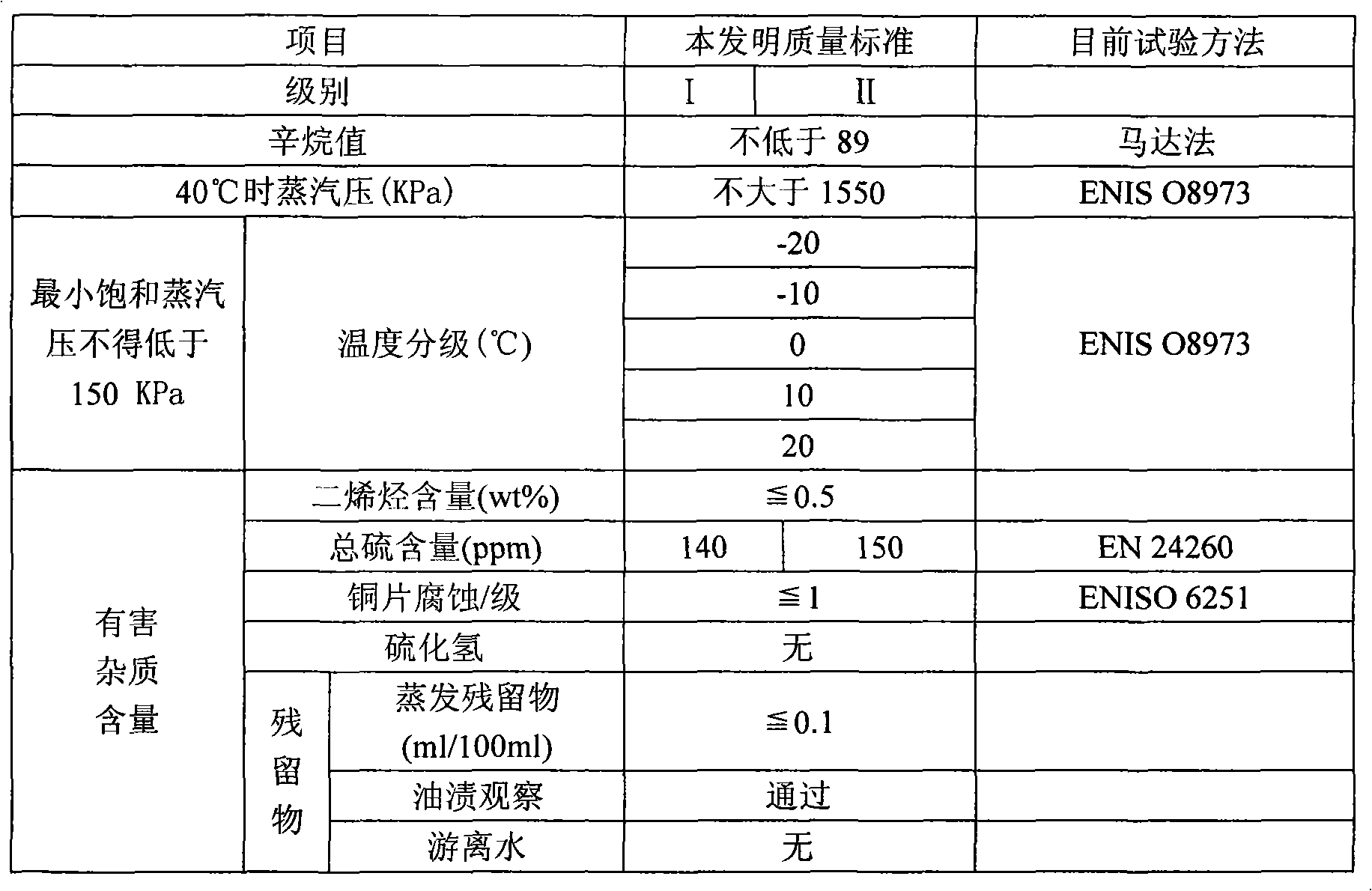

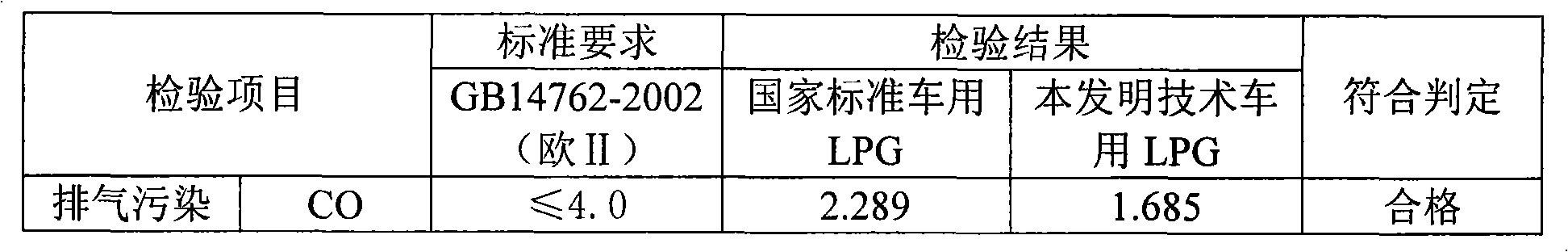

Vehicular liquefied petroleum gas containing low-propane and high-olefin, and preparation device and technique thereof

ActiveCN101260332AReduce maximum powerIncreased minimum gas consumptionGaseous fuelsLiquefied petroleum gasCombustion

The invention provides automotive liquefied petroleum gas with low propane content and high olefin content, a preparation device and a process thereof. After liquefied petroleum gas undergoes a purification treatment to remove element sulfur, polysulfide, mechanical purities, water and oil stain in the liquefied petroleum gas, a substance which does not change the chemical property and the combustion property of the liquefied petroleum gas and can increase the pressure of the liquefied petroleum gas is added under the hermetic condition to increase the pressure between 0.2 and 0.5MPa. After the liquefied petroleum gas with low propane content and high olefin content is refined, the problem of automobile fuel consumption can be solved. The automotive liquefied petroleum gas solves the problem that the popularization and application of the automotive liquefied petroleum gas are affected and limited due to the shortage of national propane resources from the resource structure.

Owner:殷乃勋 +1

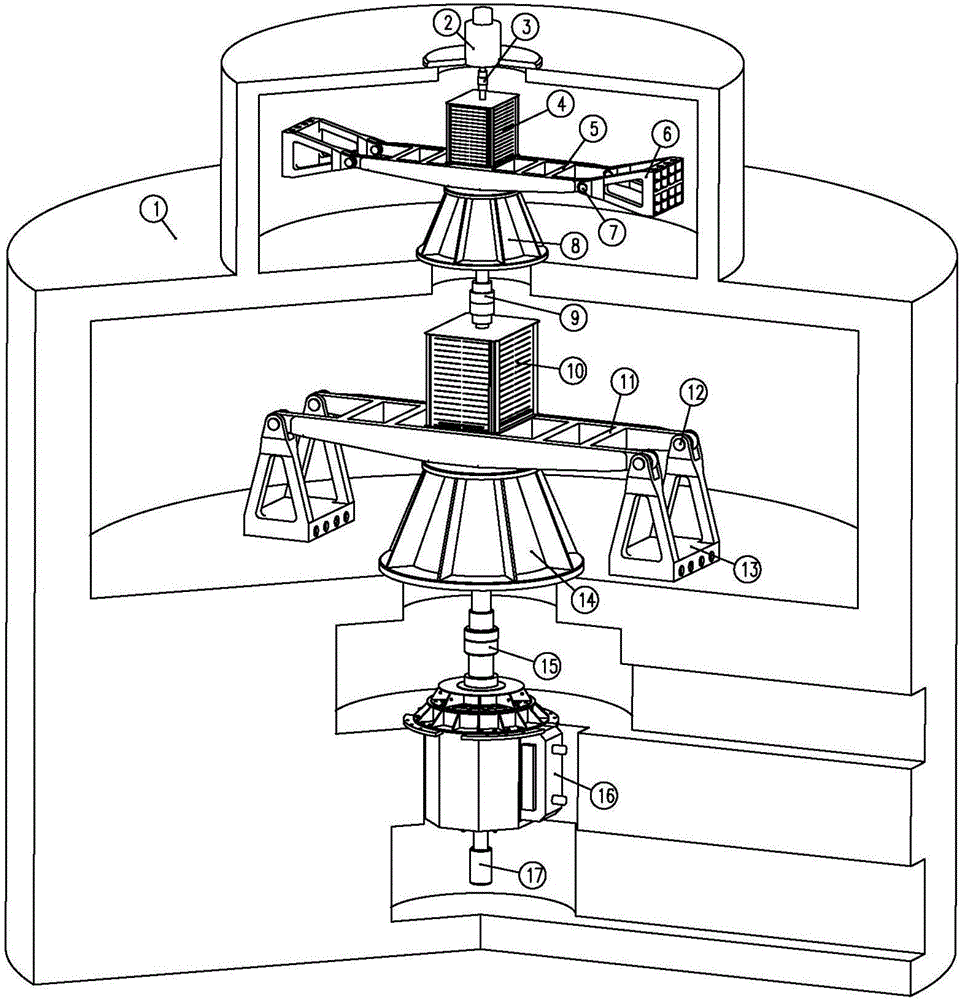

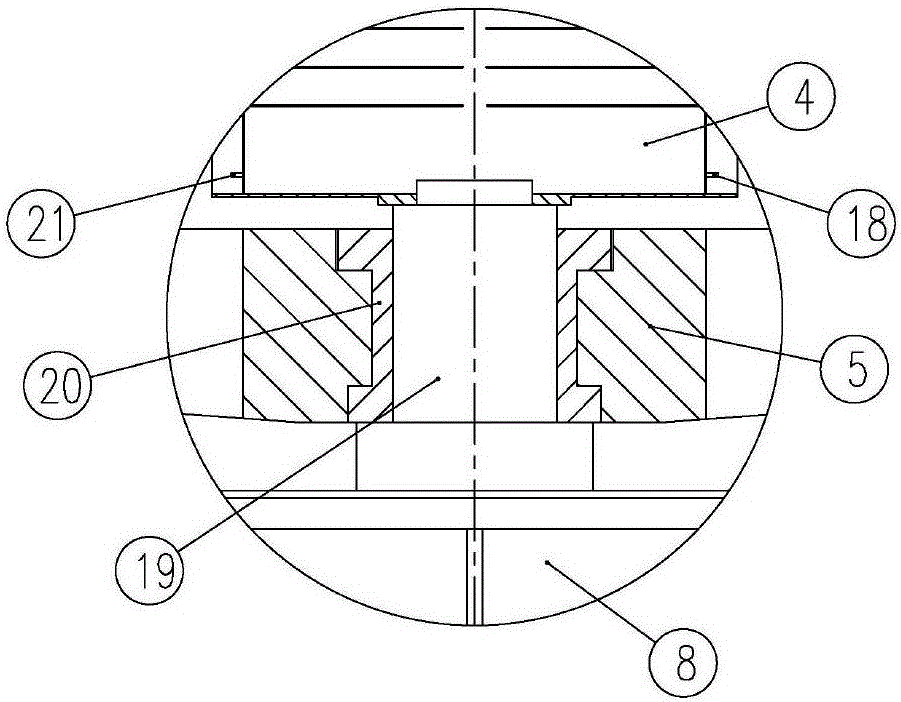

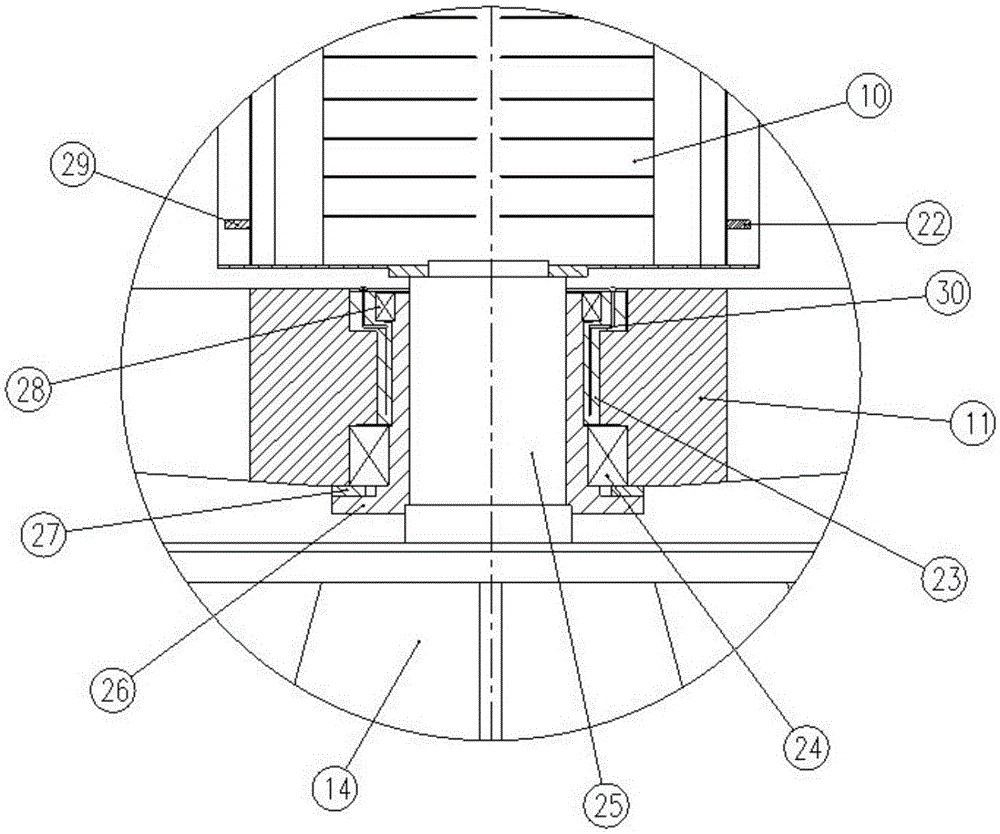

Extra-large type geotechnical centrifuge loading separable design

ActiveCN106493003AMeet the use requirementsGuaranteed separation effectCentrifugesElectric machineEngineering

The invention discloses an extra-large type geotechnical centrifuge loading separable design. The extra-large type geotechnical centrifuge loading separable design adopts two engine bases; a high-speed bearing is adopted by the small engine base to meet the demands of high rotation speed and a big g value; and a low-speed heavy loading bearing is adopted by the big engine base to meet the demands of low speed and heavy loading, so that the separation of high speed and heavy loading is realized. Two rotating arms are mounted on a main shaft system of the same driving motor; and the two rotating arms are linked with each other through a hydraulic pressure linking device, so that time-sharing work or simultaneous work of the two rotating arms is realized. Instrument cabins are mounted on main shafts and each instrument cabin is not in contact with each rotating arm; break-make and supply of fluid, signals and a power source are achieved just through pipe connectors and cable connectors; and connecting or disconnecting is guaranteed according to the experiment need, so that separation and fastening of each rotating arm relative to the main shafts are realized. One driving motor is adopted, under the working conditions of full loading of the big rotating arm in low speed and heavy loading and full loading of the small rotating arm in high speed and light loading, motor power needed by the big rotating arm and the small rotating arm is consistent, ability of the motor is brought into full play, the maximum power of the motor is reduced, and developing and using cost is reduced.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

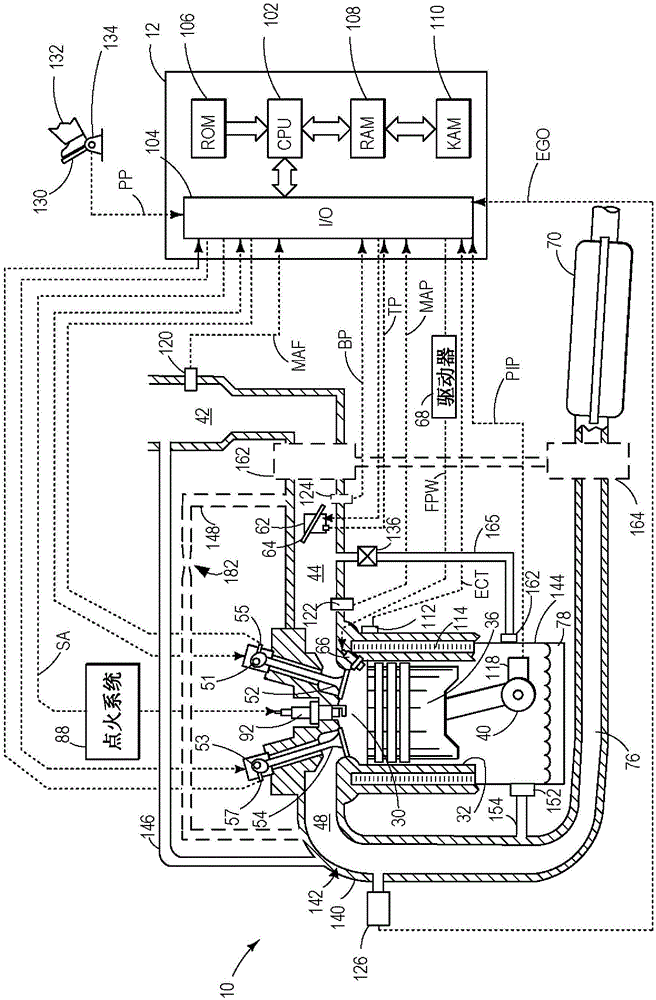

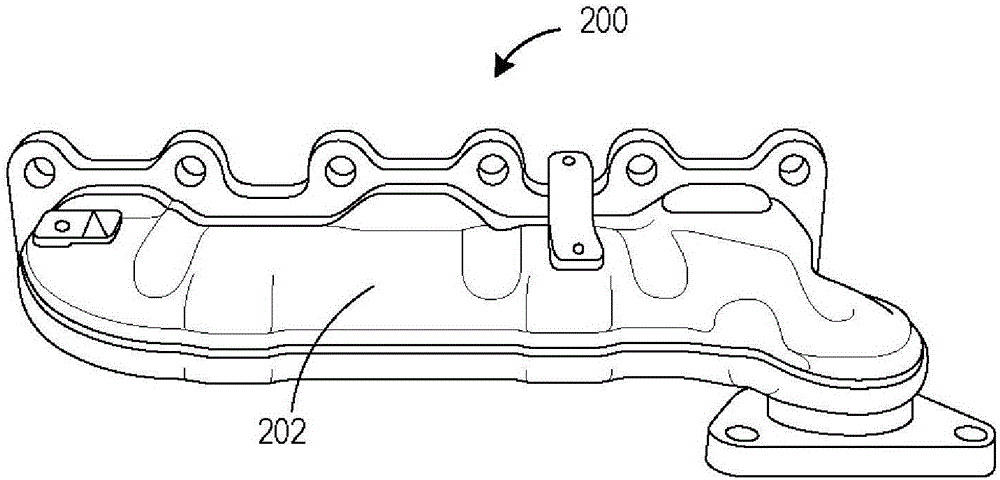

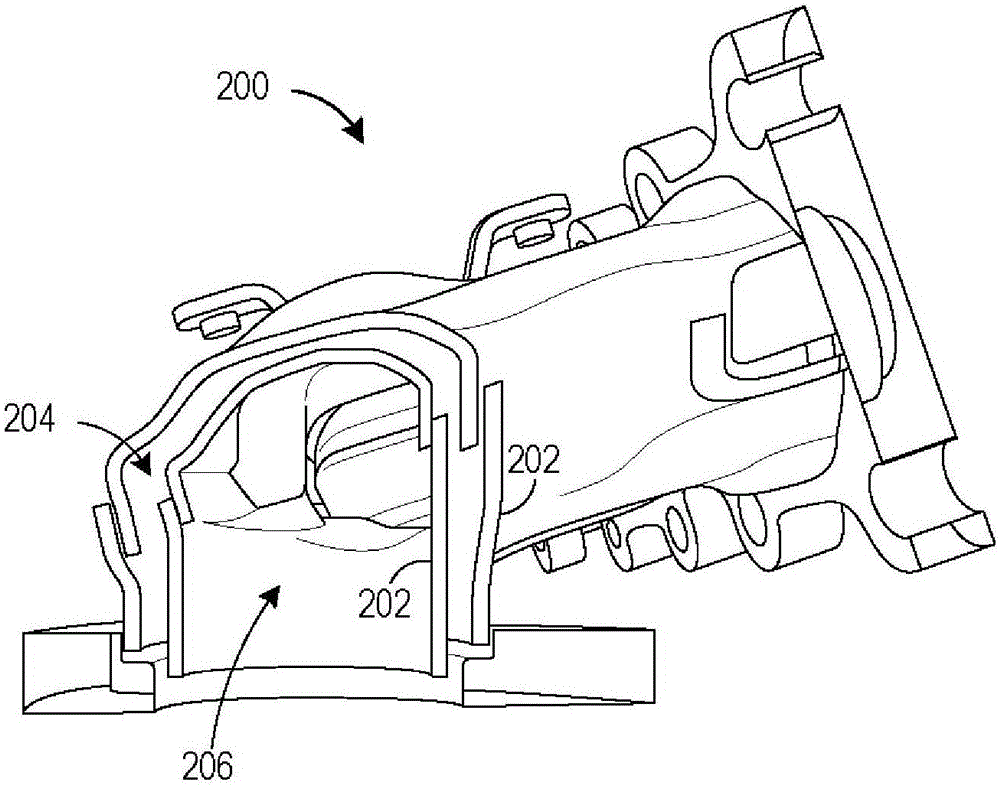

Method and system for expediting engine warm-up

ActiveCN105257436AReduce maximum powerEasy to separateElectrical controlInternal combustion piston enginesCrankcaseThrottle

The invention relates to a METHOD AND SYSTEM FOR EXPEDITING ENGINE WARM-UP. Methods and systems are provided for improving crankcase ventilation by directing heated air to a crankcase. Air is drawn into the crankcase upon passage through an interstitial space of a double walled exhaust manifold where it is heated. Crankcase vapors are then released to the engine intake, downstream of an intake throttle.

Owner:FORD GLOBAL TECH LLC

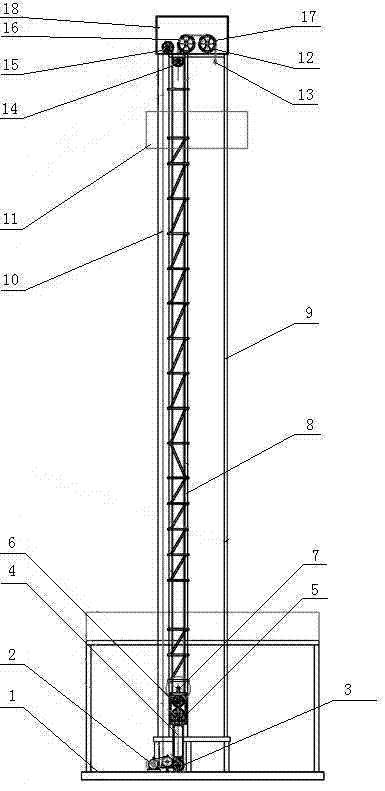

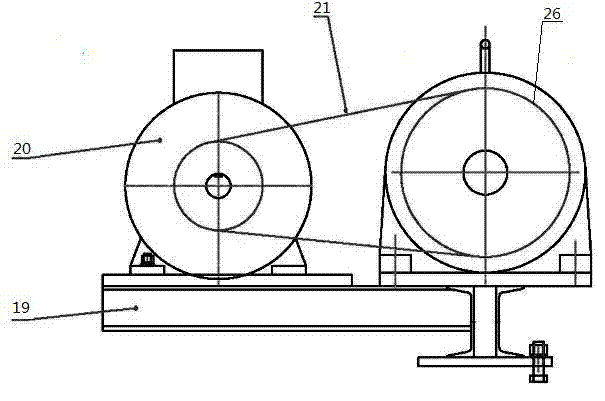

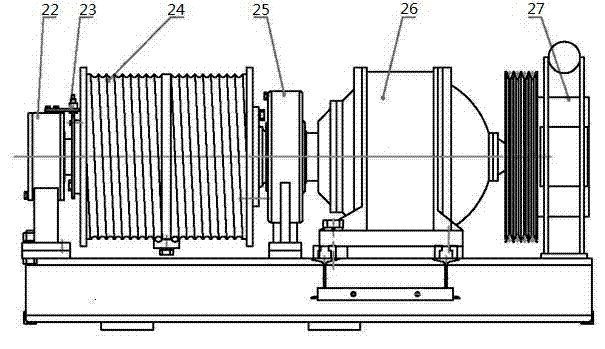

Pulley drive balance type lifting system for drilling machine

InactiveCN102765669AReduce maximum powerWith clipping effectLoad-engaging elementsCranesUltimate tensile strengthIndustrial engineering

The invention relates to oil development equipment, in particular to a pulley drive balance type lifting system for a drilling machine in the mechanical field of drilling machines. According to the pulley drive balance type lifting system for the drilling machine, hook load is balanced by a balancing box so as to reduce the maximum driving force based on a pulley drive principle. The pulley drive balance type lifting system for the drilling machine has the advantages that 1) energy is saved, and the maximum power can be reduced; the maximum drive power can be reduced effectively by a balance mode according to a movable pulley drive principle; theoretically, under the conditions of the same hook load and the same lifting speed, compared with the conventional drilling machine, the pulley drive balance type lifting system has the advantages that the maximum power can be reduced by 50 percent, and the system has obvious effects of clipping peaks and saving energy; 2) the labor intensity of operation staff can be reduced; and the balancing box has the function of an elevator type load box, so that operation staff can be lifted on a derrick of the drilling machine conveniently, and objects such as tools can be conveyed conveniently.

Owner:SHENGLI OIL FIELD HIGHLAND GASOLINEEUM EQUIP

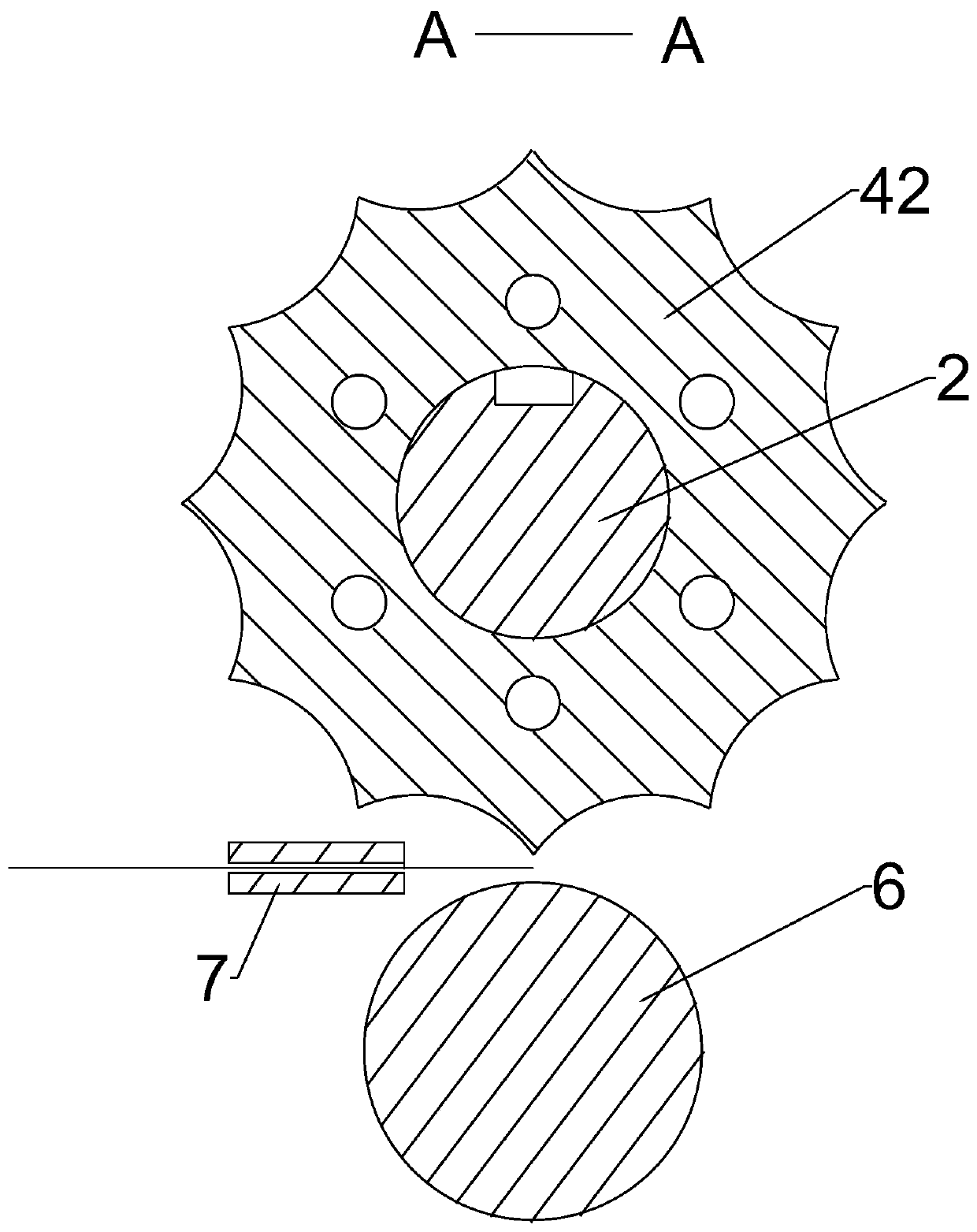

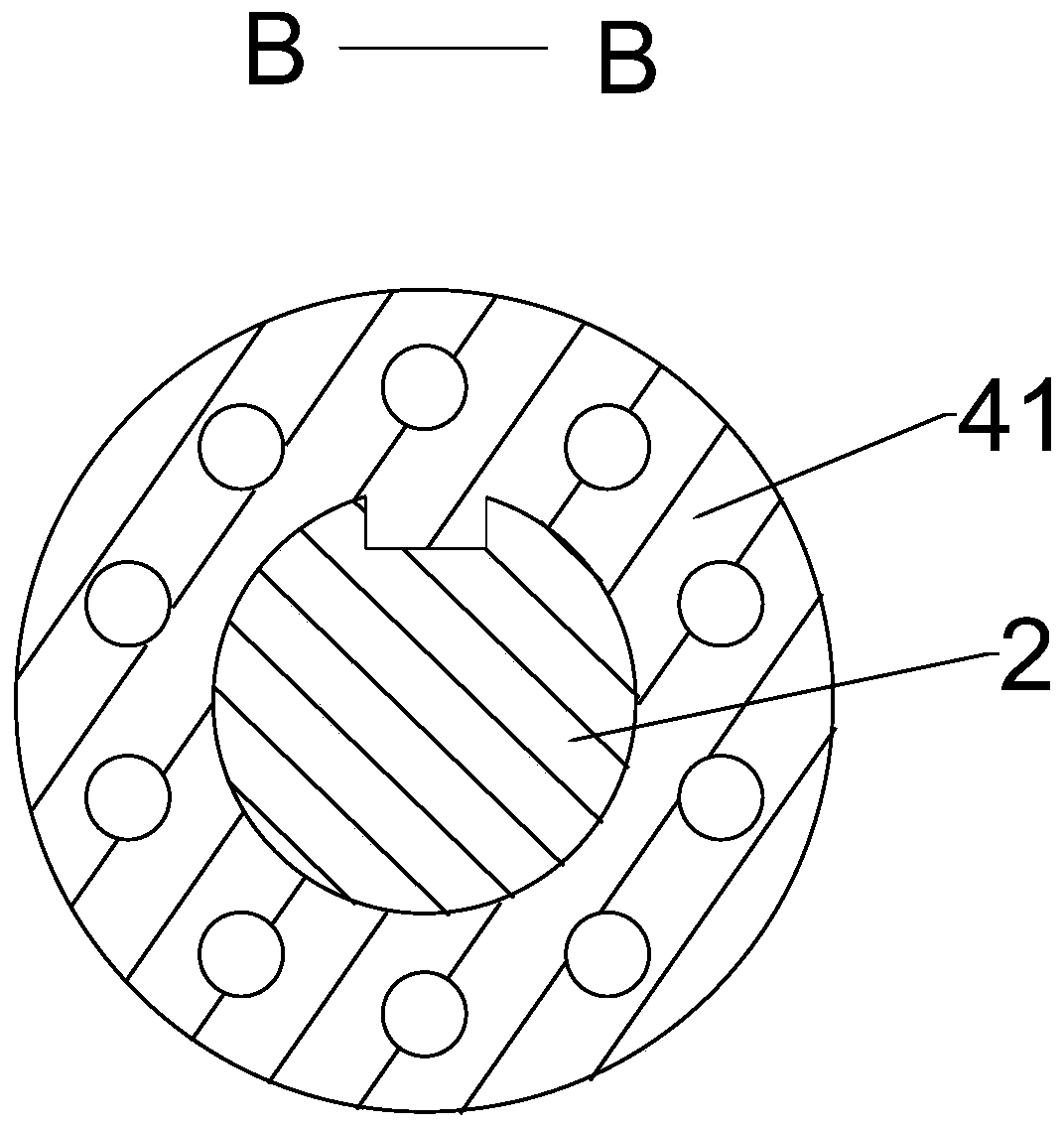

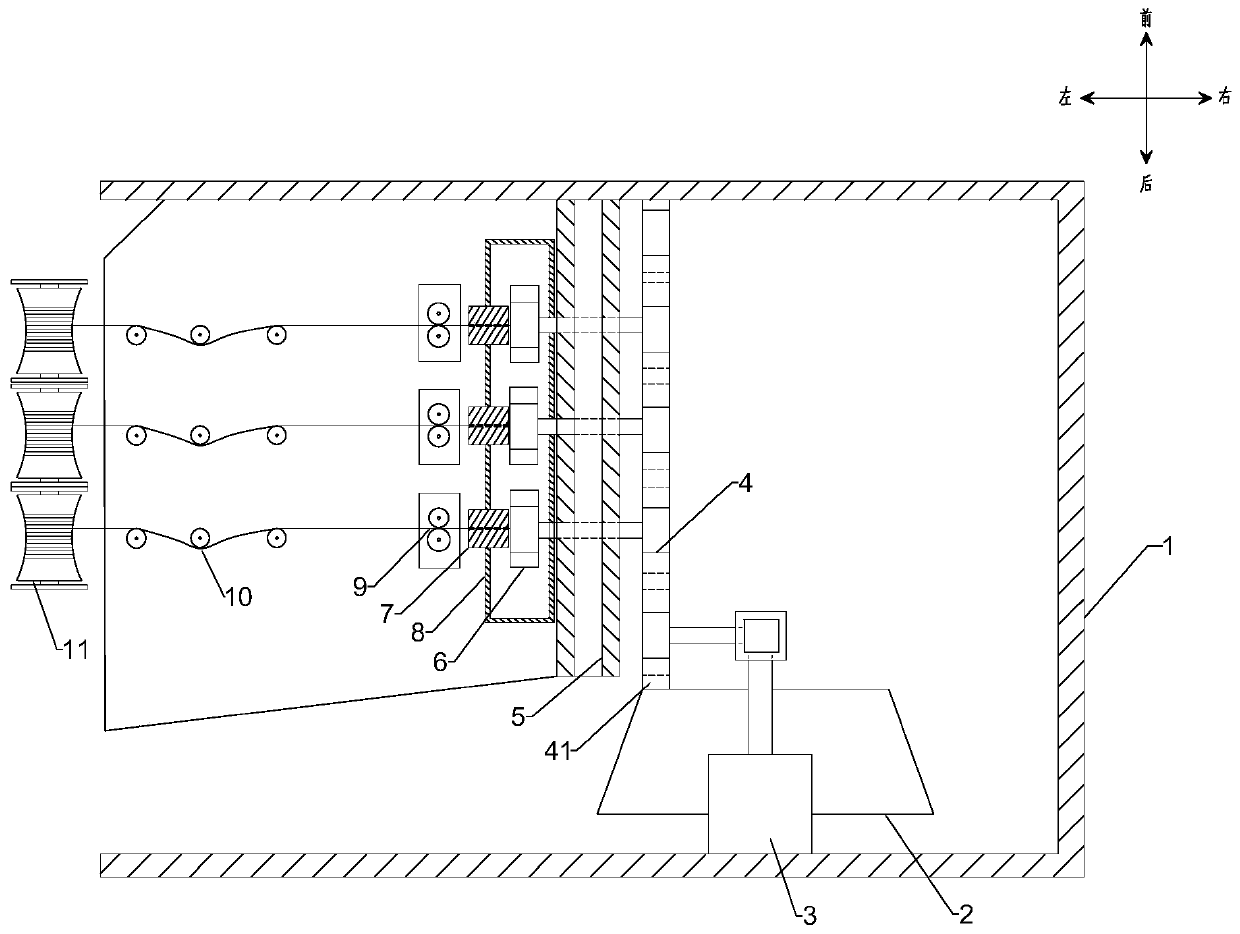

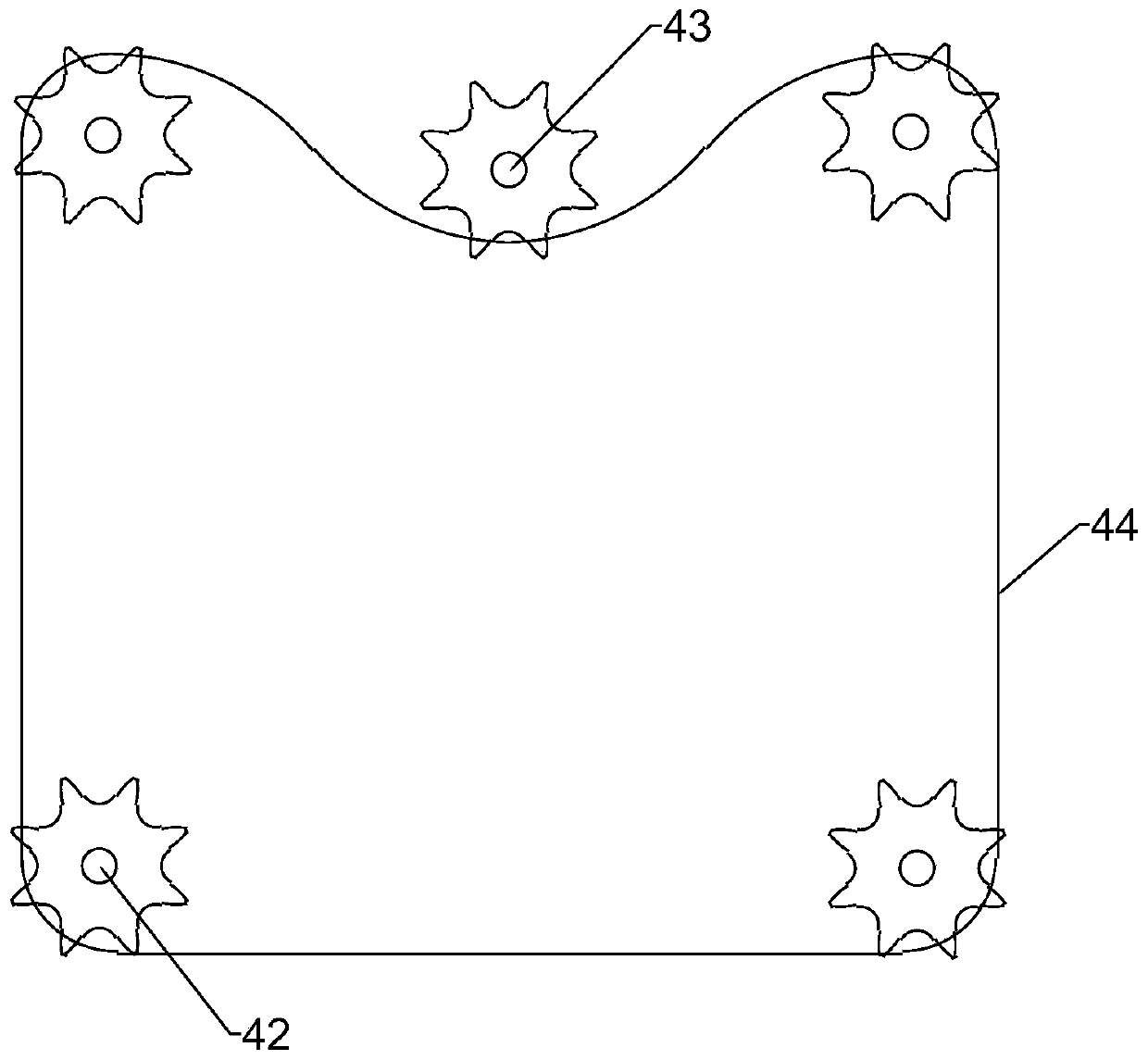

Cutting roller group of steel cut wire shot equipment

The invention relates to the field of metal abrasive processing, in particular to a cutting roller group of steel cut wire shot equipment. The cutting roller group includes a supporting frame, a rotating shaft, a motor, a plurality of cutting device, threaded sleeves, a pressure-bearing roller and an orientation column; the rotating shaft is arranged on the upper part of the supporting frame, oneend of the rotating shaft penetrates through a through hole of the supporting frame and is connected to the motor, the pressure-bearing roller is arranged on the lower part of the supporting frame, the cutting devices are arranged in a linear shape, each cutting device rotates on the self-axis at a certain angle relative to the previous cutting device to be installed on the rotating shaft, the threaded sleeves are arranged on threads at the two ends of the rotating shaft, and the orientation column is arranged on the front of the supporting frame. The cutting devices are arranged on the same rotating shaft, the centralized one-time cutting of a steel wire is turned into single scattered cutting, the time for cutting the steel wire is divided, the use efficiency of the motor is improved, and meanwhile, the impact of a cutting tool cutting the steel wire is reduced and uniform, so that the failure rate of the cutting devices is reduced.

Owner:王认认

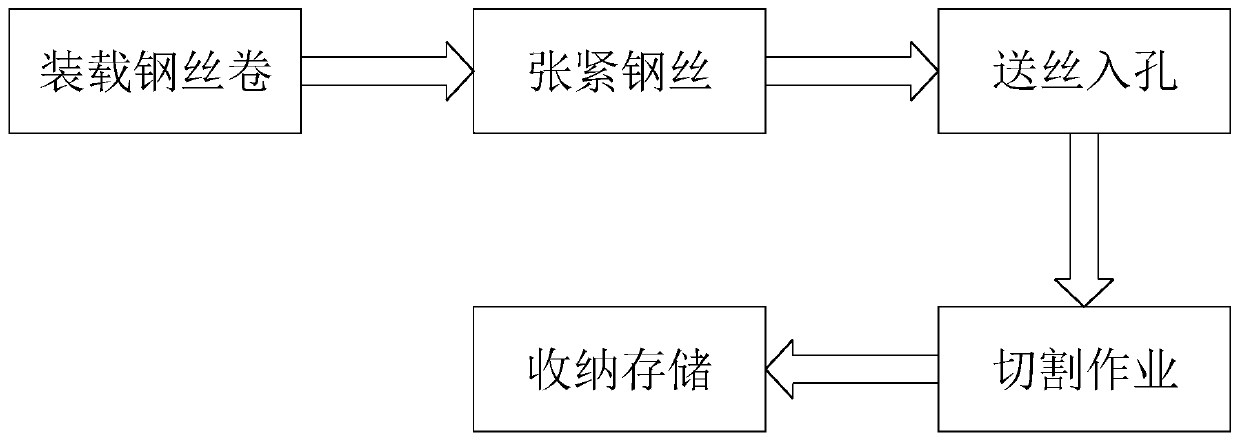

Metal abrasive processing technology

The invention relates to the processing field of metal abrasive, in particular to a metal abrasive processing technology. A device for realizing the metal abrasive processing technology comprises a housing, a base, an electric motor, a transmitting device, a supporting plate, rotary cutters, cutting platforms, a pill loading box, wire transporting devices, tensioning wheels and wire supporting wheels, wherein the base is arranged in the housing; the electric motor is mounted on the base; the transmitting device is arranged on the base; each rotary cutter penetrates through a corresponding through hole in the supporting plate to be linked to a corresponding chain wheel of the transmitting device; and a steel wire on each wire supplying wheel sequentially penetrates through the correspondingtensioning wheel, the corresponding wire transporting device and the corresponding cutting platform. According to the metal abrasive processing technology disclosed by the invention, the rotary cutters are arranged, so that integrated one-time cutting of steel wires is replaced by single repeated dispersing cutting, so that time for cutting the steel wires by the rotary cutters is dispersed, thepower of the electric motor is effectively used, impact vibration to the cutters is small, the structural stability of the movable connecting parts of the cutters is improved, and the failure rate isreduced.

Owner:王认认

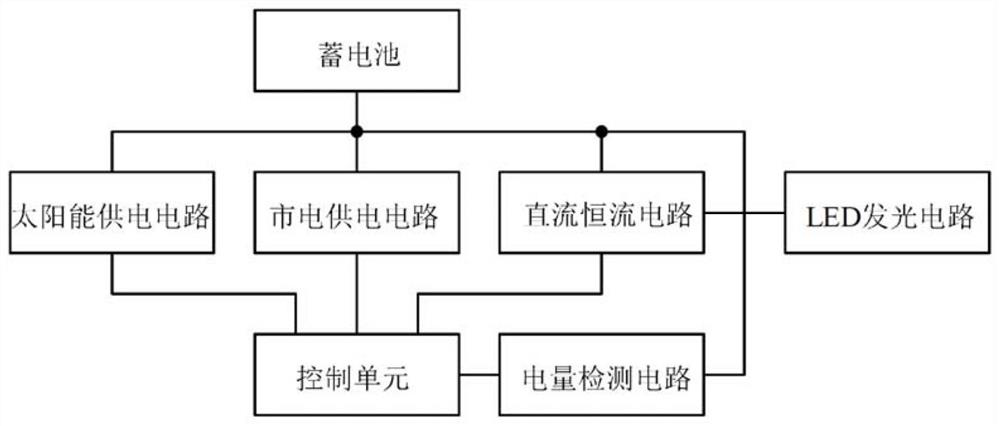

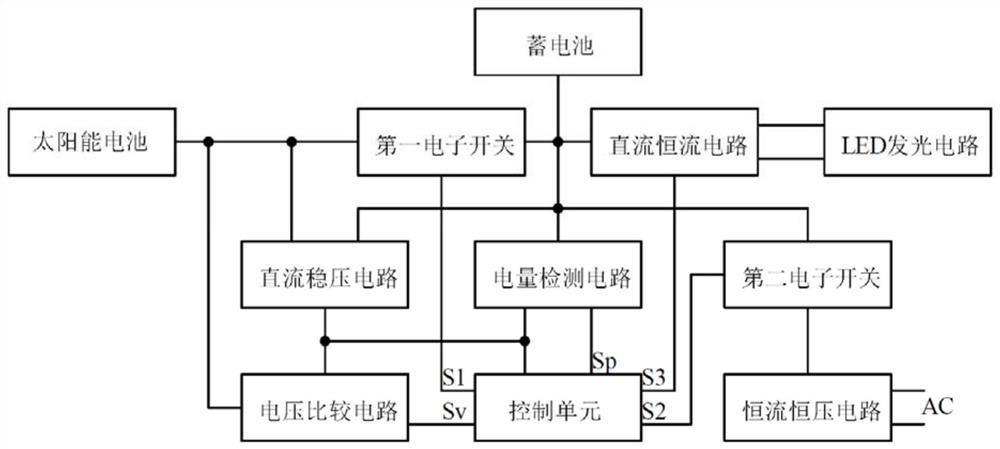

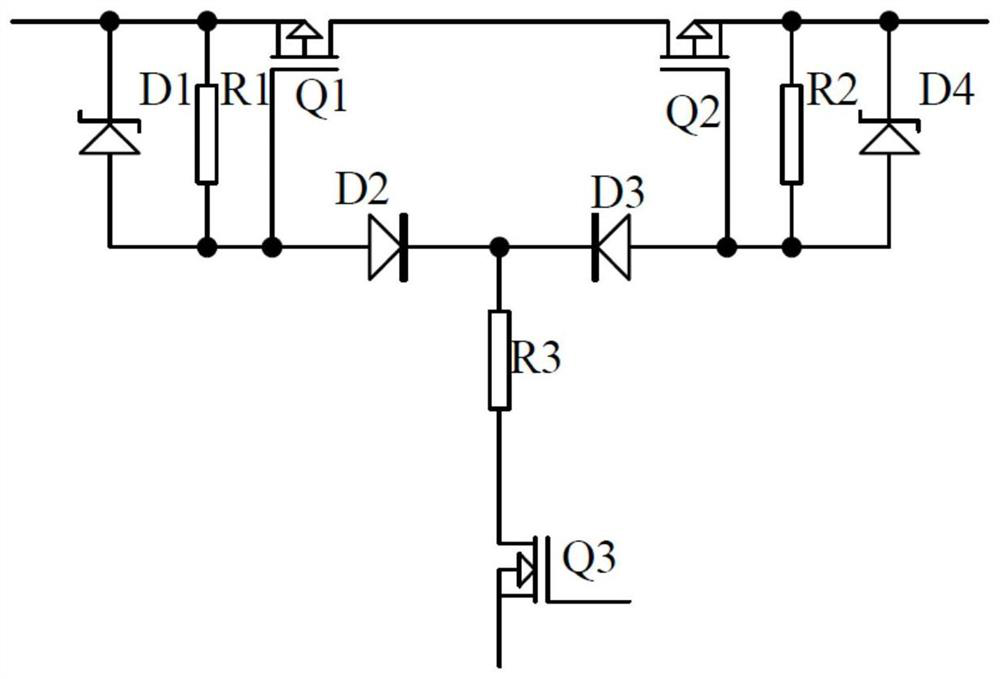

Control method and circuit for solar LED lamp with supplementary power supply by mains supply

InactiveCN112886660AThere will be no power outageReduce maximum powerCircuit monitoring/indicationEnergy saving control techniquesBattery chargeEngineering

Owner:浙江阳光照明灯具有限公司 +1

Friction-type anti-loosening structure of underwater clamp connector

The invention provides a frictional anti-loosening structure of an underwater clamp connector, which includes a clamping hand, a clamping plate, a clamping rotary block, a threaded rod, a threaded sleeve, a twist joint, a guide plate, and a pressure plate. There is knurling on the contact surface between the hand and the clamp connector, which can increase the friction coefficient between the hand and the bolt. The circumferential and axial movement of the threaded sleeve can ensure the linear movement of the threaded rod; when the threaded sleeve and the threaded rod are rusted and cannot be unscrewed, the remote control robot carries the manipulator to axially pull the threaded rod out from the side of the shell plate pressure plate , where the pressure plate acts as a limiter, which can pull the pressure plate off to ensure that the locking device and the pull-in bolt can be separated; the function of the guide plate is to limit the rotation of the card hand; the twist joint is equipped with an interface combined with a torque wrench, and is carried by ROV The torque wrench realizes the rotation of the threaded rod, thereby providing the pressure to clamp the hand and pull the bolt closer, and finally achieve the purpose of anti-loosening.

Owner:HARBIN ENG UNIV

Method and apparatus for SAR fallback in power headroom reporting

Uplink transmit power adjustment is provided by the mobile device receiving an uplink transmission grant from the serving base station. The mobile device determines a maximum power reduction and a SAR-related power reduction for uplink transmissions. The mobile device compares these values and adjusts the transmit power according to the SAR related power reduction in response to the SAR related power reduction exceeding the maximum power reduction. A power headroom report is generated when the determined SAR related power reduction exceeds a previous SAR related power reduction. Under various conditions, the power headroom report is sent from the mobile device to the serving base station.

Owner:QUALCOMM INC

Method and device for resource authorization

InactiveCN102869094BGuaranteed normal uploadGuaranteed to upload data normallyWireless communicationAuthorizationOperating system

The invention provides a method and a device for resource authorization. The method includes the steps: determining the size of an initial MAC-e PDU (protocol data unit) according to a scheduling request of a user terminal; acquiring capacity information of the initial MAC-e PDU; inquiring a pre-generated MAC-e PDU capacity information sheet and acquiring the minimum usable MAC-e PDU with capacity information as same as that of the initial MAC-e PDU as an authorized MAC-e PDU; including the sizes of all usable MAC-e PDUs and the capacity information of each usable MAC-e PDU in the MAC-e PDU capacity information sheet; and issuing the authorized MAC-e PDU and power authorization corresponding to the authorized MAC-e PDU to the user terminal. By the aid of the technical scheme, the power of UE (unified equipment) can be more reasonably authorized, MAC-e PDU resources can be more reasonably distributed, and waste of the MAC-e PDU resources and power resources is decreased.

Owner:TD TECH COMM TECH LTD

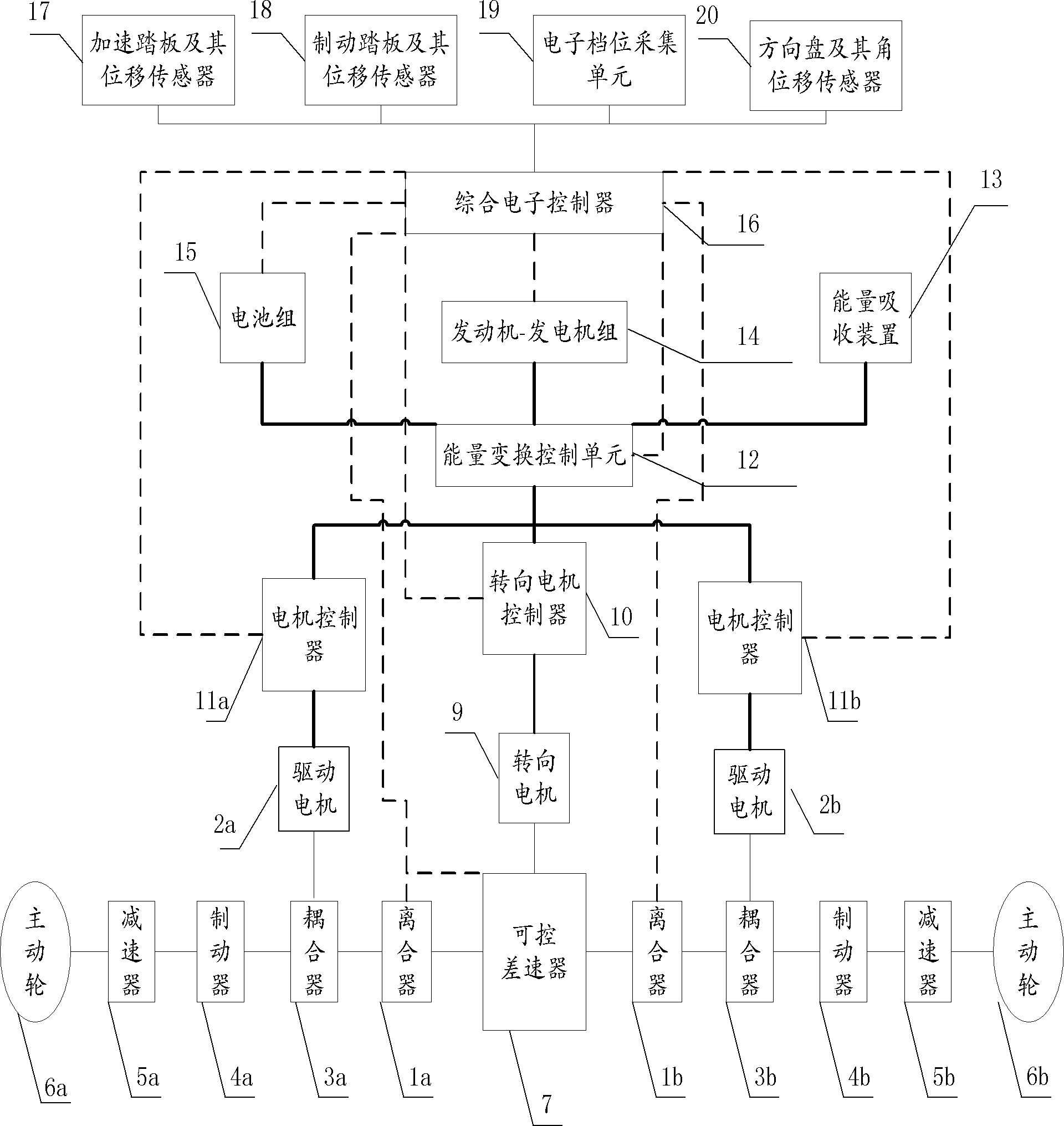

A double-sided motor-driven tracked vehicle steering system

ActiveCN102849106BReduce maximum powerGuaranteed stabilityNon-deflectable wheel steeringDrive wheelMotor drive

The invention provides a bilateral motor-drive tracked vehicle steering system which comprises a control system, a power system and a mechanical system. The mechanical system comprises a driving motor, a brake and a speed reducer, wherein the speed reducer is connected with a vehicle driving wheel. The mechanical system further comprises a steering motor controller, a steering motor, a controllable differential, a clutch and a coupler, wherein the steering motor controller, the steering motor, the controllable differential, the clutch and one input end of the coupler are connected sequentially, another input end of the coupler is connected with the driving motor, the output end of the coupler is connected with the brake, and the steering motor controller, the controllable differential and the clutch are further connected with the control system. The steering motor is arranged in the mechanical system, torque supplied by the steering motor and the driving motor is coupled through the coupler, the maximum power of the driving motor can be reduced, and the power of the driving motor is fully utilized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

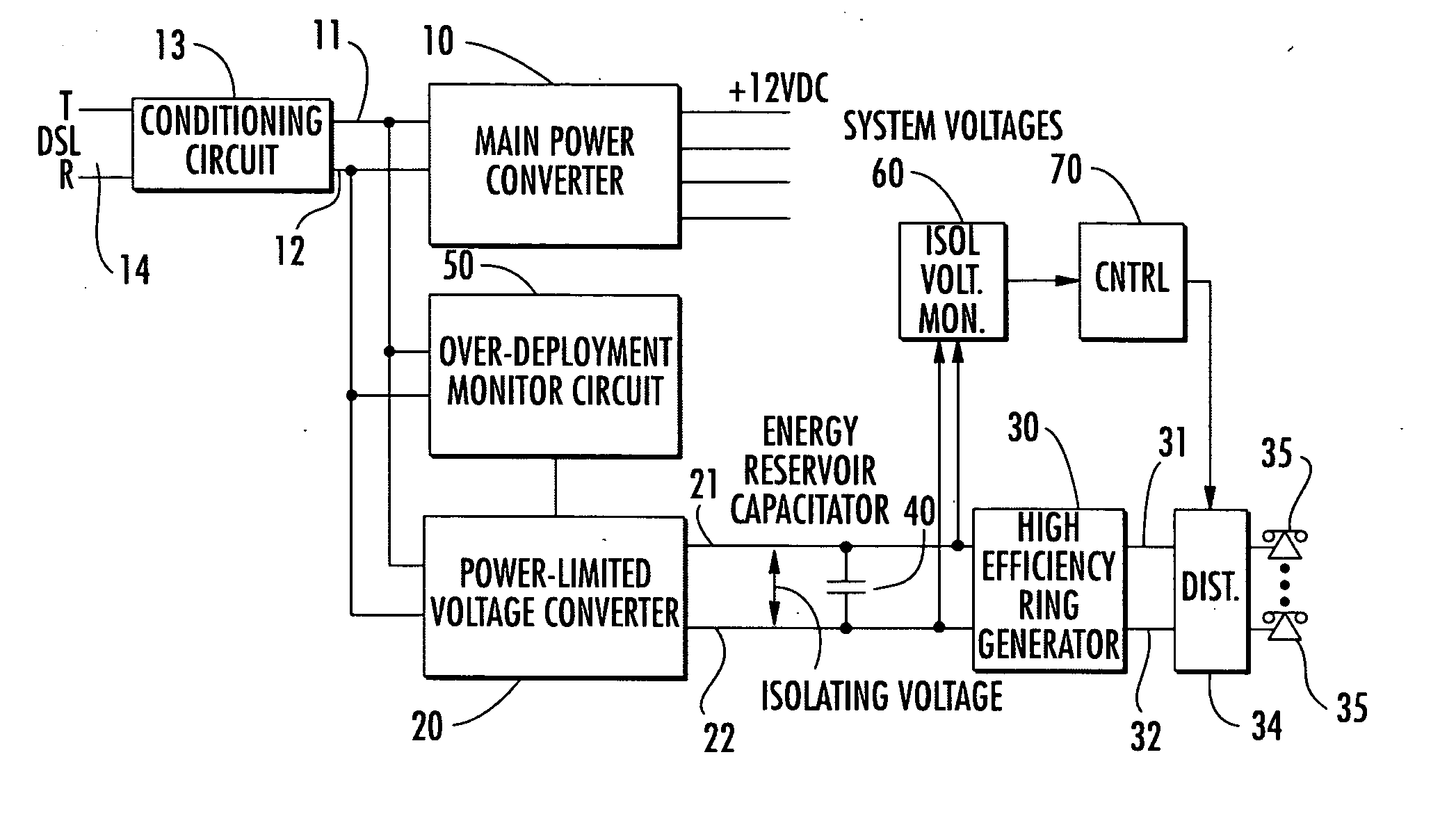

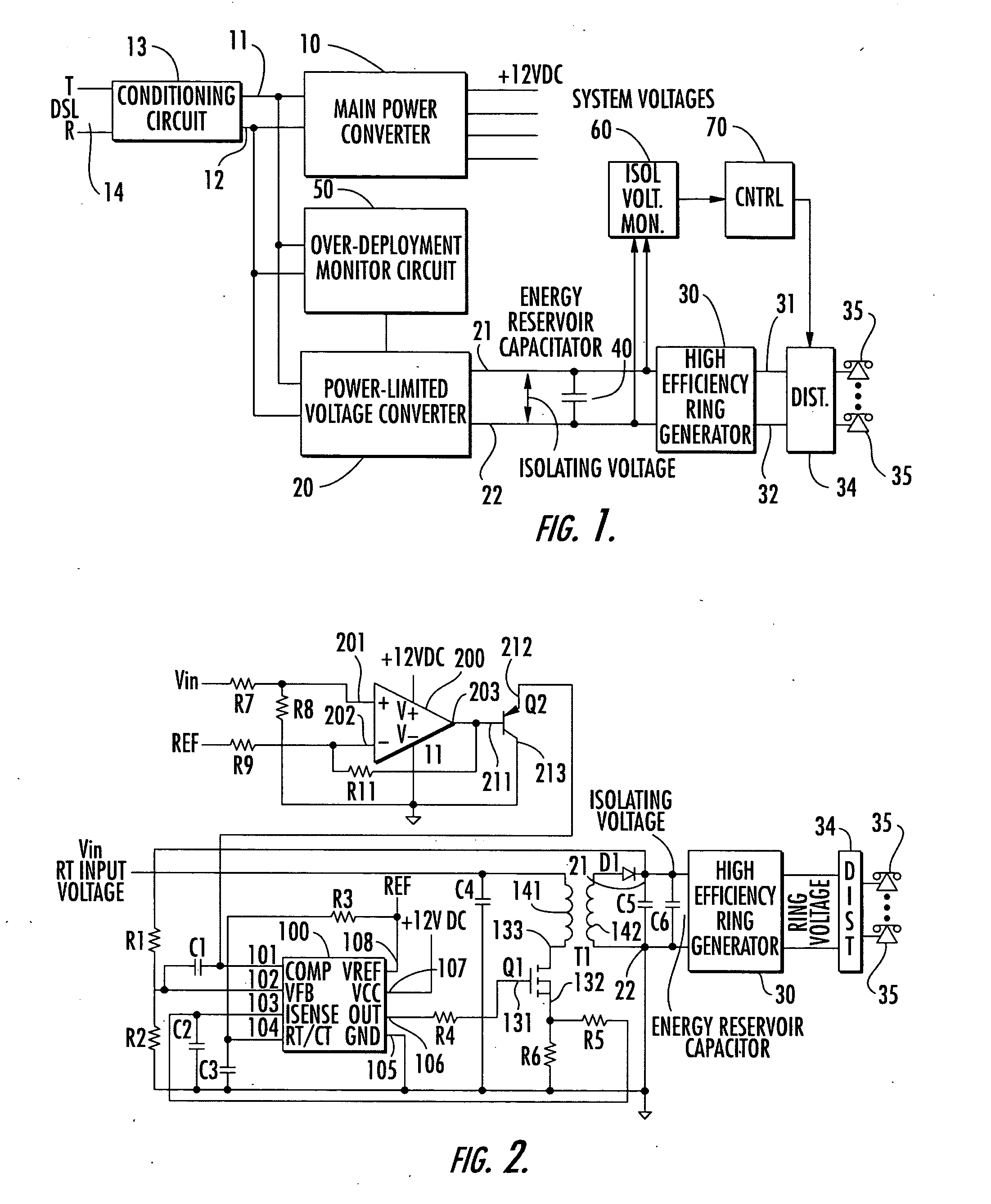

Peak power management and active decoupling arrangement for span-powered remote terminal access platforms

InactiveUS20050207184A1Reduce loadRing cadence to be reducedInterconnection arrangementsDc-dc conversionVoltage converterVoltage drop

A power management circuit for a remote access platform extracts power from a wireline for powering a ring generator that generates a ringing voltage signal that is distributed to a plurality of subscriber circuits. A power-limited voltage converter steps up the wireline voltage to a higher ‘isolating’ voltage, charging a capacitor coupled to the ring generator. A monitor circuit reduces the power that the power-limited voltage converter can draw, if the wireline voltage drops too low. This prevents the wireline voltage from collapsing should the remote terminal be deployed at a distance from wireline voltage source (the central office) greater than its specified capability.

Owner:ADTRAN

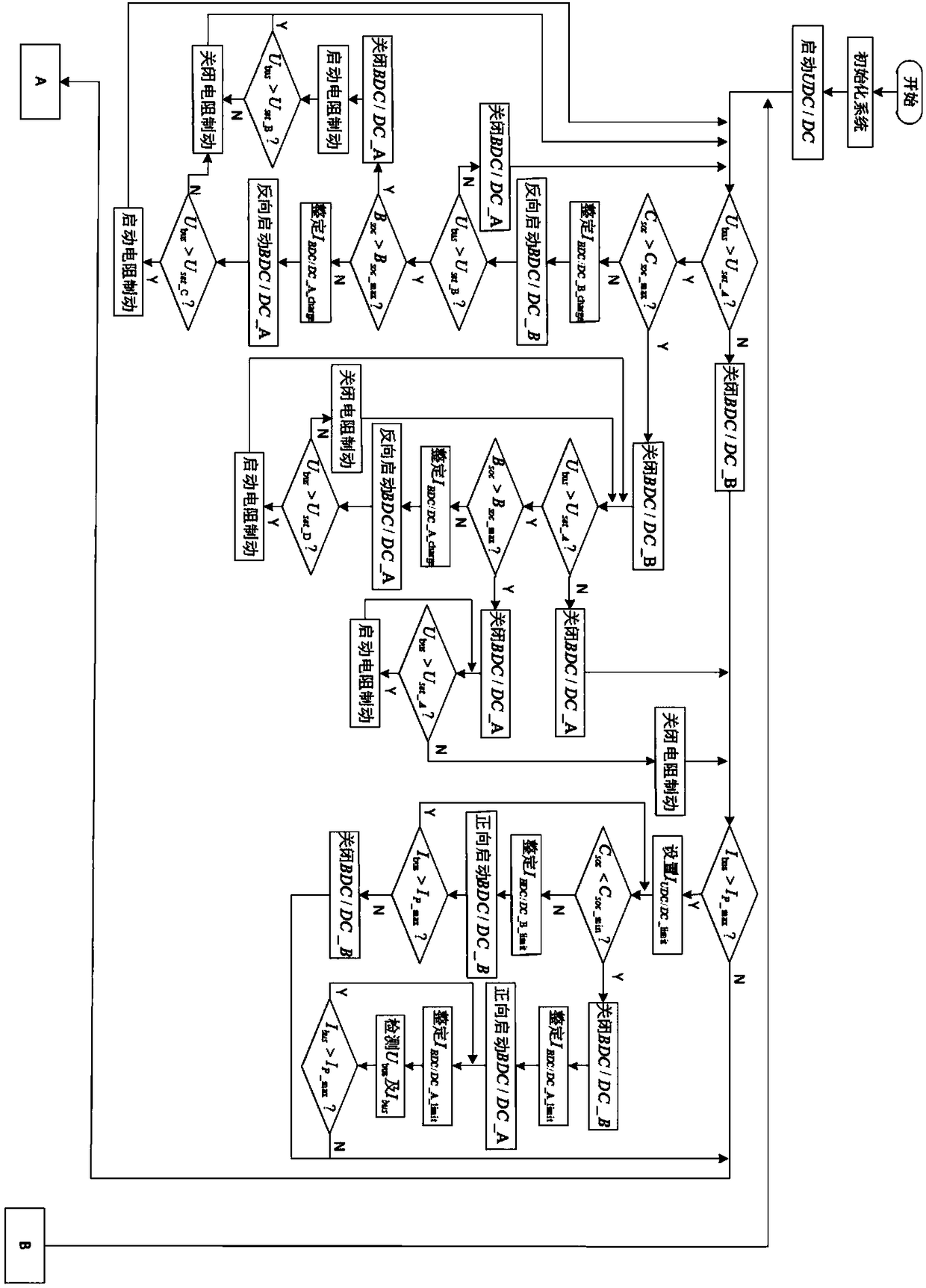

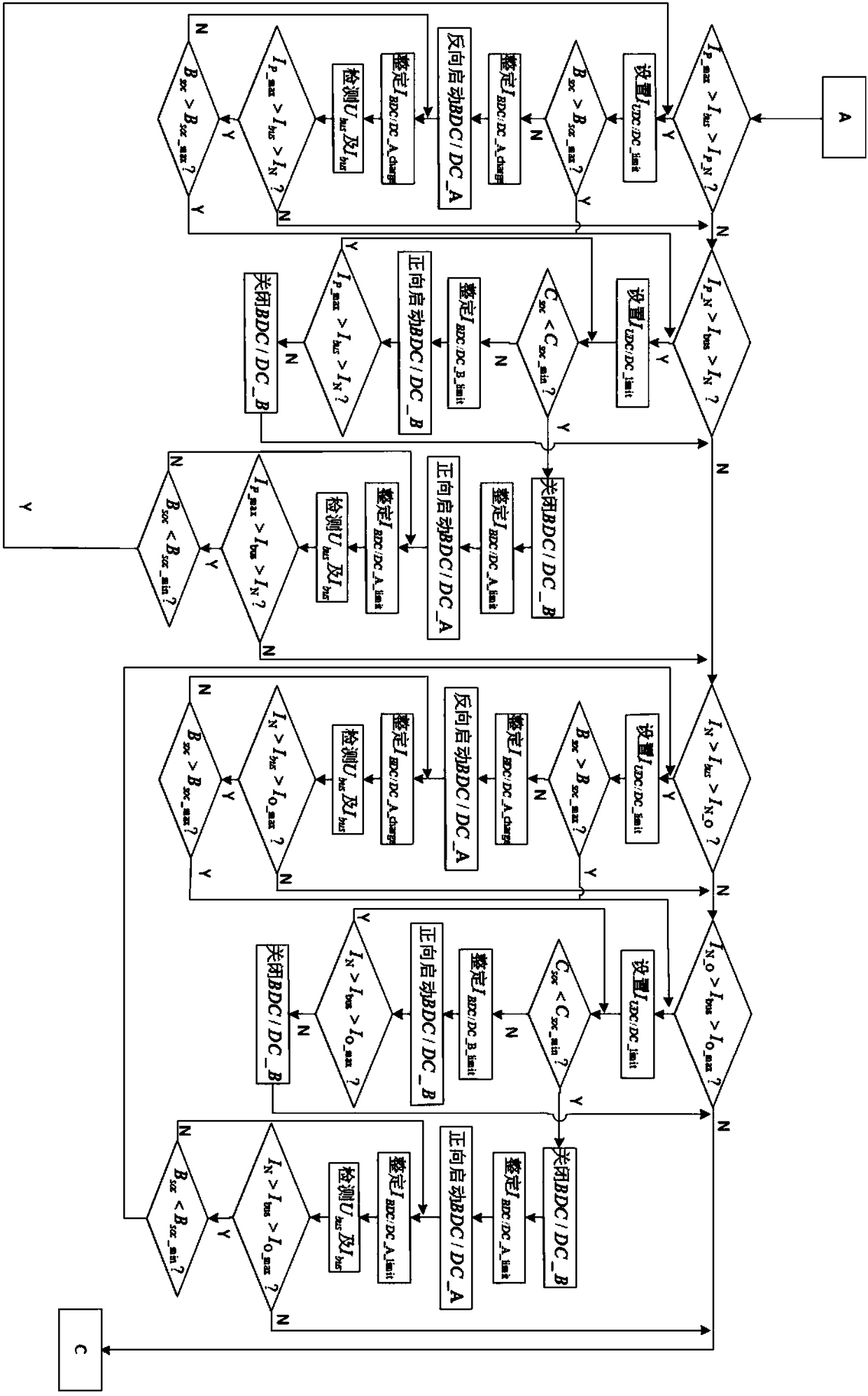

Energy management system and method for a fuel cell hybrid locomotive

ActiveCN105904976BReduce lossReduce capacityBatteries circuit arrangementsRailway vehiclesCapacitanceResistor

The invention discloses an energy management system for a fuel cell hybrid electric locomotive, which comprises a unidirectional DC / DC converter based on a DC / DC conversion module and cascaded with a fuel cell power generation system, a DC / DC conversion module based on a DC / DC conversion module and connected with a battery pack level A bidirectional DC / DC converter connected to the system, a bidirectional DC / DC converter based on a DC / DC conversion module and cascaded with a super capacitor bank, a braking resistor unit, an energy management unit, a voltage acquisition circuit, a current acquisition circuit and a load interface. The invention realizes the braking energy recovery according to the demand of the traction motor, the output characteristics of the fuel cell, and the electrical characteristics of the battery pack and the super capacitor pack. The present invention is a fuel cell hybrid locomotive energy management system based on a DC / DC conversion module. The present invention makes the fuel cell work in a "high hydrogen efficiency mode", maintains the state of charge of the battery within a certain range, and can prolong the service life of the battery .

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com