Pulley drive balance type lifting system for drilling machine

A lifting system and transmission system technology, applied in the field of drilling machinery, can solve problems such as unresolved, increased motor peak power, no fundamental change in the basic principle of oil drilling rigs, etc., to reduce the maximum driving power, reduce the maximum power, reduce the The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

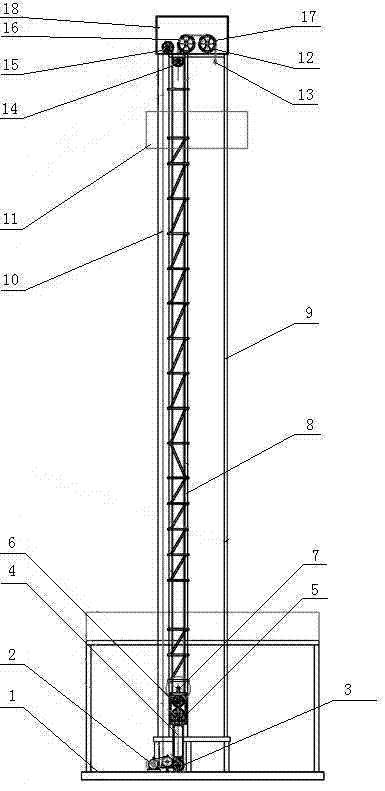

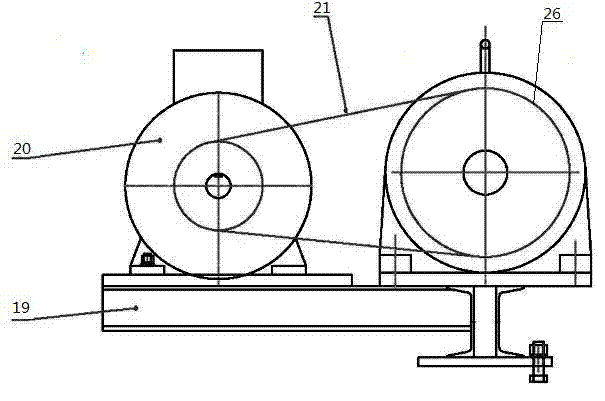

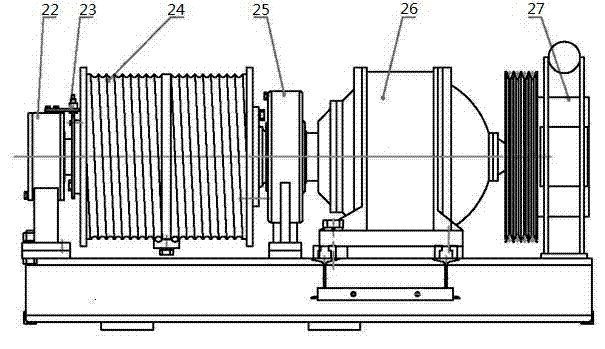

[0019] refer to Figure 1-3 , a pulley drive balanced drilling rig lifting system, mainly composed of a frame part 1, a drive system 2, a lifting part, a balance box 4, a pulley drive system, etc., the specific structure is as follows:

[0020] 1. The frame part 1 is a frame structure, which is mainly welded and assembled by section steel. The main body of the frame is divided into two parts, the main frame 8 and the support frame 9. The main frame is used as the installation and guide of the pulley transmission system, and forms the main body of the frame with the support frame to jointly bear the load of the drilling rig. The peripheral structure of the main body is respectively provided with a platform similar to a traditional drilling rig, a platform 11 on the second floor, a top platform 18 and a ladder etc. The first floor platform is used to install drilling rig auxiliary equipment, tool room, etc., as well as personnel operations, and the wellhead equipment such as bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com