Vehicular liquefied petroleum gas containing low-propane and high-olefin, and preparation device and technique thereof

A liquefied petroleum gas, propane-containing technology, used in the petroleum industry, gas fuel, fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

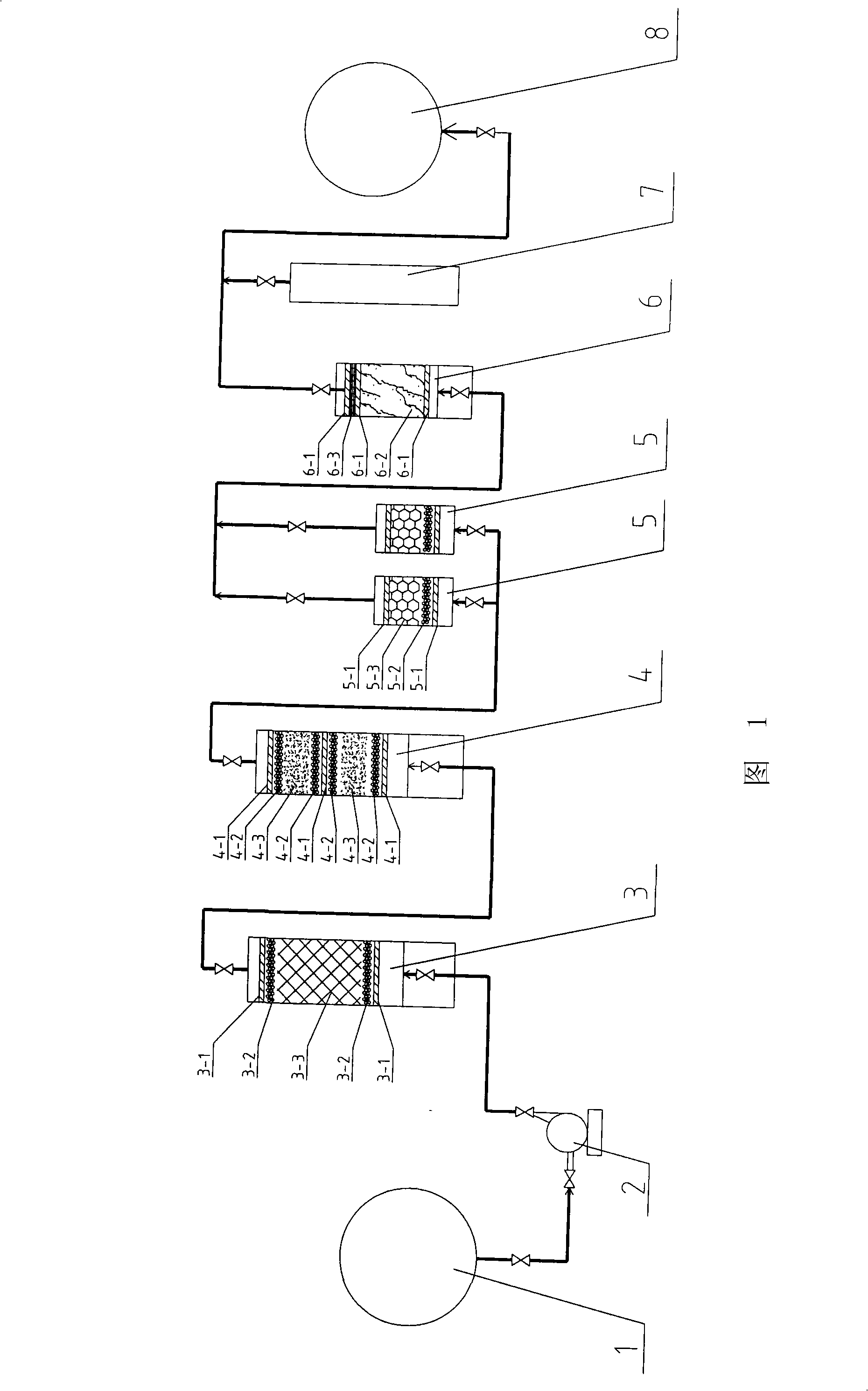

[0041] As shown in Figure 1 , the liquefied petroleum gas raw material is pulled out from the tank 1 by the pump 2 and sent to the desulfurization refining tower 3 .

[0042] The bottom of the desulfurization refining tower 3 is a metal sieve plate 3-1, and 8-10 cm glass balls or metal balls 3-2 are piled up on the sieve plate 3-1, and metal oxides 3-3 (for iron oxide or iron oxide) are piled up on the balls. Metal oxides such as zinc oxide), until the top of the tower, there is a sieve plate 3-1 on the top of the tower to suppress the metal oxide 3-3, and accumulate 8-10cm glass or metal balls 3-2 on the top of the sieve plate 3-1, Metal ball 3-2 is common carbon steel.

[0043] The liquefied petroleum gas enters from the bottom of the refining tower 3, and contacts with the oxidized metals in the tower reversely. The hydrogen sulfide and polysulfides in the liquefied petroleum gas react with the oxidized metals, and the metal salts formed are removed and refined by desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com