Sapphire crystal growing furnace side screen and preparation method thereof

A sapphire crystal and growth furnace technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of growth equipment loss, rarely mentioned, etc., achieve good stability, reduce production costs, and reduce power consumption amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] According to the design requirements of the side screen of the sapphire crystal growth furnace, in a specific mold, a zirconia fiberboard wet blank with a certain shape is produced by vacuum forming, and after drying and sintering, a zirconia fiberboard blank is obtained, which is processed by surface polishing, cutting, etc. A zirconia fiberboard with specific shape and physical and chemical properties is obtained.

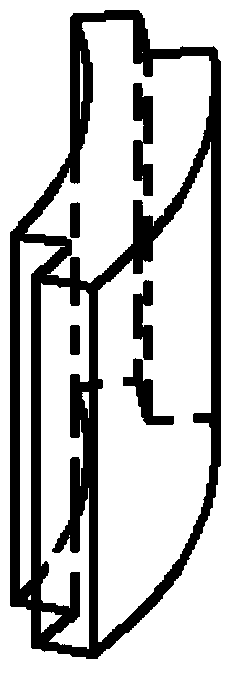

[0034] Prepared as figure 1 The shown zirconia fiberboard consists of the following components in mass percentage:

[0035]

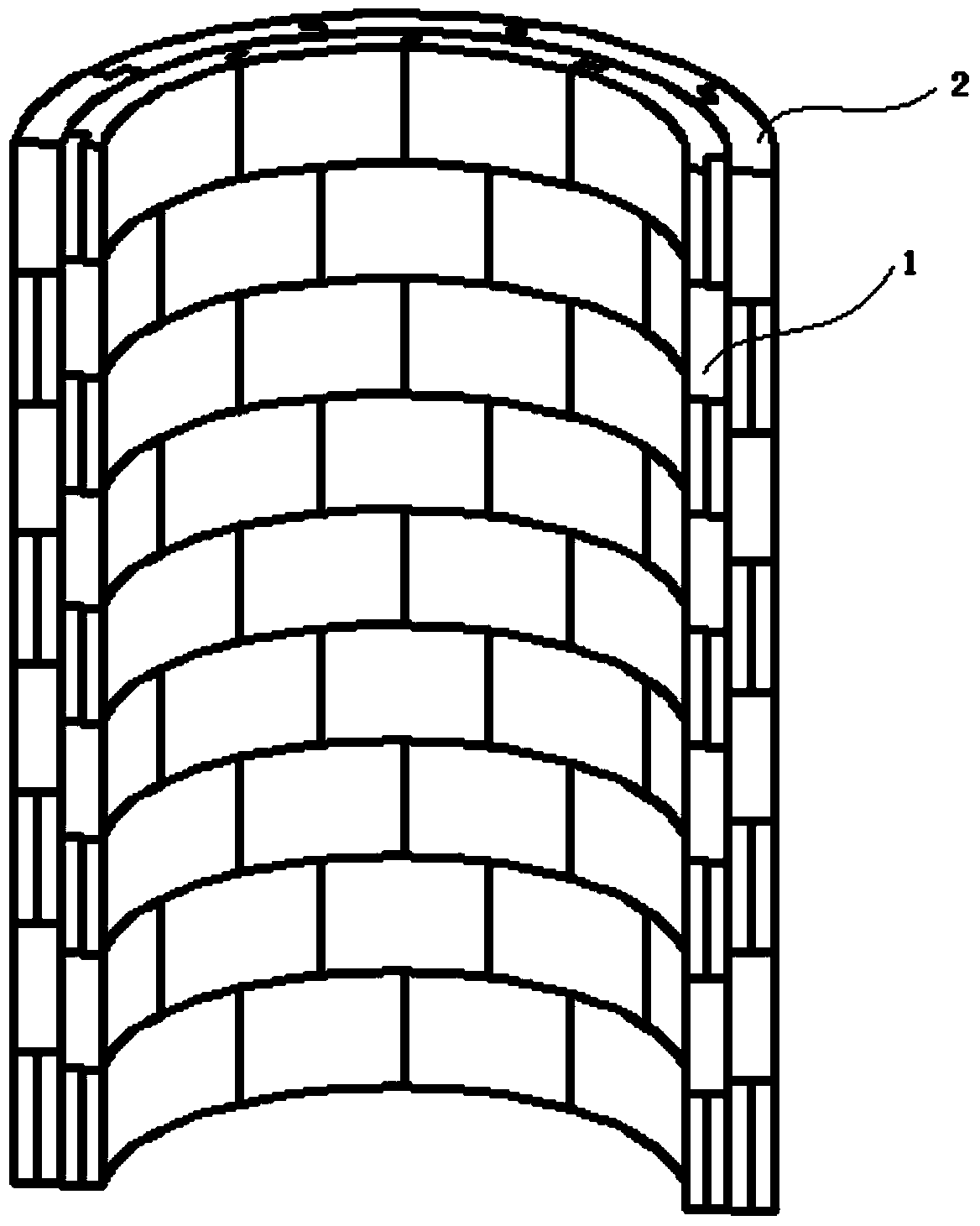

[0036] Such as figure 2 As shown, the size of the zirconia fiberboard of the inner screen 1 designed according to the first scheme is 30mm in thickness, 100mm in height, 30mm in inner diameter, 60mm in outer diameter, 5πmm in inner arc length, 11πmm in outer diameter, and the zirconia fiberboard of the outer screen 2 The size is 40mm in thickness, 113mm in height, 30mm in inner diameter, 60mm in outer diameter, 5πmm in inner arc...

Embodiment 2

[0039] According to the published patented fiberboard production method, according to the design requirements of the side screen of the sapphire crystal growth furnace, vacuum forming is used to produce a zirconia fiberboard wet blank with a certain shape in a mold with a specific shape and size, and it is dried at 90-100 °C After sintering at a high temperature above 1600°C, the zirconia fiberboard blank is obtained, and the zirconia fiberboard with specific shape and physical and chemical properties is obtained through surface polishing, cutting and other machining.

[0040] The prepared zirconia fiberboard consists of the following components by mass percentage:

[0041]

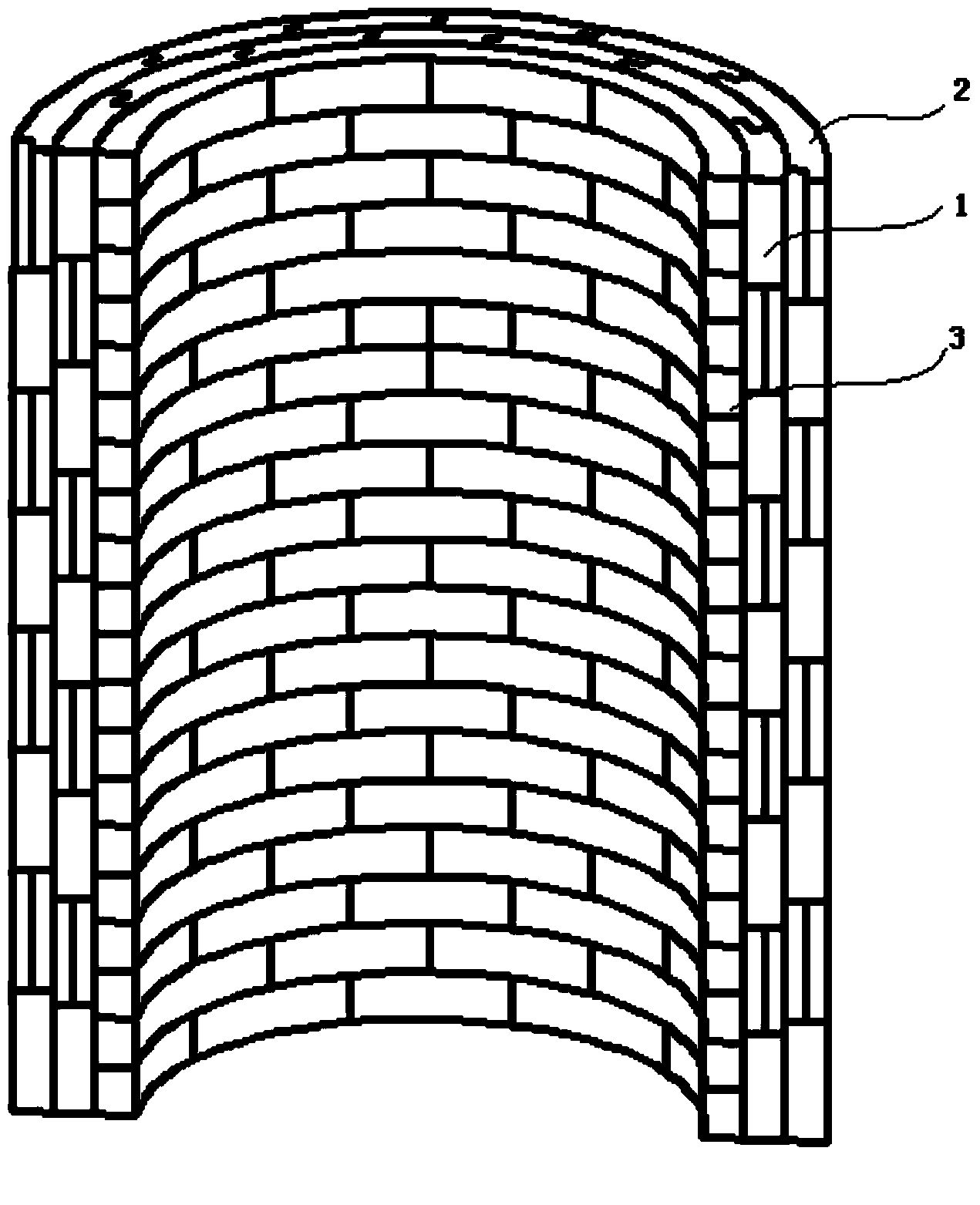

[0042] Such as image 3 As shown, the size of the zirconia fiberboard of the inner screen 1 designed according to the second scheme is 30mm in thickness, 100mm in height, 30mm in inner diameter, 60mm in outer diameter, 5πmm in inner arc length, and 11πmm in outer diameter. The dimensions of the zircon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com