Patents

Literature

35results about How to "Improve air leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

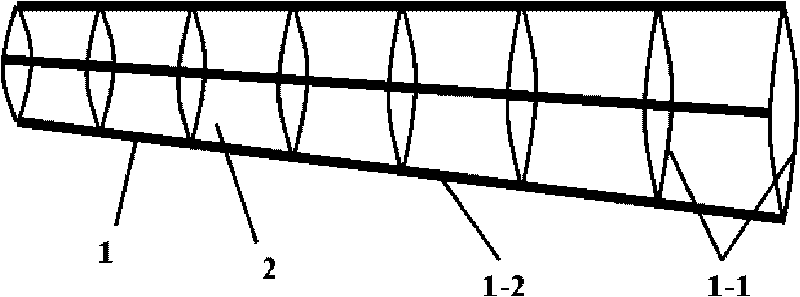

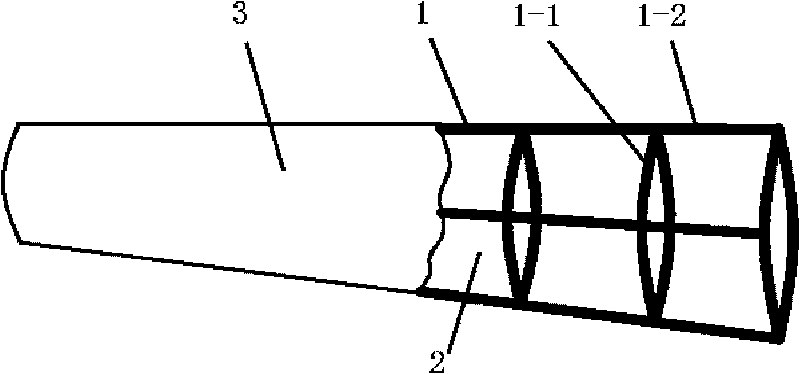

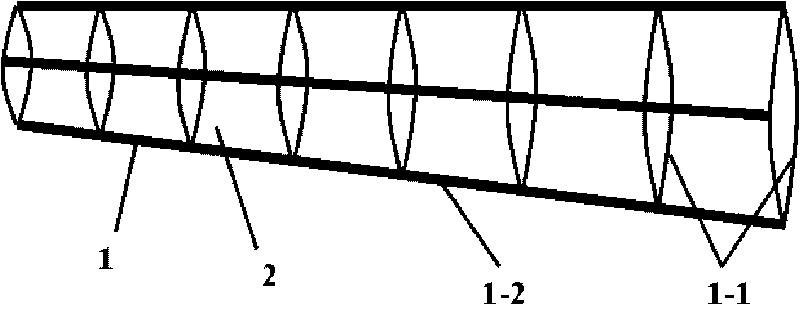

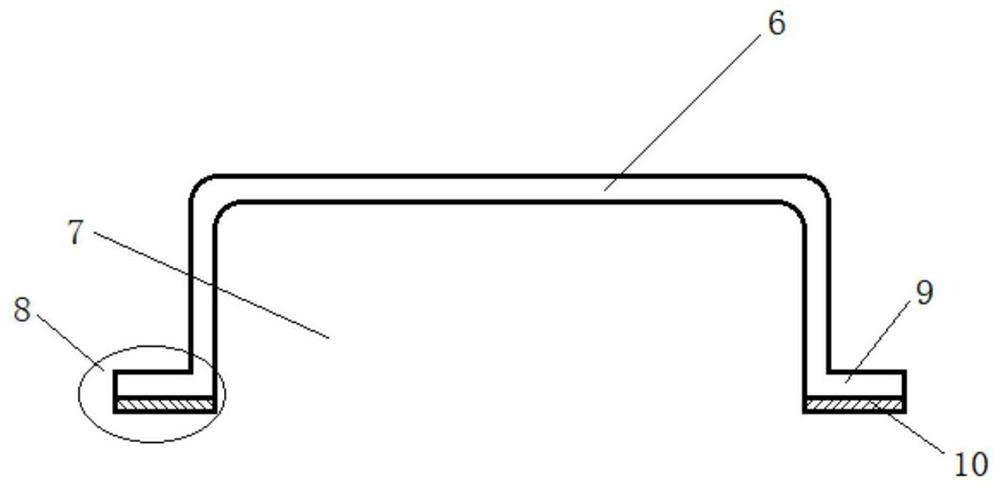

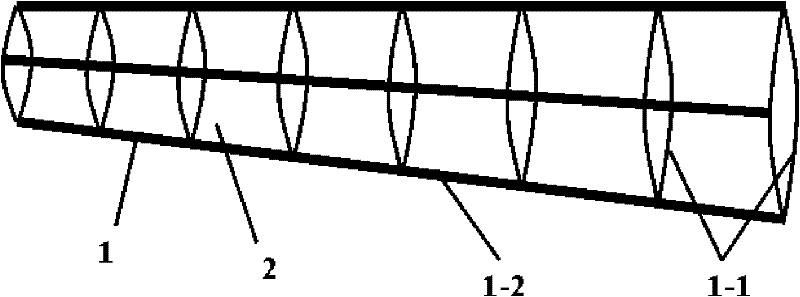

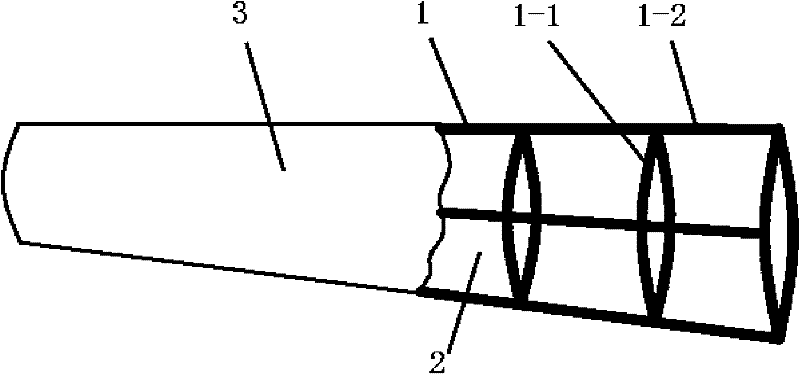

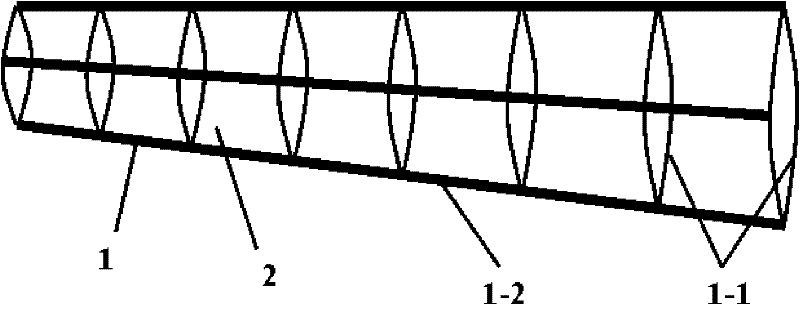

Shape memory polymer-based air filling extensible wing and methods for manufacturing same

The invention provides a shape memory polymer-based air filling extensible wing and methods for manufacturing the same, relates to an extensible wing and a method for manufacturing the same, and aims to solve the problem that the strength and the rigidity, needed for the flight of a plane, of the wing are not met, and the problem that the wing is easily damaged for air leak when the punching pressure is too big in the conventional air filling extensible wing. A skeleton of the wing is made of shape memory polymers. The method I comprises a step of manufacturing the skeleton of the wing comprise: designing a mould, manufacturing an uncured fiber reinforcement shape memory polymer blank, heating the blank at a temperature of between 70 and 80 DEG C for 16 to 24 hours, demoulding the fiber reinforcement shape memory polymer blank, which is heated to be cured, to obtain a corresponding wing rib or wing beam, and then connecting and fixing the wing rib and the wing beam to form the skeleton of the wing. The method II comprises: keeping warm for 60 minutes at a temperature of 75 DEG C, heating the skeleton of the wing to the temperature of 100 DEG C, keeping the temperature for 30 minutes, cooling skeleton of the wing to the temperature of 75 DEG C, and keeping the temperature for 24 hours. The air filling extensible wing of the invention meets the strength and the rigidity, needed for the flight of a plane, of the wing the sealing property of the wing is good, and the method for manufacturing the wing has an advantage of simple process operation.

Owner:HARBIN INST OF TECH

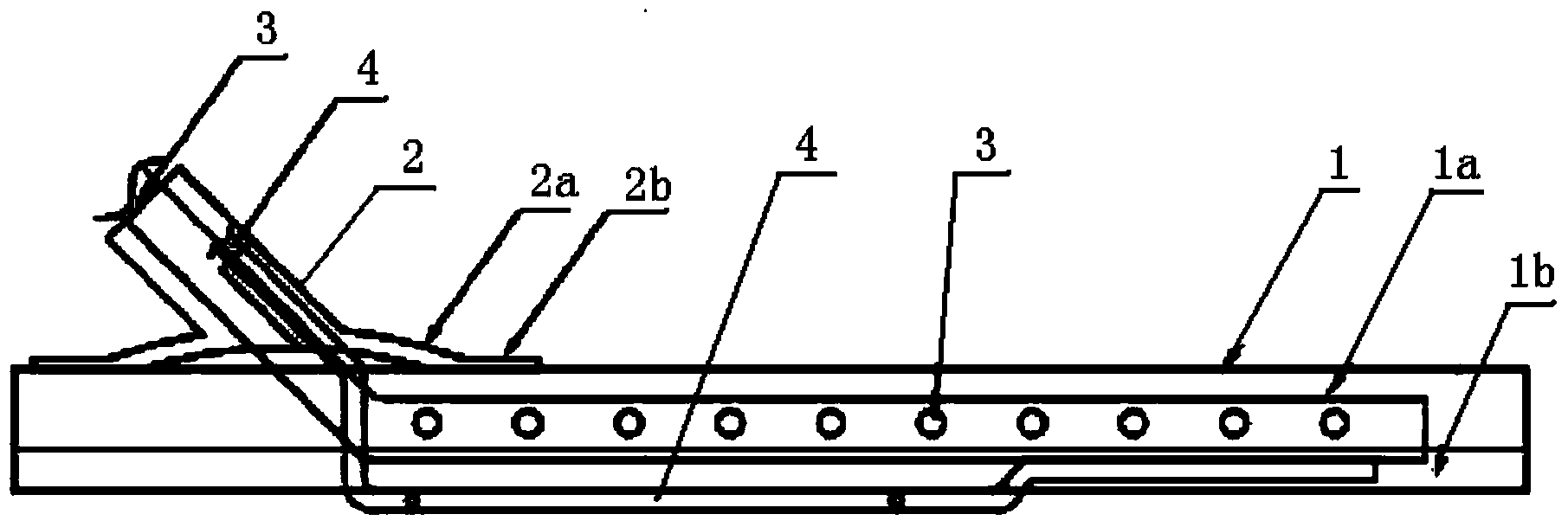

Multilayer negative-pressure closed drainage wound protecting device

ActiveCN104225768AImprove the effectGood material performanceEnemata/irrigatorsWound drainsCushionEngineering

The invention provides a multilayer negative-pressure closed drainage wound protecting device which comprises a porous foam cushion, a drainage tube and an oxygen-containing liquid flushing tube. One end of the drainage tube is positioned in the porous foam cushion, the porous foam cushion is a multilayer composite foam cushion and comprises a negative pressure conducting layer and a drainage protecting layer, the negative pressure conducting layer is a hydrophobic porous foam material layer, the drainage protecting layer is a hydrophilic porous foam material layer, and the drainage tube is disposed in the negative pressure conducting layer; the oxygen-containing flushing tube and the drainage tube enter the porous foam cushion side by side, the drainage tube penetrates the porous foam material layer to be positioned on the lower surface of the drainage protecting layer, the tail end of the drainage tube goes deeply into the drainage protecting layer for positioning, and small holes are distributed in the wall of the drainage tube. The drainage tube and a leading-in end of the oxygen-containing liquid flushing tube are fixed by a shared elastic sealing glue film floppy which comprises a disc and an elastic sealing glue film bonded with the disc and extending outwards, and a drainage leading-in tube orifice of the drainage tube and a flushing leading-in tube orifice of the oxygen-containing liquid flushing tube are arranged in the middle of the disc. A longitudinal breaking joint is formed at a drainage tube incoming end of the porous foam cushion, so that convenience is brought to overturning of the leading-in tube orifice.

Owner:WUHAN VSD MEDICAL SCI & TECH CO LTD

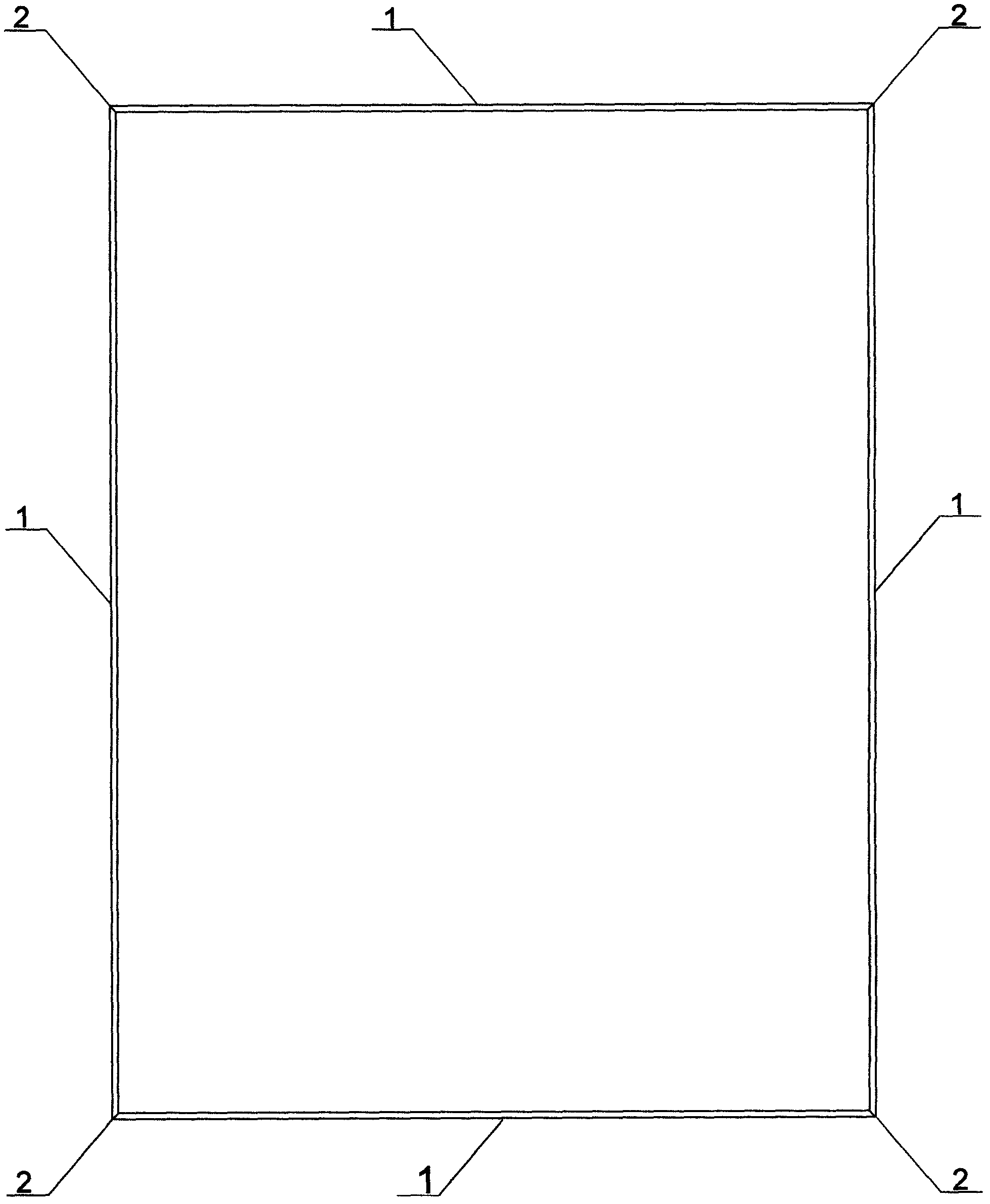

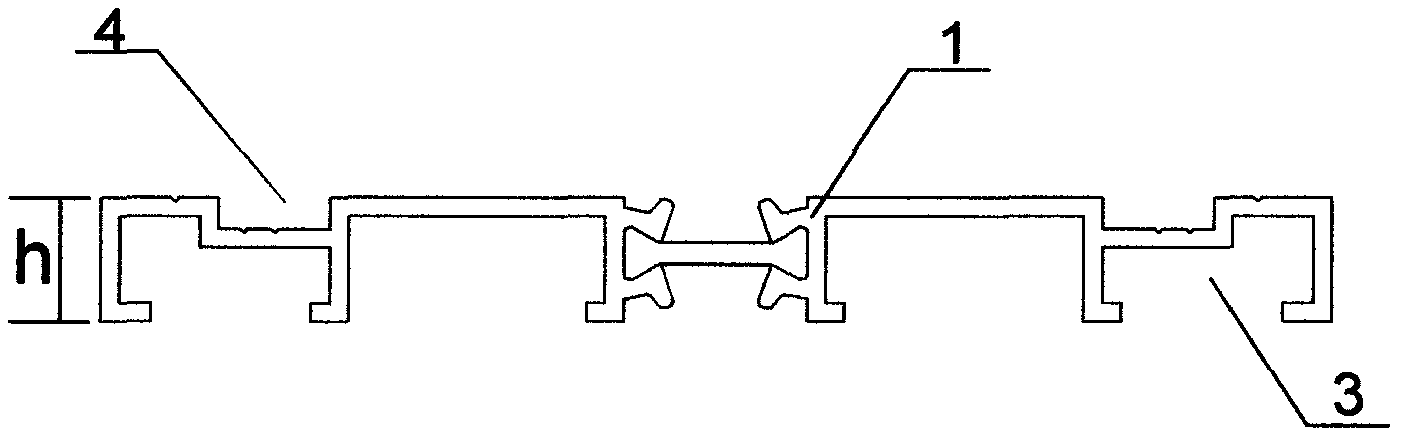

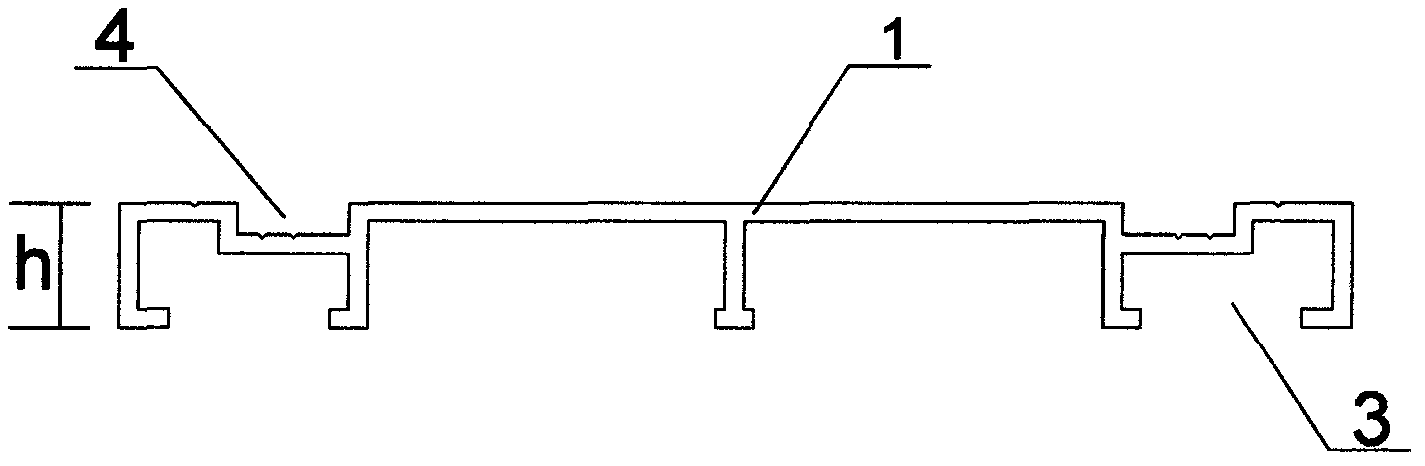

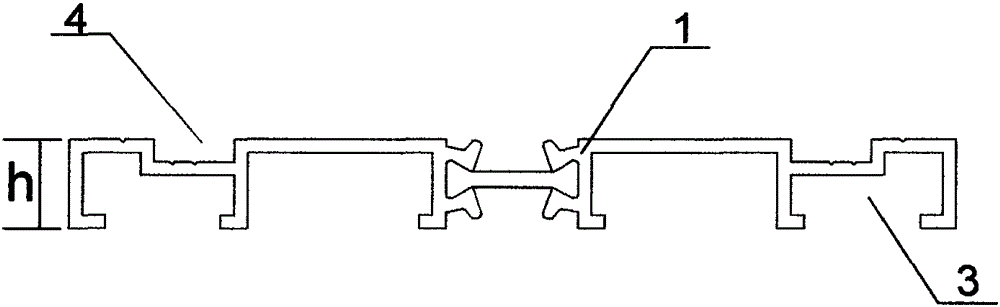

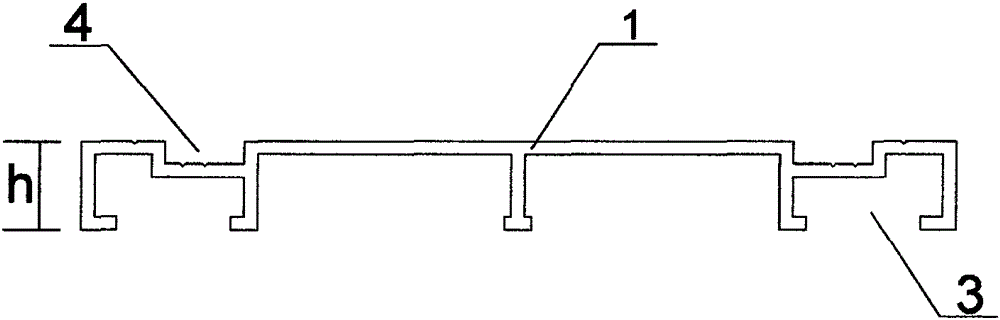

Thin combined installation door and window auxiliary frame

ActiveCN103573111ASolve the strength problemSolve Thickness ProblemsWindow/door framesPush pullAlloy

The invention discloses a thin combined installation door and window auxiliary frame which is made of metal or plastic profiles and has a bridge-breaking heat insulation type and an ordinary type, wherein each type has a push-pull mode and a sliding mode. The auxiliary frame is in a shape of double Es, the thickness of the auxiliary frame is larger than 4mm and smaller than 15mm, wall fixing screws and angle steel fixing screw grooves are arranged on the surface of the auxiliary frame, and an angle steel groove and angle steel are arranged on the back surface of the auxiliary frame. The auxiliary frame is provided with a standard seat frame for supporting the installation of the auxiliary frame, wherein the seat frame is made of aluminum alloy or metal profiles and has an adjustable mode and a fixed mode. Clamping rods, clamping hooks, horizontal correction devices, vertical correction devices, sill concentric correction devices and rulers are arranged on the seat frame. In installation, the auxiliary frame is fixed on the seat frame through the screws, the seat frame is installed in a door and window hole to be clamped tightly, correction is performed through a correction device, a wall horizontal inked line and a wall vertical inked line, hard plastic gaskets are wedged the back surface of the auxiliary frame tightly, the auxiliary frame is fixed on the wall through two lines of screws, the seat frame is dismantled, cement mortar is filled in slits between the frame and the wall, and a firm standard door and window auxiliary frame is formed after the cement mortar is coagulated.

Owner:HUIZHOU BAINIAN FANGZHENG ENG CO LTD

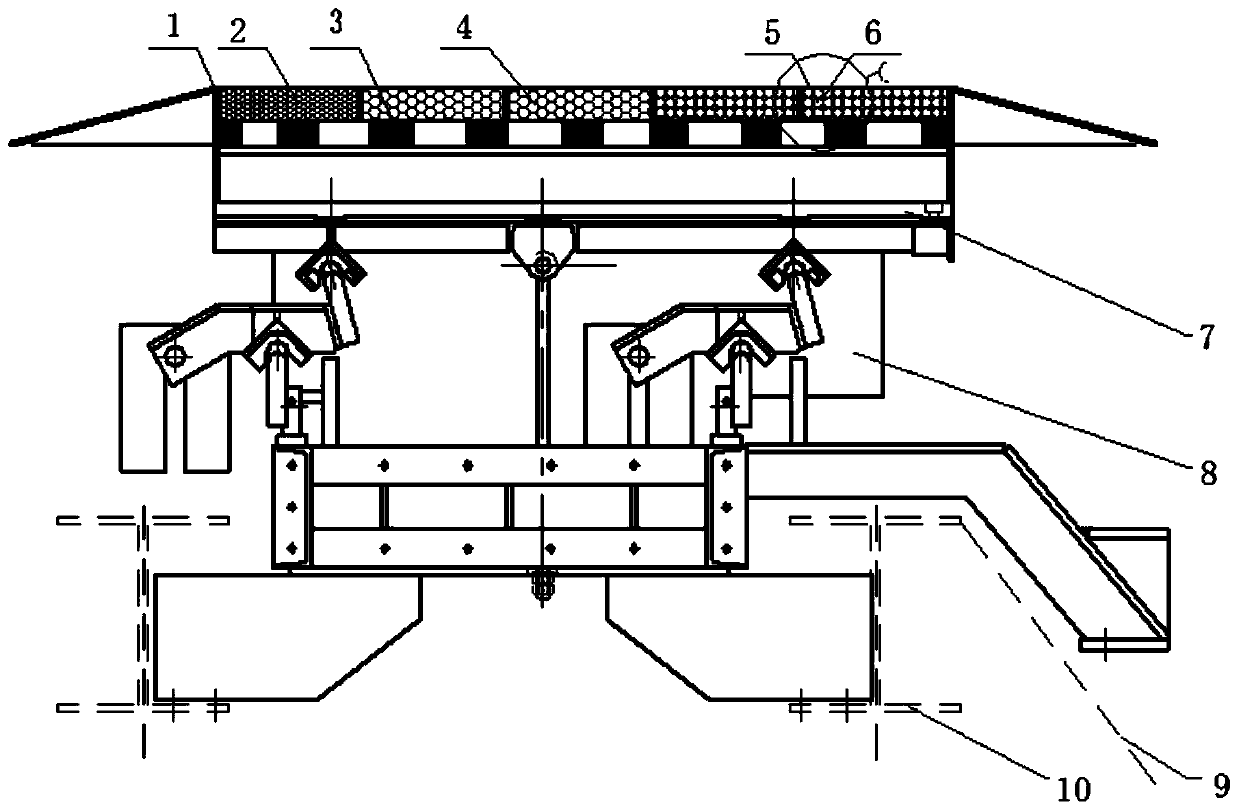

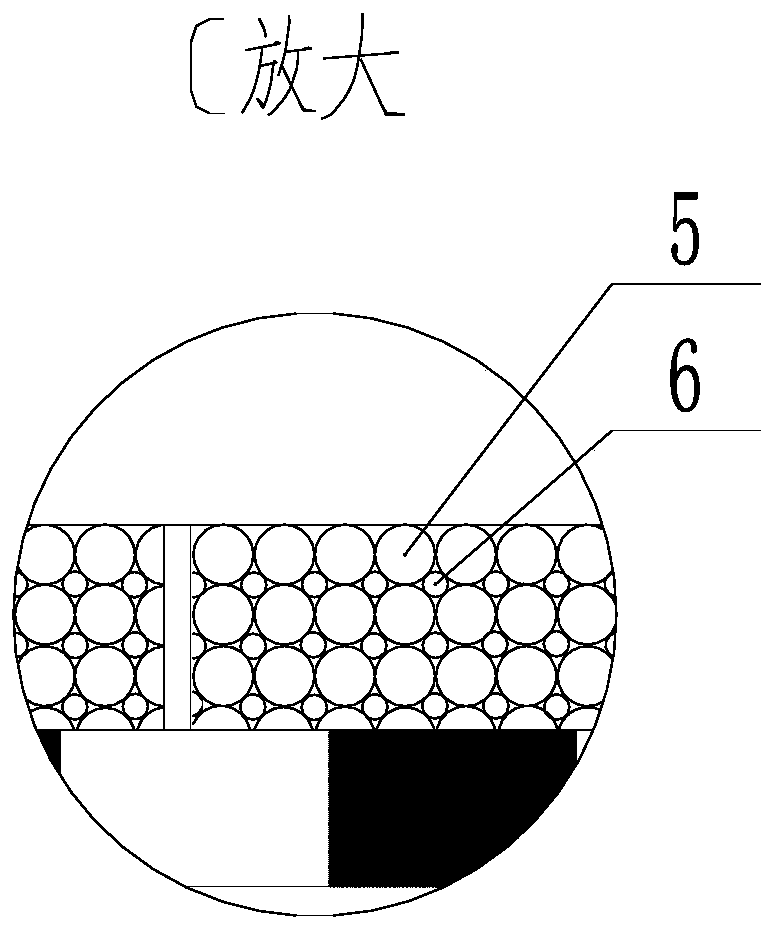

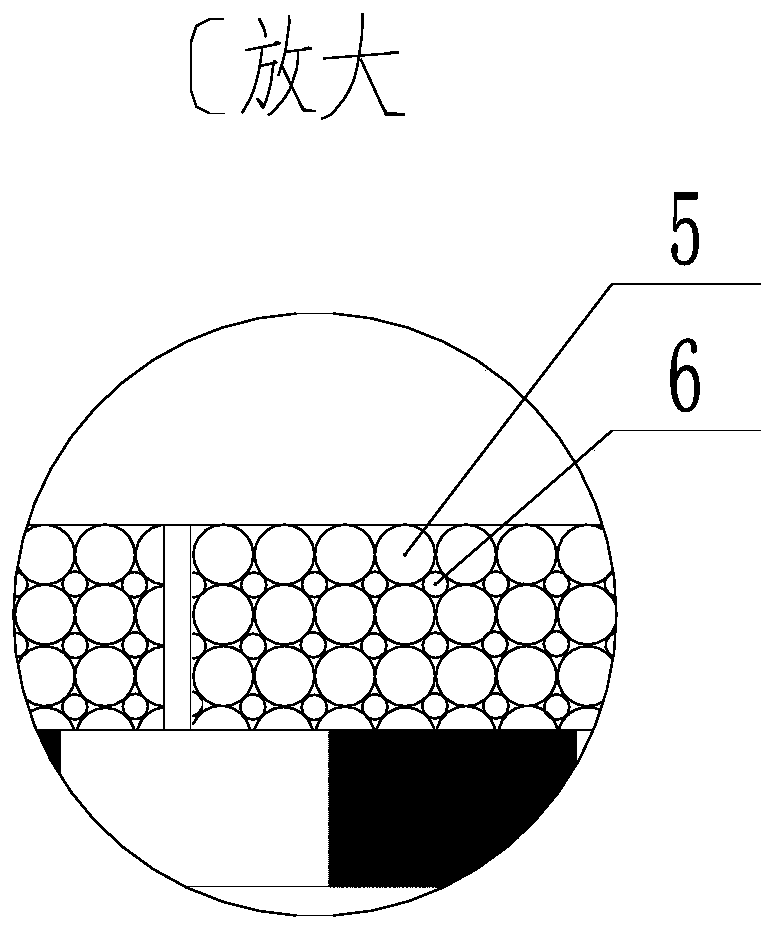

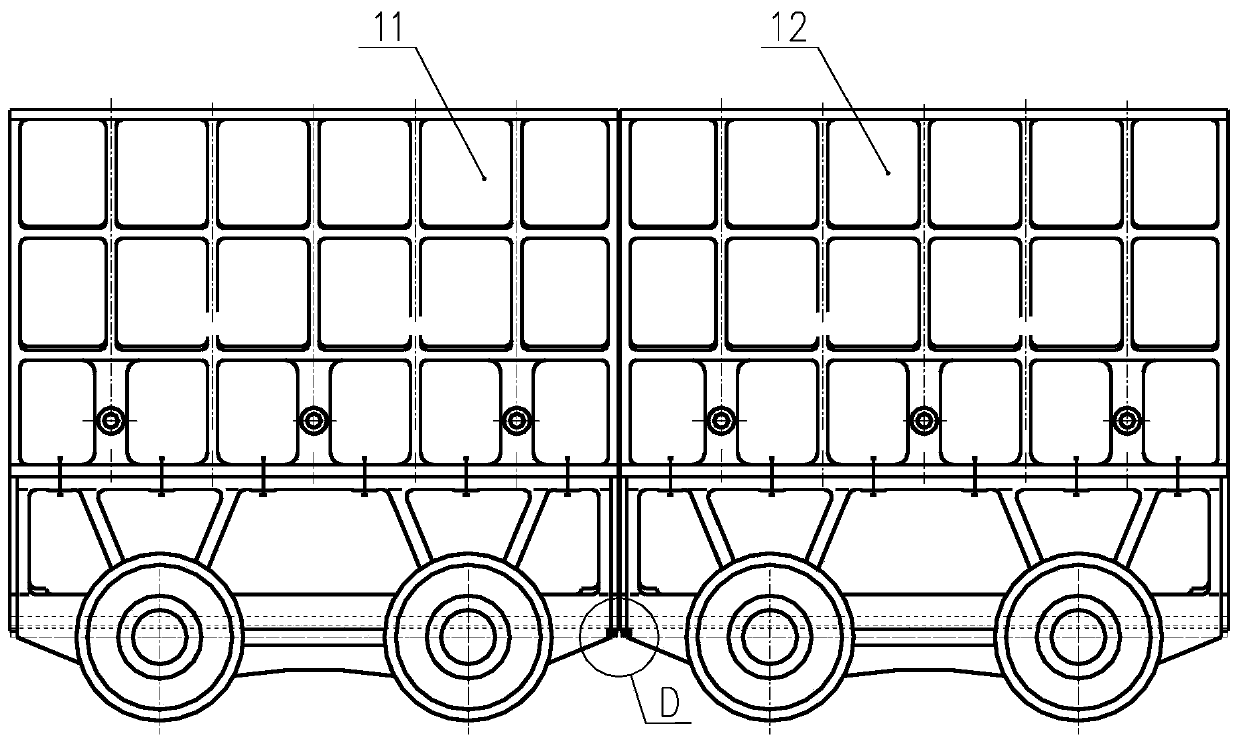

Steel ball and strong magnet compound type sealing device used for sintering machine

The invention relates to a steel ball and strong magnet compound type sealing device used for a sintering machine. The steel ball and strong magnet compound type head and tail sealing device comprisesa sealed ore tank, steel balls, high-strength magnets, a sealing beam and an adjustment base. The sealed ore tank is filled with the high-strength magnets and the steel balls of different grain diameters instead of a traditional sealing cover plate, and the rolling sealing effect is achieved. By arranging a magnetic sealing device at the positions of slide way end faces of adjacent trolleys, by means of dependence on the attraction effect of a directionally-magnetized magnet device, iron powder is firmly attracted to the positions of seams of the end portions of slide plates, and then the sealing effect is achieved. Air leakage of a whole sintering system is further reduced, and the ideal ore sintering effect is achieved; and meanwhile electric energy is saved, and high application and popularization value is achieved.

Owner:YANSHAN UNIV

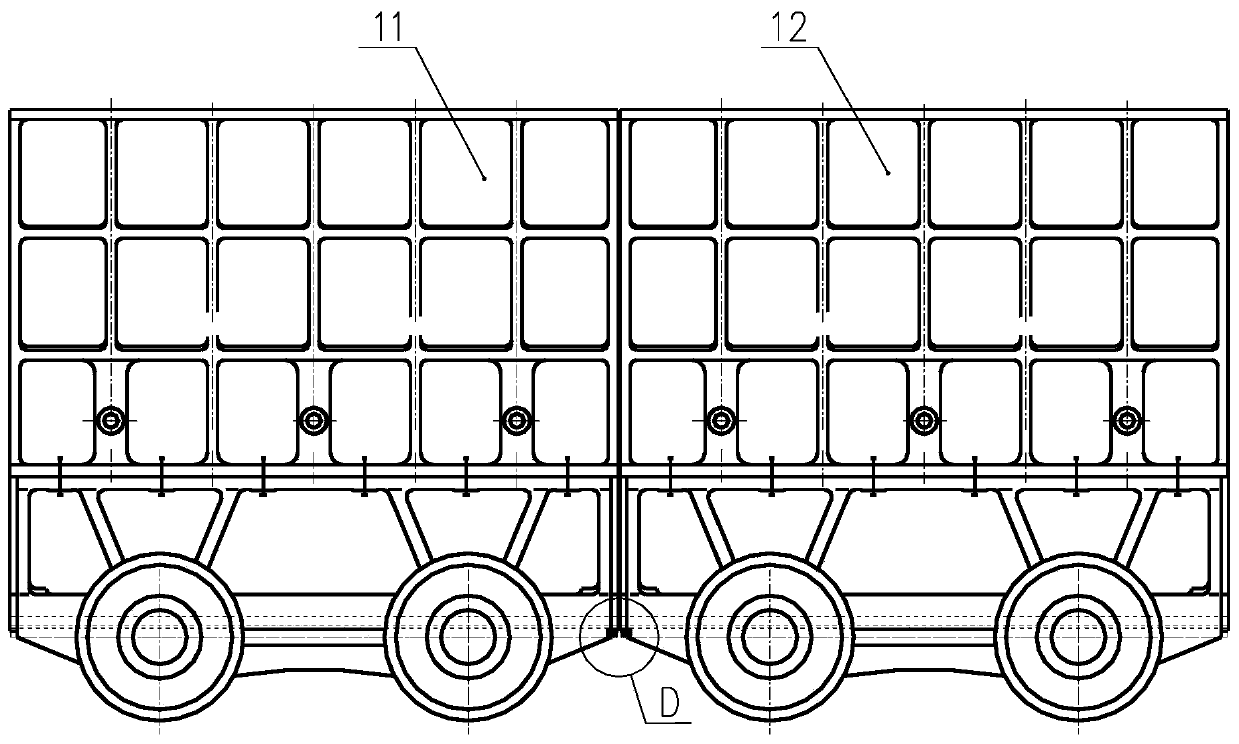

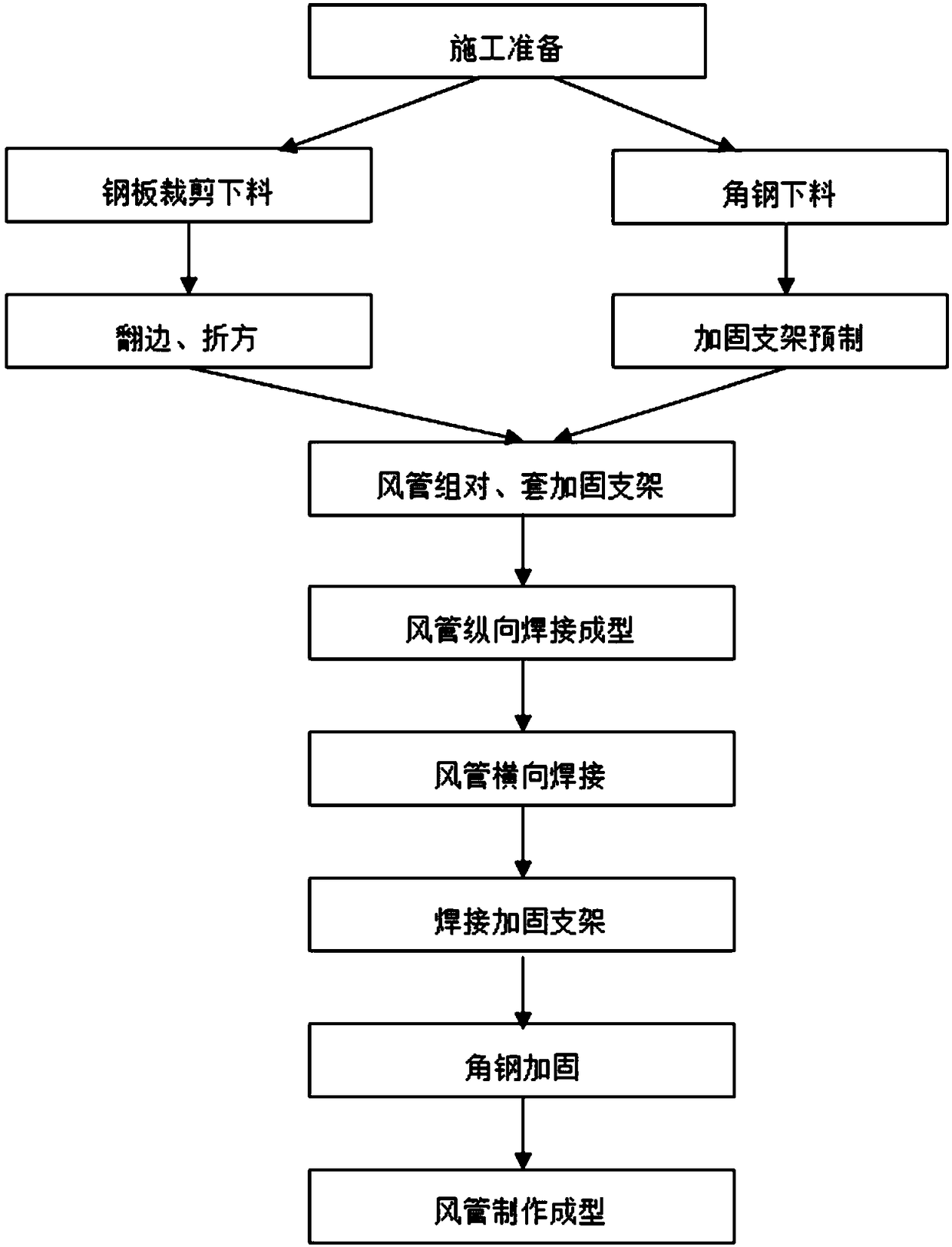

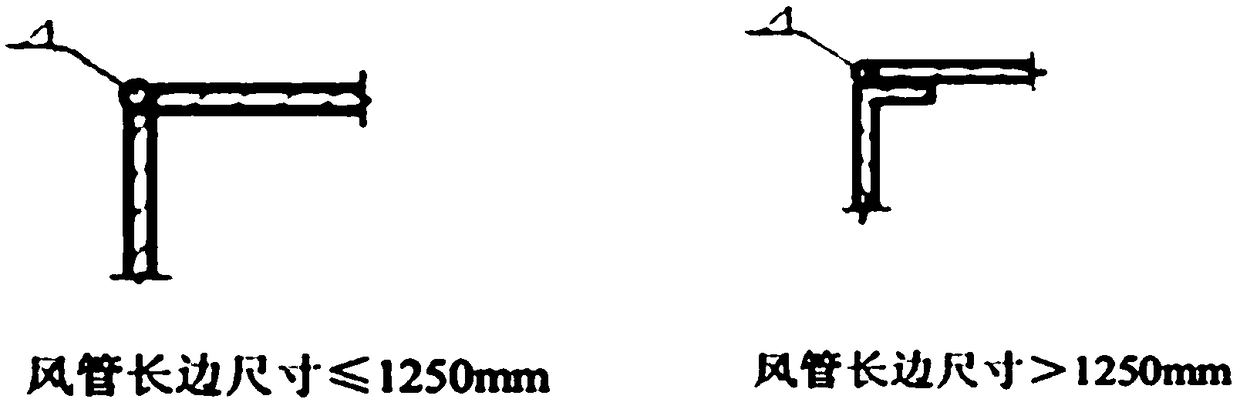

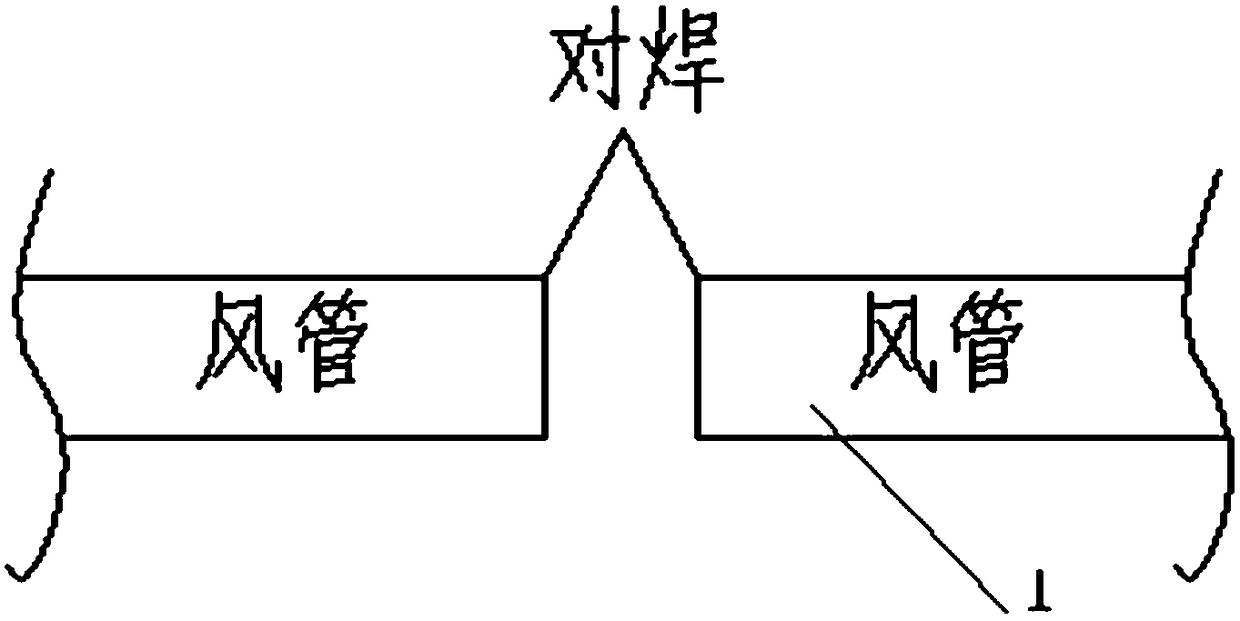

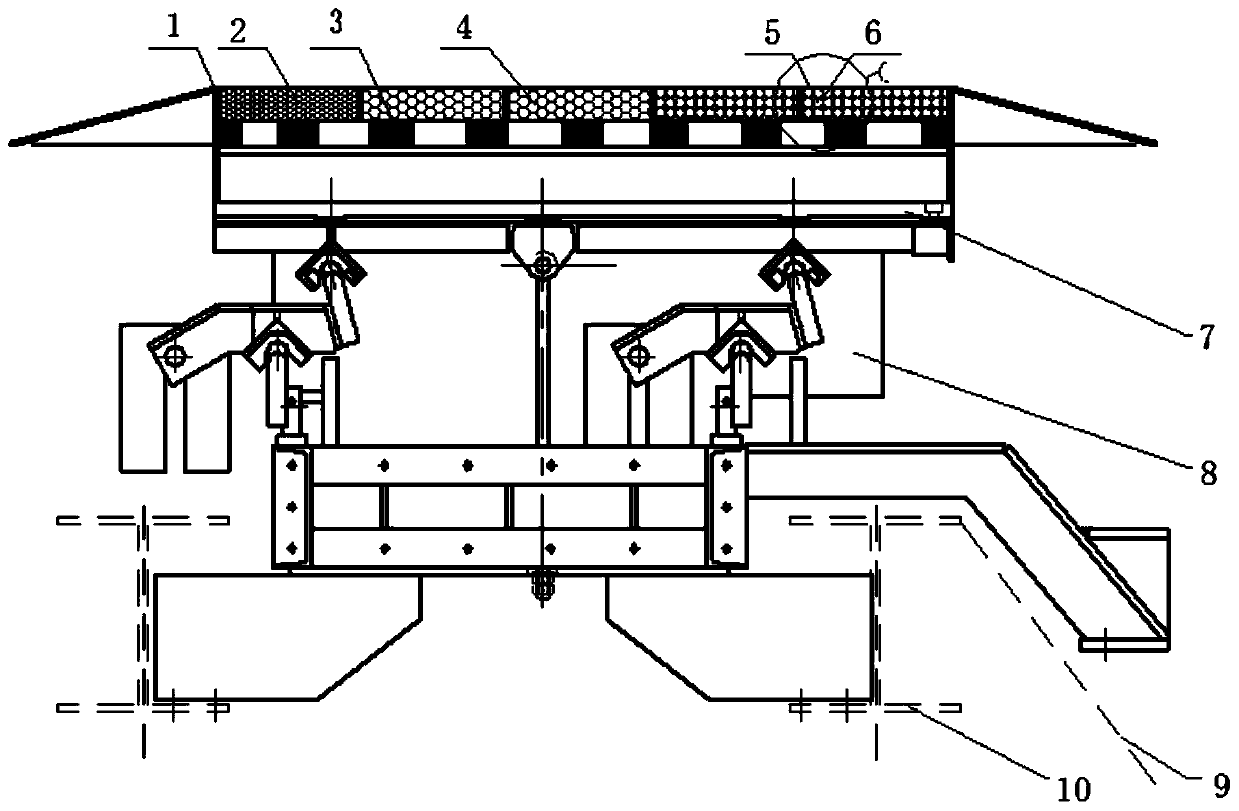

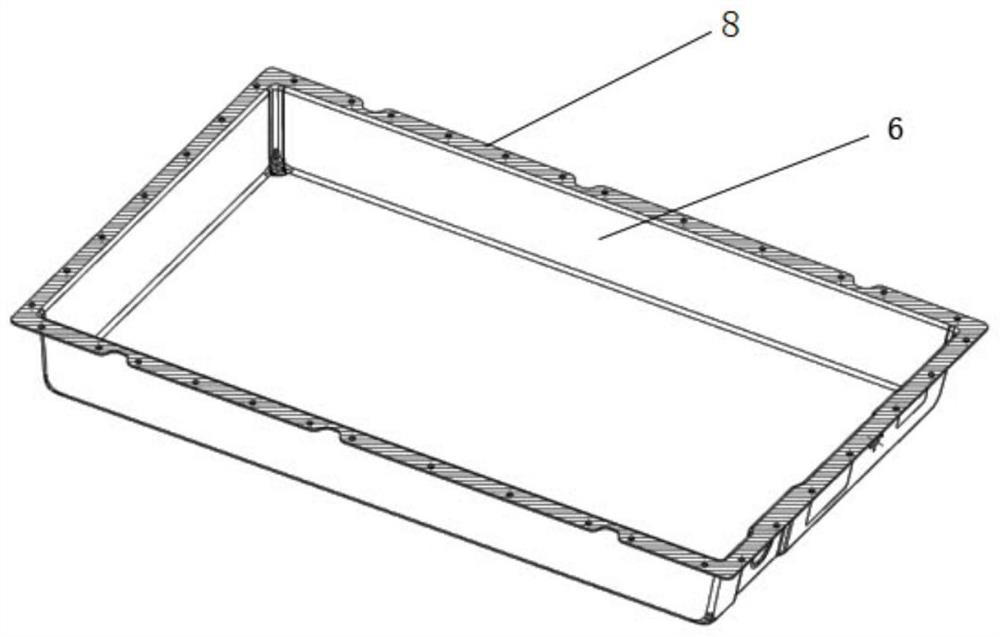

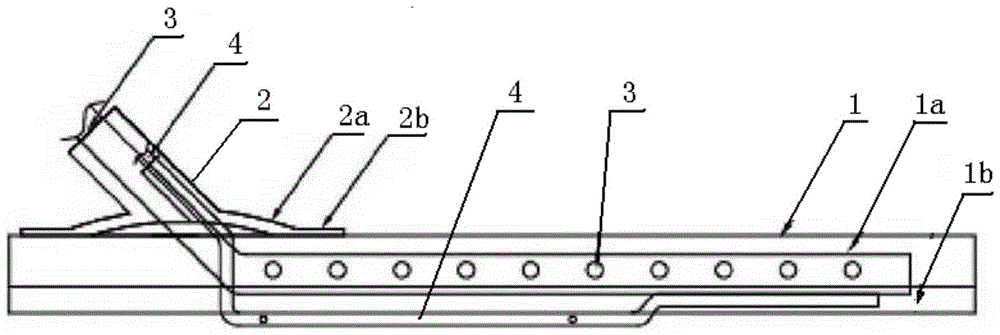

Clean air duct and manufacturing and mounting method thereof

PendingCN108644483APlay a role in standardizing constructionImprove air leakageRigid pipesArchitectural engineeringBuilding construction

The invention discloses a clean air duct which comprises a plurality of sections of rectangular air ducts, a plurality of reinforcing brackets, a plurality of enhancing brackets and a plurality of fixing brackets, wherein the rectangular air ducts are sequentially and coaxially fixedly connected to form an integrity; the enhancing brackets are mounted at the lower parts and / or upper parts of the outer walls of the corresponding rectangular air ducts in a sleeving manner to be used for being fixedly connected with floorslab layers; the fixing brackets are mounted out of the corresponding rectangular air ducts in a sleeving manner to be used for being fixedly connected with the floorslab layers; the reinforcing brackets are mounted in the middles of the outer walls of the corresponding rectangular air ducts in a sleeving manner; and the reinforcing brackets are fixedly connected onto the fixing brackets. According to the clean air duct, a normalized clean air duct, and a normalized manufacturing and mounting construction method of the clean air duct are provided for a construction unit and operating workers , so that a function for normalizing the construction unit and construction of the operating workers is realized.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

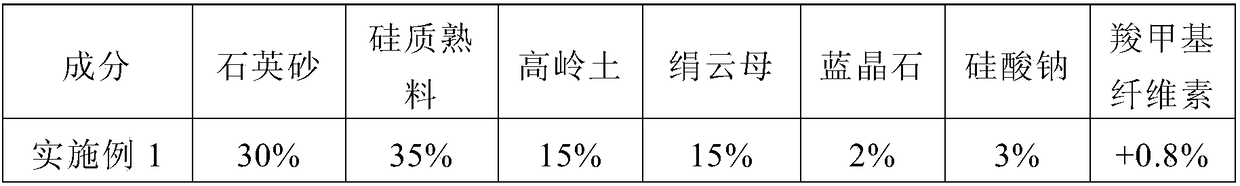

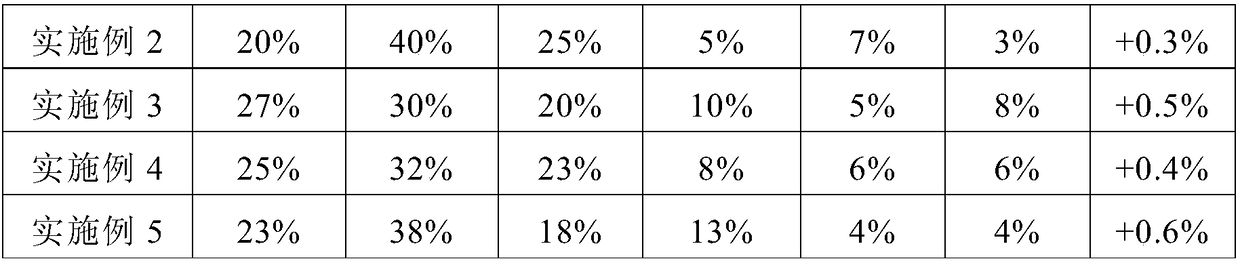

Refractory sealing material for coke oven end

The invention discloses a refractory sealing material for a coke oven head. The composition of the refractory sealing material comprises 20-30% of quartz sand, 30-40% of siliceous clinker, 15-25% of kaolin, 5-15% of sericite, 2-7% of kyanite, and 3-8% of sodium silicate, and 0.3-0.8% of carboxymethyl cellulose is additionally added. The refractory sealing material of the present invention is usedfor sealing and daily repair of space between the coke oven end and iron pieces, oven end contact seams and oven shoulder seams, and facilitates long service life and clean production of a coke oven.

Owner:BAOSHAN IRON & STEEL CO LTD

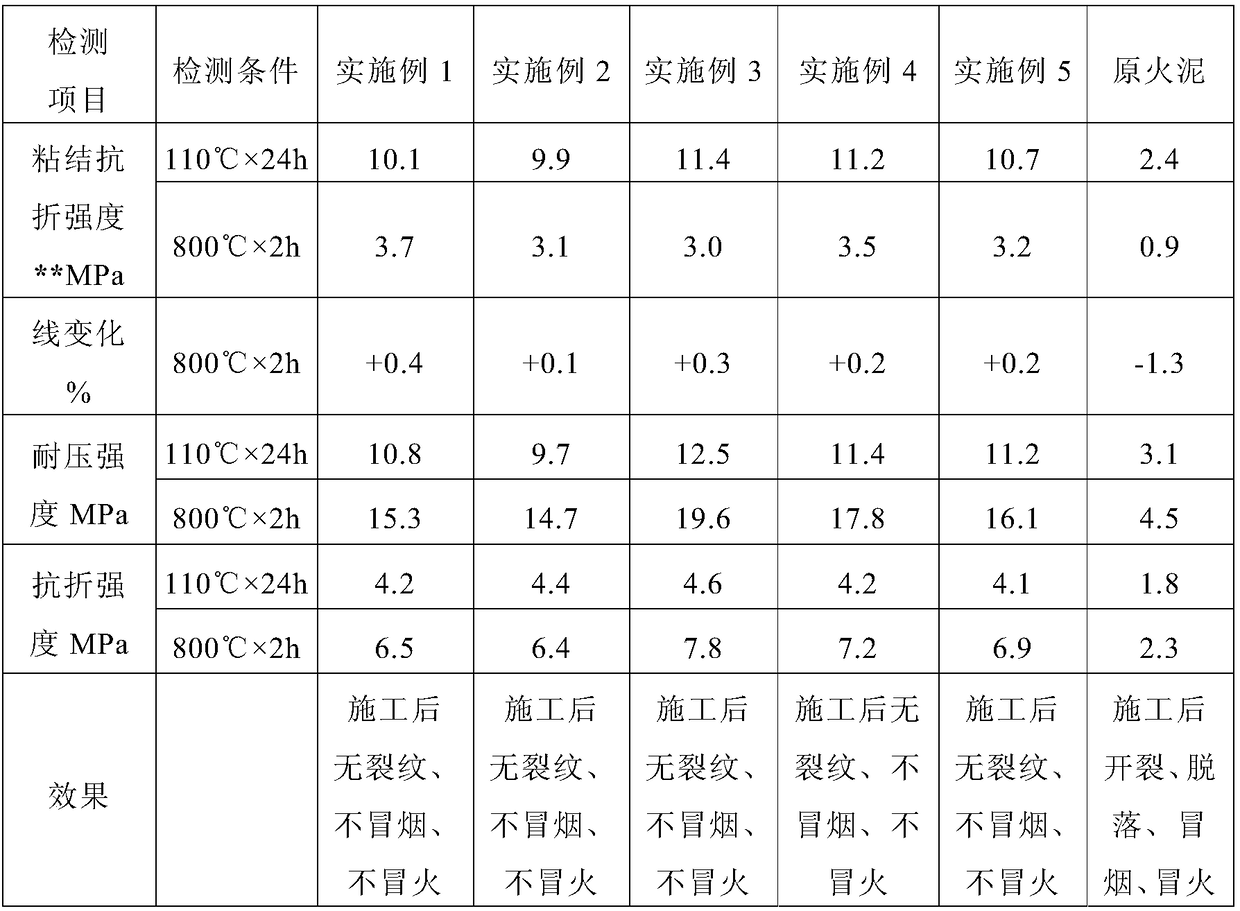

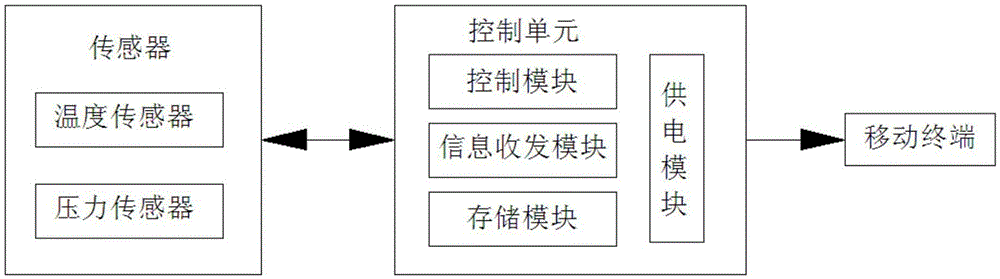

Integrated solution for flat automobile tire

The invention belongs to the technical field of automobile safety electronics, and discloses an integrated solution for a flat automobile tire. According to the integrated solution, sensors and a control unit are included, the sensors comprise the temperature sensor and the pressure sensor, and the control unit comprises a control module, an information receiving and sending module, a storage module and a power supply module. The power supply module supplies power to the control module, the information receiving and sending module and the storage module. According to the integrated solution, temperature and air pressure in the tire are detected in real time and sent to a mobile terminal, and an alarm is given aiming at an abnormal value so that a user can respond immediately to conduct the action of inflating the tire. Operation is easy, convenient and efficient.

Owner:NANJING RUICHUN ELECTRIC CO LTD

Flange sealing device

The invention discloses a flange sealing device, comprising a connecting flange body; an epoxy primer coating is arranged on a connecting flange surface; the joints of a connecting flange are connected by glue injection; an external ring and an internal ring are arranged on the connecting flange body; an external ring sealing groove is formed on the external ring; an internal ring sealing groove is formed on the internal ring; sealing rings matching with each other are embedded in the external ring sealing groove and the internal ring sealing groove; and an adjusting handwheel is arranged at the edge of the connecting flange. Compared with the prior art, the flange surface is coated with an epoxy primer, so that the flange surface is improved; meanwhile, the glue injection is adopted and the sealing rings are arranged; the sealing rings are arranged in two sealing grooves; moreover, the air-tightness can be adjusted freely by rotating the handwheel manually, and the flange sealing device is flexible and accurate to use; the air leakage of the flange surface is improved greatly, so that the air-tightness of connecting pipelines by means of flanges is ensured and the influence caused by the leakage of materials is avoided.

Owner:CHANGZHOU YISHEN MACHINERY FORGING

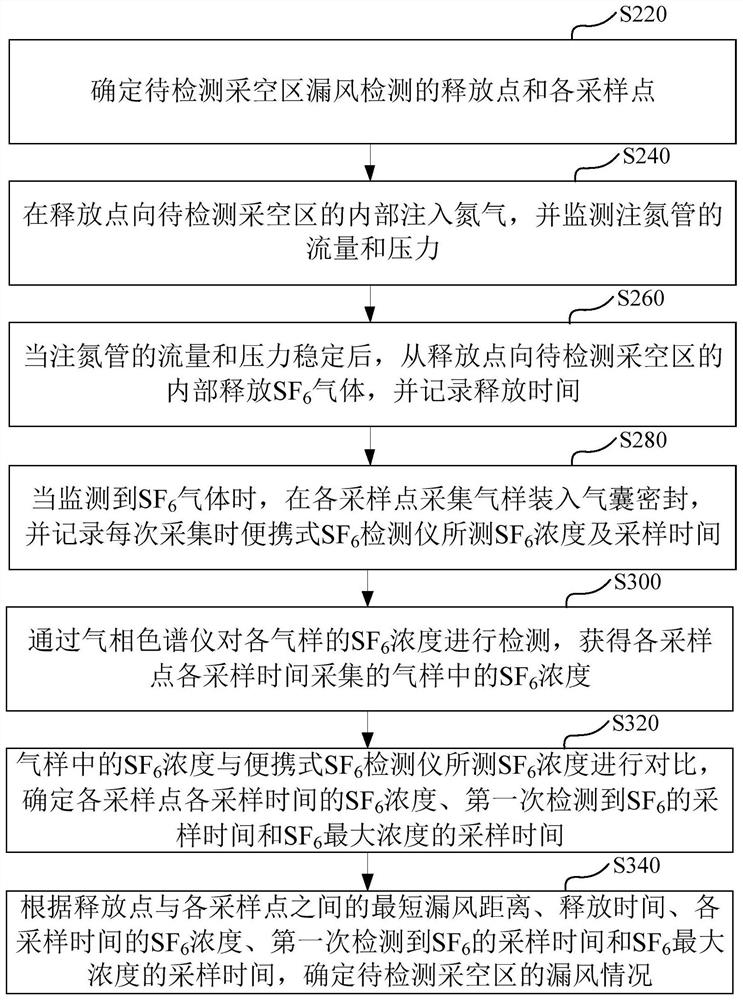

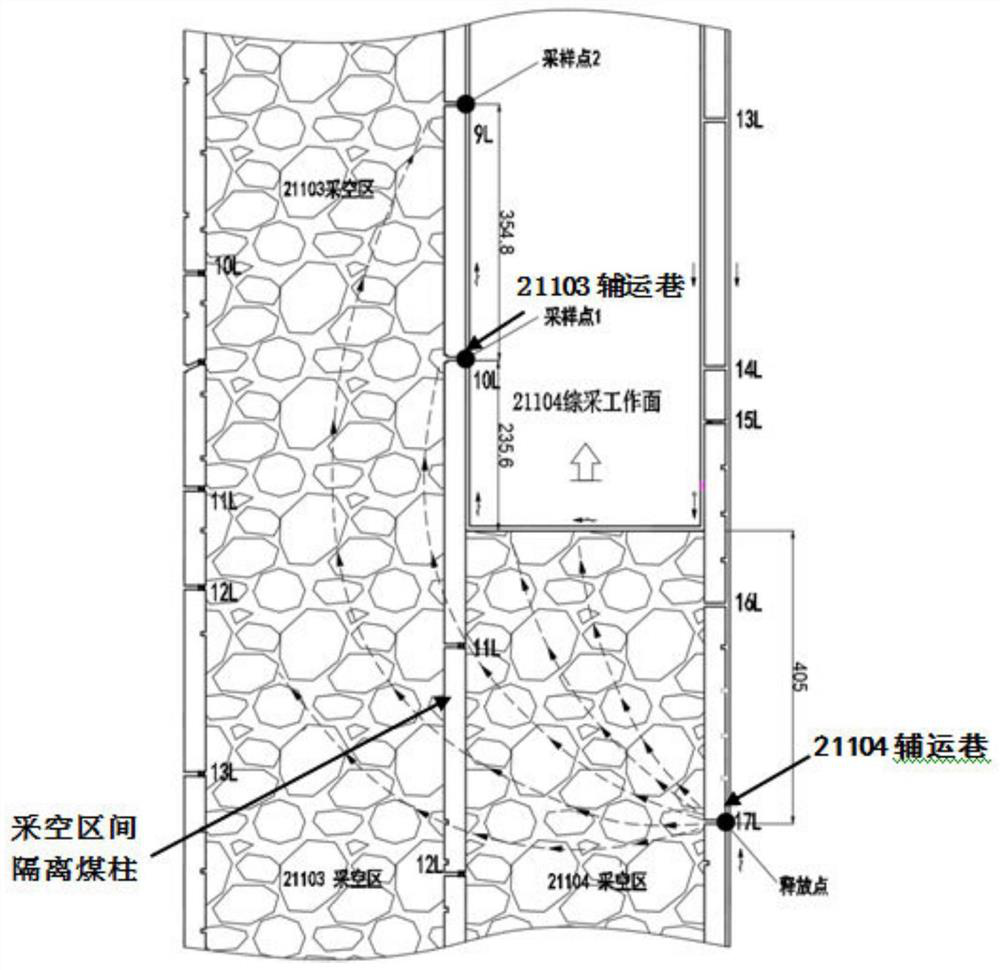

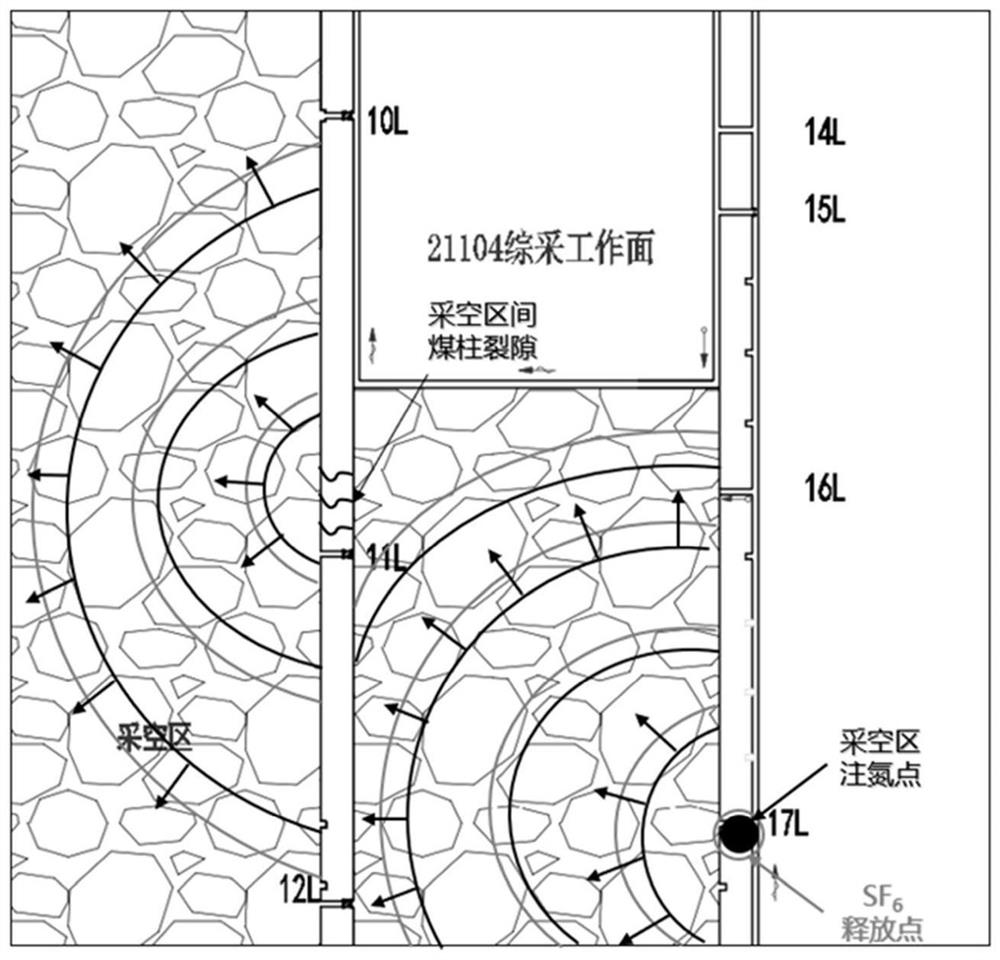

Rapid air leakage detection method for underground goaf

ActiveCN112880941AIncrease pressure differenceSpeed up the testing processDetection of fluid at leakage pointSoil scienceGas liquid chromatographic

The invention relates to a rapid air leakage detection method for an underground goaf. The method comprises the following steps: determining release points and sampling points of air leakage detection of a to-be-detected goaf according to an internal structure and a pressure difference test of the to-be-detected goaf; injecting nitrogen into the to-be-detected goaf at the release point, releasing SF6 gas into the to-be-detected goaf from the release point after monitoring that the flow and the pressure of the nitrogen injection pipe are stable, and recording the release time; when SF6 gas is monitored at each sampling point, collecting a gas sample; detecting the SF6 concentration of each gas sample through a gas chromatograph, and determining the SF6 concentration of the gas sample collected at each sampling point at each sampling time; and according to the shortest air leakage distance between the release point and each sampling point, the release time, the SF6 concentration of each sampling point at each sampling time, the sampling time of SF6 detected by each sampling point for the first time and the sampling time of SF6 detected by each sampling point at the maximum concentration, rapidly obtaining the air leakage condition of the to-be-detected goaf.

Owner:CHINA UNIV OF MINING & TECH

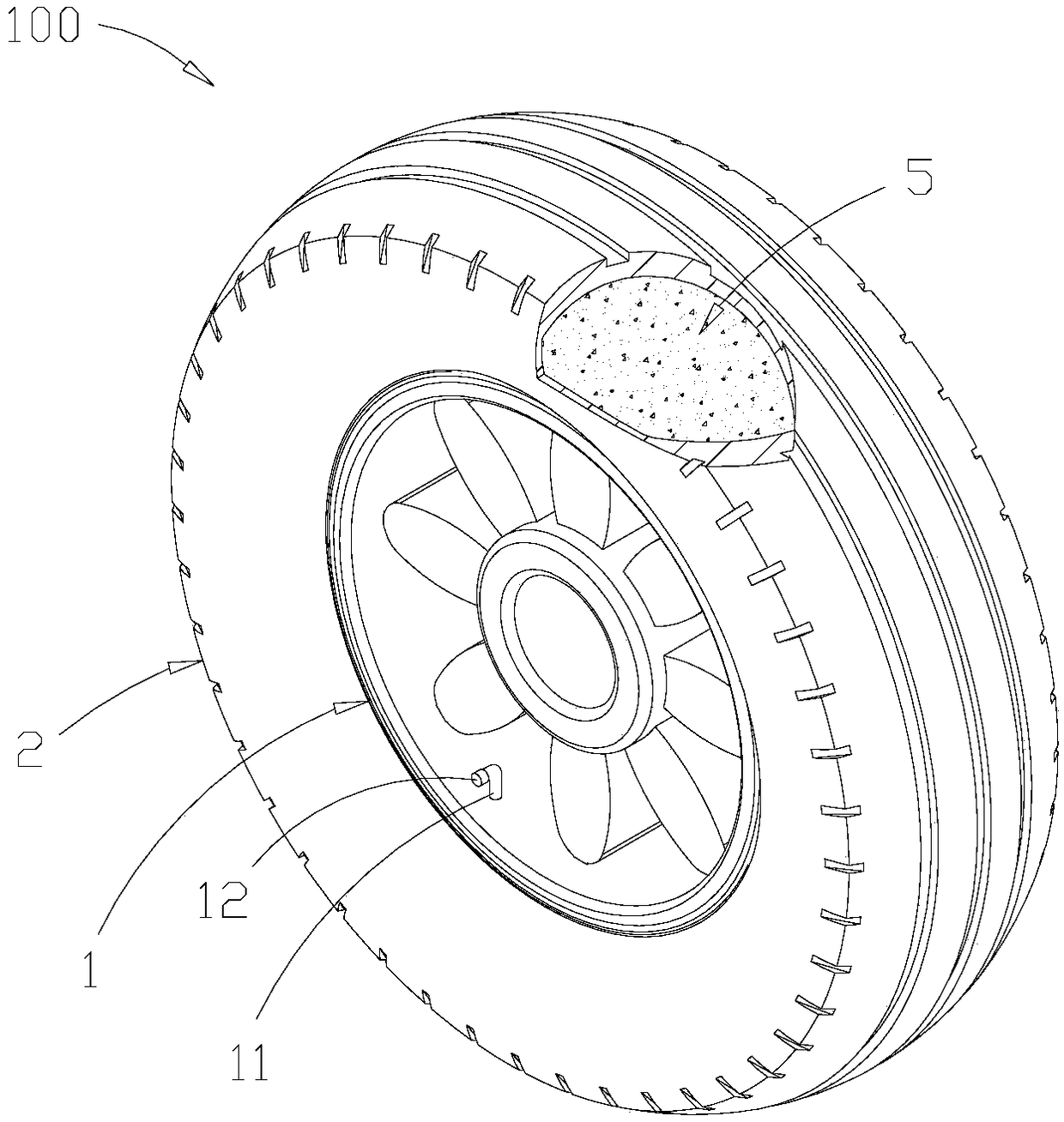

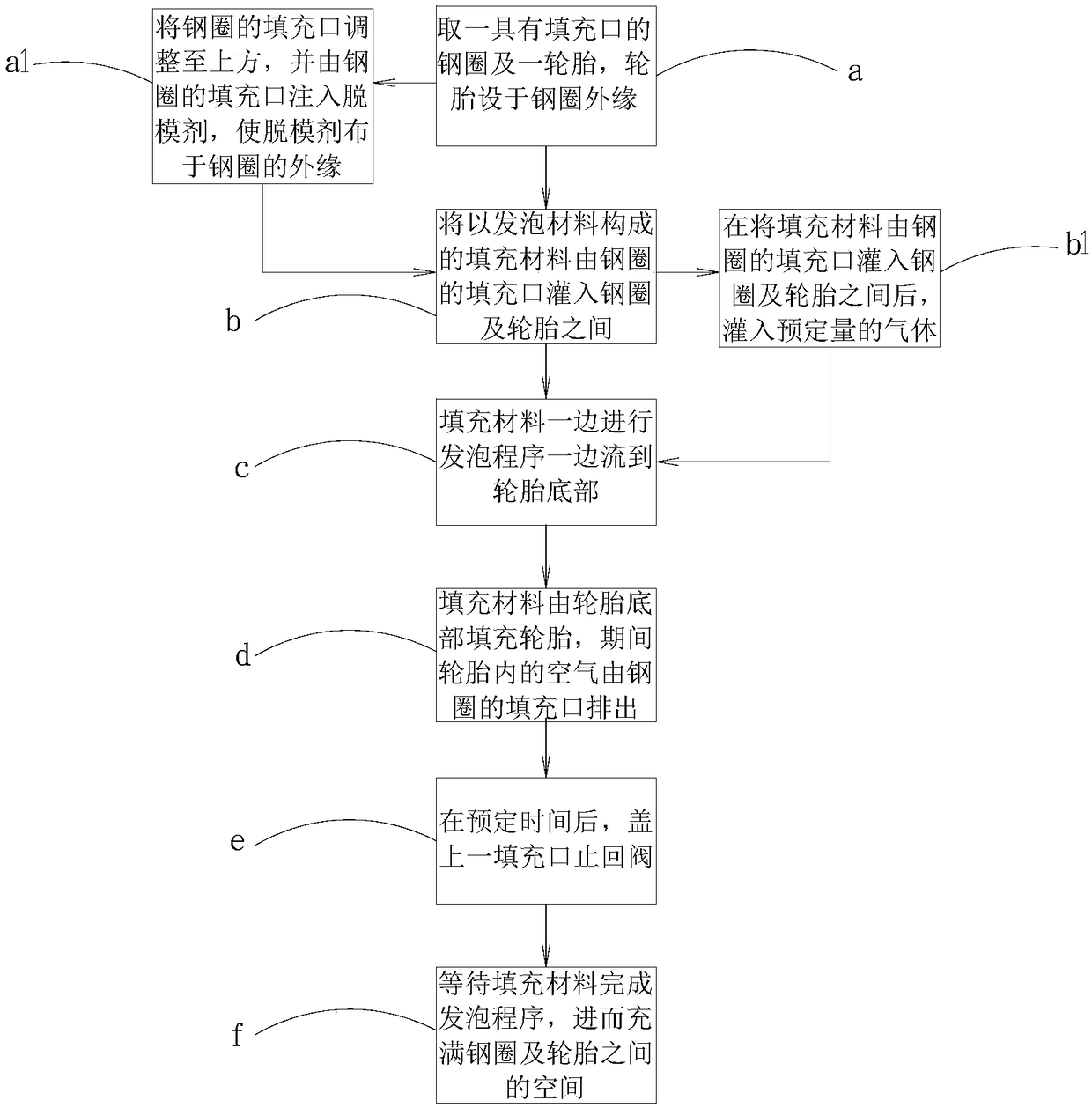

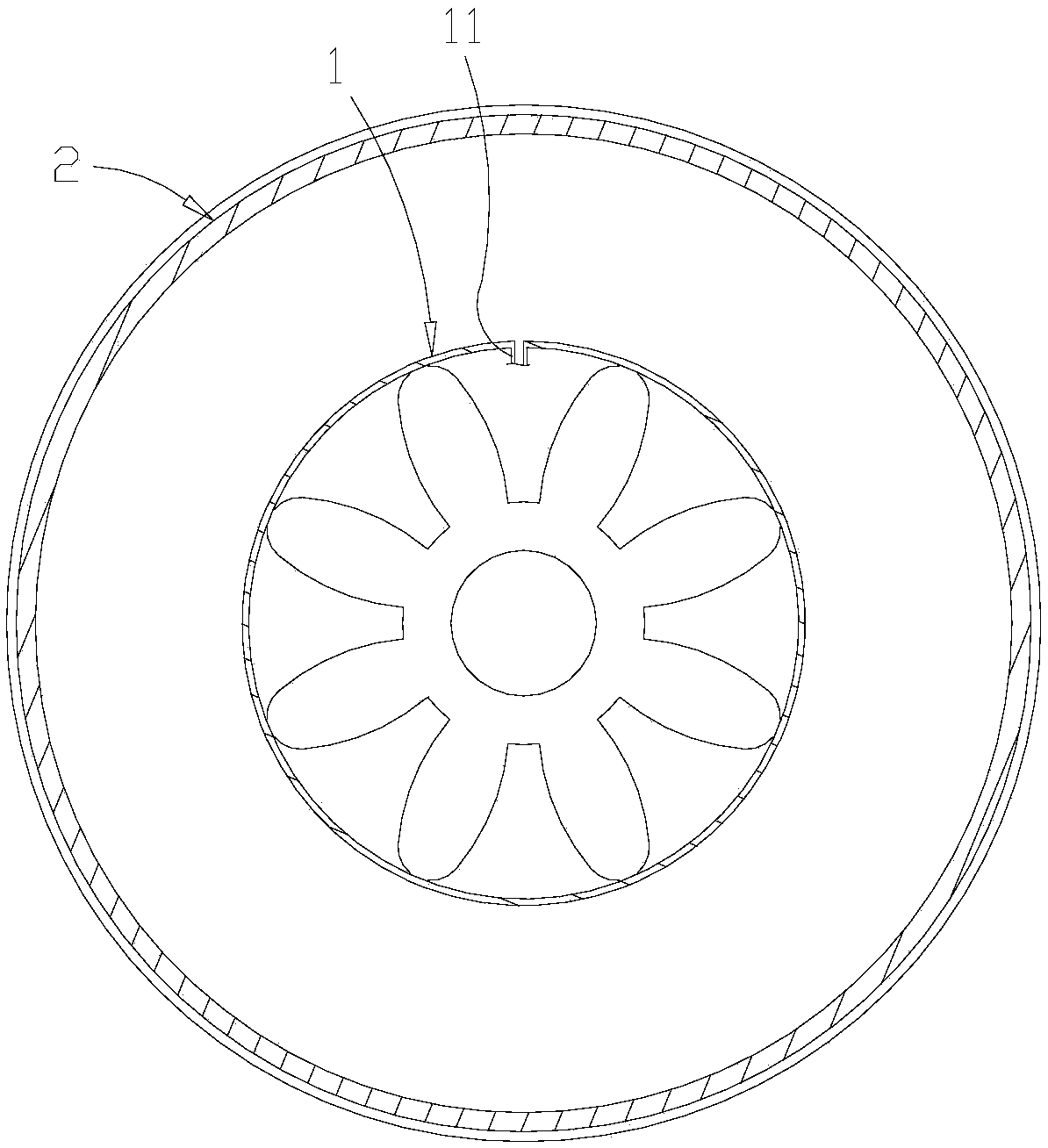

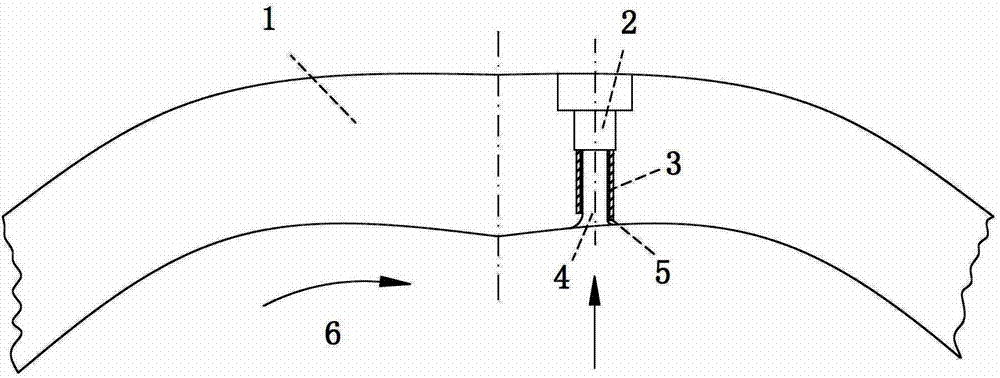

Foaming and filling type tire and manufacturing method thereof

InactiveCN109397989ATire pressure remains stableExtend tire lifeNon-inflatable tyresTyresFilling materialsAutomotive engineering

Owner:张定玮

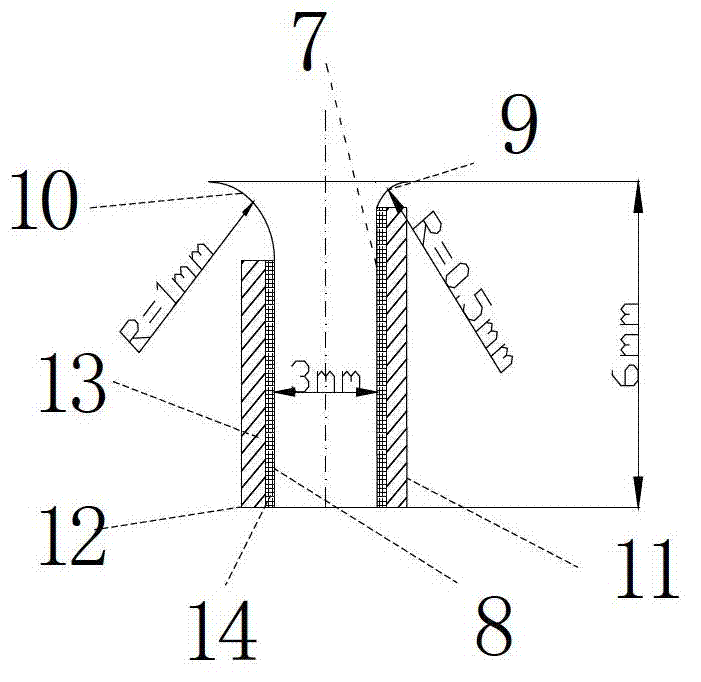

Ignition groove of natural gas rotary engine

InactiveCN103089416AImprove stabilityIncrease success rateInternal combustion piston enginesCombustionCylinder mold

An ignition groove of a natural gas rotary engine comprises a front wall face, a back wall face and a groove channel which is arranged between the front wall face and the back wall face. The front wall face is composed of an arc section and a non-arc section embedded with a carborundum sheet, and the back wall face is composed of an arc section and a non-arc section embedded with a carborundum sheet. The front wall face and the back wall face extend parallelly from the bottom to an air cylinder molded surface, and respectively extend from the position close to the air cylinder molded surface to form arc-shaped wall faces. The radius of an arc on one side of the front wall face is smaller than that of one side of the back wall face. A rectangular concave pit is formed in a non-arc wall face of the groove channel, and is embedded with a carborundum sheet which is coated with a platinum catalyst coating. The depth of the concave pit is equal to the thickness of the carborundum sheet, and therefore the arc sections of the front wall face and the back wall face and the non-arc sections which are embedded with the carborundum sheets of the front wall face and the back wall face are enabled to be respectively connected smoothly. According to the ignition groove of the natural gas rotary engine, the engine ignition is enabled to be convenient, combustion is promoted and accelerated by utilizing of a stable flame back frontal surface after ignition, combustion efficiency is improved, and whole performance of the engine is improved.

Owner:JIANGSU UNIV

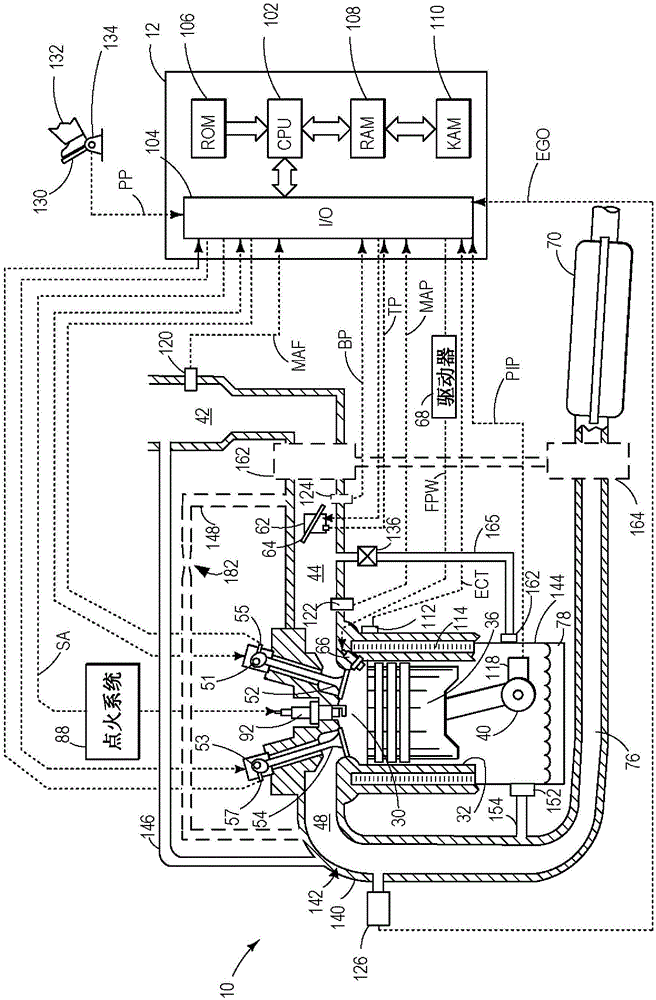

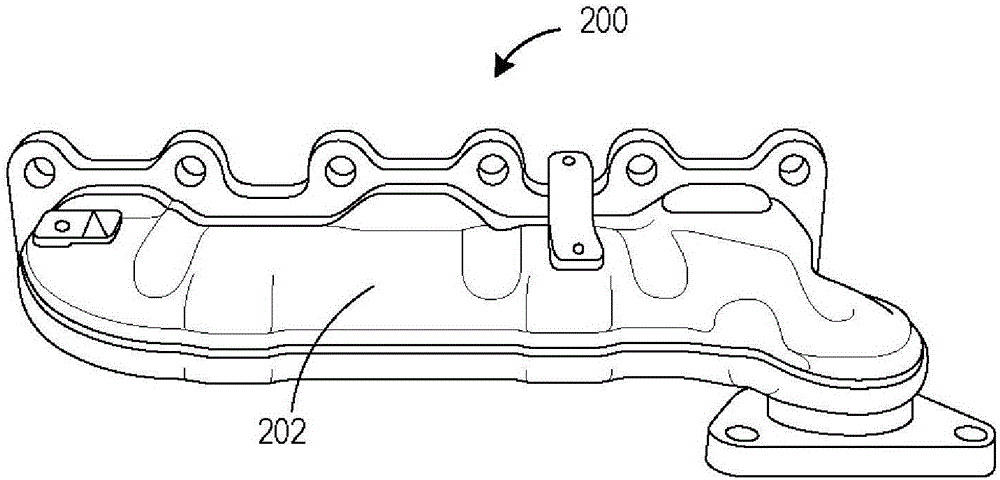

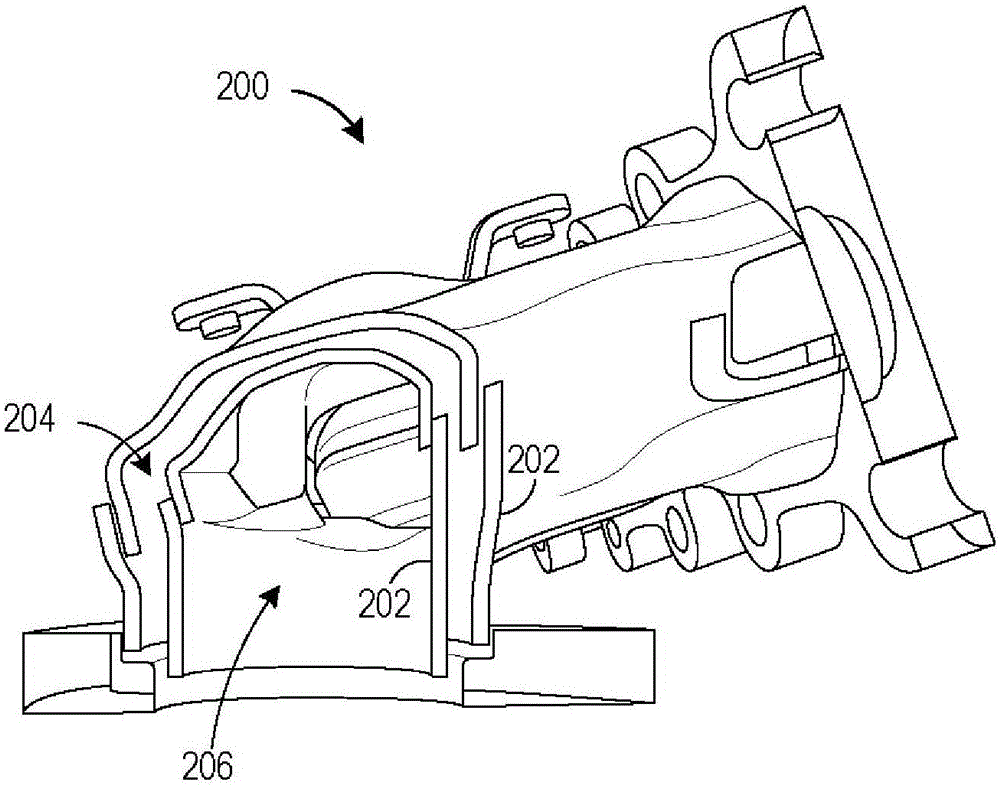

Method and system for expediting engine warm-up

ActiveCN105257436AReduce maximum powerEasy to separateElectrical controlInternal combustion piston enginesCrankcaseThrottle

The invention relates to a METHOD AND SYSTEM FOR EXPEDITING ENGINE WARM-UP. Methods and systems are provided for improving crankcase ventilation by directing heated air to a crankcase. Air is drawn into the crankcase upon passage through an interstitial space of a double walled exhaust manifold where it is heated. Crankcase vapors are then released to the engine intake, downstream of an intake throttle.

Owner:FORD GLOBAL TECH LLC

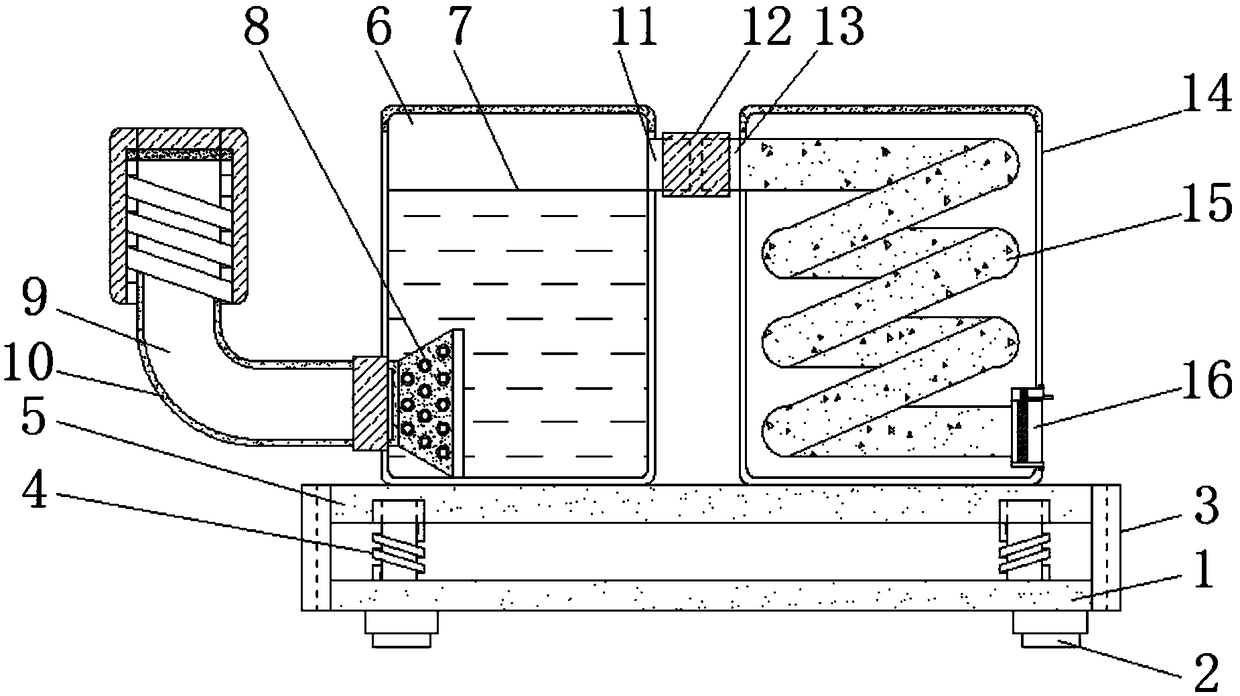

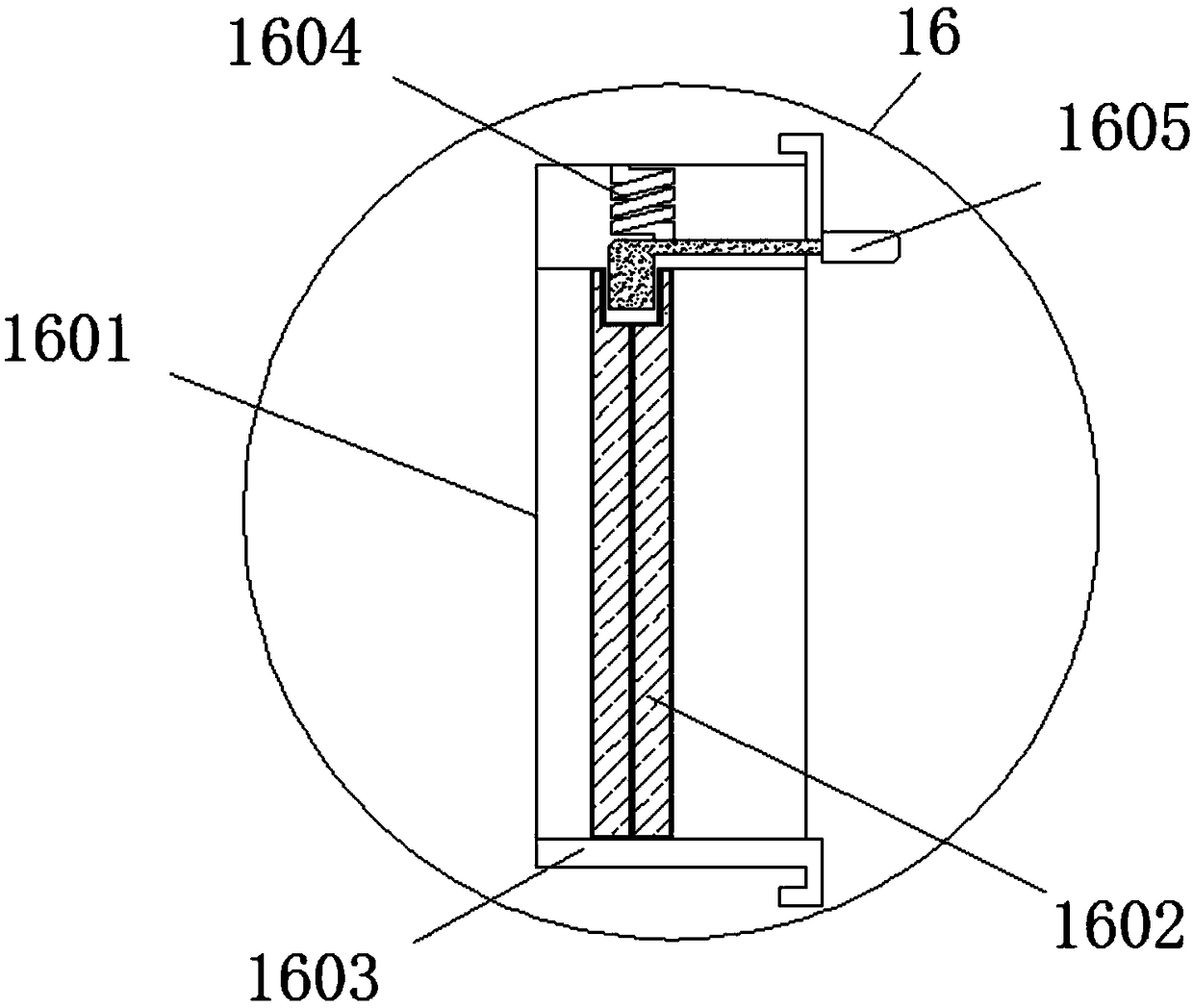

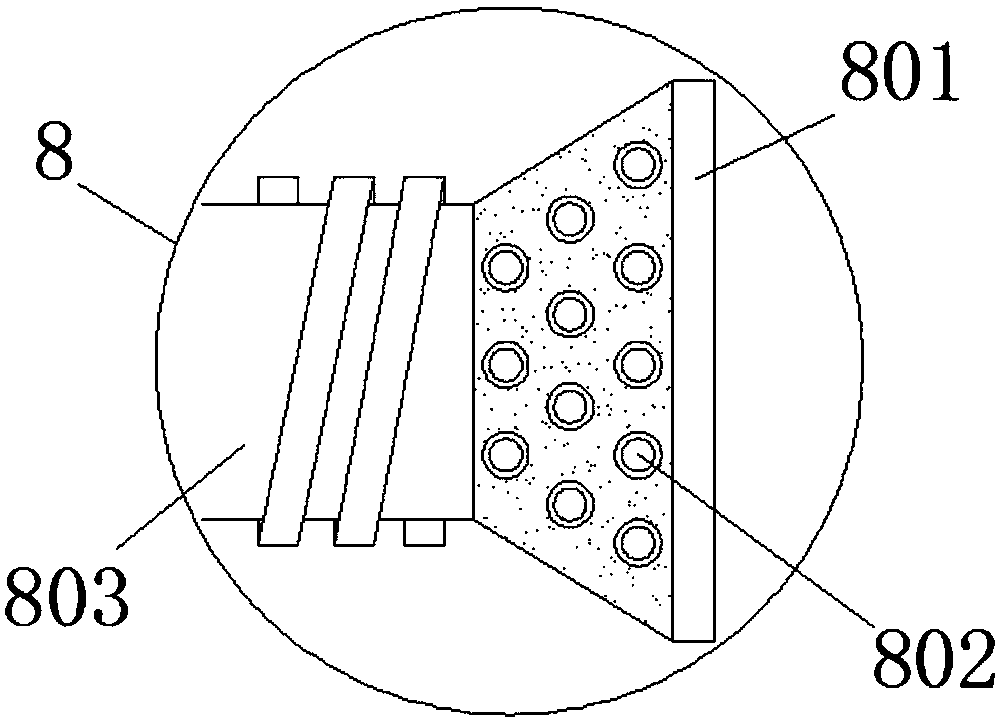

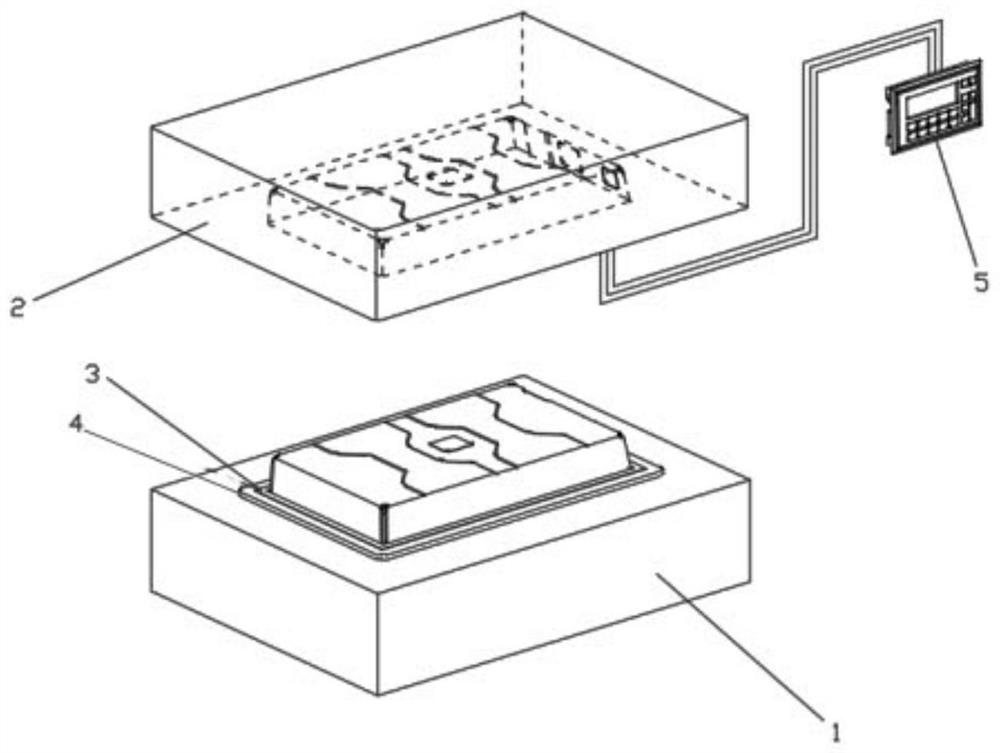

Assembled filtration pipeline for yellow phosphorus tail gas boiler

InactiveCN108592063AImprove filtering effectGood removal effectLighting and heating apparatusHazardous substanceFiltration

The invention discloses an assembled filtration pipeline for a yellow phosphorus tail gas boiler. The assembled filtration pipeline comprises a supporting bottom plate, a cooling box, a pipe head anda filter screen, wherein supporting columns are arranged at the lower end of the supporting bottom plate, buffer columns are arranged on the upper side of the supporting bottom plate, the cooling boxis located on the upper side of the supporting plate, the pipe head is located on the lower left side of the cooling box and connected with a connecting pipe, and an anticorrosion layer is arranged onthe inner side of the connecting pipe; a first threaded pipe is arranged on the upper right side of the cooling box, a second threaded pipe is arranged on the right side of the first threaded pipe, both the first threaded pipe and the second threaded pipe are connected with a sleeve, and a storage box is fixed at the right end of the second threaded pipe; and the filter screen is located at the right end of an alkaline pipe, and the alkaline pipe is located on the inner side of the storage box. The assembled filtration pipeline for the yellow phosphorus tail gas boiler is convenient to install and disassemble, meanwhile hazardous substances can be fully removed through twice filtration of water washing and alkaline washing conveniently, yellow phosphorus tail gas is conveniently treated,and use convenience is realized.

Owner:贵州开阳川东化工有限公司

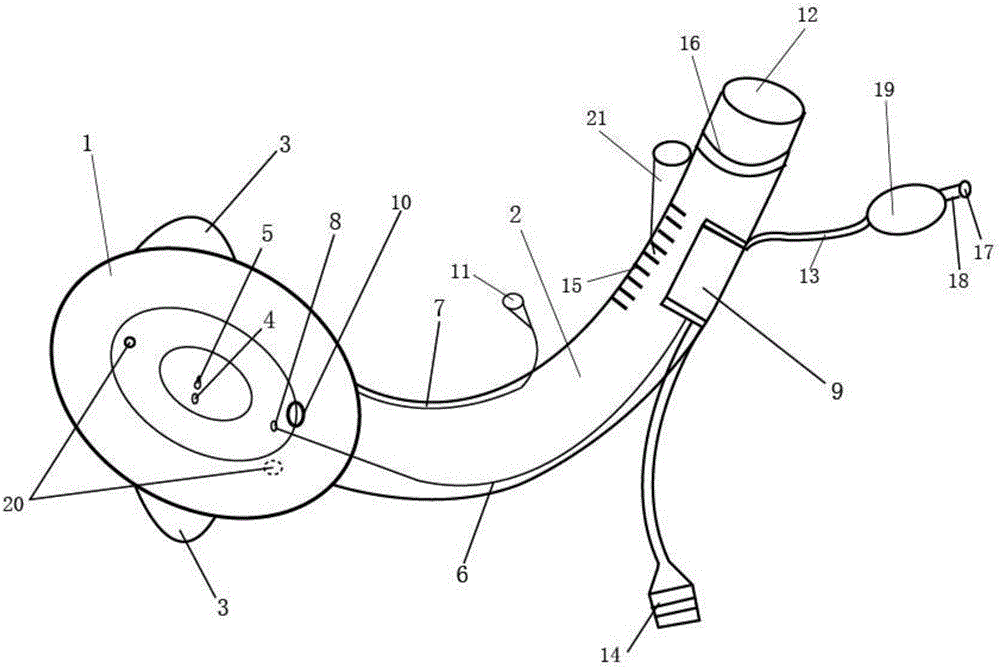

Continuous monitoring device for position of laryngeal mask

The invention provides a continuous monitoring device for a position of a laryngeal mask. The continuous monitoring device comprises an inflation bag and a ventilation pipe connected with the inflation bag, wherein ear air bags are arranged at the left and right sides of the inflation bag respectively; the inflation bag is internally provided with an air outlet and a reserved pipe inserting opening; a temprature probe connection wire is buried into one side of a pipe wall of the ventilation pipe; an ear bag inflation pipeline is arranged at the other side of the pipe wall of the ventilation pipe; a temperature measuring probe is arranged at one end, close to the inflation bag, of the temprature probe connection wire; the other end of the temprature probe connection wire is connected with a display screen; a camera is arranged at the part, close to the temperature measuring probe, of the bottom of the inflation bag; the ear air bags are communicated with an ear bag inflation opening through the ear bag inflation pipeline; a breathing opening connector is arranged at the bottom of the ventilation pipe. The continuous monitoring device for the position of the laryngeal mask has the beneficial effects that the inflation bag can be inflated at the periphery and air leakage is prevented; an air pipe inserting pipe can be inserted to help breathing when inflation is not carried out, and the laryngeal mask can be prevented from deviating through detection.

Owner:GUANGDONG ANESTHESIA MEDICAL SCI & TECH CO LTD

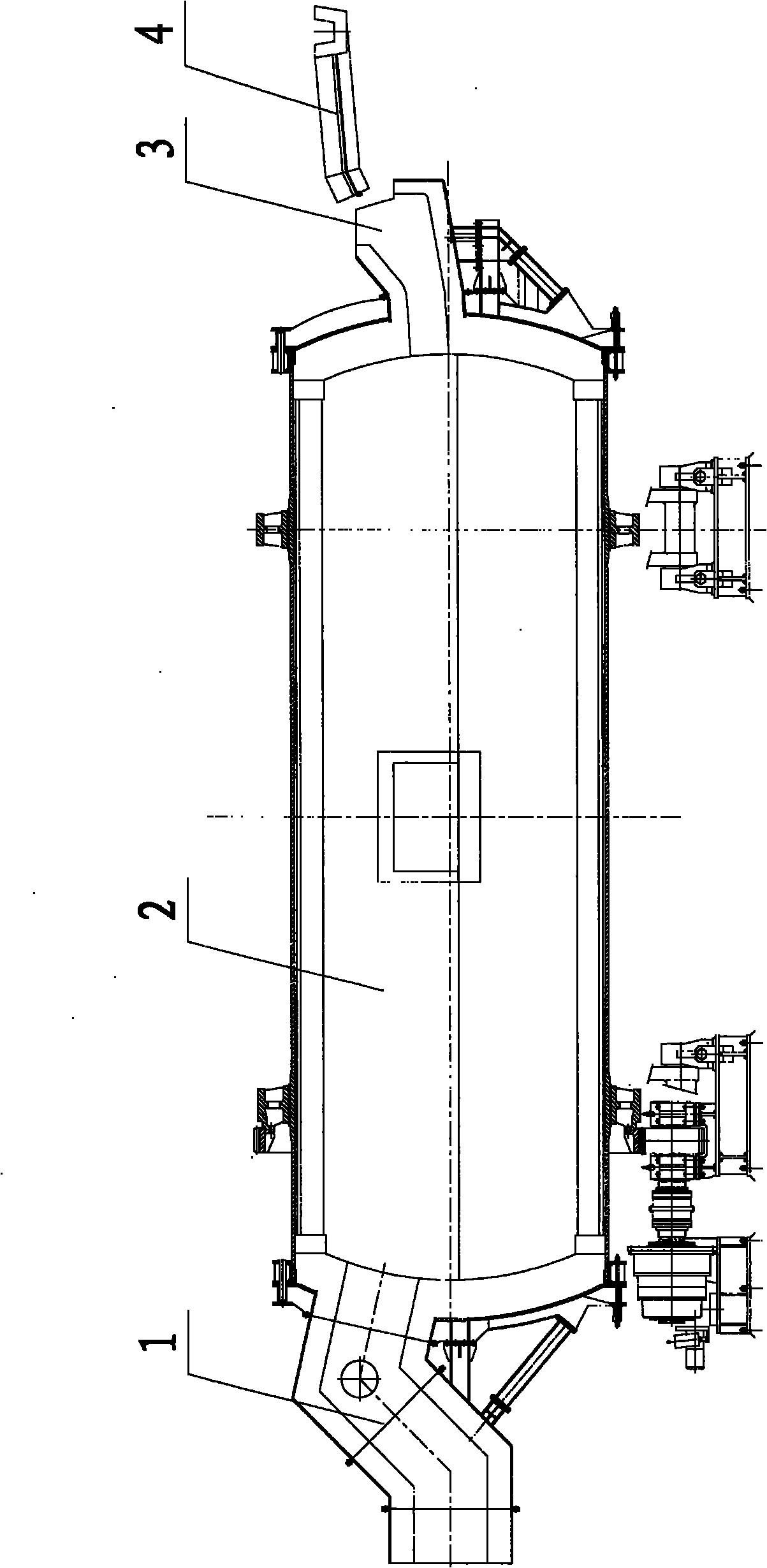

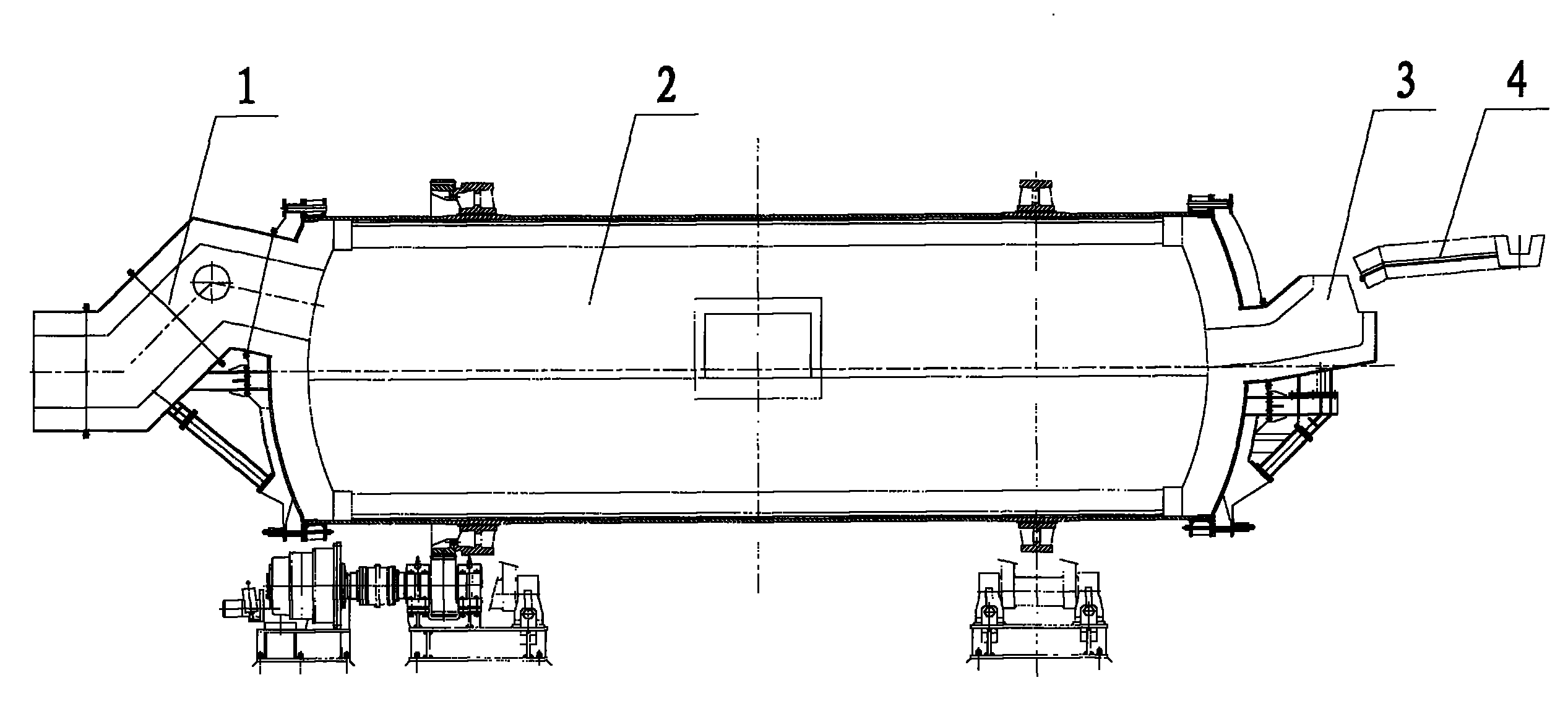

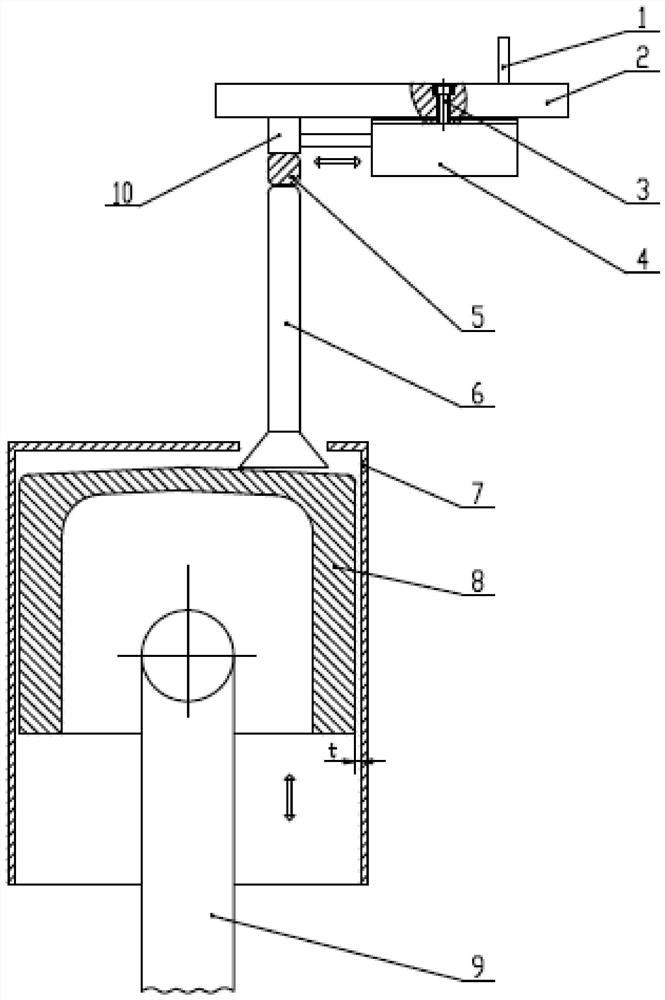

Feeding method and equipment of anode refining furnace

InactiveCN101865603APrevent air leakageImprove air leakageCharge manipulationFlue gasOperation safety

The invention discloses a feeding method and the feeding equipment of an anode refining furnace. Feeding is realized in a way that: through a connecting chute between a converting furnace and the anode refining furnace, hot crude copper produced by the converting furnace automatically flows into a feed inlet on the upper part of a headwall of the anode refining furnace due to an altitude difference between the converting furnace and the anode refining furnace, and then enters the anode refining furnace for refining. In the equipment, the feed inlet is fixedly arranged on the upper part of the headwall of the anode refining furnace by a bracket, aslant rotates with the anode refining furnace, forms the altitude difference of at least 1 cm with a copper placement opening of the converting furnace, and is jointed with the connecting chute. As the feed inlet and a smoke outlet are arranged on the two headwalls of the anode refining furnace respectively, the method has the advantages of low cost, small discharged smoke amount, high temperature and the favorability for waste heat recovery and treatment. The equipment has the characteristics of simple structure, low cost, secure operation, the capacity of avoiding the high-altitude lifting and delivery of high-temperature melt, high furnace sealing property, less air leakage, the favorability for flue gas waste heat recovery and subsequent flue gas treatment, and particular application to copper smelting plants adopting a copper continuous converting process.

Owner:CHINA NERIN ENG

Composite sealing device of steel ball and strong magnet for sintering machine

The invention relates to a steel ball and strong magnet compound type sealing device used for a sintering machine. The steel ball and strong magnet compound type head and tail sealing device comprisesa sealed ore tank, steel balls, high-strength magnets, a sealing beam and an adjustment base. The sealed ore tank is filled with the high-strength magnets and the steel balls of different grain diameters instead of a traditional sealing cover plate, and the rolling sealing effect is achieved. By arranging a magnetic sealing device at the positions of slide way end faces of adjacent trolleys, by means of dependence on the attraction effect of a directionally-magnetized magnet device, iron powder is firmly attracted to the positions of seams of the end portions of slide plates, and then the sealing effect is achieved. Air leakage of a whole sintering system is further reduced, and the ideal ore sintering effect is achieved; and meanwhile electric energy is saved, and high application and popularization value is achieved.

Owner:YANSHAN UNIV

Method for improving surface quality of upper cover of battery and composite battery upper cover

PendingCN113510942AQuality improvementImprove pass rateCell lids/coversCompression moldingMechanical engineering

The invention discloses a method for improving the surface quality of an upper cover of a battery. The method comprises the following steps that prepreg is laied in the whole lining of a mold; electronic cloth is placed at the local position of the prepreg; a press is started to close the mold and perform compression molding operation, the compression molding operation comprises continuous first-stage compression molding and second-stage compression molding, and the first-stage compression molding parameters are as follows, the compression molding pressure is 20-50T, and the pressure holding time is 15-60 seconds; the second-stage compression molding parameters are as follows, the compression molding pressure is 160-240 T, and the pressure maintaining time is 240-480 seconds; the mold closing speed is 5-10 mm / s; the temperature of the upper mold is 153-163 DEG C, and the temperature of the lower mold is 155-165 DEG C; and the mold is opened and the product is taken out.

Owner:广东百汇达新材料有限公司

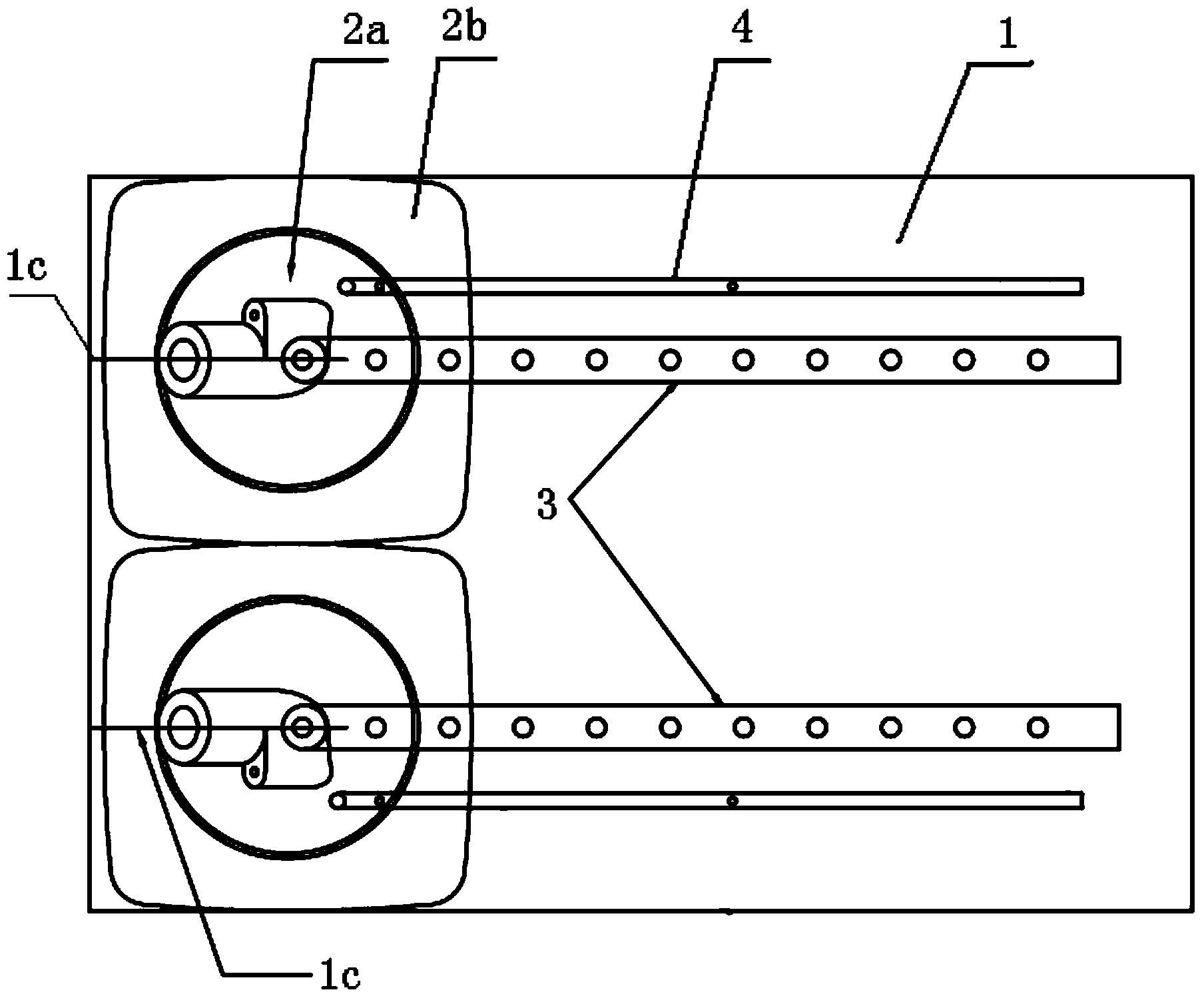

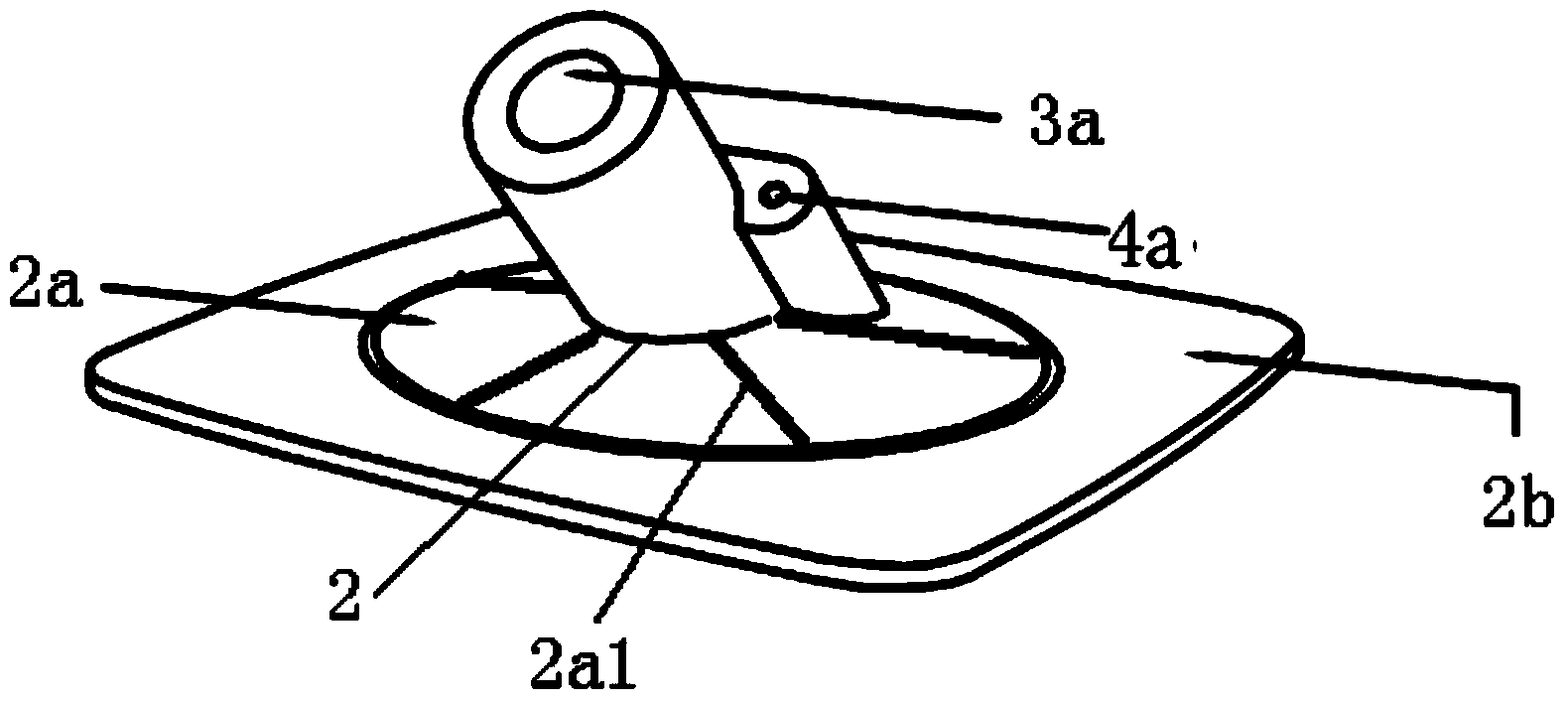

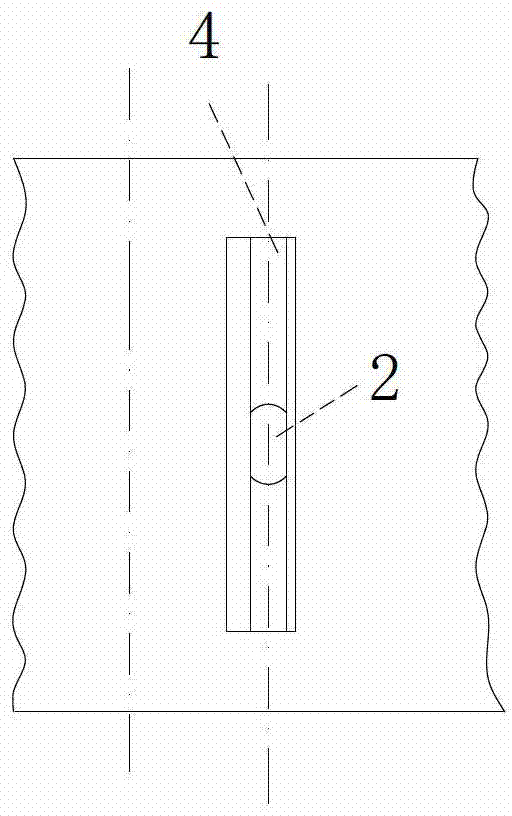

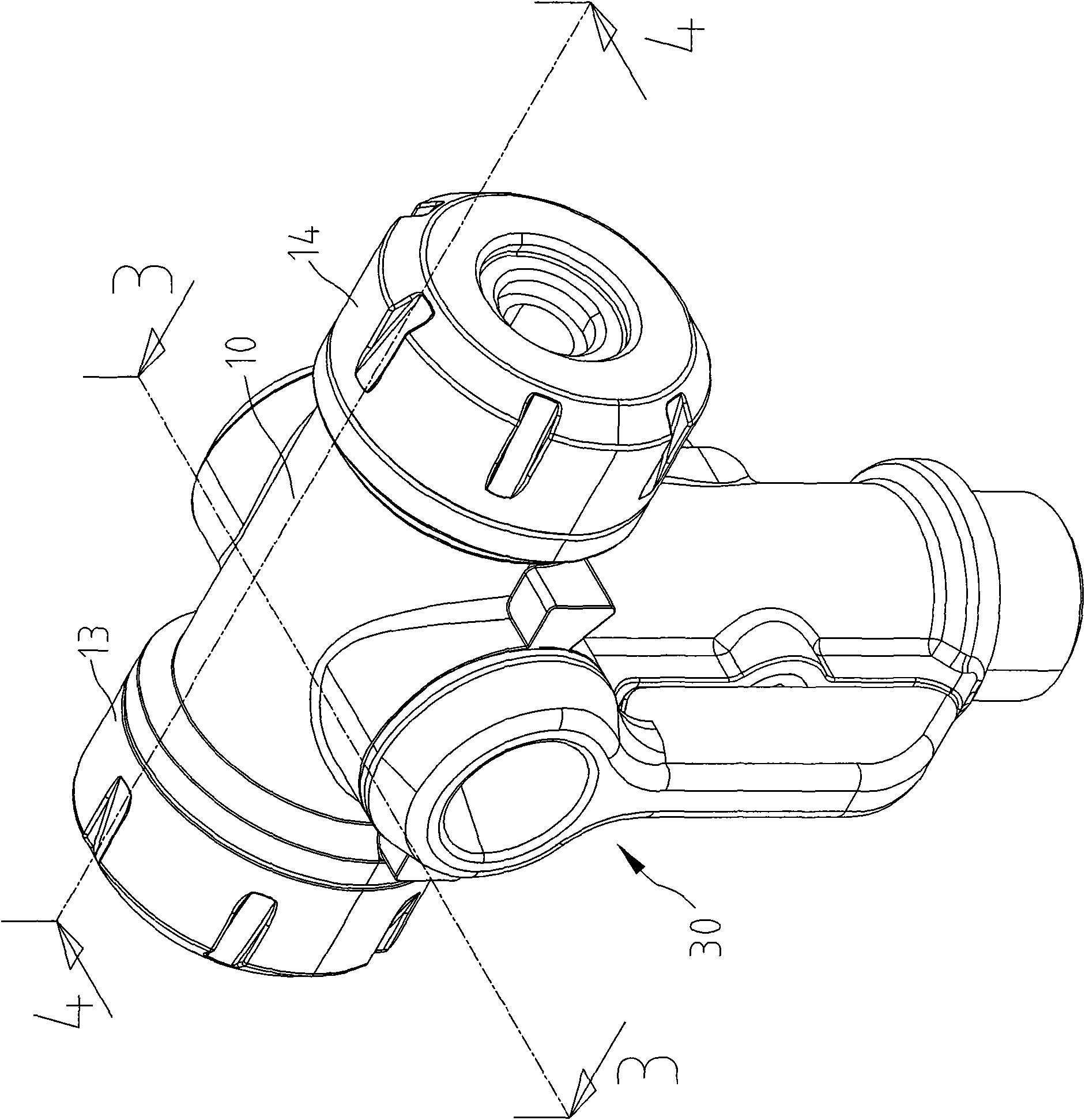

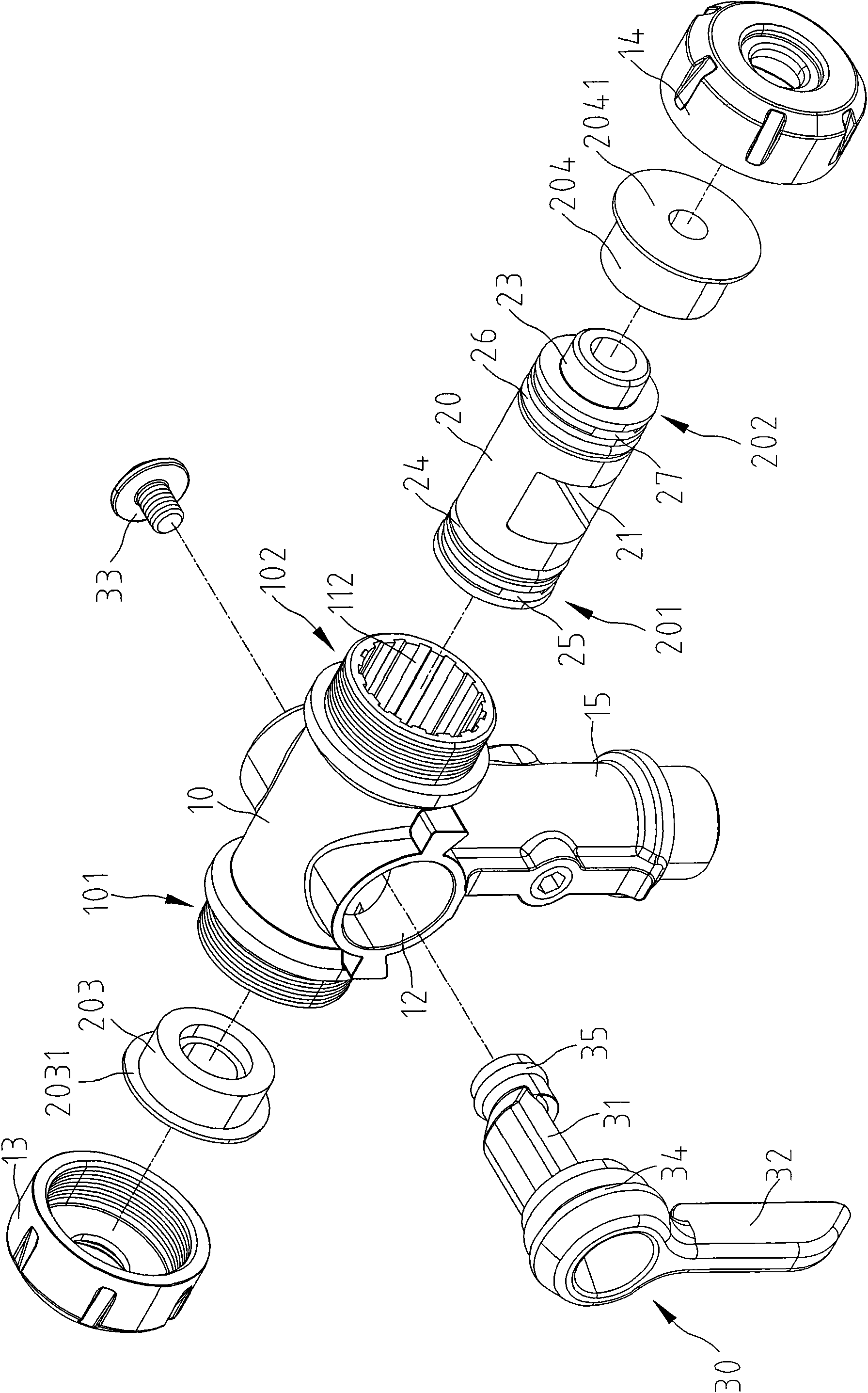

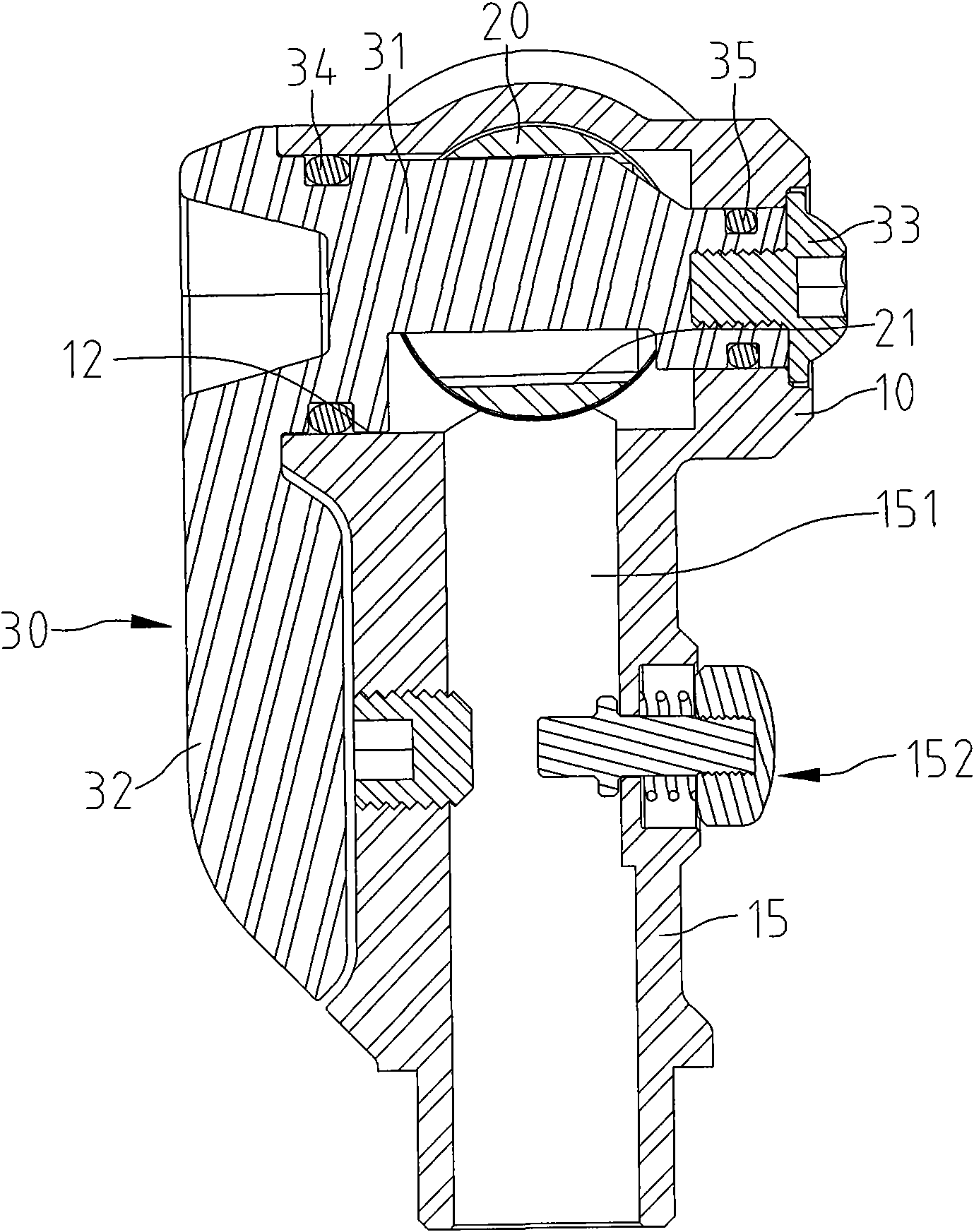

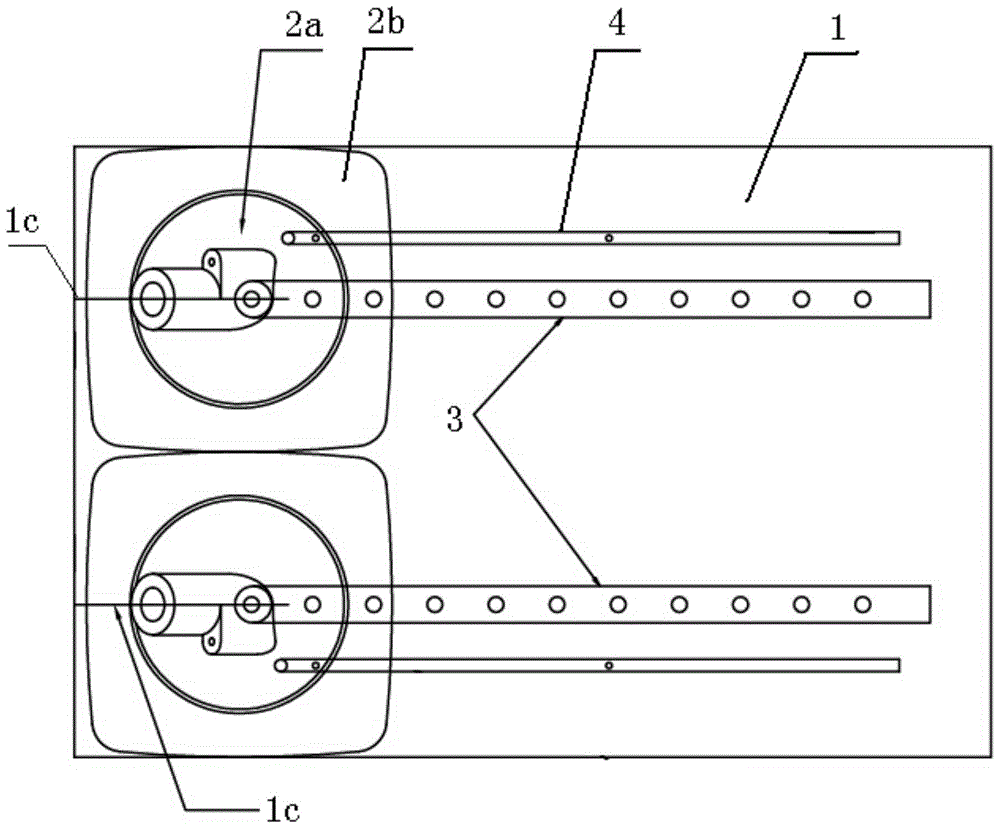

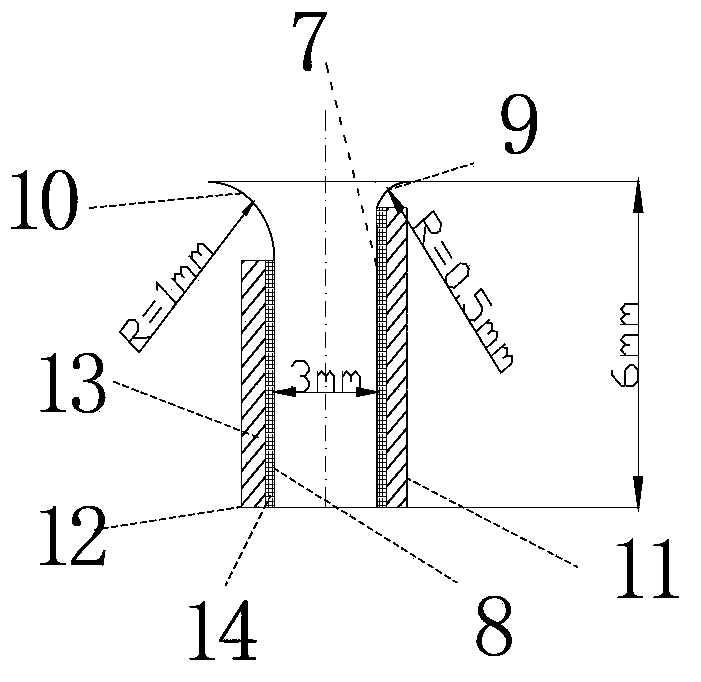

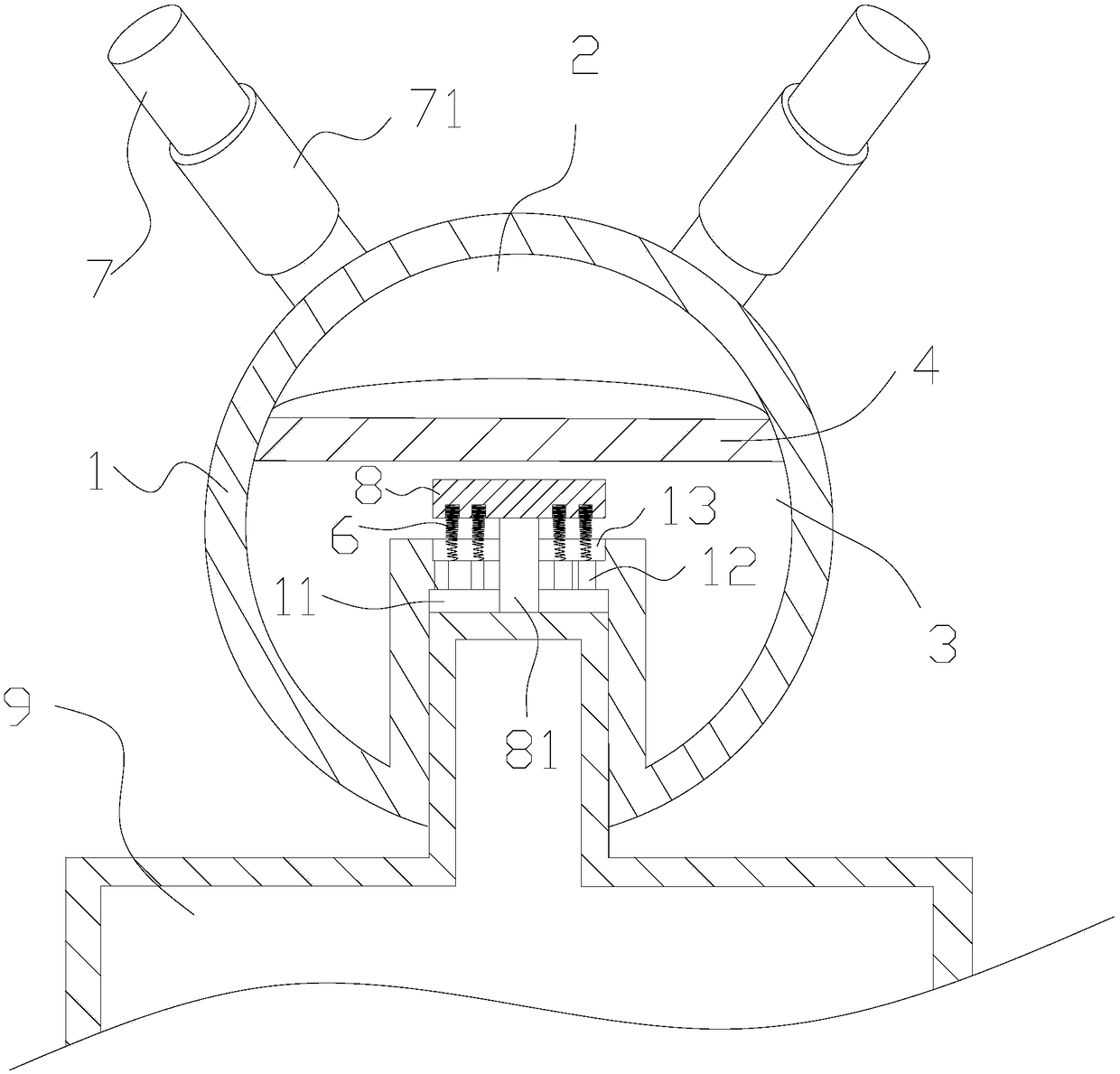

Dual-air tap inflating joint capable of improving air leakage

ActiveCN102032150BImprove air leakageEasy to processPositive displacement pump componentsPositive-displacement liquid enginesPump headElectrical and Electronics engineering

The invention provides a dual-air tap inflating joint capable of improving air leakage, comprising a dual opening cylinder, a centering piece and a toggle piece, wherein the centering piece is accommodated in an accommodation hole of the dual opening cylinder and can move relative to the accommodation hole of the dual opening cylinder; a first O-shaped ring is sleeved at the first end of the centering piece; a second O-shaped ring is sleeved at the second end of the centering piece; a penetrating hole is arranged between the first end and the second end of the centering piece; the toggle piece is provided with an eccentric block which can push the centering piece to slide left and right; O-shaped rings are sleeved at two ends of the eccentric block; when the toggle piece is not spanned, afirst inflating space and a second inflating space of the centering piece are not communicated; and the second inflating space of the centering piece is communicated with a channel of the dual opening cylinder. With the technical scheme provided by the invention, the air leakage phenomenon that a pumping head is connected with the air tap can be improved; the air leakage situation that the togglepiece is spanned after the charging is finished to release the air tap of a bicycle type can be avoided; and the dual air tap inflating joint is convenient to process, can effectively save the cost and has the convenience and the practicability.

Owner:TOPEAK INC

Shape memory polymer-based air filling extensible wing and methods for manufacturing same

The invention provides a shape memory polymer-based air filling extensible wing and methods for manufacturing the same, relates to an extensible wing and a method for manufacturing the same, and aims to solve the problem that the strength and the rigidity, needed for the flight of a plane, of the wing are not met, and the problem that the wing is easily damaged for air leak when the punching pressure is too big in the conventional air filling extensible wing. A skeleton of the wing is made of shape memory polymers. The method I comprises a step of manufacturing the skeleton of the wing comprise: designing a mould, manufacturing an uncured fiber reinforcement shape memory polymer blank, heating the blank at a temperature of between 70 and 80 DEG C for 16 to 24 hours, demoulding the fiber reinforcement shape memory polymer blank, which is heated to be cured, to obtain a corresponding wing rib or wing beam, and then connecting and fixing the wing rib and the wing beam to form the skeleton of the wing. The method II comprises: keeping warm for 60 minutes at a temperature of 75 DEG C, heating the skeleton of the wing to the temperature of 100 DEG C, keeping the temperature for 30 minutes, cooling skeleton of the wing to the temperature of 75 DEG C, and keeping the temperature for 24 hours. The air filling extensible wing of the invention meets the strength and the rigidity, needed for the flight of a plane, of the wing the sealing property of the wing is good, and the method for manufacturing the wing has an advantage of simple process operation.

Owner:HARBIN INST OF TECH

A multi-layer negative pressure sealing drainage device for wound protection

ActiveCN104225768BImprove hydrophilicityOvercome limitationsEnemata/irrigatorsWound drainsDrainage woundPolymer science

The invention provides a multi-layer negative pressure sealing drainage wound protection device, comprising a porous foam cushion, a drainage tube with one end located in the porous foam cushion, the porous foam cushion is a multi-layer composite foam cushion, including a negative pressure conduction layer and The drainage protection layer, the negative pressure conduction layer is a hydrophobic porous foam material layer, the drainage protection layer is a hydrophilic porous foam material layer, and the drainage tube is placed in the negative pressure conduction layer; it also includes an oxygen-containing liquid flushing tube, an oxygen-containing liquid The flushing tube and the drainage tube enter the porous foam cushion side by side, the drainage tube passes through the porous foam cushion and is located on the lower surface of the drainage protective layer, and its tail end goes deep into the drainage protective layer for positioning, and small holes are arranged on the tube wall. The introduction end of the drainage tube and the oxygen-containing liquid flushing tube is fixed by a common elastic sealing film floppy disk. The elastic sealing film floppy disk includes a disc and an outwardly extending elastic sealing film bonded to the disc. There is drainage in the middle of the disc. The drainage inlet nozzle of the tube and the irrigation inlet nozzle of the oxygen solution flushing tube. There is a longitudinal slit at the inlet end of the drainage tube of the porous foam cushion, which is convenient for the introduction of the nozzle to turn over.

Owner:WUHAN VSD MEDICAL SCI & TECH CO LTD

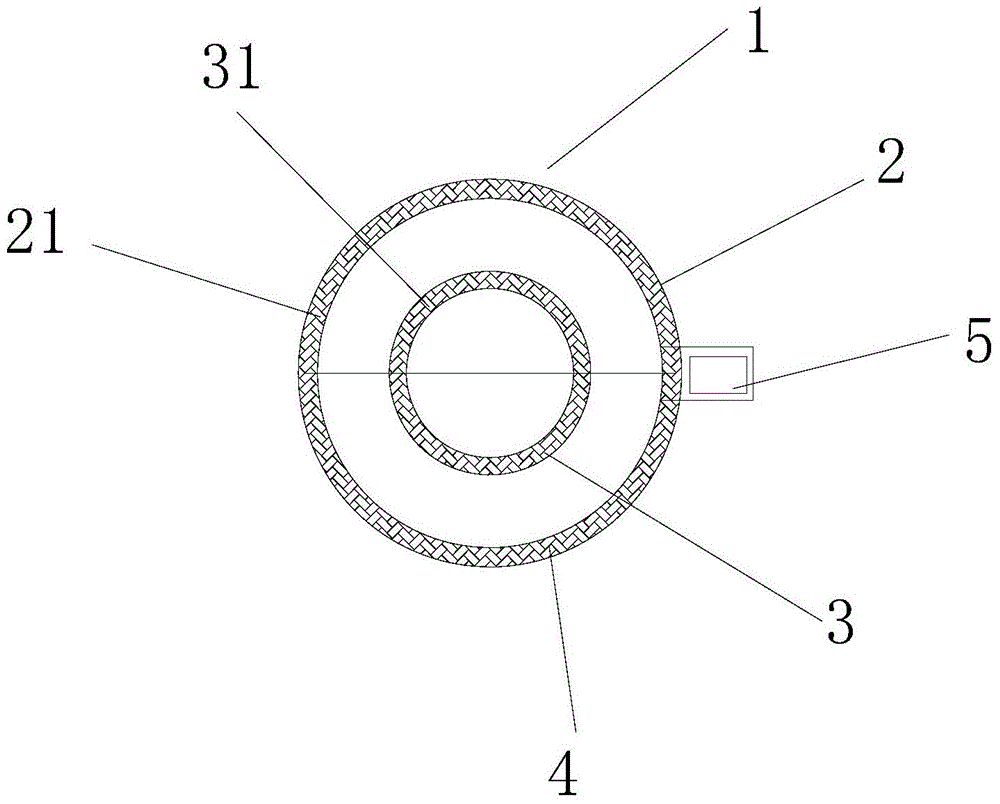

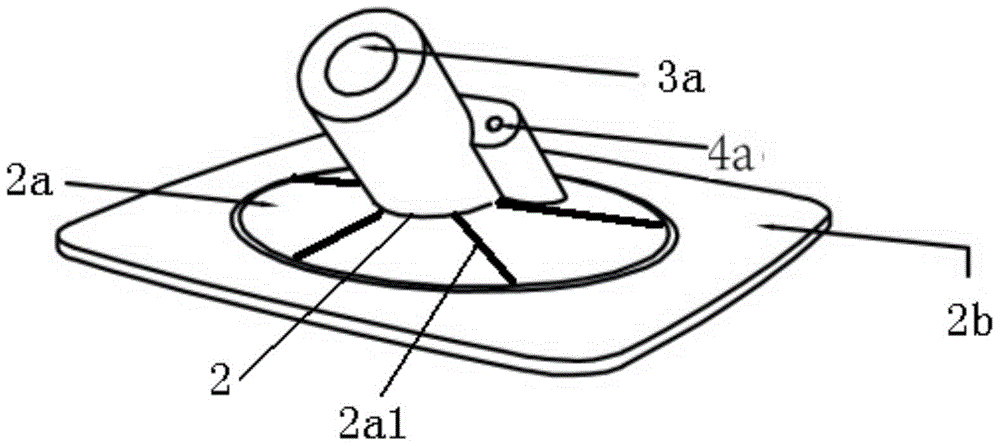

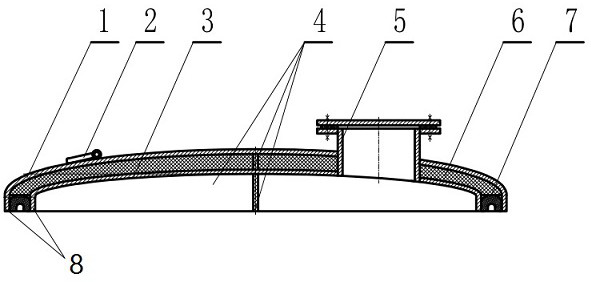

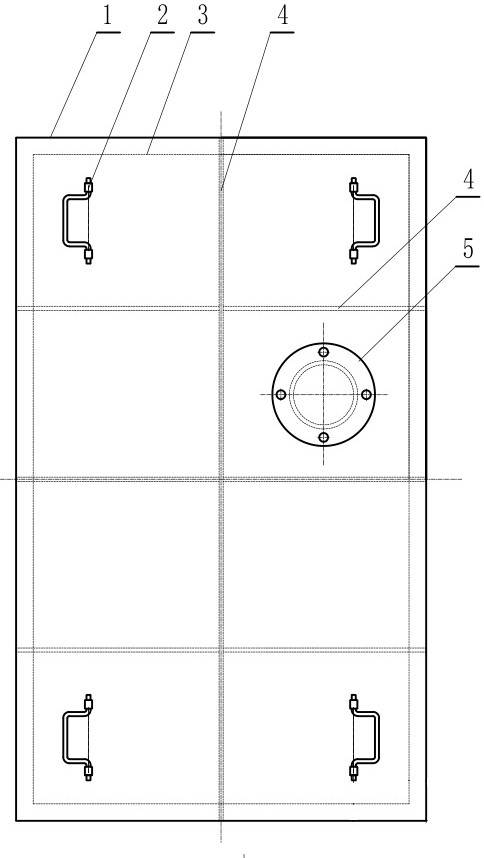

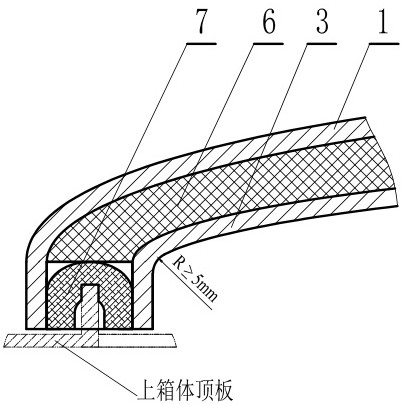

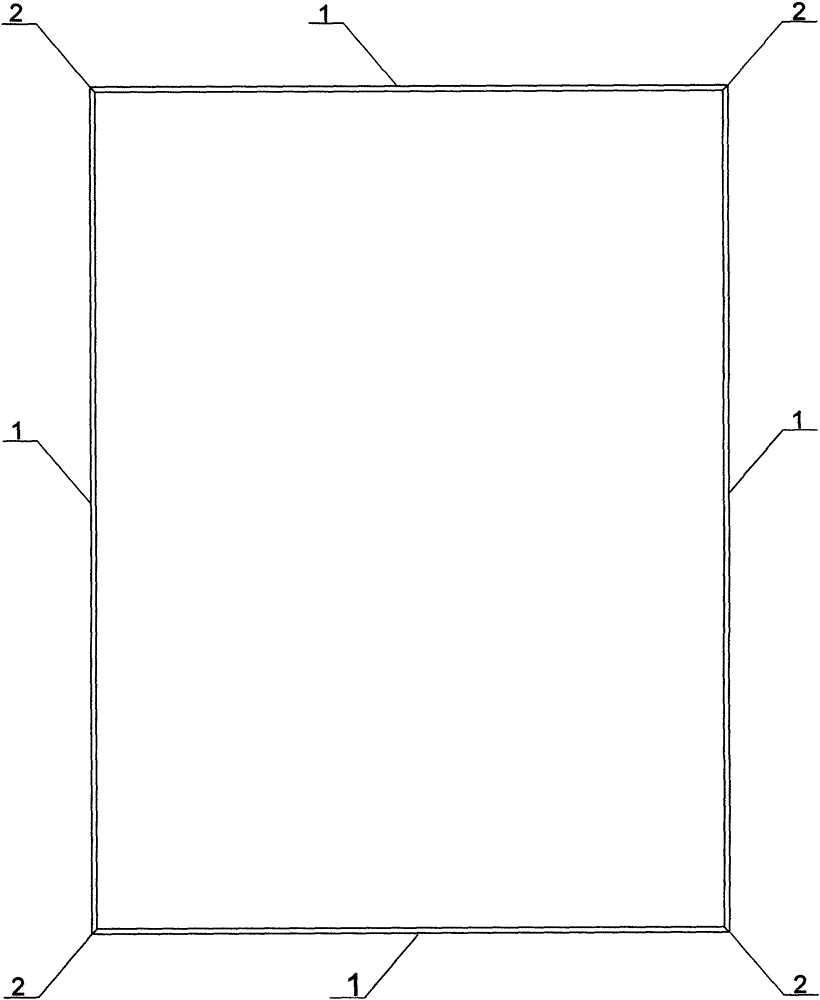

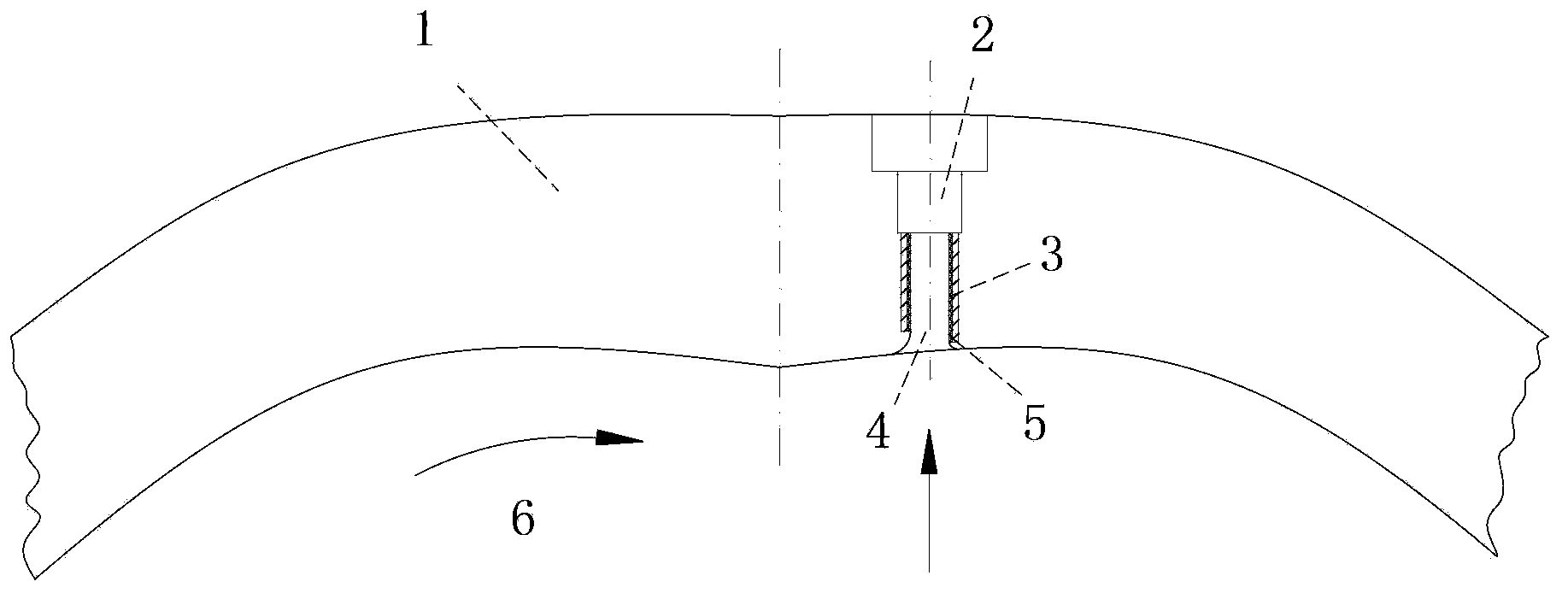

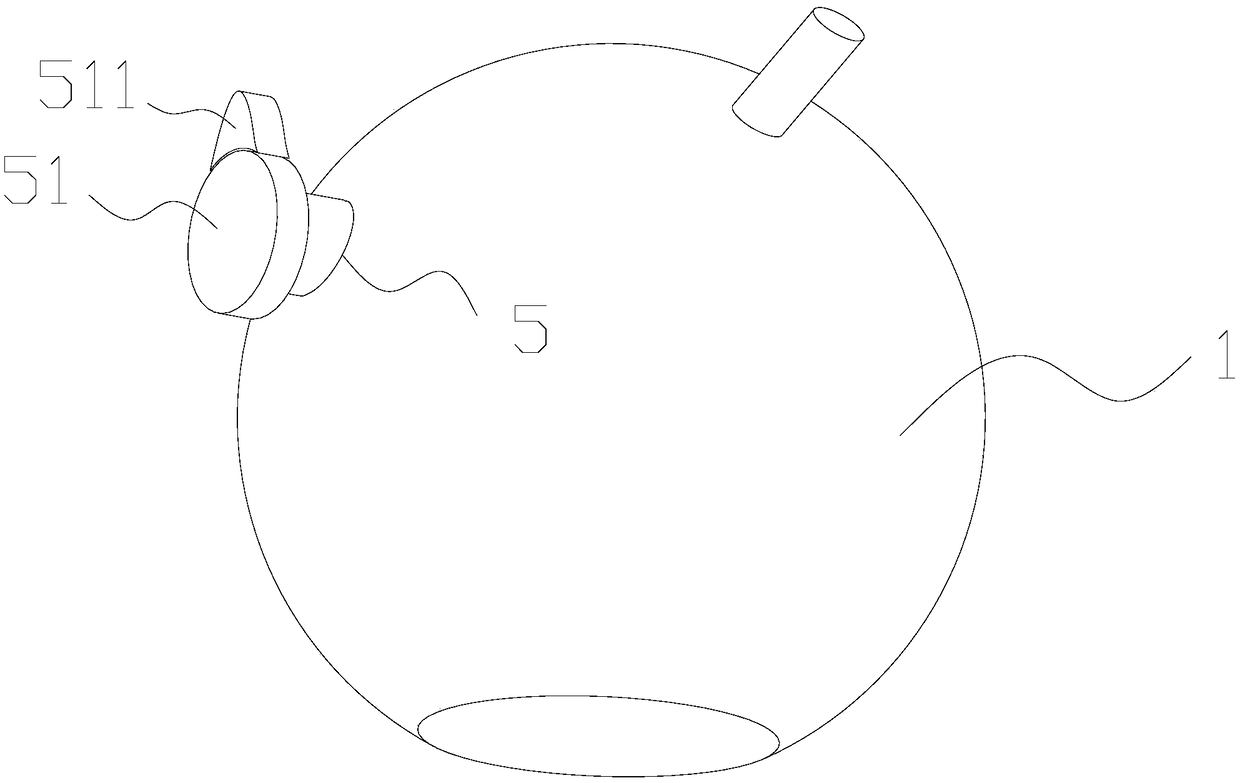

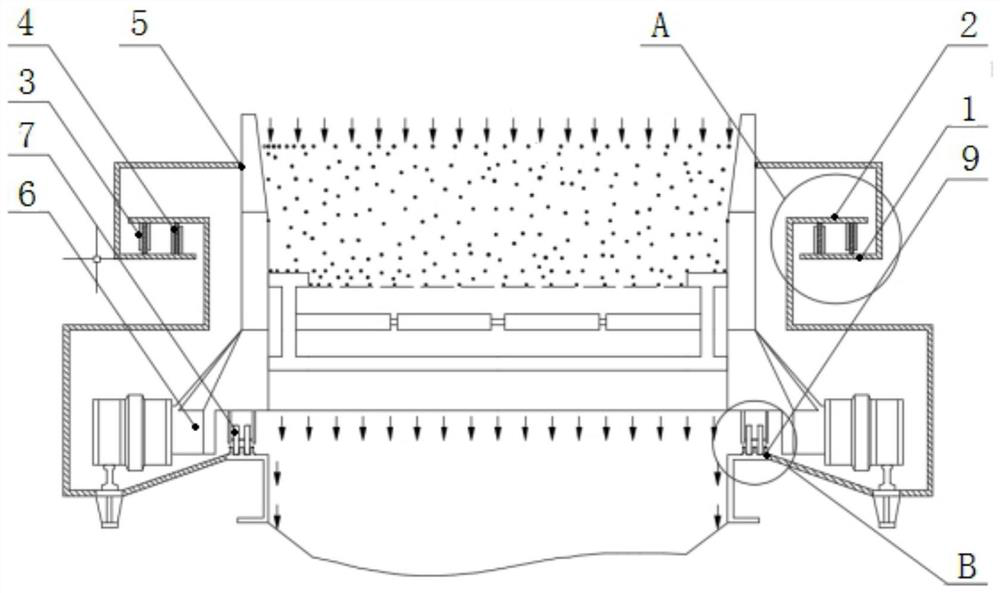

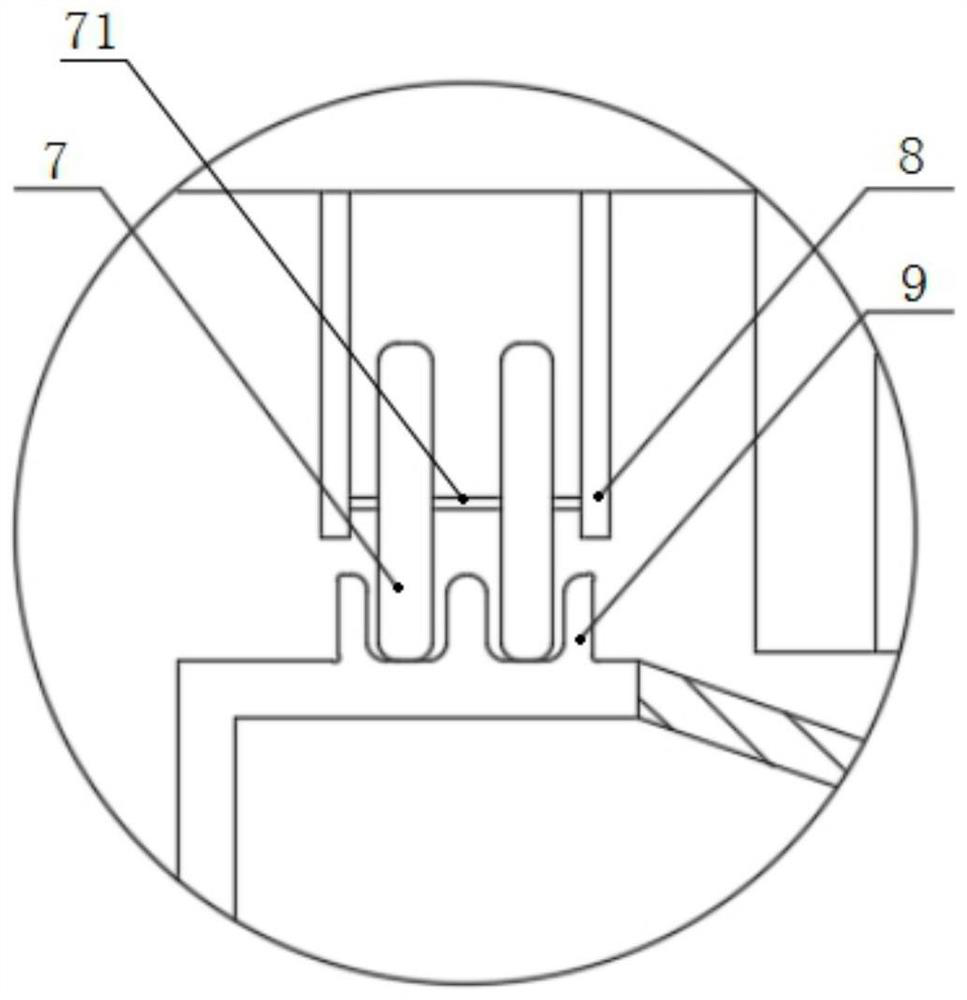

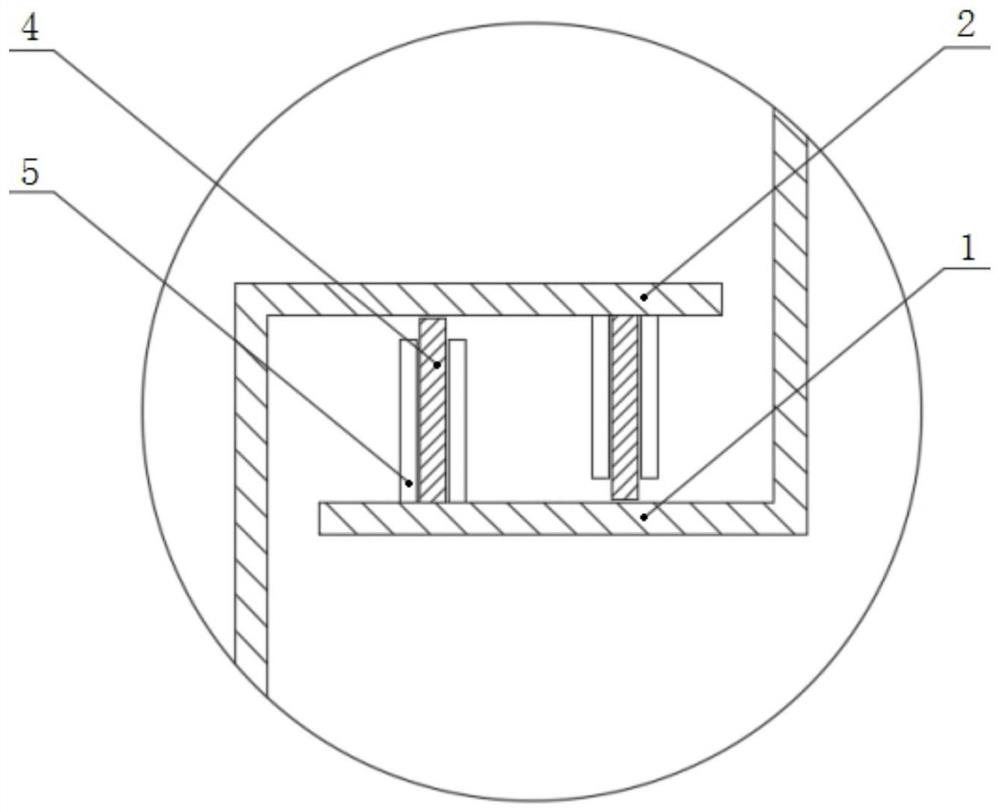

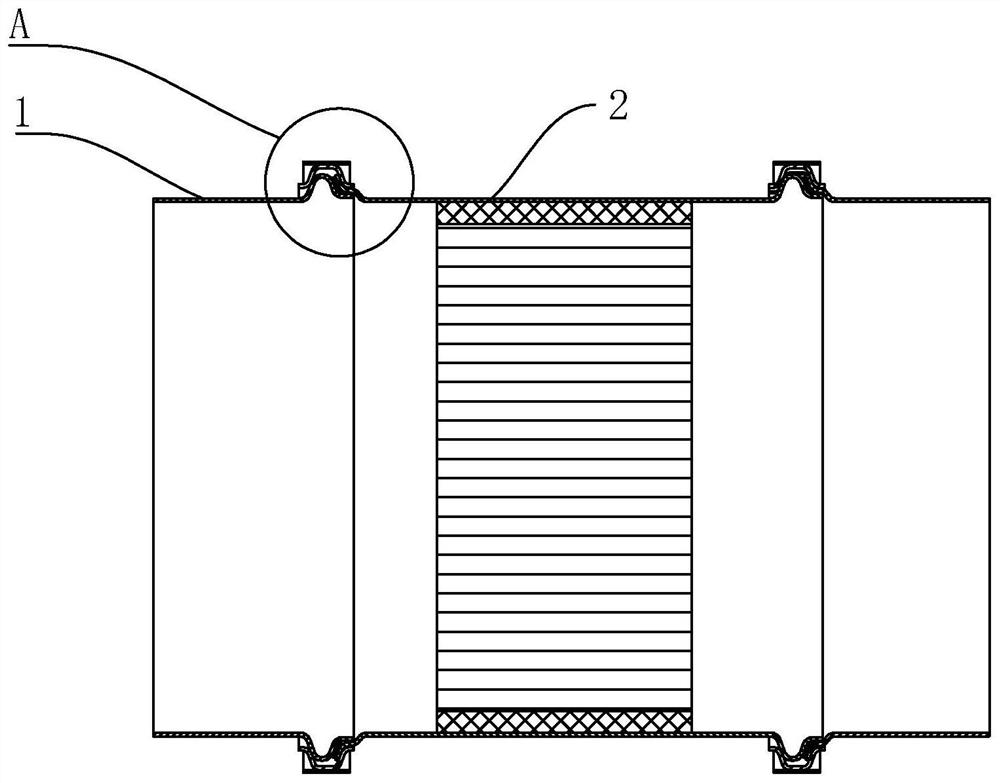

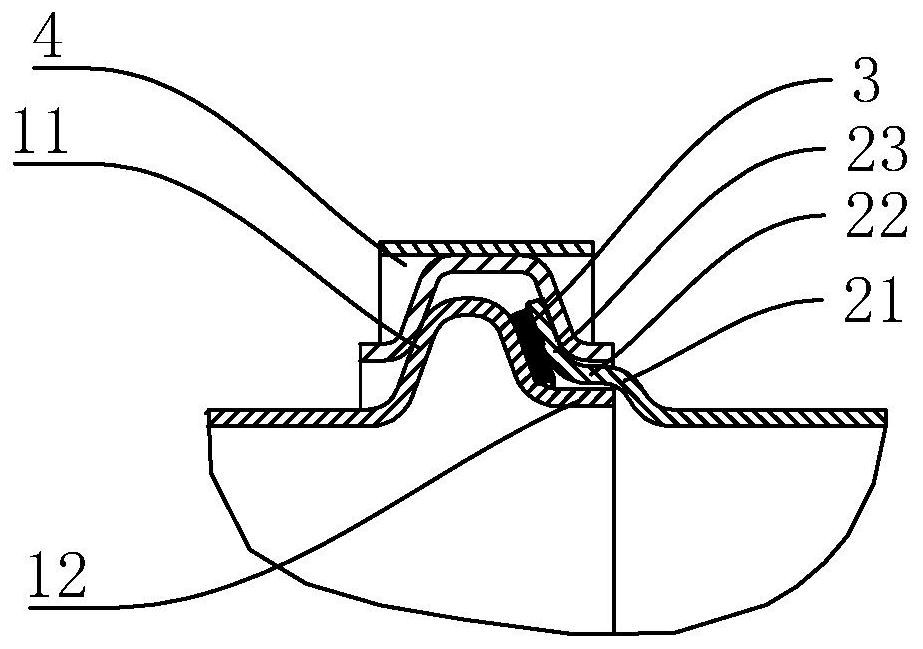

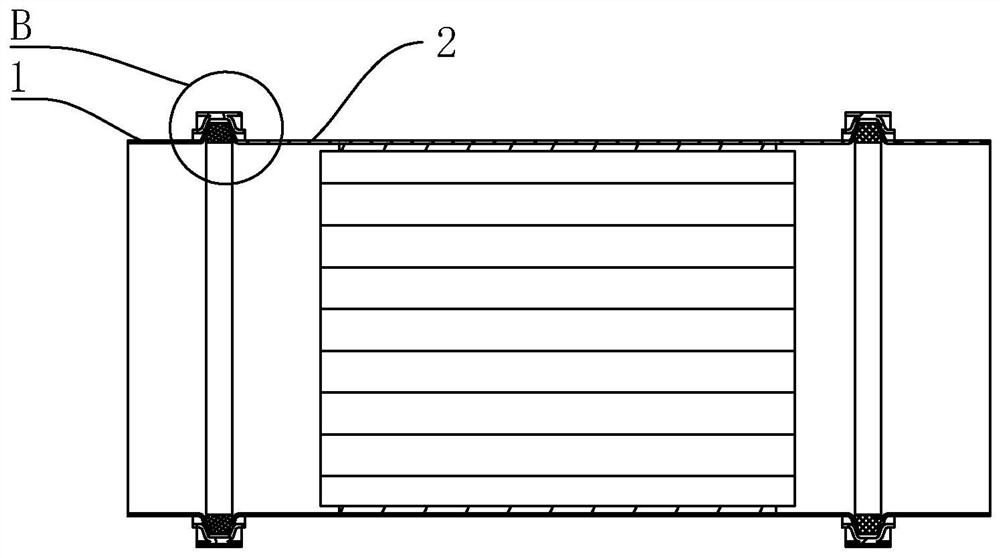

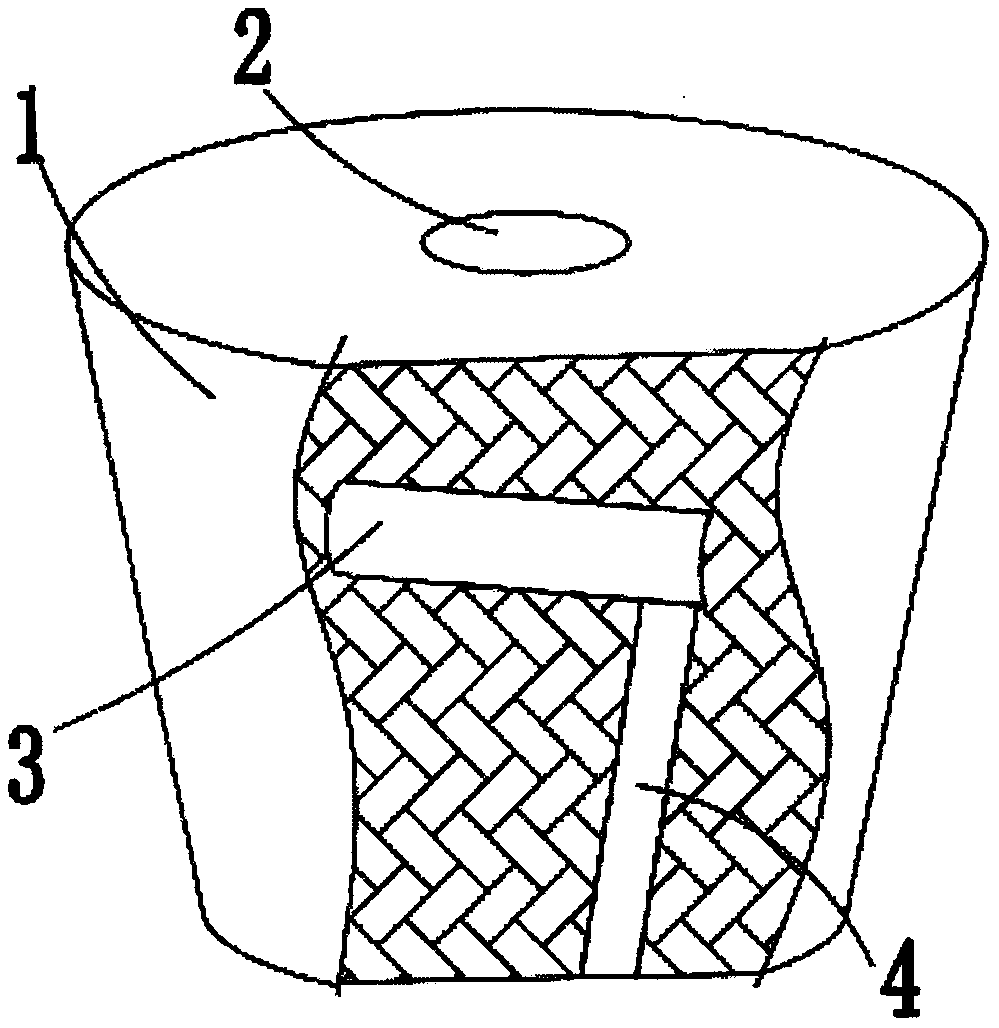

High-negative-pressure-resistant door cover of bag type dust collector

PendingCN112263881AIncreased Strength and RigidityImprove stress resistanceGas treatmentDispersed particle filtrationStructural engineeringPressure resistance

The invention discloses a high-negative-pressure-resistant door cover of a bag type dust collector. A single-layer arch-shaped door cover or a double-layer arch-shaped door cover structure is adopted,and the double-layer arch-shaped door cover comprises an arch-shaped outer shell 1, a handle assembly 2, an arch-shaped inner shell 3, reinforcing vertical ribs 4, a pressure equalizing device 5, a heat preservation material 6 and a U-shaped sealing strip 7. The handle assembly 2 is welded to the position 100-200 mm away from the inner side of the edge of a door cover on the top of the arch-shaped outer shell 1, and the reinforcing vertical ribs 4 are welded between the arch-shaped outer shell 1 and the arch-shaped inner shell 3 and on the inner side of the arch-shaped inner shell 3. The pressure equalizing device 5 is arranged at the top of the arched-shaped door cover and keeps away from the reinforcing vertical ribs 4; a gap between the arch-shaped outer shell 1 and the arch-shaped inner shell 3 is filled with the heat preservation material 6; and the U-shaped sealing strip 7 is embedded in a groove formed by the arch-shaped outer shell 1 and the arch-shaped inner shell 3. The strength and rigidity of the dust remover door cover can be greatly improved, the pressure resistance of the dust remover door cover is remarkably improved, and maintenance and overhaul operation conditions are improved; the high-negative-pressure-resistant door cover has the characteristics of simple and reasonable structure, convenience in operation, strong practicability and the like.

Owner:中钢集团天澄环保科技股份有限公司

A kind of thin combined installation door and window sub-frame

ActiveCN103573111BSolve the strength problemSolve Thickness ProblemsWindow/door framesCement mortarMechanical engineering

The invention discloses a thin combined installation door and window auxiliary frame which is made of metal or plastic profiles and has a bridge-breaking heat insulation type and an ordinary type, wherein each type has a push-pull mode and a sliding mode. The auxiliary frame is in a shape of double Es, the thickness of the auxiliary frame is larger than 4mm and smaller than 15mm, wall fixing screws and angle steel fixing screw grooves are arranged on the surface of the auxiliary frame, and an angle steel groove and angle steel are arranged on the back surface of the auxiliary frame. The auxiliary frame is provided with a standard seat frame for supporting the installation of the auxiliary frame, wherein the seat frame is made of aluminum alloy or metal profiles and has an adjustable mode and a fixed mode. Clamping rods, clamping hooks, horizontal correction devices, vertical correction devices, sill concentric correction devices and rulers are arranged on the seat frame. In installation, the auxiliary frame is fixed on the seat frame through the screws, the seat frame is installed in a door and window hole to be clamped tightly, correction is performed through a correction device, a wall horizontal inked line and a wall vertical inked line, hard plastic gaskets are wedged the back surface of the auxiliary frame tightly, the auxiliary frame is fixed on the wall through two lines of screws, the seat frame is dismantled, cement mortar is filled in slits between the frame and the wall, and a firm standard door and window auxiliary frame is formed after the cement mortar is coagulated.

Owner:HUIZHOU BAINIAN FANGZHENG ENG CO LTD

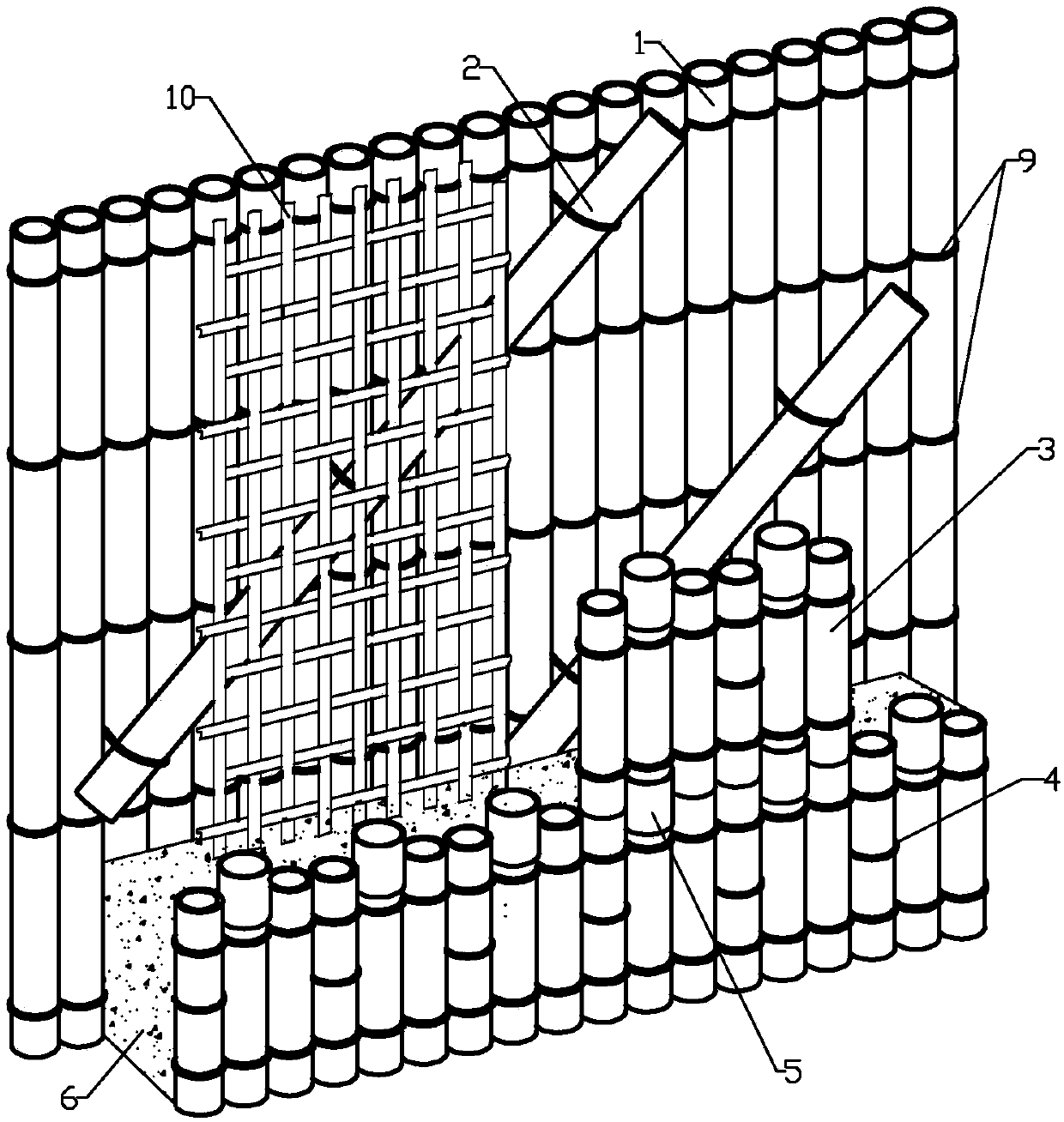

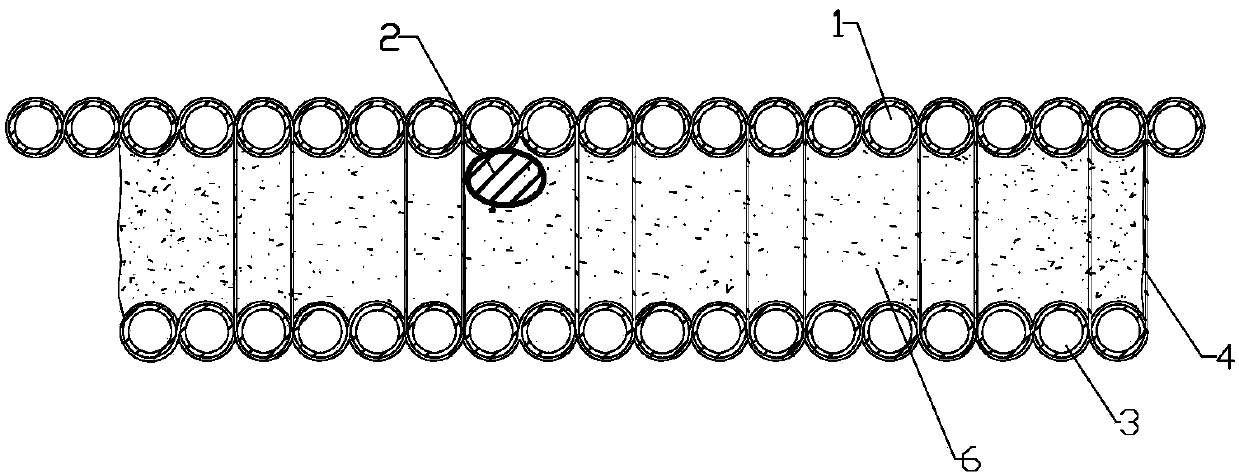

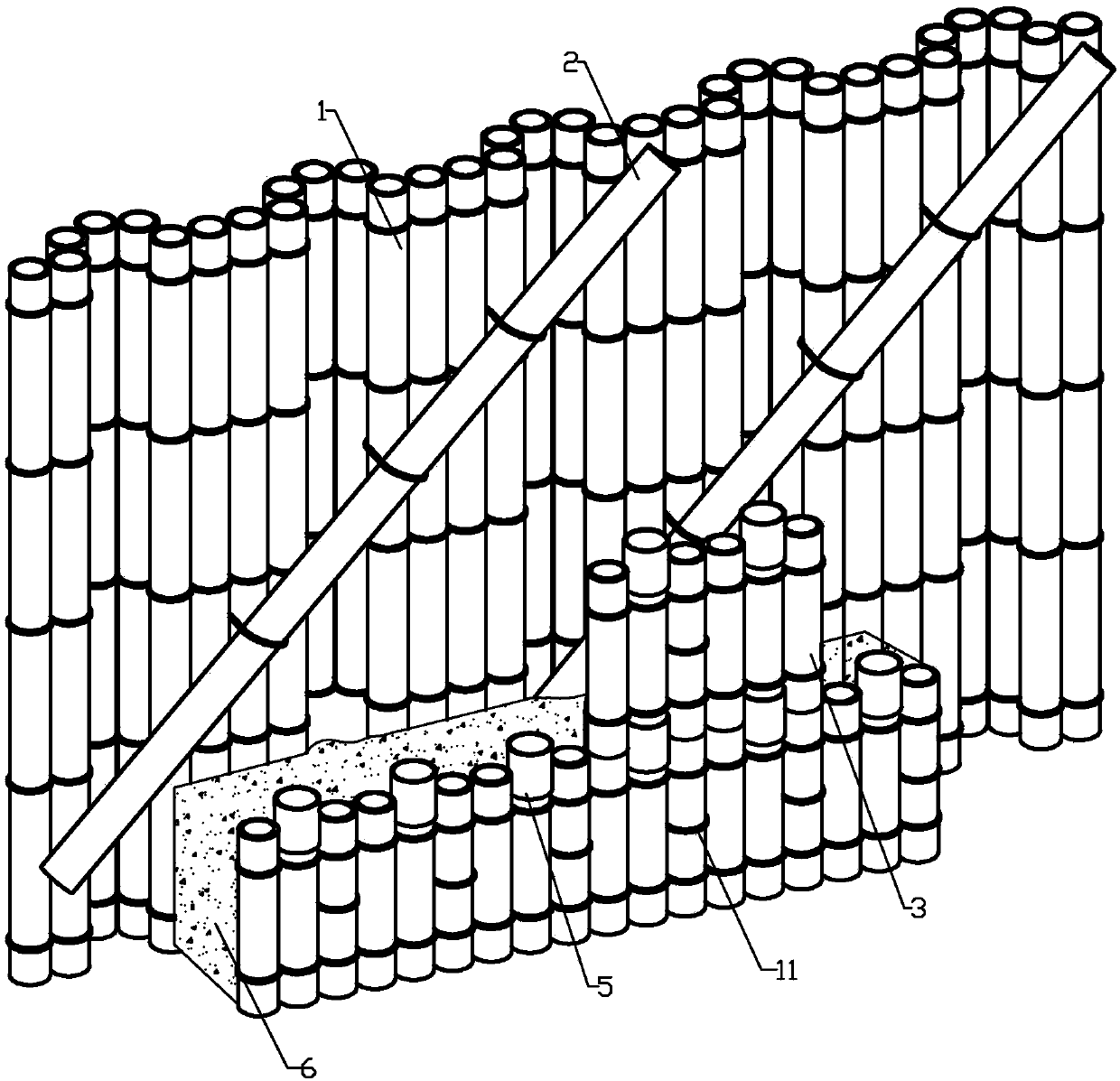

Flexible bamboo-formwork ecological and energy-saving wall and manufacturing method

The invention discloses a flexible bamboo-formwork ecological and energy-saving wall and a manufacturing method. The wall comprises an external bamboo formwork and an internal bamboo formwork which are connected through one or more of rebars, lead wires or flexible cords in a pulling mode, and the portion between the external bamboo formwork and the internal bamboo formwork is filled with raw soilstraw mixture, modified soil, foamed concrete and other materials. The external bamboo formwork is formed in the mode that a plurality of upright bamboo poles similar in thickness are in close connection by using flexible cords, and a plurality of parallel and oblique supporting rods are fixed to the inner vertical surface of the external bamboo formwork; the internal bamboo formwork is formed inthe mode that a plurality of bamboo rafts consistent in size are stacked in a herringboned mode, and the bamboo rafts on the lower layer and the bamboo rafts on the upper layer are in sleeved connection through positioning sleeves, wherein each bamboo raft is formed in the mode that a plurality of 450-500-m long bamboo poles are connected side by side. In the wall, the bamboo materials are made into a wall formwork, then the wall is built through the wall formwork in a solid reinforcement mode, so that it is ensured the bamboo wall is stable in structure and capable of bearing load, resistingto wind and resisting to earthquake, the defects that an existing bamboo wall lets air in and is uninsulated are overcome, the manufacturing method is simple in step, and convenience is brought to modeling of the upright surface of the wall.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Ignition groove of natural gas rotary engine

InactiveCN103089416BImprove stabilityIncrease success rateInternal combustion piston enginesCombustionCylinder mold

An ignition groove of a natural gas rotary engine comprises a front wall face, a back wall face and a groove channel which is arranged between the front wall face and the back wall face. The front wall face is composed of an arc section and a non-arc section embedded with a carborundum sheet, and the back wall face is composed of an arc section and a non-arc section embedded with a carborundum sheet. The front wall face and the back wall face extend parallelly from the bottom to an air cylinder molded surface, and respectively extend from the position close to the air cylinder molded surface to form arc-shaped wall faces. The radius of an arc on one side of the front wall face is smaller than that of one side of the back wall face. A rectangular concave pit is formed in a non-arc wall face of the groove channel, and is embedded with a carborundum sheet which is coated with a platinum catalyst coating. The depth of the concave pit is equal to the thickness of the carborundum sheet, and therefore the arc sections of the front wall face and the back wall face and the non-arc sections which are embedded with the carborundum sheets of the front wall face and the back wall face are enabled to be respectively connected smoothly. According to the ignition groove of the natural gas rotary engine, the engine ignition is enabled to be convenient, combustion is promoted and accelerated by utilizing of a stable flame back frontal surface after ignition, combustion efficiency is improved, and whole performance of the engine is improved.

Owner:JIANGSU UNIV

Diesel engine starting device and method based on cold region operation and paver

PendingCN113250780ALow starting resistanceIncrease speedValve arrangementsCylinder headsElectric machineryPeak current

The invention discloses a diesel engine starting device and method based on cold region operation and a paver. The device comprises a pressing plate, a bidirectional electromagnet, a cylinder sleeve and an air valve, wherein the bidirectional electromagnet is connected to the bottom surface of the pressing plate, and a wiring device for electrifying the bidirectional electromagnet is connected to the pressing plate; a piston is arranged in an inner cavity of the cylinder sleeve, and the air valve communicates with an upper area defined by the cylinder sleeve and the piston; the output end of the bidirectional electromagnet is connected to a stopper, the bidirectional electromagnet is used for controlling the stopper to be located at a first position or a second position, and the stopper stretches out at the first position to prevent a rocker arm from returning so as to open the air valve; and at the second position, the stopper retracts, and the rocker arm returns to close the air valve. According to the device, the problem that a diesel engine is difficult to start due to a large load is solved, and as starting resistance is reduced, a peak current of a starting motor is also reduced, and the service life of the starting motor is prolonged.

Owner:XCMG CONSTR MACHINERY

Canned bottle leakage detection device

InactiveCN108956022AImprove air leakageLeakage is easy to observeFluid-tightness measurement using fluid/vacuumEngineeringBottle

The invention discloses a canned bottle leakage detection device comprising a housing; a vacuum device is arranged in the housing; a ventilated membrane is arranged in the housing so as to split the housing into a gas chamber and a detection chamber; the detection chamber is filled with sodium so as to detect whether or not air exists in the housing; the housing recesses and is provided with a fixed chamber used for clamping the canned bottle; a movable plug is arranged in the gas chamber; the housing is provided with a groove used for embedding the movable plug; the movable plug isolates thegas chamber from the outer side; the end face, far away from the gas chamber, of the movable plug is fixedly provided with a push rod that is capable of penetrating the housing and abutting against the top end of the canned bottle; a plurality of elastic members are arranged between the groove and the movable plug; the movable plug is provided with a storage chamber used for receiving the elasticmembers; the housing encircles the push rod and is provided with a plurality of connecting ports; all connecting ports are connected with the gas chamber. The canned bottle leakage detection device can reduce detection procedures, and can improve the take effect efficiency.

Owner:SUZHOU ICOOLMACH EQUIP MFG

A composite sealing device on the side of a sintering machine

ActiveCN112212696BReduce wearExtended service lifeCharge treatment typeFurnace typesStructural engineeringManufacturing engineering

The invention relates to a side compound sealing device of a sintering machine, which includes a side sealing assembly: the assembly includes an upper sealing cover plate, a lower sealing cover plate, a high-strength magnet, flexible rubber and a flexible rubber panel; and a roller guide assembly; the The assembly includes rollers, roller support plates and roller tracks; the roller support plates are fixedly connected in pairs to the left and right sides of the bottom of the trolley, and the rollers are respectively rotatably connected between each pair of roller support plates, and the roller tracks correspond to It is arranged at the bottom of the roller, and one end of the roller track is fixedly connected to the side of the trolley, and the other end is fixedly connected to one side of the bottom end of the lower sealing cover plate. During the sintering process, the negative pressure of the bellows is used to make the flexible rubber contact with the upper and lower sealing cover plates to form a sealing wall, and the rollers are used to replace the original side slideway device at the bottom of the trolley, so that the sliding seal becomes a rolling seal, which effectively reduces the contact between the trolley and the sliding It also has a certain guiding effect to reduce the air leakage caused by the deviation of the trolley.

Owner:临沂玫德庚辰金属材料有限公司

DPF cylinder assembly sealing structure

PendingCN111810635AImprove air leakageLow costEngine sealsExhaust apparatusEngineeringMechanical engineering

The invention provides a DPF cylinder assembly sealing structure. The structure comprises a front cylinder, a DPF cylinder, a sealing ring and a V-shaped hoop, the side, close to the DPF cylinder, ofthe front cylinder is axially positioned and radially matched, the side, close to the DPF cylinder, of the front cylinder is in the shape of an arc with straight edges, the sealing ring is arranged between the front cylinder and the DPF cylinder in a clamped mode, and the upper part of the joint between the front cylinder and the DPF cylinder is sealed through the V-shaped hoop in a matched mode.According to the structure, excessive air leakage points are reduced, the problem of air leakage is solved, costs are saved, and the resistance of a DPF cylinder assembly to radial vibration is increased.

Owner:江苏伟博动力技术有限公司

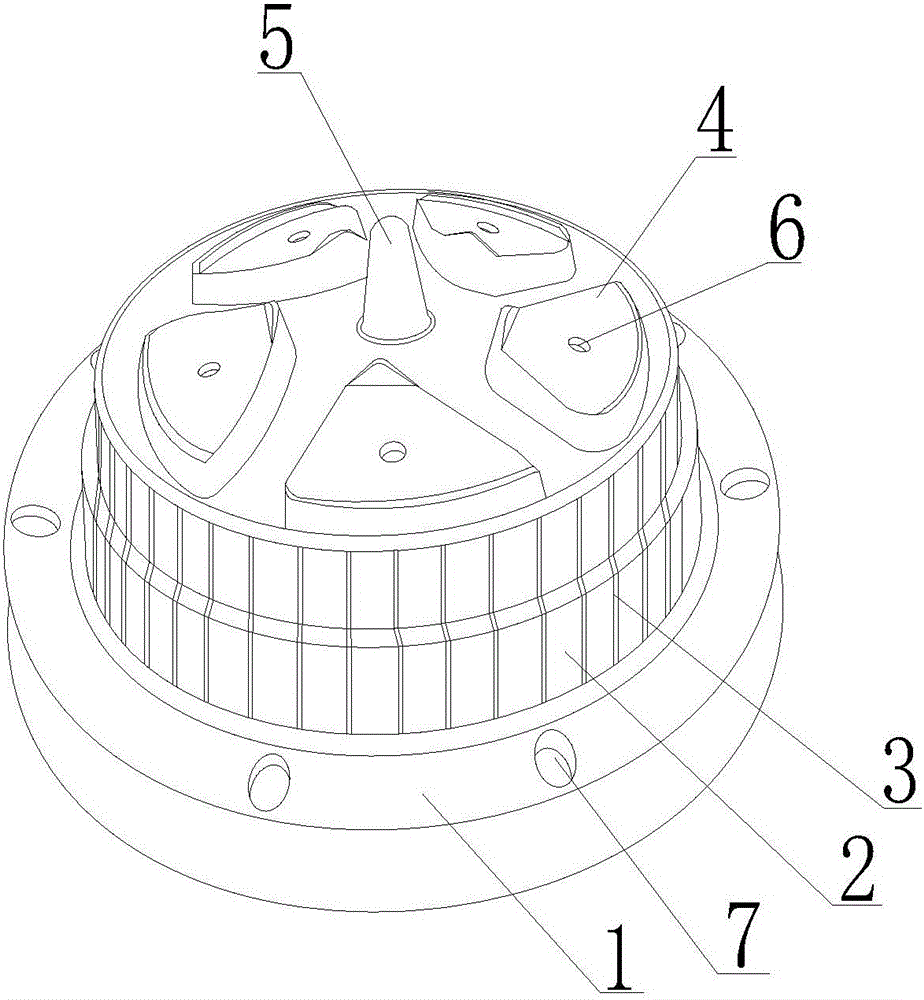

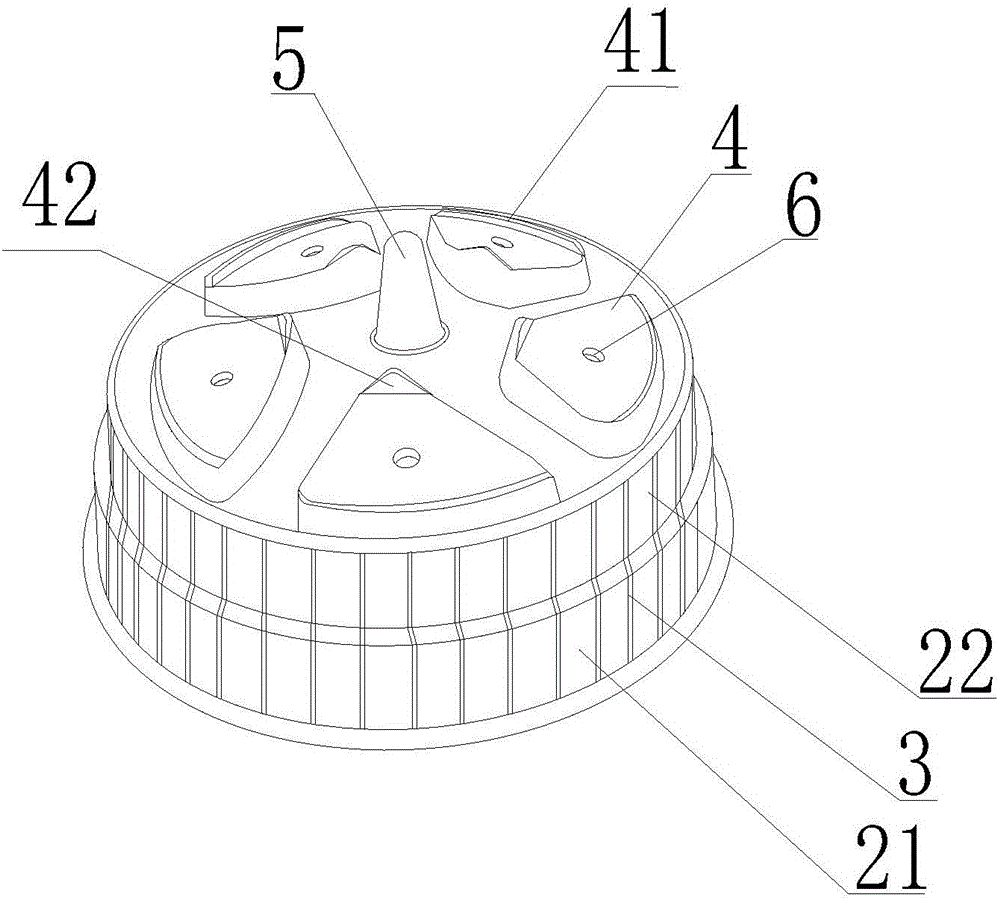

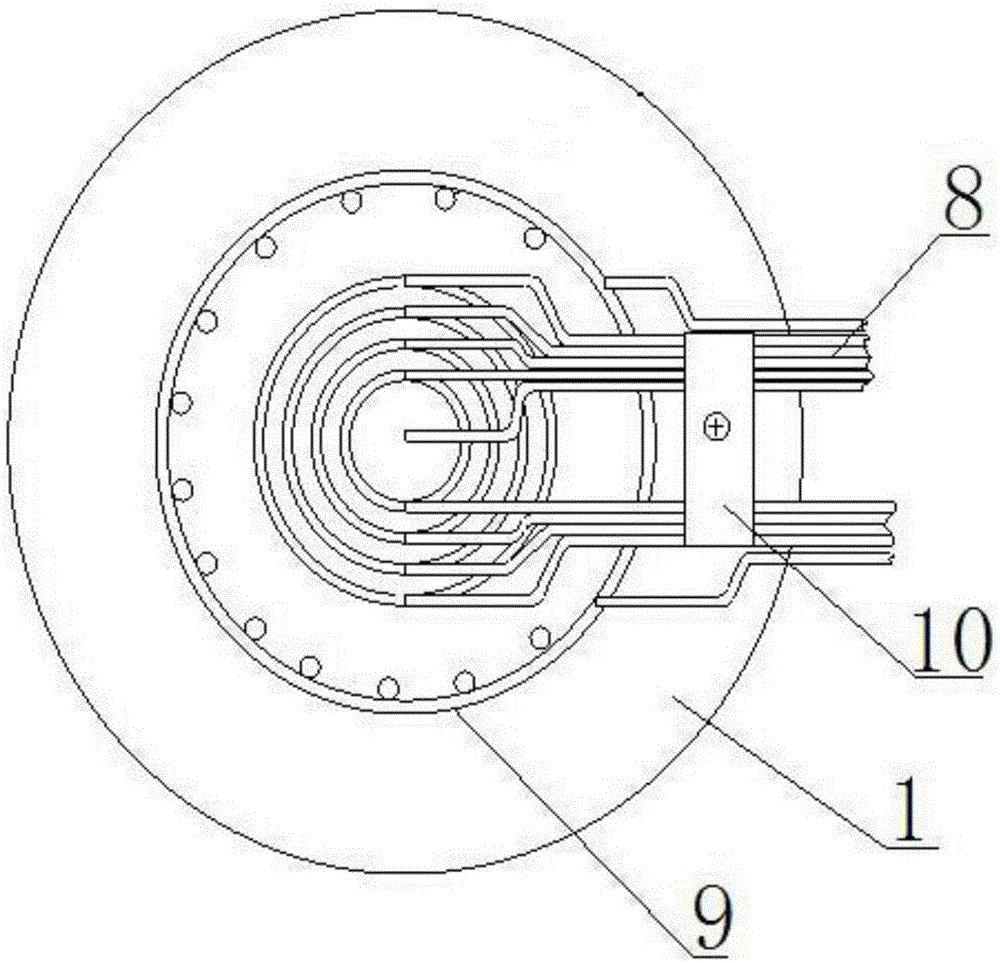

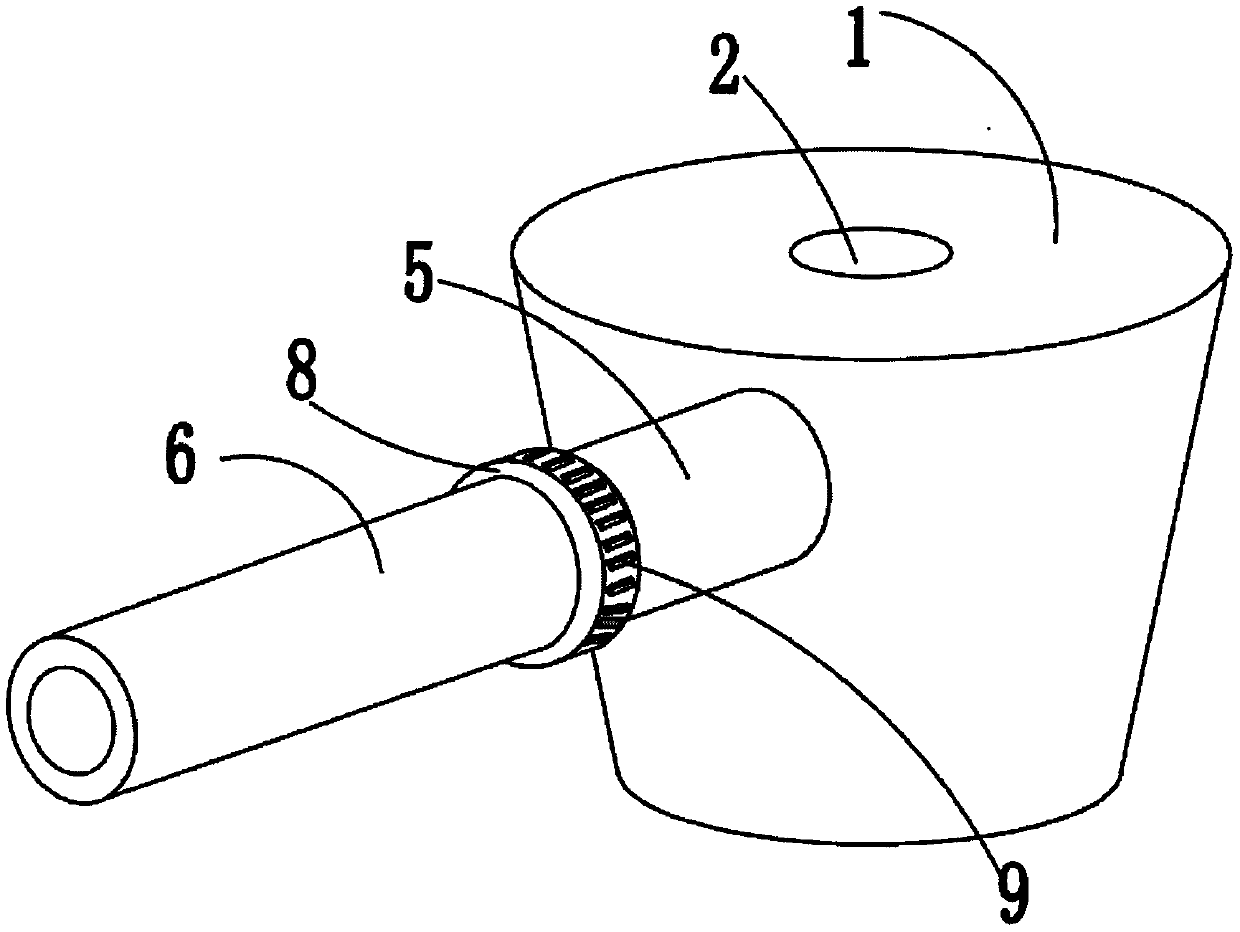

A wheel hub mold

ActiveCN104525873BIncrease the amount of feedImprove performanceFoundry mouldsFoundry coresMaterials science

The invention discloses a hub mold which comprises a lower mold bearing seat, a lower mold, lower mold windows and a spure spreader, wherein the lower mold is arranged in the center of the lower mold bearing seat; the lower mold comprises a first lower mold and a second lower mold; multiple lower mold marks which are circumferentially and uniformly arranged are arranged on the side surfaces of the first lower mold and the second lower mold; the spure spreader is arranged in the center of the second lower mold; multiple lower mold windows are raised on the upper surface of the second lower mold; a lower mold window positioning hole is formed in the center of each lower mold window; a circular groove is formed in the bottom of the lower mold bearing seat; multiple lower mold air pipe rings are arranged in the circular groove; the lower mold air pipe rings are contacted with outside by virtue of lower mold air pipes positioned at two ends of the lower mold air pipe rings; an opening is formed in the bottom of the lower mold bearing seat; and one end of each lower mold air pipe is fixed in the opening by virtue of a fixing piece.

Owner:ANHUI HUILIAN MACHINERY IND

Portable carbon arc air gouging nozzle

InactiveCN110814466AStrengthen the occlusionAvoid dischargeElectrode supporting devicesStructural engineeringConical shell

The invention discloses a portable carbon arc air gouging nozzle. The nozzle comprises a conical shell, wherein a carbon rod hole is formed in the top of the conical shell, and an air inlet handle isarranged on one side of the conical shell, and consists of a first pipe and a second pipe; the end, away from the second pipe, of the first pipe remote is fixedly connected with the outer side of theconical shell; a transverse chute is formed in the side, close to the air inlet handle, of the conical shell, and communicates with the first pipe; an inclined air outlet is formed in the inner wall of the bottom of the transverse chute; a first annular groove is formed in the outer side of the second pipe, and the side, close to the first pipe, of the first annular groove, is arranged as an opening. The nozzle is reasonable in design, practical and portable; the total length of the air inlet handle can be conveniently and quickly adjusted and fixed as required, automatic retraction in use canbe effectively avoided, the air inlet amount is convenient to adjust, the sealing effect can be improved under cooperation of two sealing rings, so that air leakage is prevented, and use requirementsare met.

Owner:张春雨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com