Rapid air leakage detection method for underground goaf

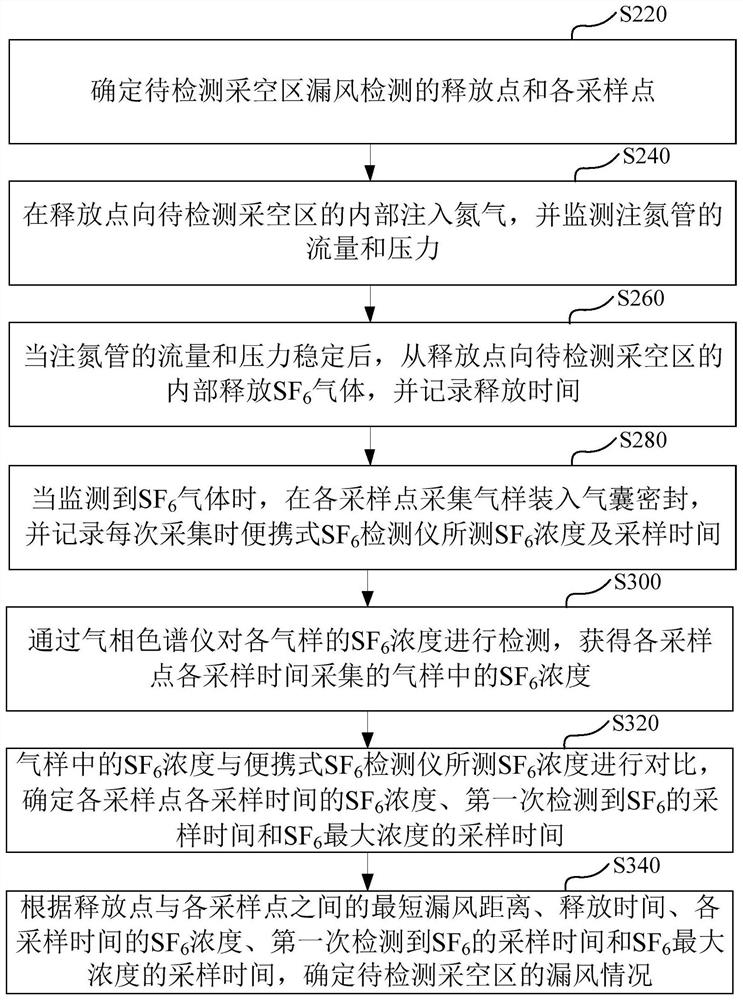

A detection method and goaf technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of slow gas migration, slow detection process, and untimely gas samples collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

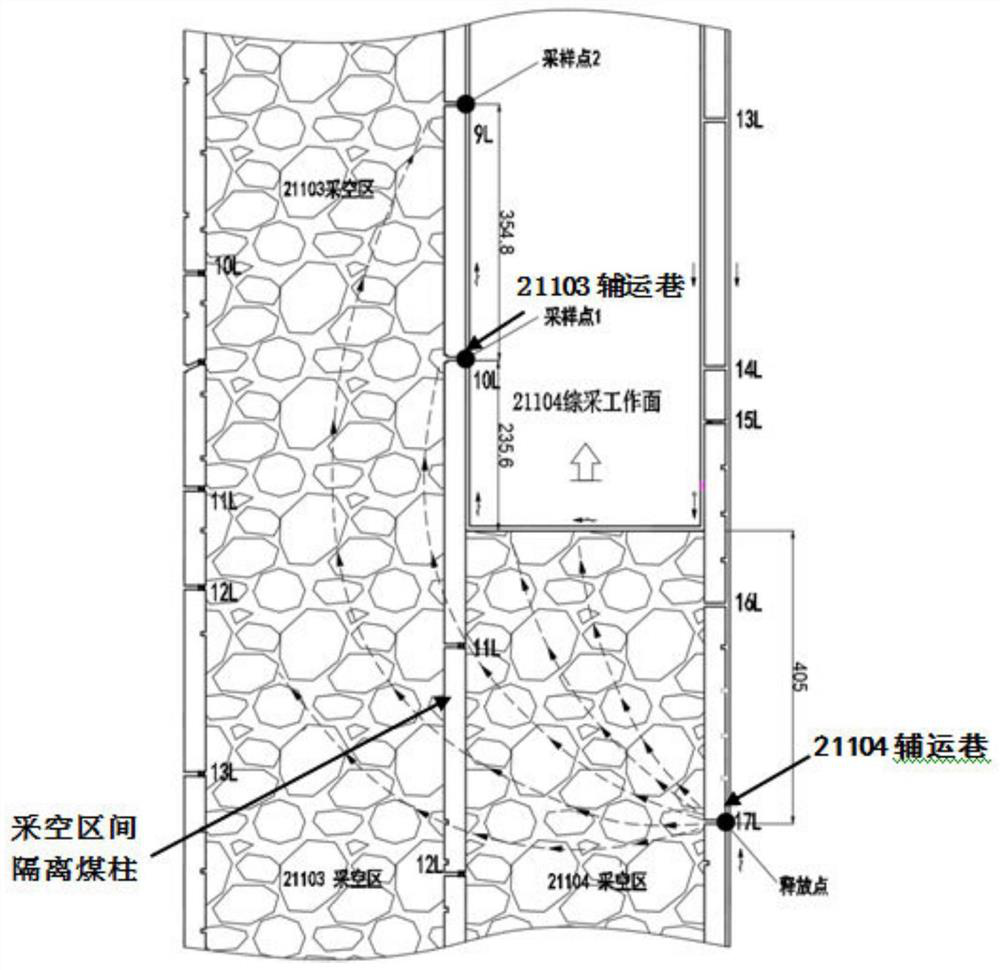

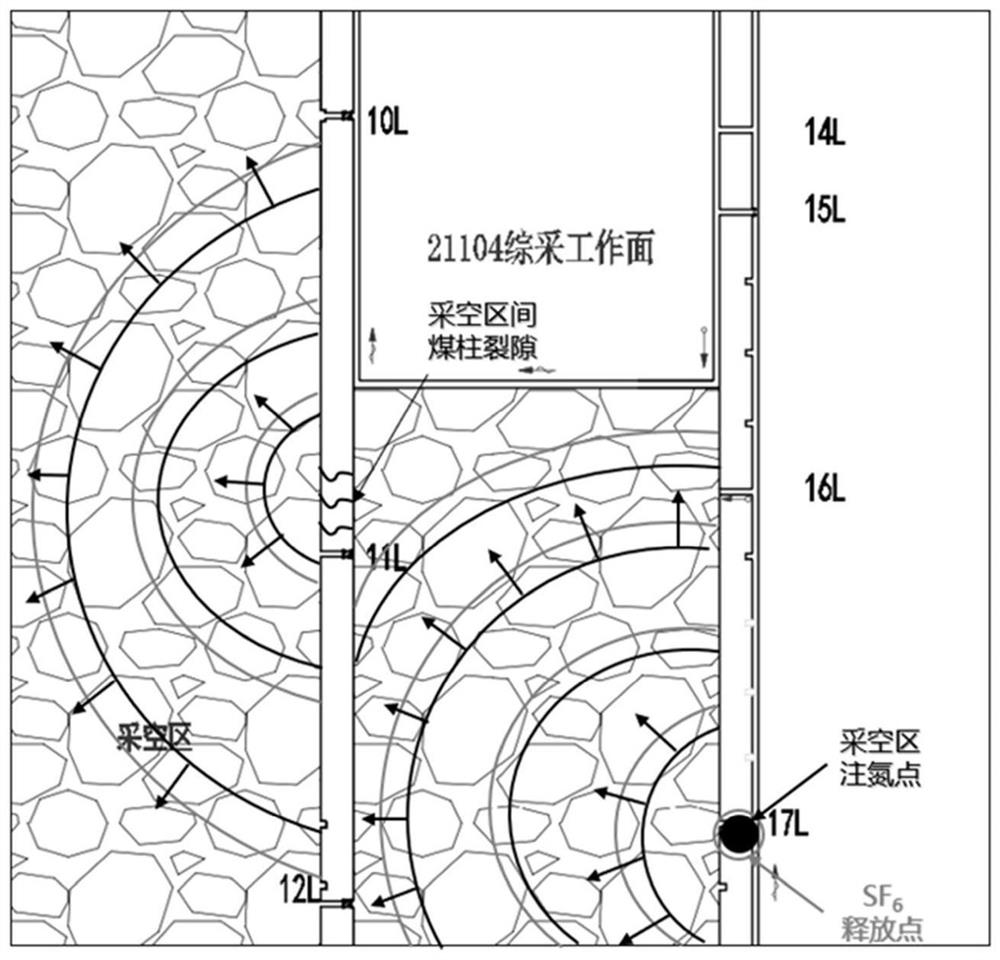

[0048] Taking the implementation background of the 2-1 coal seam in a mine in the south of Ordos, China as an example: the geological structure of the 2-1 coal seam in a mine in the south of Ordos is simple, with an overall dip angle of 1°-3° and a local dip angle of 5°-6°, which is a gently inclined coal seam. The buried depth is 634m-638m, the average thickness of the coal seam is 2.77m, and the bulk density is 1.31t / m 3 . There are three working faces 21102, 21103 and 21104 arranged side by side. The length of each working face is about 320m, and a 30m-wide isolated co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com