Method and system for expediting engine warm-up

An engine and exhaust system technology, applied in the direction of engine starting, engine components, combustion engines, etc., can solve problems such as limiting heat, fuel economy defects, and deteriorating engine knock limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

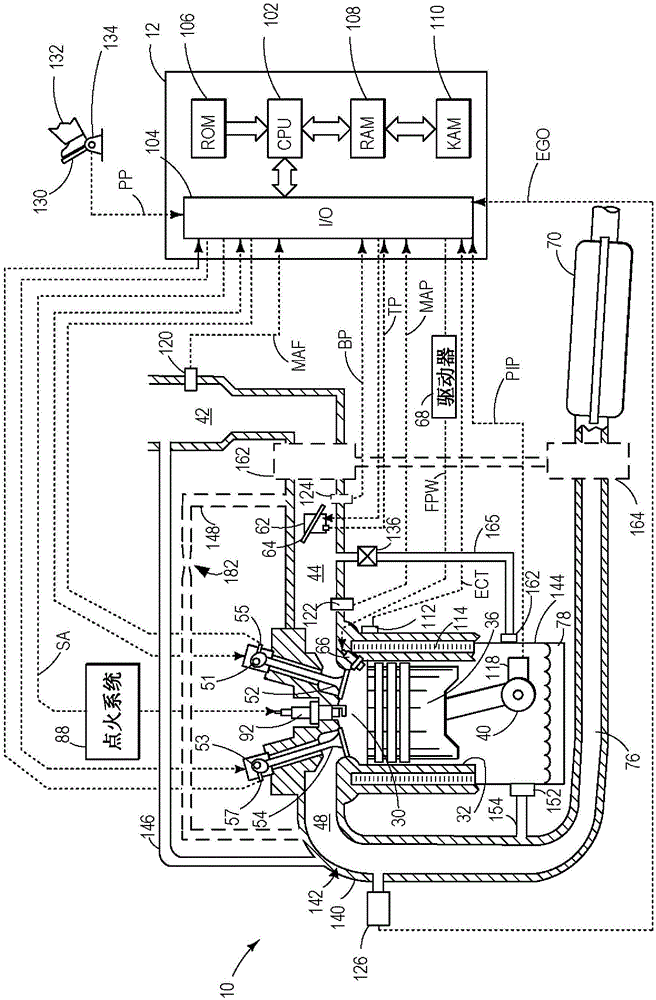

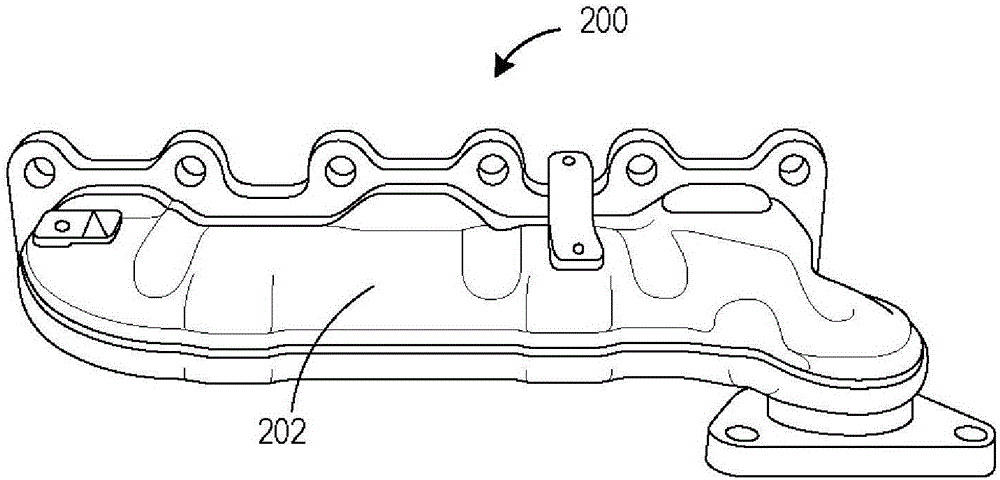

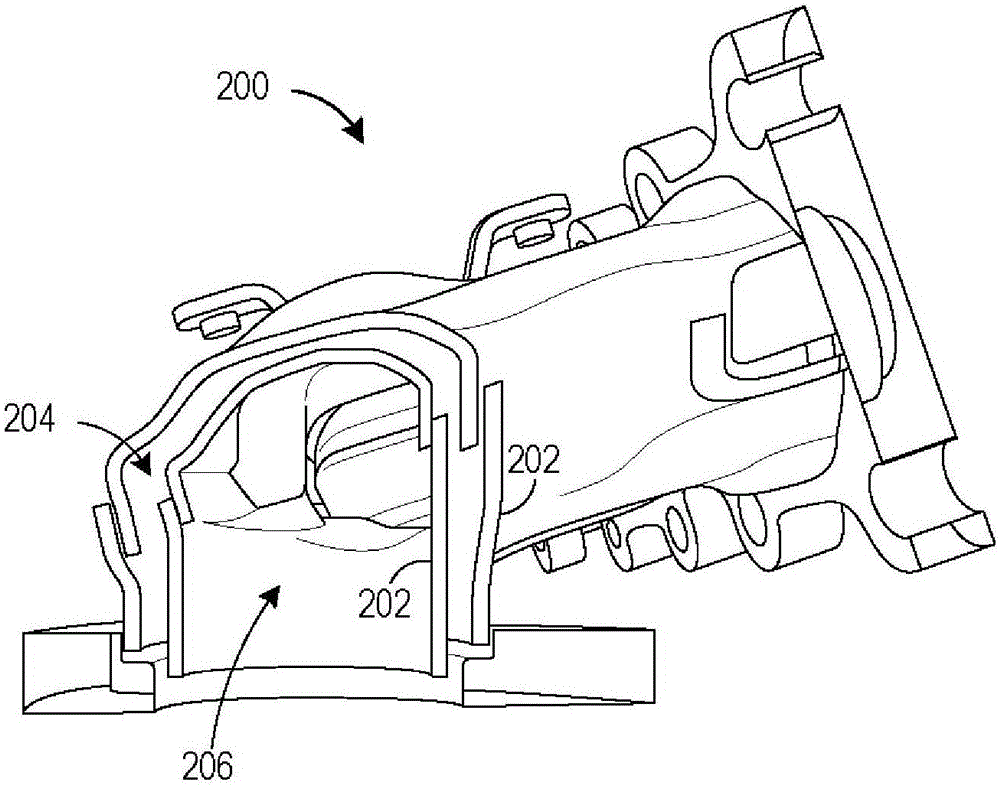

[0019] This application describes a method for heating an engine system such as, figure 1 A method and system for a crankcase in an engine system). As the exhaust circulates through a double wall exhaust system such as, Figure 2-3 In the interstitial space of the exhaust system shown in ), heat from the exhaust can heat the intake air. Intake air in a naturally aspirated engine may be drawn into the interstitial space upstream of the intake throttle ( Figure 4 ). In a forced conduction engine, intake air can be drawn from downstream of the compressor ( Figure 5 ) and upstream of the intake throttle are drawn into the clearance space. Alternatively, intake air heated via the compressor can heat the crankcase ( Figure 6 ) without heating via the interstitial space. The controller can be configured to execute programs such as, Figure 7 program) to flow intake air through the crankcase and adjust fuel injection and / or throttle position based on the amount of crankcase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com