Metal abrasive processing technology

A processing technology and metal abrasive technology, which is applied in the field of metal abrasive processing technology, can solve the problems of reduced pellet cutting quality and production efficiency, fast cutting knife wear, energy waste, etc., and achieves small impact vibration, reduced failure rate, and reduced wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

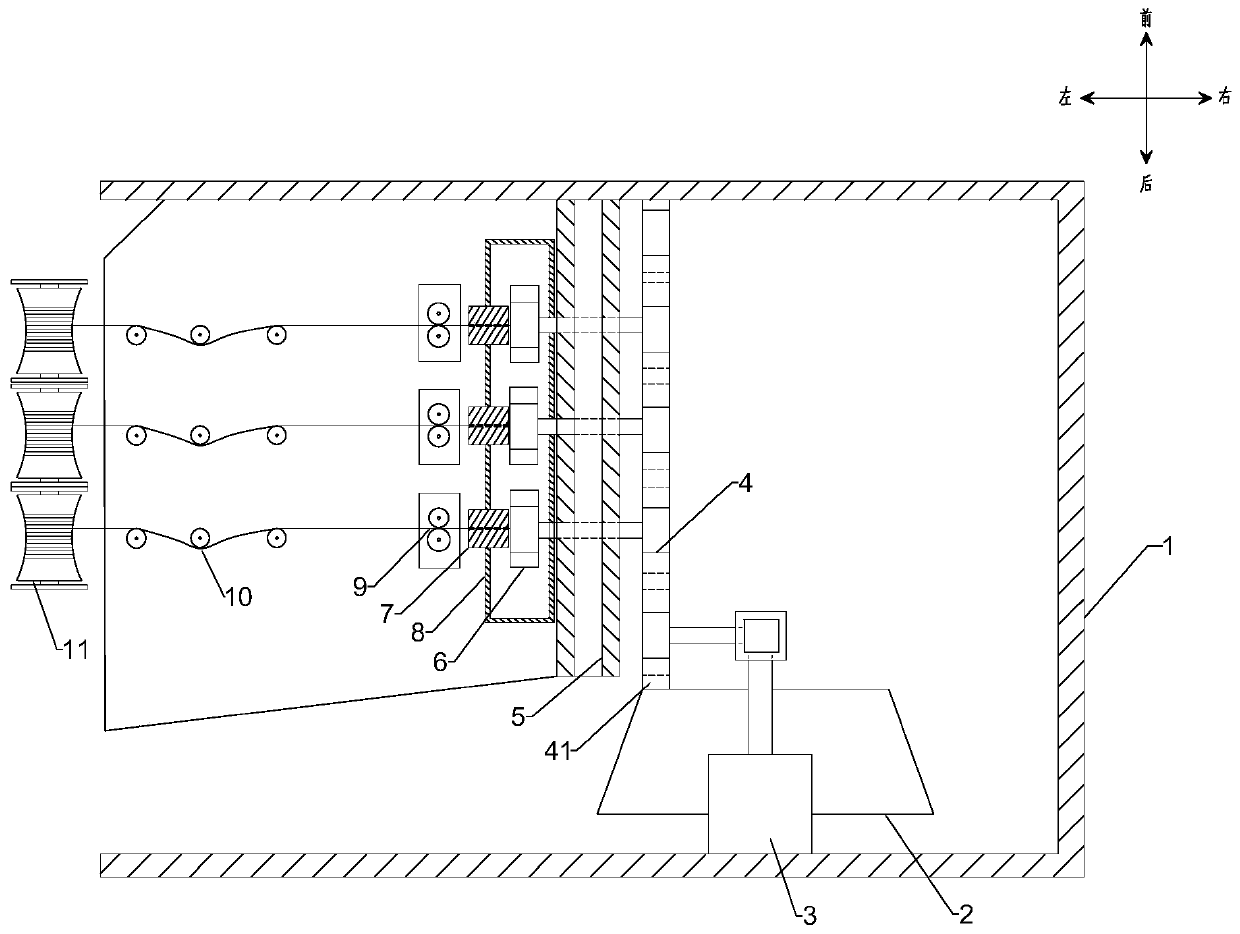

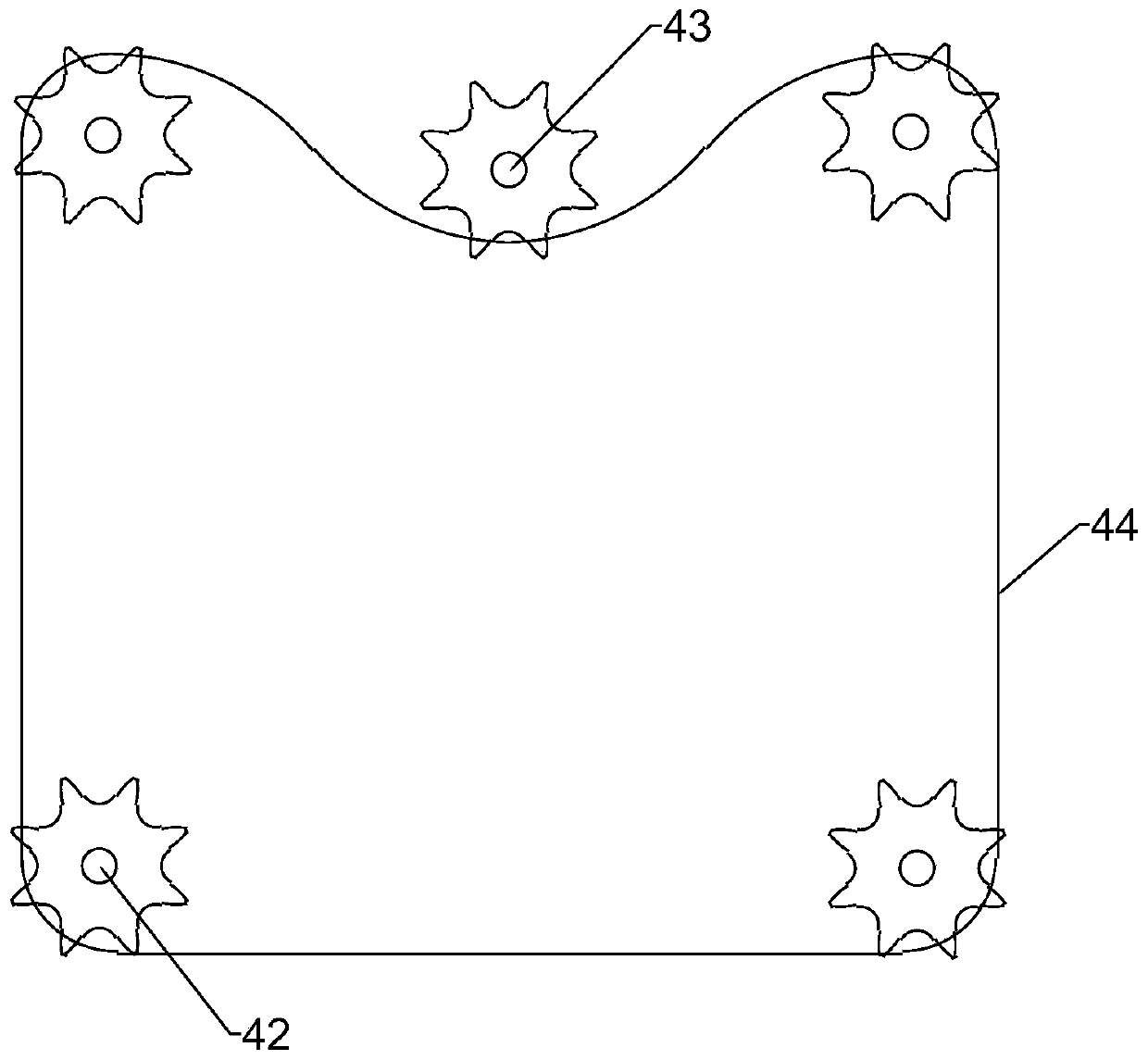

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

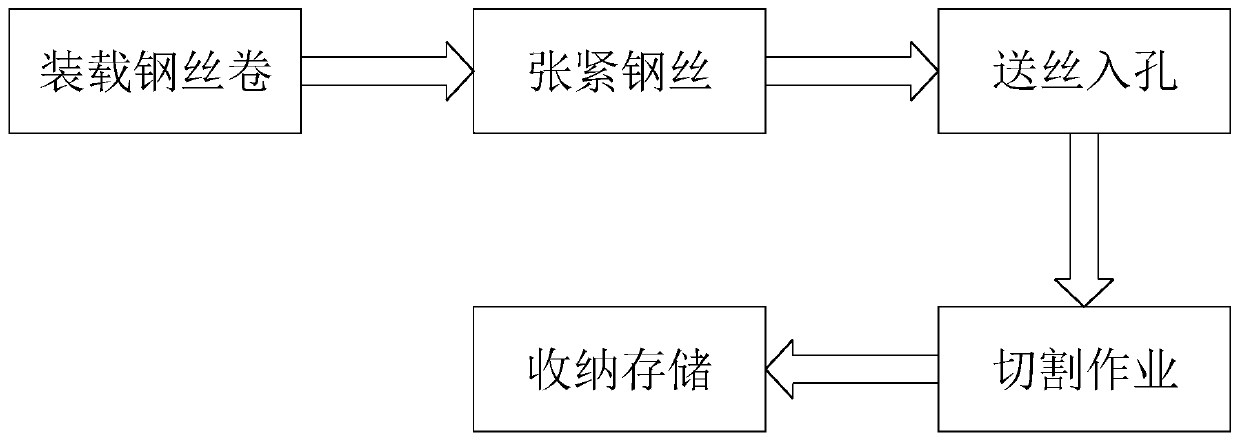

[0030] like Figure 1 to Figure 5 Shown, a kind of metal abrasive processing technology, comprises the following steps:

[0031] Step 1. Loading steel wire coils: take a plurality of wire feeding reels 11 wound with steel wires, install them on wire winding posts respectively and arrange them in a row;

[0032] Step 2. Tensioning the steel wire: pull out the steel wire on the wire feeding wheel 11, make the steel wire go around the tensioning wheel 10 in turn, and connect to the wire feeding device 9, and the wire feeding device 9 uses power to pull the steel wire to tension the steel wire;

[0033] Step 3, feeding the wire into the hole: after the motor of the wire feeding device 9 is started, the steel wire is pulled into the through hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com